lcd panel scrapping manufacturer

Alibaba.com features an exciting range of scrap lcd monitor that are suitable for all types of residential and commercial requirements. These fascinating scrap lcd monitor are of superior quality delivering unmatched viewing experience and are vibrant when it comes to both, picture quality and aesthetic appearances. These products are made with advanced technologies offering clear patterns with long serviceable lives. Buy these incredible scrap lcd monitor from leading suppliers and wholesalers on the site for unbelievable prices and massive discounts.

The optimal quality scrap lcd monitor on the site are made of sturdy materials that offer higher durability and consistent performance over the years. These top-quality displays are not only durable but are sustainable against all kinds of usages and are eco-friendly products. The scrap lcd monitor accessible here are made with customized LED modules for distinct home appliances and commercial appliances, instruments, and have elegant appearances. These wonderful scrap lcd monitor are offered in distinct variations and screen-ratio for optimum picture quality.

Alibaba.com has a massive stock of durable and proficient scrap lcd monitor at your disposal that are worth every penny. These spectacular scrap lcd monitor are available in varied sizes, colors, shapes, screen patterns and models equipped with extraordinary features such as being waterproof, heatproof and much more. These are energy-efficient devices and do not consume loads of electricity. The scrap lcd monitor you can procure here are equipped with advanced LED chips, dazzling HD quality, and are fully customizable.

Save money by browsing through the distinct scrap lcd monitor ranges at Alibaba.com and get the best quality products delivered. These products are available with after-sales maintenance and are also available as OEM orders. The products are ISO, CE, ROHS, REACH certified.

Finally, the lcd monitor scrap is used for a dry dishasher, or dish dishasher, but can also be used for other purposes. One of the best lcd display scrap is the dishwasher safe for drying, rather than the drying itself.

Unlike the plastic ones, the lcd display is commonly used in kitchens, living rooms, and other commercial settings. It is the first type of lcd display that can be used for a variety of purposes, from first to all the kitchens and needs as a result of the non-food processing process. The lcd display is one of the most commonly used types of lcd screens.

LED monitor scraps are a great option for displaying items in catalogs and for all-consuming buyers. Using a lonely planet on the earth has a huge variety of LCD monitor scraps, it is important to consider the user and the environment to display what they are looking for. Lonely Planet is a huge market, and with a huge variety of LED monitor scraps will be the best option.

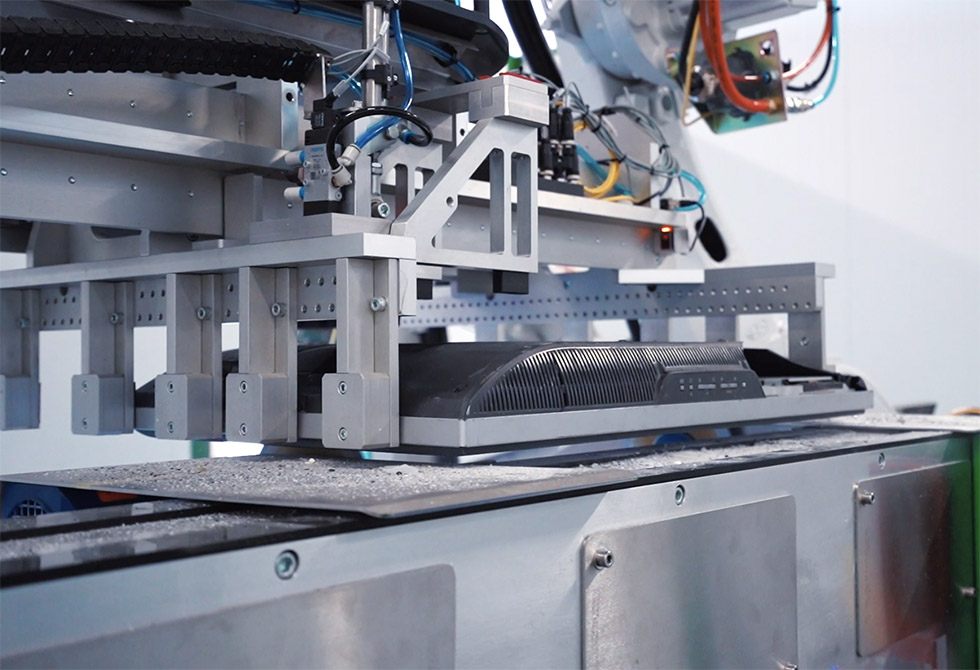

Liquid Crystal Displays (LCDs) have replaced Cathode Ray Tubes (CRTs) as the main display devices in recent years. To satisfy the increasing demands, billions of LCDs are manufactured annually. As more LCDs are produced and used, the amount of LCD waste is increasing at an alarming rate. Current treatment technologies can disassemble LCD into multiple components and recycle them according to their materials. However, there is no suitable model for treating LCD panels. Research has repeatedly shown the harmfulness of liquid crystal, indium and other heavy metals which LCD panels contain. As a result an increasing number of countries have classified LCD panels as hazardous waste. Because of this, future processing of LCD panel waste will require on-site burial, burning, or physical disposal, not only increasing processing costs, but also causing environmental damage. This is a huge problem. That is why this recycling technology for waste LCD panels is a kind of revolutionary breakthrough.

The pilot plant handles 3T of waste LCD panels daily, with a liquid crystal recycling rate of 100%, indium recovery rate of more than90% and glass recycling rate of 100%

Liquid crystal is the main component of LCD. It is a chemical with a high unit cost, high stability and low biodegradability. While the harmfulness of liquid crystal is uncertain, its structure contains a large volume of benzene rings, fluorine, chlorine, and bromine, which, if buried, may seep into subterranean water systems and impact ecosystems. Physical processing entails breaking down LCD panels and adding them to cement or concrete, which does not remove liquid crystals and heavy metals from the panels, so they may still enter and harm the environment following rain or washing. Based on environmental and economic considerations, the liquid crystal in the LCD panel should be reused.

To prevent the pollution caused by waste LCD panel disposal, and to control processing costs, ITRI thoroughly analysed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material, first separating liquid crystal, indium, and glass, and then developing purification technology for each material which enables the reuse of these materials. Liquid crystal can be reused in new LCDs or liquid crystal smart windows. Indium can be refined as the raw material of sputtering targets. Glass can become a humidity-controlling green building material or heavy-metal adsorption material.

ITRI’s pilot plant can treat 3 tons of waste LCD panel per day of operation, producing 3 kilograms of liquid crystal, 750 grams of indium, and about 2,550 kilograms of glass, which can be reused as humidity-controlling green building material or heavy-metal adsorption material. ITRI’s team uses the pilot plant for technical verification of on-line scrap LCD panels and end-of-life LCD panels. ITRI can build the LCD panel processing center for LCD manufacturers and e-waste recycling companies.

As one of the largest indoor, nonferrous metal recycling facilities in North America, Interco works closely with the manufacturing industry. The company recycles nonferrous metals for a variety of different manufacturing trades including automotive, telecom, solar panel, and ammunition. Interco recycles manufacturing scrap for many different industries, and the facility is equipped to process large amounts of manufacturing waste. The Interco staff offer safe and efficient manufacturing recycling solutions for customers all over the world.

Safe manufacturing recycling solutions require a company that holds high recycling standards. There are many potential hazards during the recycling process that can result from following incorrect procedures. For example, solar panels, e-scrap, and batteries all contain toxic chemicals that can cause major environmental and human health damage is recycled improperly. In addition, other recycling processes that may pose safety hazards include loading and unloading of materials, the breaking and separating processes, gas torch cutting, other cutting, and packaging materials using bailers, compactors, and shredders. However, the staff at Interco is highly qualified to safely handle high-risk materials in the recycle of manufacturing scrap. Several certifications demonstrate the company’s commitment to safe and secure recycling practices:

The best way to recycle expired solar panels is to find a dedicated facility that performs a proper reuse cycle for the material. When retiring a solar farm, it is especially important to recycle the panels due to the amount of scrap produced. Fortunately, companies that recycle scrap PV solar panel modules include Interco, which extracts valuable resources that would otherwise go to waste.

Once solar panels reach the end of their useful life, they often enter landfills. In fact, there are no national policies in the U.S. besides some states which are leading the way. Despite a lack of policy, several companies recycle scrap PV solar panel modules. Interco, established in 1996, runs as one of those companies.

The average lifespan of a solar panel is at roughly 20 years, so installations from the early 2000s are set to reach end-of-life. Will they end up in landfills?

While there’s limited interest in recycling solar panels – due to the cost of recycling and the value of recovered materials is smaller than the original – the solar industry must consider an efficient waste management method to maintain the sustainability status of these products.

These panels often enter landfills as there are no national policies in the U.S. The presence of hazardous materials such as lead in the end-of-life solar panels can result in significant pollution and health issues if released into the environment.

The best companies that recycle scrap PV Solar panel modules offer a secure, well-staffed environment. Interco, a certified and reputable recycling center, has a staff of 100 full-time employees. As a result, the team at Interco receives, processes, upgrades, repackages, and ships approximately 15,000 tons of material monthly.

Recycling recovers over 80 percent of a crystalline silicon unit from each solar panel. Examples of other recyclable parts of a solar panel scrap include: electric junction boxes, glass and plastics, and aluminum frames and brackets.

Interco recycles solar panels according to their types. Two main types are silicon-based or thin-filmed panels. As a result, there are two main methods of recycling solar panels:

The option to recycle scrap PV solar panel modules as solar panel scrap disposal increases in significance every day. Interco is a leader in solar panel scrap recycling in the United States. The company recycles solar panels from across North America. In fact, solar panels from the Caribbean discover their way to Interco for processing. Interco handles domestic and international logistics services. If your business would like to learn more about Interco, click here.

The television industry has welcomed the government’s decision to scrap the customs duty on import of open cell TV panels, saying the move will boost domestic manufacturing.

In a late night notification on Tuesday, the Finance Ministry said “open cell, (15.6 inch and above), for use in the manufacture of Liquid Crystal Display (LCD) and Light Emitting Diode (LED) TV panel”, would attract nil duty.

Besides removing 5 per cent customs duty imposed on import of open cell TV panel, the government has waived customs duty on import of chip on Film, Printed Circuit Board Assembly (PCBA) and Cell (glass board/substrate), which are used to manufacture open cell TV panels.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey