apple lcd panel manufacturer brands

While Samsung will continue to supply approximately 80 per cent of iPhone displays, rumours claim that a little-known company called BOE looks set to become Apple’s second-largest OLED supplier. Not only is this a sign that Apple’s lowest-cost iPhone 12 model will likely make the leap from LCD to OLED this year, but it’s also a sign that Apple is looking to diversify which manufacturers it uses, and potentially looking to ready itself for a move into the display market itself.

You, like many of us when we first read the rumours, are probably wondering who the hell BOE is, and how it managed to score such a big deal despite its relatively unknown status. However, BOE is, in fact, the largest display manufacturer in China, supplying screens for smartphones, TVs and other electronic devices and home appliances.

The company, which was founded in Bejing in 1993 and acquired SK Hynix"s STN-LCD and OLED businesses back in 2001, is ranked second in the world when it comes to flexible OLED shipments, holding a market share of 11 per cent during the first quarter of this year. It, naturally, is still a long way behind market leader Samsung, which owned 81 per cent market share of the OLED market in the same quarter. Still, with a sizable chunk of the OLED market already under its belt, it perhaps won’t come as too much of a surprise – now, at least – that the firm already has some big-name allies.

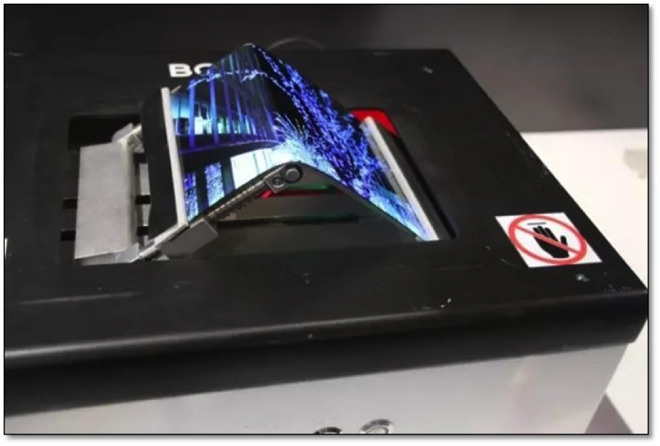

BOE’s display technology is currently being utilised in Huawei"s most popular smartphone models, including the high-end P and Mate series, and it reportedly will manufacturer the palm-stretching screen set to appear on this year’s Huawei Mate 40.

BOE’s surprising alliance with Apple isn’t the only time the two companies have worked together, either; the Chinese manufacturer already makes LCD screens for Apple"s older iPhones, and its tiny OLED panels are currently used in some Apple Watch models. It’s unclear how much BOE and Apple’s latest deal is worth, but it’s likely in the billions. According to online reports, Samsung’s deal with the iPhone maker is thought to be worth around $20 billion annually, so if BOE manages to secure 20 per cent of Apple’s display orders going forward, such a deal could be worth as much as $4bn.

Although BOE has managed to muscle its way into Apple’s exclusive list of OLED suppliers, and has invested heavily in facilities and equipment in order to meet the firm’s demands, the new partnership hasn’t got off to a flying start. According to reports, the company’s flexible OLED panels have not yet passed Apple’s final validation. This means, according to rumours, that BOE’s screens might not show up in the first batch of iPhone 12 models, and will instead start shipping on handsets at the beginning of 2021, with Apple instead set to re-increase its reliance on LG in the short term.

Scenarios like this, along with the fact that Apple is clearly looking to lessen its reliance on big-name display makers, makes us think that it won’t be long until the company ultimately stops relying on others altogether; after all, it’s no secret that Apple wants to control every aspect of its hardware development.

The display market could be Apple’s next target. Not only does the company already manufacturer screen technology in the form of its Pro Display XDR, but a recent Bloomberg report claims that Apple is “designing and producing its own device displays” and is making a “significant investment” in MicroLED panels. This technology utilises newer light-emitting compounds that make them brighter, thinner and less power-intense than the current OLED displays.

Apple’s efforts in MicroLED are reportedly in the “advanced stages”; the company has applied for more than 30 patents, and recent rumours suggest the firm is also considering investing over $330 million in a secretive MicroLED factory with the goal of bringing the technology to its future devices.

As Apple mainly relies on Samsung and LG to manufacture its OLED panels for the iPhone, another Chinese factory wants a piece of Cupertino’s company money. As reported by

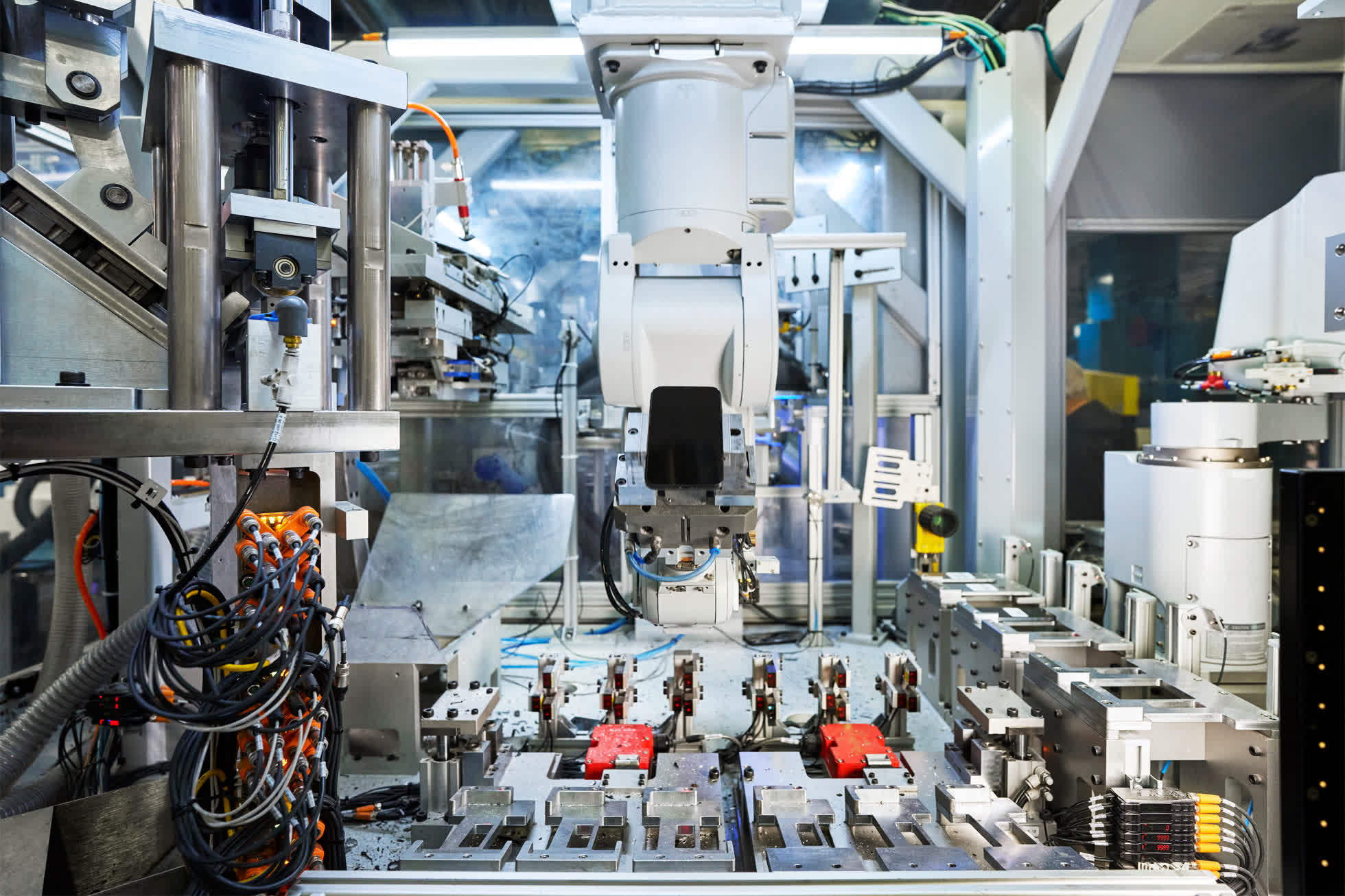

CSOT, together with Apple, first review the OLED panel produced from its T4 factory at Wuhan, China, sources said. The factory is designed to house three phases for a total capacity of 45,000 substrates per month. Two phases are currently live.

As of now, the Chinese company had supplied OLED panels for Samsung’s Galaxy M models in 2021. CSOT will also supply OLED panels for Galaxy A73 this year, The Elecreports.

The publication notes that it won’t be an easy path for CSOT, as China’s largest display panel maker BOE had failed “multiple times in Cupertino’s evaluation processes before finally being able to supply OLED panels to the iPhone maker.”

As 9to5Mac reported earlier this week, BOE, which currently manufactures OLED panels for iPhone 12 and iPhone 13 – and will do the same for this year’s iPhone 14 – will try to supply displays for iPhone 15 Pro as well.

Although Apple has a very high standard on its supply chains, having more options is good. As The Elec notes, “Cupertino can also already use BOE to pressure Samsung Display and LG Display into lowering their unit prices. BOE’s OLED production capacity will also expand to 144,000 substrates per month by the end of this year or early next year, triple that of the maximum capacity at CSOT’s T4 factory.”

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Apple Inc. sold a variety of LCD and CRT computer displays in the past. Apple paused production of their own standalone displays in 2016 and partnered with LG to design displays for Macs.Pro Display XDR was introduced, however it was expensive and targeted for professionals. Nearly three years later, in March 2022, the Studio Display was launched as a consumer-targeted counterpart to the professional monitor. These two are currently the only Apple-branded displays available.

In the beginning (throughout the 1970s), Apple did not manufacture or sell displays of any kind, instead recommending users plug-into their television sets or (then) expensive third party monochrome monitors. However, in order to offer complete systems through its dealers, Apple began to offer various third party manufactured 12″ monochrome displays, re-badged as the Monitor II.

Apple"s manufacture history of CRT displays began in 1980, starting with the Apple III business computer. It was a 12″ monochrome (green) screen that could display 80×24 text characters and any type of graphics, however it suffered from a very slow phosphor refresh that resulted in a "ghosting" video effect. So it could be shared with Apple II computers, a plastic stand was made available to accommodate the larger footprint of the display.

Three years later came the introduction of the Apple manufactured Apple IIc computer to help complement its compact size. This display was also the first to use the brand new design language for Apple"s products called Monitor 100, a digital RGB display for the Apple III and Apple IIe (with appropriate card), followed shortly by the 14″ ColorMonitor IIe (later renamed to ColorMonitor IIc (later renamed to AppleColor Composite Monitor IIc), composite video displays for those respective models. All of these Apple displays support the maximum Apple II Double Hi-Res standard of 560×192.

In 1986 came the introduction of the AppleColor RGB Monitor, a 12″ analog RGB display designed specifically for the Apple IIGS computer. It supported a resolution of 640×400 interlaced (640×200 non-interlaced) and could be used by the Macintosh II, in a limited fashion, with the Apple High Resolution Display Video Card. Also introduced that year was the Apple Monochrome Monitor, which cosmetically was identical to the former model but was a black and white composite display suitable in external appearance for the Apple IIGS, Apple IIc or Apple IIc Plus.

A new external AppleColor High-Resolution RGB Monitor was introduced in 1987 for the Macintosh II. It had a 13″ Trinitron CRT (the first Apple display to use an aperture grille CRT) with a fixed resolution of 640×480 pixels. The Macintosh II was a modular system with no internal display and was able to drive up to six displays simultaneously using multiple graphics cards. The desktop spanned multiple displays, and windows could be moved between displays or straddle them. In 1989, Apple introduced a series of monochrome displays for the Macintosh, the 20″ Macintosh Two Page Monochrome Display which could display two pages side by side, the 15″ Macintosh Portrait Display with a vertical orientation to display one page, and the 12″ High-Resolution Monochrome Monitor. In 1990, two 12″ displays were introduced for the low end, a 640×480 monochrome model and a 512×384 color model (560×384 for compatibility with Apple IIe Card), meant for the Macintosh LC. These were succeeded by the Apple Macintosh 16″ Color Display, and Apple Macintosh 20″ Color Display with resolutions of 640×480, 832×624 and 1152×870, respectively. There were also the Apple Performa Plus Display (a low-end Goldstar-built 14″ display with 640×480 resolution) for the Macintosh Performa series and the Apple Color Plus 14″ Display.

The third generation of displays marked the end of the monochrome display era and the beginning of the multimedia era. The first display to include built-in speakers was introduced in 1993 as the Multiple Scan series of displays began with the Multiple Scan 17 and 20 with Trinitron CRTs and the Multiple Scan 14 with shadow mask CRT, and would ultimately become Apple"s value line of shadow mask displays. The AppleVision series of displays then became the high-end display line, using 17″ and 20″ Trinitron CRTs and with AV versions containing integrated speakers. The AppleVision line was later renamed to Steve Jobs returned to Apple.

The Macintosh Color Classic introduced a 10″ color Trinitron display to the Classic compact Macintosh, with a slightly enhanced resolution of 512×384 (560×384 to accommodate the Apple IIe Card) like the standalone 12″ color display. Apple continued the all-in-one series with the larger 14″ Macintosh LC 500 series, featuring a 14″, 640×480 Trinitron CRT until the LC 580 in 1995, which heralded the switch to shadow mask CRTs for the remainder of Apple"s all-in-one computers until the switch to LCDs in 2002. The last Macintosh to include an integrated CRT was the eMac, which boosted the display area to 17″ with support up to 1280×960 resolution. It used a 4th generation flat-screen CRT and was discontinued in 2006.

The fourth generation of displays were introduced simultaneously with the Blue & White Power Macintosh G3 in 1999, which included the translucent plastics of the iMac (initially white and blue "blueberry", then white and grey "graphite" upon the introduction of the Power Mac G4). The displays were also designed with same translucent look. The Apple Studio Display series of CRT displays were available in a 17″ Diamondtron and a 21″ Trinitron CRT, both driven by an LG-Manufactured chassis. The 17″ displays were notorious for faulty flybacks and failing in a manner that could destroy the monitor and catch fire. It"s also reported that these monitors can destroy GPU"s, and sometimes the entire computer. The last Apple external CRT display was introduced in 2000 along with the Power Mac G4 Cube. Both it and the new LCD Studio Displays featured clear plastics to match the Cube, and the new Apple Display Connector, which provided power, USB, and video signals to the display through a single cable. It was available only in a 17″ flat screen Diamondtron CRT. It was discontinued the following year.

The history of Apple LCDs started in 1984 when the Apple Flat Panel Display was introduced for the Apple IIc computer, principally to enhance the IIc"s portability (see Apple IIc Portability enhancements). This monochrome display was capable of 80 columns by 24 lines, as well as double hi-res graphics, but had an odd aspect ratio (making images look vertically squished) and required a very strong external light source, such as a desk lamp or direct sunlight to be used. Even then it had a very poor contrast overall and was quite expensive (US$600), contributing to its poor sales and consequently it dropping from the market not long after its introduction. An estimated 10,000 IIc LCD displays were produced.

The next attempt at a flat panel was with the Macintosh Portable. More of a "luggable" than a laptop, it contained a high-resolution, active-matrix, 1-bit black & white, 9.8″ LCD with 640×400 resolution. Like the IIc Flat Panel, it was not backlit and required a bright light source to be used. A second generation model employed a backlit LCD. The PowerBook and MacBook series would continue to use LCD displays, following an industry-wide evolution from black-and-white to grayscale to color and ranging from 9″ to 17″. Two primary technologies were used, active matrix (higher quality and more expensive) and passive matrix displays (lower quality and cheaper). By 1998 all laptops would use active-matrix color LCDs, though the Newton products and eMate portables would continue to use black and white LCDs. Apple"s current MacBook portable displays include LED backlighting and support either 2560×1600 or 2880×1800 pixel resolutions depending on screen size. The iPod series used black-and-white or color LCDs, the iPhone line uses LCD and OLED displays, and the Apple Watch uses OLED.

In 1997, Apple released the Twentieth Anniversary Macintosh (TAM), its first all-in-one desktop with an LCD display. Drawing heavily from PowerBook technology, the TAM featured a 12.1″ active matrix LCD capable of displaying up to 16 bit color at 800×600. While Apple chose to retain traditional and cheaper CRTs for its all-in-one desktop line for the next 4 years, the TAM is undoubtedly the predecessor for the successful LCD-based iMac line of all-in-one desktops starting with the iMac G4 released in 2002. A substantial upgrade over the TAM, it contained a 15″ LCD supporting up to 1024×768 resolution. It was followed by a 17″ and 20″ models boasting resolution of up to 1680 × 1050. In 2005, the iMac G5 dropped the 15″ configuration and in 2007, the new iMac dropped the 17″ and added a 24″ to the line-up, further boosting resolution to 1920 x 1200. In October 2009, new iMac models moved to 16:9 aspect ratio screens at 21.5 and 27 inches.

The first desktop color flat-panel was introduced on March 17, 1998, with the 15″ Apple Studio Display (15-inch flat panel) which had a resolution of 1024×768. After the eMate, it was one of the first Apple products to feature translucent plastics, two months before the unveiling of the iMac. Apple called its dark blue color "azul". It had a DA-15 input as well as S-video, composite video, ADB and audio connectors, though no onboard speakers. In January 1999 the coloring was changed to match the blue and white of the new Power Macintosh G3s, and the connector changed to DE-15 VGA.

In 2000 the 22″ Cinema Displays switched to the ADC interface, and the 15″ Studio Display was remodeled to match the Cinema Display"s easel-like form factor and also featured the Apple Display Connector. In 2001 an LCD-based 17″ Studio Display was introduced, with a resolution of 1280×1024. In 2002 Apple introduced the

In 2004 a new line was introduced, utilizing the same 20″ and 23″ panels alongside a new 30″ model, for $3,299. The displays had a sleek aluminum enclosure with a much narrower bezel than their predecessors. The 20″ model featured a 1680×1050 resolution, the 23″ 1920×1200, and the 30″ 2560×1600. The 30″ version requires a dual-link interface, because a single-link DVI connection (the most common type) doesn"t have enough bandwidth to provide a picture to a display of this resolution. Initially, the only graphics cards that could power the new 30″ display were the Nvidia GeForce 6800 DDL series, available in both GT and Ultra forms. The DDL suffix signified the dual-link DVI capability. The less expensive of the two cards retailed for US$499, raising the net cost of owning and using the display to nearly $3,800. Later graphics options included the NVIDIA Quadro FX 4500; the card included two dual-link DVI connectors which allowed a Power Mac G5 to run two 30″ Cinema Displays simultaneously with the total number of pixels working out to 8.2 million.

In 2006 along with the introduction of the Mac Pro, Apple lowered the price of the 30″ Cinema Display to US$1999. The Mac Pro featured an NVIDIA GeForce 7300GT as the graphics card in its base configuration which is capable of running a 30″ Cinema Display and another 23″ display simultaneously. The Mac Pro is also available with both the ATI Radeon X1900XT card and the NVIDIA Quadro FX 4500 as build-to-order options. Each of these cards is capable of driving two 30″ Cinema Displays.

With the introduction of the Unibody MacBook family, Apple introduced the 24-inch LED Cinema Display, its first desktop display to use the new Mini DisplayPort connector, and also the first with an LED-backlit LCD. It had built-in speakers, a powered 3-port USB hub on the rear, an iSight camera and microphone, and a MagSafe power adapter for laptops. It also connected by USB for peripherals. It has a resolution of 1920×1200 and retailed for US$899.00. In 2010 it was replaced with a new 27-inch version with a resolution of 2560×1440.

In 2011 Apple released the Apple Thunderbolt Display, replacing the Mini DisplayPort and USB connector with a Thunderbolt plug for display and data. A Gigabit Ethernet port, a FireWire 800 port and a Thunderbolt 2 port were added as well, and the iSight camera was upgraded with a 720p FaceTime camera. On June 23, 2016, Apple announced it had discontinued the Thunderbolt Display, ending Apple"s production of standalone displays.

After Apple discontinued production of standalone displays in 2016, they partnered with LG to design the UltraFine line, with a 21.5-inch 4K display and 27-inch 5K display (27MD5KA-B), released in November 2016 alongside the Thunderbolt 3-enabled MacBook Pro.USB-C connector, with the 27-inch version integrating Thunderbolt 3 connectivity. On the rear of the displays is a three port USB-C hub. The 21.5-inch version provides up to 60W charging power, while the 27-inch provides up to 85W. The 21.5-inch is compatible with all Macs with a USB-C port, while the 27-inch version can only be used natively at full resolution with Macs with Thunderbolt 3, which includes all Macs with USB-C except the Retina MacBook. The 27-inch model is compatible with older Thunderbolt 2-equipped Macs using an adapter, but is limited to displaying their maximum output resolution.

In May 2019 the 21.5-inch model was discontinued and replaced with a 23.7-inch model which added Thunderbolt 3 connectivity and increased the power output to 85W. In July 2019, the 27-inch model (27MD5KL-B) was updated with USB-C video input, adding compatibility with the 3rd generation iPad Pro at 4K resolution, and increased power output to 94W.Apple Studio Display, but the display is still in production according to LG.

Apple announced the Pro Display XDR at the 2019 WWDC, the first Apple-branded display since the Apple Thunderbolt Display was discontinued in 2016. The display contains a 6016×3384 6K color-calibrated Extreme Dynamic Range (XDR) panel.

Apple announced the Apple Studio Display at the March 2022 Apple Special Event. It features a 27-inch, 5K Retina monitor, with 5120-by-2880 resolution at 218 pixels per inch, 600 nits brightness, wide color (P3), and True Tone technology.

The Apple Display Connector (ADC), which carries DVI, VGA, USB and power in one connector, was used on the PowerMac G4 and early models of the PowerMac G5.

Phono connector video out on the Apple II, II+, IIe, IIc, IIc+, IIGS, III, and III+. While not technically NTSC or PAL compatible, a suitable image would display on NTSC/PAL television monitors

The Apple Video Adapter was specially designed to allow users to connect to S-video or composite video devices. The video adapter cable plugs into the video output port (Mini-VGA) built into the back of certain Macintosh computers. The video output port supports VGA, S-Video and Composite video out. The Apple Video Adapter is for S-Video or Composite video output only, use a separate Apple VGA Adapter for VGA video output options. With the Apple Video Adapter you can connect to your TV, VCR, or overhead projector via S-Video or Composite cables.

The Apple VGA Display Adapter was specially designed to allow users to connect certain Macintosh computers to an extra VGA display or external projector (equipped with VGA) for 24-bit video-mirroring. The VGA cable from your external display or projector cable plugs into the Mini-VGA video port built into your Macintosh via the Apple VGA Display Adapter.

Compatible with: eMac, iMac G5, iMac G4 flat-panel, 12-inch PowerBook G4, or iBooks having a Mini-VGA port. Most Macintosh computers with the Mini-VGA port can also use the Apple Video Adapter for S-video & Composite output options.

"Apple"s Online Store Now Offering New 5K 27-Inch LG UltraFine Display". www.macrumors.com. Archived from the original on September 26, 2022. Retrieved April 3, 2020.

Welch, Chris (March 8, 2022). "Apple announces 27-inch 5K Studio Display for $1,599". The Verge. Archived from the original on March 15, 2022. Retrieved March 8, 2022.

Chinese display manufacturer Beijing Oriental Electronics (BOE) could lose out on 30 million display orders for the upcoming iPhone 14 after it reportedly altered the design of the iPhone 13’s display to increase yield rate, or the production of non-defective products, according to a report from The Elec (via 9to5Mac).

Apple tasked BOE with making iPhone 13 displays last October, a short-lived deal that ended earlier this month when Apple reportedly caught BOE changing the circuit width of the iPhone 13’s display’s thin-film transistors without Apple’s knowledge. (Did they really think Apple wouldn’t notice?).

This decision could continue to haunt BOE, however, as Apple may take the company off the job of making the OLED display for the iPhone 14 as well. According to The Elec, BOE sent an executive to Apple’s Cupertino headquarters to explain the incident and says it didn’t receive an order to make iPhone 14 displays. Apple is expected to announce the iPhone 14 at an event this fall, but The Elec says production for its display could start as soon as next month.

In place of BOE, The Elec expects Apple to split the 30 million display order between LG Display and Samsung Display, its two primary display providers. Samsung will likely produce the 6.1 and 6.7-inch displays for the upcoming iPhone 14 Pro, while LG is set to make the 6.7-inch display for the iPhone 14 Pro Max.

According to MacRumors, BOE previously only manufactured screens for refurbished iPhones. Apple later hired the company to supply OLED displays for the new iPhone 12 in 2020, but its first batch of panels failed to pass Apple’s rigorous quality control tests. Since the beginning of this year, BOE’s output has also been affected by a display driver chip shortage.

Apple Card Monthly Installments (ACMI) is a 0% APR payment option available only in the U.S. to select at checkout for certain Apple products purchased at Apple Store locations, apple.com, the Apple Store app, or by calling 1-800-MY-APPLE and is subject to credit approval and credit limit. See support.apple.com/kb/HT211204 for more information about eligible products. Variable APRs for Apple Card other than ACMI range from 13.99% to 24.99% based on creditworthiness. Rates as of October 1, 2022.

If you choose the pay‑in‑full or one‑time‑payment option for an ACMI‑eligible purchase instead of choosing ACMI as the payment option at checkout, that purchase will be subject to the variable APR assigned to your Apple Card. Taxes and shipping are not included in ACMI and are subject to your card’s variable APR. See the Apple Card Customer Agreement for more information. ACMI is not available for purchases made online at the following special stores: Apple Employee Purchase Plan; participating corporate Employee Purchase Programs; Apple at Work for small businesses; Government, and Veterans and Military Purchase Programs, or on refurbished devices. iPhone activation required on iPhone purchases made at an Apple Store with one of these national carriers: AT&T, Sprint, Verizon, or T‑Mobile.

To access and use all the features of Apple Card, you must add Apple Card to Wallet on an iPhone or iPad with the latest version of iOS or iPadOS. Update to the latest version by going to Settings > General > Software Update. Tap Download and Install.

Service coverage is available only for the Apple display, its original included accessories, and one Apple-branded display stand and one Apple-branded mount purchased at the same time for protection against (i) defects in materials or workmanship and (ii) unlimited incidents of accidental damage from handling, each incident being subject to a service fee of $99 for screen damage or external enclosure damage, or $299 for other accidental damage, plus applicable tax.

Availability of each option depends on country or region in which service is requested and location of Apple Authorized Service Provider. Apple may also request that the customer replace components with readily installable parts.

Cupertino, California Apple today introduced Mac Studio and Studio Display, an entirely new Mac desktop and display designed to give users everything they need to build the studio of their dreams. A breakthrough in personal computing, Mac Studio is powered by M1 Max and the new M1 Ultra, the world’s most powerful chip for a personal computer. It is the first computer to deliver an unprecedented level of performance, an extensive array of connectivity, and completely new capabilities in an unbelievably compact design that sits within arm’s reach on the desk. With Mac Studio, users can do things that are not possible on any other desktop, such as rendering massive 3D environments and playing back 18 streams of ProRes video.1 Studio Display, the perfect complement to Mac Studio, also pairs beautifully with any Mac. It features an expansive 27-inch 5K Retina display, a 12MP Ultra Wide camera with Center Stage, and a high-fidelity six-speaker sound system with spatial audio. Together, Mac Studio and Studio Display transform any workspace into a creative powerhouse. They join Apple’s strongest, most powerful Mac lineup ever, and are available to order today, arriving to customers beginning Friday, March 18.

“We couldn’t be more excited to introduce an entirely new Mac desktop and display with Mac Studio and Studio Display,” said Greg Joswiak, Apple’s senior vice president of Worldwide Marketing. “Mac Studio ushers in a new era for the desktop with unbelievable performance powered by M1 Max and M1 Ultra, an array of connectivity, and a compact design that puts everything users need within easy reach. And Studio Display — with its stunning 5K Retina screen, along with the best combination of camera and audio ever in a desktop display — is in a class of its own.”

With the power and efficiency of Apple silicon, Mac Studio completely reimagines what a high-performance desktop looks like. Every element inside Mac Studio was designed to optimize the performance of M1 Max and M1 Ultra, producing an unprecedented amount of power and capability in a form factor that can live right on a desk.

Built from a single aluminum extrusionwith a square footprint of just 7.7 inches and a height of only 3.7 inches, Mac Studio takes up very little space and fits perfectly under most displays. Mac Studio also features an innovative thermal design that enables an extraordinary amount of performance. The unique system of double-sided blowers, precisely placed airflow channels, and over 4,000 perforations on the back and bottom of the enclosure guide air through the internal components and help cool the high-performance chips. And because of the efficiency of Apple silicon, Mac Studio remains incredibly quiet, even under the heaviest workloads.

Powered by either M1 Max or M1 Ultra, Mac Studio delivers extraordinary CPU and GPU performance, more unified memory than any other Mac, and new capabilities that no other desktop can achieve. With M1 Max, users can take their creative workflows to new levels, and for those requiring even more computing power, M1 Ultra is the next giant leap for Apple silicon, delivering breathtaking performance to Mac Studio. M1 Ultra builds on M1 Max and features the all-new UltraFusion architecture that interconnects the die of two M1 Max chips, creating a system on a chip (SoC) with unprecedented levels of performance and capabilities, and consisting of 114 billion transistors, the most ever in a personal computer chip.

Mac Studio is powered by macOS Monterey, the latest version of the world’s most advanced desktop operating system. The combination of macOS Monterey with M1 Max or the powerful new M1 Ultra delivers breakthrough performance, security, and productivity for users. FaceTime includes audio and video features that make calls feel more natural and lifelike, and SharePlay enables Mac users to have shared experiences through FaceTime. Live Text and Visual Lookup are intelligence features that surface useful information, Safari includes powerful tab organization with Tab Groups, and Shortcuts bring the ease of automation to the Mac. Continuity tools like AirPlay to Mac enable Apple devices to work even better together, and with next week’s release of macOS Monterey 12.3 and iPadOS 15.4, Universal Control will make it easy for users to work effortlessly across Mac and iPad for unparalleled productivity.5

Mac Studio and Studio Display were designed to minimize their environmental impact. Mac Studio uses far less energy than competitors to deliver its extraordinary performance. For example, over the course of a year, Mac Studio will use up to 1,000 kilowatt-hours less energy than a high-end PC desktop.6Both Mac Studio and Studio Display use 100 percent recycled rare earth elements in all magnets and recycled tin in the solder of the main logic board — as well as recycled aluminum and plastic in various components. Both products also meet Apple’s high standards for energy efficiency, are free of numerous harmful substances, and use wood fiber in the packaging that comes from recycled sources or responsibly managed forests.

Today, Apple is carbon neutral for global corporate operations, and by 2030, plans to have net-zero climate impact across the entire business, which includes manufacturing supply chains and all product life cycles. This means that every Apple device sold, from component manufacturing, assembly, transport, customer use, charging, all the way through recycling and material recovery, will be 100 percent carbon neutral.

The new Mac Studio and Studio Display are available to order today on apple.com/store and in the Apple Store app. They will begin arriving to customers, and will be in select Apple Store locations and Apple Authorized Resellers, beginning Friday, March 18.

Studio Display is $1,599 (US), and $1,499 (US) for education. Additional technical specifications, including nano-texture glass and a choice of stand options, are available at apple.com/store.

Magic Keyboard with Touch ID and Numeric Keypad ($199 US), Magic Trackpad ($149 US), and Magic Mouse ($99 US) in the new silver-and-black color option are available at apple.com/store.

With Apple Trade In, customers can trade in their current computer and get credit toward a new Mac Studio. Customers can visit apple.com/shop/trade-in to see what their device is worth.

Apple revolutionized personal technology with the introduction of the Macintosh in 1984. Today, Apple leads the world in innovation with iPhone, iPad, Mac, Apple Watch, and Apple TV. Apple’s five software platforms — iOS, iPadOS, macOS, watchOS, and tvOS — provide seamless experiences across all Apple devices and empower people with breakthrough services including the App Store, Apple Music, Apple Pay, and iCloud. Apple’s more than 100,000 employees are dedicated to making the best products on earth, and to leaving the world better than we found it.

Testing was conducted by Apple in February 2022 using preproduction Mac Studio systems with Apple M1 Ultra, 20-core CPU and 64-core GPU, and 128GB of RAM, and configured with 8TB SSD. Prerelease Final Cut Pro 10.6.2 was tested using a one-minute picture-in-picture project with 18 streams of Apple ProRes 422 video at 8192x4320 resolution and 30 frames per second, as well as a one-minute picture-in-picture project with nine streams of Apple ProRes 422 video at 8192x4320 resolution and 30 frames per second. Performance tests are conducted using specific computer systems and reflect the approximate performance of Mac Studio.

Testing was conducted by Apple in February 2022 using preproduction Mac Studio systems with Apple M1 Max, 10-core CPU, 64GB of RAM, and 8TB SSD. The test was conducted with FIO 3.27, 1024KB request size, 150GB test file, and IO depth=8. Performance tests are conducted using specific computer systems and reflect the approximate performance of Mac Studio.

Testing was conducted by Apple in February 2022 using preproduction Mac Studio systems with Apple M1 Ultra with 20-core CPU and 64-core GPU. Power was measured using a representative workload in a commercial application. High-end PC desktop data comes from testing Alienware Aurora R13 with Core i9-12900KF and GeForce RTX 3090. Performance tests are conducted using specific computer systems and reflect the approximate performance of Mac Studio.

Apple Inc. is designing and producing its own device displays for the first time, using a secret manufacturing facility near its California headquarters to make small numbers of the screens for testing purposes, according to people familiar with the situation.

The ambitious undertaking is the latest example of Apple bringing the design of key components in-house. The company has designed chips powering its mobile devices for several years. Its move into displays has the long-term potential to hurt a range of suppliers, from screen makers like Samsung Electronics Co., Japan Display Inc., Sharp Corp. and LG Display Co. to companies like Synaptics Inc. that produce chip-screen interfaces. It may also hurt Universal Display Corp., a leading developer of OLED technology.

Display makers in Asia fell after Bloomberg News reported the plans. Japan Display dropped as much as 4.4 percent, Sharp tumbled as much as 3.3 percent and Samsung slid 1.4 percent. Shares in Apple were down 1.3 percent during early trading at 5:21 a.m. in New York.

Controlling MicroLED technology would help Apple stand out in a maturing smartphone market and outgun rivals like Samsung that have been able to tout superior screens. Ray Soneira, who runs screen tester DisplayMate Technologies, says bringing the design in-house is a “golden opportunity” for Apple. “Everyone can buy an OLED or LCD screen,” he says. “But Apple could own MicroLED.”

None of this will be easy. Mass producing the new screens will require new manufacturing equipment. By the time the technology is ready, something else might have supplanted it. Apple could run into insurmountable hurdles and abandon the project or push it back. It’s also an expensive endeavor.

Ultimately, Apple will likely outsource production of its new screen technology to minimize the risk of hurting its bottom line with manufacturing snafus. The California facility is too small for mass-production, but the company wants to keep the proprietary technology away from its partners as long as possible, one of the people says. “We put a lot of money into the facility,” this person says. “It’s big enough to get through the engineering builds [and] lets us keep everything in-house during the development stages.”

Right now smartphones and other gadgets essentially use off-the-shelf display technology. The Apple Watch screen is made by LG Display. Ditto for Google’s larger Pixel phone. The iPhone X, Apple’s first OLED phone, uses Samsung technology. Phone manufacturers tweak screens to their specifications, and Apple has for years calibrated iPhone screens for color accuracy. But this marks the first time Apple is designing screens end-to-end itself.

The secret initiative, code-named T159, is overseen by executive Lynn Youngs, an Apple veteran who helped develop touch screens for the original iPhone and iPad and now oversees iPhone and Apple Watch screen technology.

The 62,000-square-foot manufacturing facility, the first of its kind for Apple, is located on an otherwise unremarkable street in Santa Clara, California, a 15-minute drive from the Apple Park campus in Cupertino and near a few other unmarked Apple offices. There, about 300 engineers are designing and producing MicroLED screens for use in future products. The facility also has a special area for the intricate process of “growing” LEDs.

Another facility nearby houses technology that handles so-called LED transfers: the process of placing individual pixels into a MicroLED screen. Apple inherited the intellectual property for that process when it purchased startup LuxVue in 2014.

About a year after that acquisition, Apple opened a display research lab (described internally as a “Technology Center”) in Taiwan. In a test to see if the company could pull off in-house display manufacturing, engineers in Taiwan first built a small number of LCD screens using Apple technology. They were assembled at the Santa Clara factory and retrofitted into iPhone 7 prototypes. Apple executives tested them, then gave the display team the go-ahead to move forward with the development of Apple-designed MicroLED screens.

The complexity of building a screen manufacturing facility meant it took Apple several months to get the California plant operational. Only in recent months have Apple engineers grown confident in their ability to eventually replace screens from Samsung and other suppliers.

In late 2017, for the first time, engineers managed to manufacture fully functional MicroLED screens for future Apple Watches; the company aims to make the new technology available first in its wearable computers. While still at least a couple of years away from reaching consumers — assuming the company decides to proceed — producing a functional MicroLED Apple Watch prototype is a significant milestone for a company that in the past designed hardware to be produced by others.

The latest MicroLED Apple Watch prototypes aren’t fully functioning wearables; instead the screen portion is connected to an external computer board. The screens are notably brighter than the current OLED Watch displays, and engineers have a finer level of control over individual colors, according to a person who has seen them. Executives recently approved continued development for the next two years, with the aim of shipping MicroLED screens in products.

It’s unlikely that the technology will reach an iPhone for at least three to five years, the people say. While the smartphone is Apple’s cash cow, there is precedent for new screen technologies showing up in the Apple Watch first. When it was introduced in 2014, the Apple Watch had an OLED screen. The technology finally migrated to the iPhone X last year.

Creating MicroLED screens is extraordinarily complex. Depending on screen size, they can contain millions of individual pixels. Each has three sub-pixels: red, green and blue LEDs. Each of these tiny LEDs must be individually created and calibrated. Each piece comes from what is known as a “donor wafer” and then are mass-transferred to the MicroLED screen. Early in the process, Apple bought these wafers from third-party manufacturers like Epistar Corp. and Osram Licht AG but has since begun “growing” its own LEDs to make in-house donor wafers. The growing process is done inside a clean room at the Santa Clara facility.

Engineers at the facility are also assembling prototype MicroLED screens, right down to attaching the screen to the glass. The backplanes, an underlying component that electronically powers the displays, are developed at the Taiwan facility. Apple is also designing its own thin-film transistors and screen drivers, key components in display assemblies. Currently, the Santa Clara facility is capable of manufacturing a handful of fully operational Apple Watch-sized (under 2 inches diagonally) MicroLED screens at a time.

Until MicroLED is ready for the world to see, Apple will still — at least publicly — be all-in on OLED. The company plans to release a second OLED iPhone in the fall, a giant, 6.5-inch model, and is working to expand OLED production from Samsung to also include LG.

Samsung, a key Apple supplier that manufactures a number of vital components for iPhone, iPad and Mac, on Tuesday said it plans to cease traditional LCD panel production by the end of 2020.

In announcing the development, a spokeswoman for Samsung Display, a subsidiary of Samsung Electronics, said the company will end all LCD manufacturing in South Korea and China by year"s end, reports Reuters. The company in October announced the shutdown of one domestic plant due to weak demand.

Over the next five years, the tech giant will sink money into converting one of its two South Korean LCD plants into a production facility for quantum dot displays.

Used in conventional hardware like LED-backlit LCD panels, quantum dots can be "tuned," or manufactured, to emit very narrow spectrums of light when struck by energy from a common blue backlight, making them a prime candidate for display makers. Further, the construction of a quantum dot LCD panel is similar to that of a traditional LCD screen, with the addition of quantum tubes or films situated next to or on top of backlight LEDs.

Samsung has not decided what to do with the two LCD factories in China that will wind down operations as part of the strategy announced today, the report said.

Samsung has in the past supplied LCD screens for products including iPhone, iPad and Mac, but demand has waned as Apple and other smartphone brands move to OLED. The Korean company fills a bulk of Apple"s OLED orders for flagship iPhone models and Apple Watch, with LG picking up the slack. Chinese firm BOE is reportedly set to enter Apple"s supply chain in 2020 or 2021.

In the immediate future, Apple is rumored to launch at least six devices with mini LED screens, another LCD-based technology that enhances picture quality through highly specific local dimming and better color reproduction.

Samsung"s shift leaves Apple with LG, Japan Display and Sharp as its major LCD screen suppliers, though each are readying their own proprietary OLED products.

A number of 2023 LG TVs from its OLED, QNED, and LCD series have bagged certification from the NRRA in Korea. For starters, there are two models from the 2023 LG G3 OLED series: LG OLED77G3 LG OLED55G3 It is complemented by four models from the 2023 LG C3 OLED series: LG OLED77C3 LG OLED55C3 LG OLED48C3 LG OLED42C3 The 2023 LG OLED models are also complemented by two models from the LG B3 and one model from the LG...

The LG 27GR95QE UltraGear gaming monitor is a new offering by the brand that most probably features LG"s own WOLED 26.5" display panel - LW270AHQ. The 27-inch OLED gaming monitors by LG presented so far, feature JOLED"s solution. LG will start the production of 27-inch (26.5) and 32-inch (31.5) by the end of this year and a 42-inch WOLED display panel will enter production at a later stage. The upcoming LG 45GR95QE...

Demand for LTPS TFT LCD shipments rose 30 percent in September 2015 to reach 51.6 million units, due to strong demand from Apple and Chinese brands. Total smartphone panel shipments grew 4 percent month over month to reach 160 million units in September 2015. While amorphous silicon (a-Si) thin-film transistor (TFT) liquid-crystal display (LCD) panels continue to lead the smartphone display market, low-temperature polysilicon (LTPS) TFT LCD panel shipment share is growing, according to IHS Inc., a of critical information and insight.

“TFT-LCD, based on a-Si substrate, has been the leading panel technology for mobile phones because it is easy to manufacture and costs less to produce than other display technologies. However, since Apple adopted LTPS for its popular iPhones, demand for the new technology has continued to increase,” said Brian Huh, senior analyst for IHS Technology. “While LTPS panels cost greater, they boast lower power consumption and higher resolution compared to a-Si LCD panels. Greater demand for higher definition screens, especially in China, has also increased the adoption of LTPS LCD mobile phone displays.”

Based on the latest information in the IHS Smartphone Display Shipment Tracker,the market share for the a-Si TFT LCD panel fell 10 percent month over month, but the panel still comprised the majority of smartphone display shipments, reaching 79.6 million in September 2015. Active-matrix organic light-emitting diode (AMOLED) panel shipments grew 7 percent to reach just 25 million units.

As a point of differentiation in the smartphone display market, Samsung Electronics adopted AMOLED-based LTPS displays in 2009. At that time Samsung Display was not looking to expand its customer base because Samsung Electronics digested almost all of the company’s AMOLED capacity. However as Samsung Electronics’ AMOLED smartphone business began to decline last year, Samsung Display has been expanding its customer lineup. “Since the end of last year, Samsung Display has been actively and aggressively promoting AMOLED displays to other electronics companies, especially in China, and AMOLED panel shipments for Chinese brands have increased remarkably since September,” Huh said.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey