tft lcd screen burn quotation

TFT LCD image retention we also call it "Burn-in". In CRT displays, this caused the phosphorus to be worn and the patterns to be burnt in to the display. But the term "burn in" is a bit misleading in LCD screen. There is no actual burning or heat involved. When you meet TFT LCD burn in problem, how do you solve it?

Burn in is a noticeable discoloration of ghosting of a previous image on a display. It is caused by the continuons drive of certain pixels more than other pixels. Do you know how does burn in happen?

When driving the TFT LCD display pixels Continously, the slightly unbalanced AC will attract free ions to the pixels internal surface. Those ions act like an addition DC with the AC driving voltage.

Those burn-in fixers, screen fixer software may help. Once the Image Retention happened on a TFT, it may easy to appear again. So we need to take preventive actions to avoid burn in reappearing.

For normal white TFT LCD, white area presenting minimal drive, black area presenting maximum drive. Free ions inside the TFT may are attracted towards the black area (maximum drive area)

When the display content changed to full screen of 128(50%) gray color, all the area are driving at the same level. Those ions are free again after a short time;

It"s called "Remanence effect". Basically the games sections which stay static were displayed at the same place for too long and got "stuck" on that place in your screen. This is a common issue with liquid crystal displays. That"s why on TVs like Samsung, the on screen display (OSD) keeps moving and does not stay static. It only happens if the image stays for very long.

It could go away if you let the screen turned off for a while, but dont quote me on that. You can also try to make a blank (white color) video run for several hours and it might get the job done.

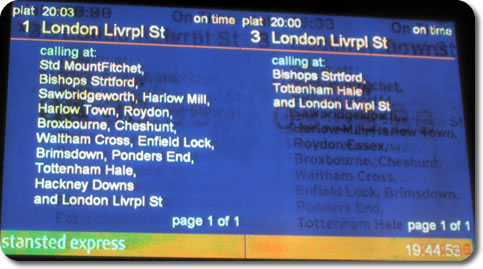

If you"ve ever left your LCD monitor on a single static screen for an extended period, say 24 hours or more, and then changed the on-screen image and seen a "ghost" of the previous screen, you"ve experienced Image Persistence. You can also sometimes see this phenomenon while traveling through an airport and seeing the flight status monitors. The good news is that the persistence is not permanent, unlike previous technologies such as plasma displays or CRTs.

The previous technologies of plasma displays and CRTs are phosphor-based, and extended static images create a "burn-in" that affects the properties of the phosphor material and create permanent damage. The damage is called burn-in, whereas static image "ghosts" on an LCD are Image Persistence. Image Persistence is not permanent damage and is reversible. Modern LCDs include design, driver ICs and chemical improvements that minimize these effects.

Image persistence can happen with any LCD panel, and almost all specifications will have some reference to image persistence. Many will have a specific criterion of acceptable levels of it.

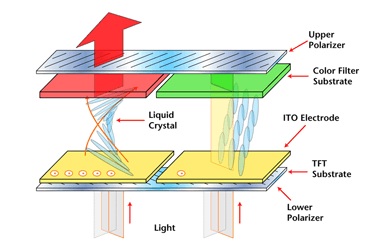

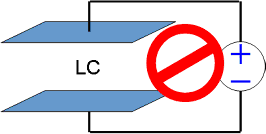

To understand why image persistence happens, we must first understand the basic structure of an LCD TFT. Within the TFT, a voltage is applied to the liquid crystal material to align or twist the crystals in each pixel to allow light to pass through or block light, thus creating the on-screen image. By allowing a static image to remain on screen for an extended duration, the polarity of that voltage on the crystals remains. During this time, ions within the liquid crystal fluid will migrate to either the + or – electrode of the transistor (source or drain). As these ions accumulate on the electrodes, the voltage applied to the crystals to align or twist is no longer sufficient to completely change the image on-screen, resulting in a "ghost effect" from the previous image.

The best method for preventing Image Persistence is to avoid having any static images on the screen for an extended time. If the image changes periodically, the ion flow will never have an opportunity to accumulate on any internal electrode. However, depending upon the use of the display, it is not always possible to avoid static images on the screen. In cases such as these, there are steps that you can do to reduce the chance of persistence.

Panel manufacturers specifically test for the phenomenon and have designed the TFT cell and improved the purity of the liquid crystal fluid to minimize any effect of image persistence.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

:max_bytes(150000):strip_icc()/Emerson-McDonalds_CNN_Burn-In-5692ad0d3df78cafda81df58-5c619daec9e77c0001d92fc1.jpg)

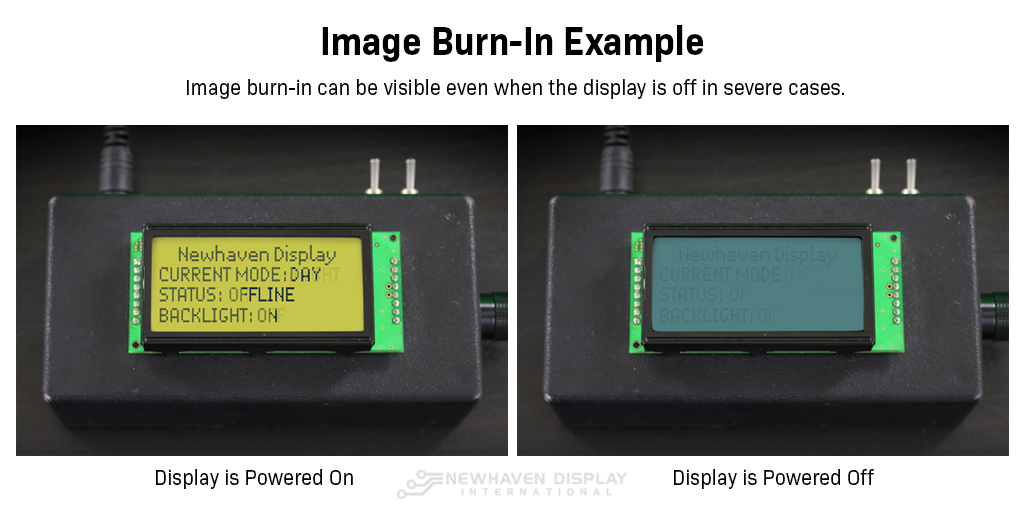

Image burn-in, also referenced as screen burn-in or ghost image, is a permanent discoloration of sections on an electronic display caused by increasing, non-uniform use of the screen.

The term burn-in dates back to when old monitors using phosphor compounds that emit light to produce images lost their luminance due to severe usage in specific display areas.

Chances are you"ve encountered image burn-in and image retention before, but you didn"t know which one you were seeing. They both have the same visual effects, so it"s easy to mistake them for each other, but there"s one key difference:

Most of the time, these guides explain how image retention works and how you can speed up its recovery process. We want to clear up any confusion you might have about image burn-in and image retention on LCD and OLED displays.

Image retention, also known as ghosting or image persistence, is the temporary effect of images remaining visible on LCDs or OLEDs for a short period, usually a few seconds.

If the images fade away after a short time, you are dealing with temporary image retention. If the images stay permanently, you are dealing with image burn-in.

Image retention doesn"t require any intervention from the user to make it go away – it"ll do that by itself. Retention will often occur before burn-in does on newer display technology like our

using a screen saver, cycling various graphics on the screen to exercise the pixels, and powering off the display whenever possible will help clear the image retention on your display.

These are the same tricks you"ll see advertised as a "cure" for image burn-in, but don"t be fooled. There"s no fix for burn-in, only ways to prolong it from happening.

Before you assume your screen has burn-in damage, try these tips and wait to see if it"s just image retention. Image retention is a harmless and common occurrence on many screens.

Image burn-in is caused by screen pixels that stay activated in a static position for long periods of time.Think of a TV in a lobby or waiting area that"s always playing the same news channel. The news channel footer and logo get burned into the screen permanently, even when you change the channel.

When LCD or OLED pixels stay activated in a static position, they"ll eventually become "stuck" in that position. When this happens, you"ll notice a faded, stubborn image that persists on the screen.

When pixels fail to activate or deactivate entirely, it results in faded images that won"t clear from the screen. This is common in applications using character LCDs where the alphanumeric characters are updated less frequently.

Remember: There"s no way to remove or reduce burn-in after it occurs. If a stubborn image persists for extended periods or after restarting your display, you"re likely dealing with image burn-in.

Even the most advanced displays will experience burn-in at some point, but there are some simple actions you can take to extend your screen"s lifespan before burn-in occurs. With the proper practices, you can get years of outstanding performance from your display without any burn-in effects.

A screensaver is a good alternative if you can"t turn your display off. For displays that don"t need to be ON at all times, it"s helpful to let the screen rest when not in use.

Get those pixels moving! The longer a pixel stays activated in a static position, the closer it gets to being burned in. You can exercise your screen"s pixels with scrolling text, moving images, or changing colors.

For an OLED display, decreasing the contrast will lower the brightness and reduce the rate of image burn. More illumination (brightness) requires more current, which reduces OLED pixel lifespans.

For a LCD display, lowering the contrast will put less stress on the liquid crystals and will help to reduce the rate of pixels becoming weak, or sticking.

Remember that image burn-in is not reversible and can not be fixed once it happens. Whether it is a scrolling effect, rotating pixels, using a screensaver, or turning off the screen when not in use, it"s essential to establish image burn-in preventive measures to help extend the lifespan of your display.

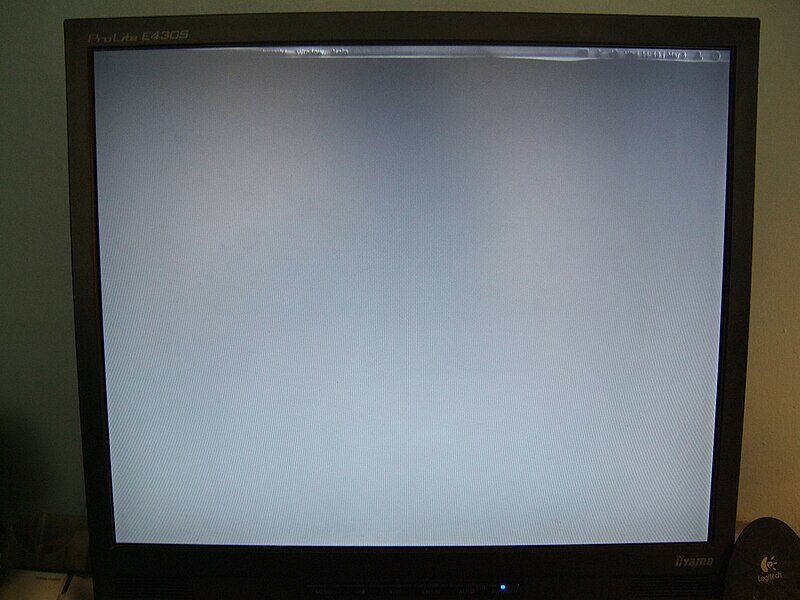

Screen burn-in, image burn-in, or ghost image, is a permanent discoloration of areas on an electronic display such as a cathode ray tube (CRT) in an old computer monitor or television set. It is caused by cumulative non-uniform use of the screen.

One way to combat screen burn-in was the use of screensavers, which would move an image around to ensure that no one area of the screen remained illuminated for too long.

With phosphor-based electronic displays (for example CRT-type computer monitors, oscilloscope screens or plasma displays), non-uniform use of specific areas, such as prolonged display of non-moving images (text or graphics), repetitive contents in gaming graphics, or certain broadcasts with tickers and flags, can create a permanent ghost-like image of these objects or otherwise degrade image quality. This is because the phosphor compounds which emit light to produce images lose their luminance with use. This wear results in uneven light output over time, and in severe cases can create a ghost image of previous content. Even if ghost images are not recognizable, the effects of screen burn are an immediate and continual degradation of image quality.

The length of time required for noticeable screen burn to develop varies due to many factors, ranging from the quality of the phosphors employed, to the degree of non-uniformity of sub-pixel use. It can take as little as a few weeks for noticeable ghosting to set in, especially if the screen displays a certain image (example: a menu bar at the top or bottom of the screen) constantly and displays it continually over time. In the rare case when horizontal or vertical deflection circuits fail, all output energy is concentrated to a vertical or horizontal line on the display which causes almost instant screen burn.

Screen burn on an amber CRT computer monitor. Note that there are two separate burned-in images: one of a spreadsheet program, and another of an ASCII-art welcome screen.

Phosphor burn-in is particularly prevalent with monochromatic CRT screens, such as the amber or green monochrome monitors common on older computer systems and dumb terminal stations. This is partly because those screens displayed mostly non-moving images, and at one intensity: fully on. Yellow screens are more susceptible than either green or white screens because the yellow phosphor is less efficient and thus requires a higher beam current. Color screens, by contrast, use three separate phosphors (red, green, and blue), mixed in varying intensities to achieve specific colors, and in typical usage patterns such as "traditional" TV viewing (non-gaming, non-converged TV usage, non-Internet browsing, broadcasts without tickers or flags, no prolonged or permanent letterboxing) are used for operations where colors and on-screen object placement approach uniformity.

Modern CRT displays are less susceptible than older CRTs prior to the 1960s because they have a layer of aluminum behind the phosphor which offers some protection. The aluminum layer was provided to reflect more light from the phosphor towards the viewer. As a bonus, the aluminum layer also prevented ion burn of the phosphor and the ion trap, common to older monochrome televisions, was no longer required.

A nearly two-year-old LCD television showing extreme burn-in of CNN"s circa 2008 digital on-screen graphic; this television is in a McDonald"s restaurant where CNN is permanently turned on and displayed throughout the business day.

In the case of LCDs, the physics of burn-in are different than plasma and OLED, which develop burn-in from luminance degradation of the light-emitting pixels. For LCDs, burn-in develops in some cases because pixels permanently lose their ability to return to their relaxed state after a continued static use profile. In most typical usage profiles, this image persistence in LCD is only transient.

Both plasma-type and LCD-type displays exhibit a similar phenomenon called transient image persistence, which is similar to screen burn but is not permanent. In the case of plasma-type displays, transient image persistence is caused by charge build-up in the pixel cells (not cumulative luminance degradation as with burn-in), which can be seen sometimes when a bright image that was set against a dark background is replaced by a dark background only; this image retention is usually released once a typical-brightness image is displayed and does not inhibit the display"s typical viewing image quality.

Screensavers derive their name from their original purpose, which was an active method of attempting to stave off screen burn. By ensuring that no pixel or group of pixels was left displaying a static image for extended periods of time, phosphor luminosity was preserved. Modern screensavers can turn off the screen when not in use.

In many cases, the use of a screensaver is impractical. Most plasma-type display manufacturers include methods for reducing the rate of burn-in by moving the image slightly,Android Wear watches with OLED displays can request that Android Wear enable "burn protection techniques" that periodically shift the contents of the screen by a few pixels.

Other examples: Apple"s iPhone X and Samsung"s Galaxy series both mitigate or delay the onset of burn-in by shifting the pixels every minute or so for the battery, Wi-Fi, location, and service bars. Also, parallax scrolling may be enabled for the home screen to give icons a 3D-like effect, a setting Apple refers to as "perspective zoom". AG Neovo patented Anti-burn-in technology is also using pixel shifting to activate the pixels to move by the designed time interval to prevent burn in effect on LCD monitors.

Google requests that when these techniques are enabled, watch face developers do not use large blocks of pixels so that different pixels are burned in with each shift, reducing the overall wear of the pixels.

Some screensavers move around, such as those on DVD players or those on some television sets that move around paused video after a long period of inactivity.

Depending on the type of screen, it is sometimes possible to remedy screen burn-in through the use of remedial software and remedial devices. In the case of OLED screens on Android phones, burn-in reduction apps can display an inverted image of the navigation and status bars (which are constantly displayed and therefore the most likely elements to be burned in) to burn in opposite pattern, resulting in a screen whose sub-pixels have more even luminosity and therefore less visible burn-in artifacts.

The most prevalent burn-in image on early televisions was said to be that of the RCA Indian-head test pattern, which would often follow the formal television station sign-off. This was due to the viewer leaving the television set on at the end of the day, which was not recommended by the television manufacturers.

The X-17E 5:4 semi-industrial monitor with the metal casing is designed for reliable 24/7 operation in demanding environments. With selectable gamma curves and versatile connectivity, this monitor provides an optimal visual experience with excellent colour, brightness, and contrast ratio. NeoV Optical Glass screen and corrosion-resistant metal casing shield it from scratches and chemical exposure which make it ideal for public, laboratory, and light industrial applications.

The X-24E semi-industrial monitor with the metal casing is designed for reliable 24/7 operation in demanding environments. With selectable gamma curves and versatile connectivity, this monitor provides an optimal visual experience with excellent colour, brightness, and contrast ratio. NeoV Optical Glass screen and corrosion-resistant metal casing shield it from scratches and chemical exposure which make it ideal for public, laboratory, and light industrial applications.

Screen:Limited to only 1 or 2 minor scratches, chips or scuff marks on glass. It will have no more than 2 dead pixels and the picture does not have "screen burn". The screen has a the correct level of contrast and brightness consistent with its age. The LCD Display may have slight bruising, no more than a nickel size, which may affect the picture quality.

HP Compaq LA1905 19"" 1440x900 16:10 Widescreen LCD Monitor VGA DVI DP Grade B. This is a HP 19"" widescreen LCD monitor. The resolution is 1440x900 with an aspect ratio of 16:10. Our technicians have tested every monitor to guarantee that they are fully functional.

Screen: No scratches, chips or scuff marks on glass. It will have NO dead pixels and the picture does not have "screen burn". The screen has a the correct level of contrast and brightness consistent with its age. The LCD Display will NOT have light or dark patches (bruising) which may affect the picture quality.

I am developing a user interface on a cheap Kinco color LCD HMI unit. After leaving a test UI on the screen for about 3 days, there was a very decided "ghosting" effect.

I was able to eliminate the ghost outlines by alternating a solid black and white screen over the course of about 2 days. Now the screen is back to normal and the ghosted image does not appear.

Since this HMI will be in service for several years with basically the same screens always in use, I want to build a screen-saver which will prevent ghosting. Note that users will view/interact with the HMI very little, as it"s in a remote location and may be visited a couple times per week.

In building a screen saver, should the display constantly alternate between solid black and white screens, or is there a specific color which places the least "strain" on an LCD pixel, which would avoid ghosting and ensure pixels remain as bright and color-accurate as possible? For example, is Black considered "full on" or "full off" by the LCD circuitry and pixels? Would a black or white pixel create more prominent ghost image, or is the issue going to appear for any pixel that does not change over a period of time?

At this point I don"t know whether alternating between colors is better or worse than filling the screen with a single, unchanging color. I"m looking to implement whichever scheme preserves the pixel brightness/dynamic response and eliminates ghosting.

Just recently I"ve noticed a very sticky liquid leaking out of one corner of the screen. There are now bright and dark patches on the screen near where it"s leaking. As well as round the screen the sticky stuff gets onto the base of the laptop where I rest my hands to type. lt"s really hard to clean off and I"m worried it may be toxic.

TFT LCD screen after using a period of time, you will find that the display often adsorbed a layer of dust (turn off the LCD side look more obvious), and sometimes also accidentally stick to a variety of water stains, which will certainly greatly affect the visual effect, how to clean it?

②Move the LCD to a place with better natural light so that you can see where the dust is, which is more conducive to targeting and thus achieving better cleaning results.

③ clean TFT LCD does not need any special solution or wipe, experience tells us that water + soft lint-free cloth or cotton lint-free cloth is the best TFT LCD cleaning tools (no flakes paper towels also work). In the cleaning can be used cotton lint-free cloth dipped in water and then slightly wrung out, and then slightly wet soft lint-free wet cloth on the display of dust to gently wipe (do not squeeze the display), wipe recommended from one side of the display wipe to the other side until all wipe clean, do not wipe indiscriminately.

Tip: Do not use hard cloth, hard paper wipe. At the same time, do not use the cleaning solution containing alcohol or acetone or chemical cleaning agents, not to mention the liquid directly sprayed onto the screen surface, so as to avoid liquid penetration into the protective film.

④After cleaning the LCD screen with a damp soft cloth, use a damp cloth that is wrung dry to clean again. Finally, let the water on the LCD screen in a ventilated place to dry naturally.

① Avoid vibration, the LCD screen is very fragile, to avoid strong shock and vibration. Do not put pressure on the LCD screen or LCD display back cover collision, squeeze.

② Avoid using the screen for a long time. Long-term work is not a good thing for LCDs, so be sure to power off the monitor if it is not in use. By the same token, be careful with wallpapers and screensavers when using LCD. Most of the wallpaper and screensavers program images are colorful, light and dark changes in contrast, long time use will make the LCD color distortion, which affects the life of the LCD display. Therefore, it is best to use a monochrome screen and cancel the screensaver when using the LCD.

③ anti-electromagnetic interference. Both CRT or TFT LCD screen should be away from objects with strong magnetic fields, the strong magnetic field around the display will cause additional internal voltage, which affects the stability of the display voltage. Long time in a strong magnetic field, but also make the color distortion, thus affecting the LCD display effect and life.

④ Pay attention to humidity. Do not let any moisture into the LCD, such as indoor humidity is too high LCD internal condensation may occur, so that the LCD leakage and short circuit, serious will also burn the display. For some southern regions with higher humidity, the LCD can be placed in a warmer and drier place, but also regularly bake the back of the LCD with a small power lamp in order to let the moisture evaporate.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey