low power lcd display arduino manufacturer

This graphic LCD module acts as a shield for Arduino Uno-style microcontrollers. The pins on the carrier board match up to the Arduino Uno"s ports, so the module simply presses on and is fully and correctly connected. Plus, this carrier board is able to be connected to either a 3.3v logic level or a 5v logic level device. (Read our blog post if you have questions about logic level.)

This module is also available with a white-on-blue graphic display, or as a fully built kit with an included Seeeduino (Arduino Uno clone) loaded with code to demonstrate the graphic display.

I"m drooling over Sharp Memory LCD, but they are pricey. I mean $40 is not terrible for one, but I need to get a bunch for battery powered LCD boards I"m working on

From my breadboard tests ATmega328p board w/ Nokia 5110 is using 140-170uA (depending on number of characters on display) when chip is sleeping which is not bad at all, but I want to explore all alternatives...

Alas I don"t know of a display that matches your requirements (price/power) and apart from an e-ink or memory LCD that updates vary rarely I don"t think you will ever get one to run for a year on 2x AAA batteries.

The reflective version (without backlight) of the DOGS102 might meet your requirements. According to the datasheet, the current will be 250uA for LCD and LCD-Controller (if I interpret the datasheet correctly).

The reflective version (without backlight) of the DOGS102 might meet your requirements. According to the datasheet, the current will be 250uA for LCD and LCD-Controller (if I interpret the datasheet correctly).

Alas I don"t know of a display that matches your requirements (price/power) and apart from an e-ink or memory LCD that updates vary rarely I don"t think you will ever get one to run for a year on 2x AAA batteries.

Yeah you could be right. Besides display I forgot that I need to keep radio module awake, that eats a lot of power. But how they heck do they do this with commercial temperature/humidity devices? I have one that"s been running for 2 years on single AA battery

Yeah you could be right. Besides display I forgot that I need to keep radio module awake, that eats a lot of power. But how they heck do they do this with commercial temperature/humidity devices? I have one that"s been running for 2 years on single AA battery

My commercial module only last about 6 months on 2x AAA. It would probably last longer without the LCD to display temperature/humidity and flash an LED every time it transmits (every 30 seconds). Your doing very well with yours, must have one of them plutonium batteries.

Note that these do not use the highly multiplexed display system with the bias ladder of the graphical or 1602/ 2004 devices, they are generally one pin per segment so the electronics is far more efficient.

Darn. I"ve been searching and it seems everyone in Arduinoland uses OLEDs and TFTs. I want a 1" display that I can run off of a coin battery for a year. I know they exist, I own a bunch of them. But the best thing I"ve found draws 125uA.

That"s a 2.2" display. I"m looking for a 1" display, like many of the little OLEDs you can buy on eBay for $5 or less. But with 1/500th the power consumption. My $10 wristwatch has a display like that.

It appears that you simply haven"t weighed up the real issues. If you finally get a display with 1/500th the consumption of what ever, all you get is that but, if that is what you need, the real problem isn"t the display and never was. It"s the Arduino that drives it.

I"m not planning on using an Arduino. Why would you assume that? If the display drew 20uA instead of 10mA it would still be the major consumer of current.

Fair enough. What"s an Arduino? AVR (and non-AVR) chips are also discussed in this forum. But even an official Arduino board like the Pro Mini, with the regulator isolated, is capable of drawing a very low average current.

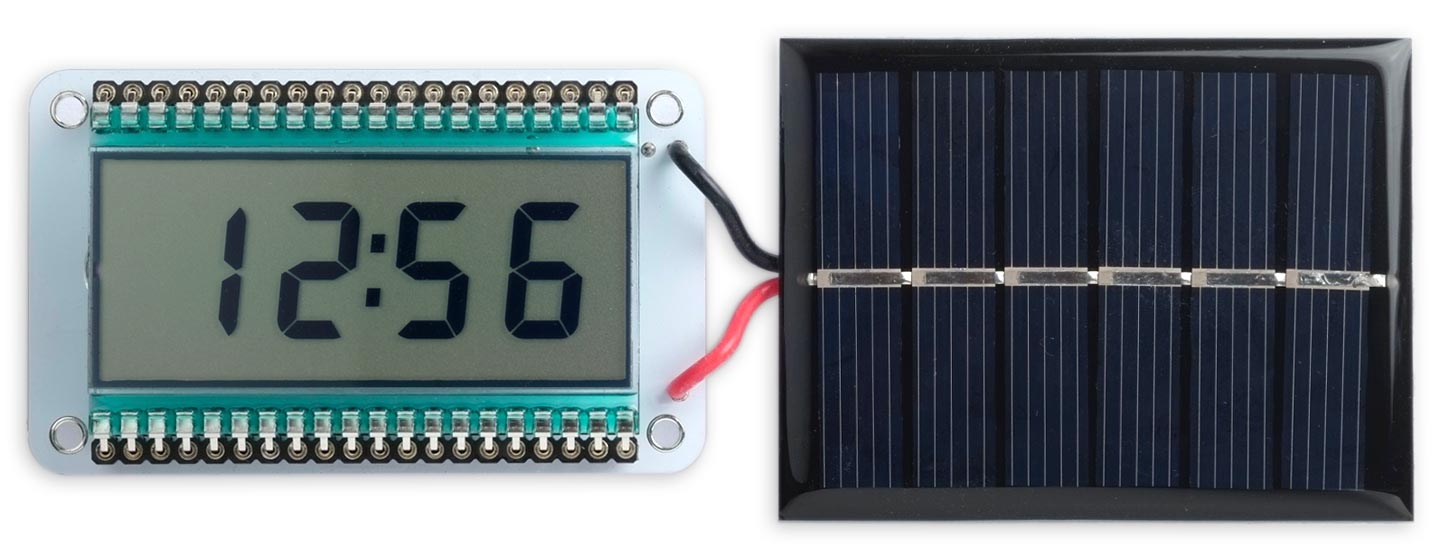

This is a very low-power LCD clock, based on an AVR128DA48, capable of running for over three years from a CR2032 button cell, or for ever from a solar cell:

Every minute it also briefly displays the temperature, using the AVR128DA48"s on-chip temperature sensor, and the battery voltage, by using the ADC to read its own supply voltage. There"s also an I2C connection so you can add an external sensor, for example to show the humidity in addition to the other readings.

Although liquid crystal displays (LCDs) are relatively old technology, they still offer several advantages over newer types of display, including low power, low cost, and readability.

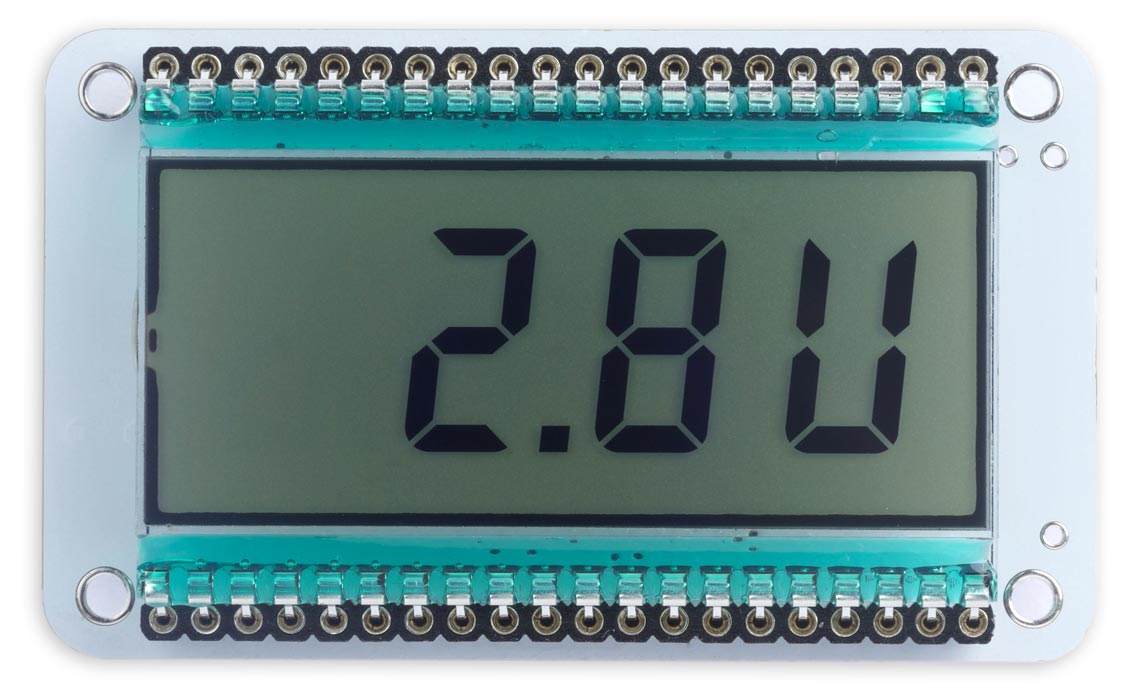

I recently bought some Densitron LCD displays on eBay for a few pounds/dollars, and I"d been wanting to try building a low-power clock around them, to see just how low I could get the power consumption. The displays are a standard type, available with compatible pinouts from several manufacturers. They are called static (as opposed to multiplexed), which means that every segment comes to a separate pin on the edge connector. This makes 28 pins for the segments plus three decimal points, a colon, and a common pin, adding up to 33 pins altogether. The displays I"ve found usually have two common pins, and also typically have other special-purpose segments, such as a minus sign, in a 40-pin package.

The displays are usually clear, but when you apply a voltage of about 3.3V between a segment and the common line the segment turns black. The displays I"m using have a reflective backing; they are also available with a translucent backing so you can add a backlight behind them.

There"s one catch; you can"t use a DC voltage to turn on the segments, because this would cause electrolysis to occur which would slowly degrade the display. The solution is to use AC by switching the polarity across the segment at a low frequency; 32Hz is usually recommended. Fortunately this is easy to do in software

Most 40-pin, 33mm row spacing displays should be compatible with this board; here are some I"ve found. These all have 4 digits and 3 decimal points on pins 5 to 27, 29 to 32, and 34 to 37, and commons on 1 and 40, plus a few extra symbols as shown:

The circuit is less complicated than it looks. Each segment simply connects to one I/O line on the processor. All the segments for one digit go to the same port, with the decimal point going to bit 7, segment A going to bit 6, through to segment G going to bit 0 (with a couple of exceptions explained below).

Because of the number of interconnections I didn"t fancy prototyping this project by hand, but went straight to designing a PCB in Eagle, and I sent it to PCBWay for manufacture. I tried to make the PCB as general purpose as possible. It caters for any of the displays in the above table; to select which of the extra symbols you want to display you need to fit an 0Ω resistor to the board to act as a link.

The processor is an AVR128DA48 in a TQFP-48 package, but the PCB would work with a range of other 48-pin processors. The AVR128DB48 would be suitable, as would the lower memory versions of these two devices, down to the AVR32DA48 and AVR32DB48. However, you only save a few pence/cents by choosing the lower memory versions, so I don"t really see the point.

The ATmega4809 and its lower-memory siblings, down to the ATmega809, are pin compatible with the DA and DB chips in the same packages, and so could also be used on this board; the only restriction is that the pins I"ve used for I2C, PF2 and PF3, only support slave I2C on the ATmega4809.

Alternatively, if you want to power the clock from a 3V solar cell there are holes to allow you to fit a supercapacitor in place of the coin cell; I used a PowerStor 0.47F 5V one

The PCB also includes a 4-pin JST PH socket, providing an I2C interface compatible with Adafruit"s STEMMA system or the Grove system. You can use this to connect a sensor to the board, for example to show the humidity as well as the time and temperature, or you could use it to make the board an I2C slave so it can be used as an I2C display for other projects.

There"s no multiplexing, so to display a segment pattern we just need to write the appropriate value from the segment array, Char[0] to Char[11], to the port corresponding to the digit. Ports D, C, and A provide eight I/O lines each, so these map in a logical way to the seven segments and decimal point in digits 0 to 2. There"s a slight complexity with digit 3 because Port B only has six I/O lines available, so the segment corresponding to bit 6 is provided by PF5. The colon or other symbol is controlled by PF4.

The interrupt service routine first toggles all the I/O lines connected to the LCD segments, and the common connections. Every 32 calls, or every half second, it calculates the current time, and checks whether the buttons are pressed. If the MINS or HRS buttons are pressed it advances the time by a minute or an hour respectively. It then calls the routine DisplayTime() to update the time, or at the end of each minute it calls DisplayVoltage() to display the battery voltage for three seconds, followed by DisplayTemp() to display the temperature for three seconds:

DisplayTime() copies the digits representing the current time to the corresponding output ports, specified by Digit[0] to Digit[3]. It also flashes the colon:

Unlike earlier AVR microcontrollers, where you had to calibrate the temperature sensor, the AVR DA and DB series have been calibrated during manufacture and contain calibration parameters in ROM. The temperature display is therefore pretty accurate without any additional calibration.

The processor spends most of its time in power-down sleep mode, to save power, and is woken up by the 64Hz interrupt from the Real-Time Clock peripheral. I measured the average power consumption at 3.3V for four different clock frequencies:

Usually you"d expect the power consumption to increase with processor clock frequency, so at first sight these figures are puzzling. The explanation is that at higher clock frequencies the time taken to execute the interrupt service routine is shorter, allowing the processor to spend a higher proportion of the time asleep.

The 32.768kHz external crystal oscillator has a low-power mode, and selecting this reduced the average power consumption with a 24MHz clock from 9.5µA to 7.3µA. The AVR128DA48 datasheet doesn"t seem to mention any downside to choosing the low-power mode, so I used this setting.

With a 0.47F supercapacitor you can expect a current of 0.47A for 1 second. This gives an expected life of 0.47/7.3x10‑6/60/60 or about 18 hours, which I confirmed by testing it. This should be sufficient to keep the clock running overnight with a suitable solar cell providing power during daylight.

The HRS button doesn"t affect the seconds and minutes timing; this is designed to allow you to switch between Standard Time and Daylight Saving Time without affecting the clock setting.

Compile the programs using Spence Konde"s Dx Core on GitHub. Choose the AVR DA-series (no bootloader) option under the DxCore heading on the Board menu. Check that the subsequent options are set as follows (ignore any other options):

Make a UPDI programmer from an Arduino Uno, or other ATmega328P-based board, as described in Make UPDI Programmer, and set the Programmer option to "jtag2updi".

STONE intelligent TFT LCD display module manufacturer focuses on the research and development of HMI display module products, which are widely used in the fields of medical equipment LCD, industrial terminal TFT LCD, civil terminal display screen, and intelligent home control panel.(Click here to see the Display Heart Rate on the LCD with Arduino development case: https://www.stoneitech.com/arduino-lcd-display-project

low voltage application, low drive voltage, solid use safety, and reliability improvement; Flat, light, and thin, saving a lot of raw materials and space; Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT-LCD is only about one percent of the CRT, saving a lot of energy; TFT LCD products also have specifications, models, size series, variety, convenient and flexible use, maintenance, update, upgrade easy, long service life and many other characteristics.

no radiation, no flicker, no harm to users’ health. In particular, the appearance of TFT-LCD electronic books and periodicals will bring mankind into the era of a paperless office and paperless printing, and trigger the revolution of human learning, communication, and recording civilization.

From -20℃ to +50℃ temperature range can be used normally, after temperature reinforcement TFT-LCD low temperature working temperature can reach minus 80℃. It can be used as a mobile terminal display, desktop terminal display, and large screen projection TV. It is a full-size video display terminal with excellent performance.

It is a perfect combination of large-scale semiconductor integrated circuit technology and light source technology and has great potential for further development. There are amorphous, polycrystalline, and monocrystalline TFT-LCDs, and there will be TFTs of other materials, both glass, and plastic.

The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of glass substrate has been expanded to 680mm×880mm.

TFT was first used as a matrix location circuit to improve the characteristics of liquid crystal optical valves. For high-resolution display screens, the accurate control of object elements is achieved through voltage adjustment in the range of 0-6v (its typical value is 0.2 to 4V), thus making it possible for LCD to achieve a high-quality high-resolution display.

Liquid Crystal displays or LCDs have been used in electronics equipment since the late 1970s. LCD displays have the advantage of consuming very little current And they are ideal for your Arduino projects.

In this article and in the accompanying video I’ll show you how easy it is to add an LCD display to your next Arduino design. I’ll also show you a very popular Arduino Shield that has a keypad which you can use in your projects as well.

Today LCD displays are used in a variety of items from test equipment to televisions. They’re inexpensive and versatile, this makes them ideal for all sorts of designs.

LCD displays do not emit light. Instead they block the passage of light, like little windows which open and shut the let light through. The liquid crystals used inside LCD displays are sandwiched between two layers of polarized material. By changing the orientation of the liquid crystals they allow light to pass or they block the light entirely.

Because transmissive LCD displays (the type we will be using) work by blocking light they require a backlight. Several methods have been used to create back lights including electroluminescent panels and fluorescent tubes. these days the most common form of backlight is an LED, in fact so-called LED televisions are usually just LCD screens with an LED backlight system.

Another type of LCD display, the passive-matrix display, does not require a backlight, it works using reflected light. This type of display is often found in digital watches.

The principles of liquid crystals were discovered in the late 1880s but work on Modern LCD displays did not begin until the mid-1960s. a number of patents were filed in the early 1970s and in 1973 the Sharp Corporation introduced LCD displays for calculators.

The first color LCD displays were developed in the early 1980s but production units were not commonly available until the mid-1990s. By the late 1990s LCD displays were quite common.

A number of LCD displays are available for experimenters. These low-cost monochrome displays are ideal for use with microcontrollers like the Arduino and micro computers like the Raspberry Pi.

These displays are available in a number of different configurations. The part number for the display generally relates to the number of rows and columns in the display.

Common display configurations include 16 x 2, 16 x 4 and 20 x 4. All of these displays are used in a virtually identical fashion the only difference being the number of columns and rows they have.

The LCD1602 display module is a very popular and inexpensive LCD display. It is available in a number of different colors such as blue yellow and green and can easily be connected to an Arduino or Raspberry Pi.

In operation data is sent down the parallel data lines for the display. There are two types of data that can be sent to the display. The first type of data are the ASCII characters which are to be displayed on the display. The other type of data are the control characters that are used to activate the various display functions.

Brightness– This is the input for the brightness control voltage, which varies between 0 and 5 volts to control the display brightness. On some modules this pin is labeled V0.

Because the LCD module uses a parallel data input it requires 8 connections to the host microcontroller for the data alone. Add that to the other control pins and it consumes a lot of connections. On an Arduino Uno half of the I/O pins would be taken up by the display, which can be problematic if you want to use the I/O pins for other input or output devices.

We will begin our experiments by hooking up the LCD1602 to an Arduino Uno and running a few of the example sketches included with the Arduino IDE. This will allow you to get familiar with the display without needing to write any code.

We need to hookup our LCD display to our Arduino. The display can use any of the Arduino digital I/O pins as it has no special requirements, but if you hook it up as I’ve illustrated here you can run the example sketches without needing to make any modifications.

In addition to the LCD1602 display ands the Arduino Uno you will need a 10K trimpot ot potentiometer, this is used a s a brightness control for the display. You’ll also need a 220 ohm resistor to drop the voltage for the displays LED backlight.

The Arduino IDE includestheLiquidCrystallibraryand this library has a number of example sketches. I’ll go over three of them here but you can also try the other ones.

The sketch starts with a number of credits and a description of the required hardware hookup. You’ll note that this is the same hookup you just performed on your Arduino and LCD module.

We then initialize an object that we call “lcd” using the pinouts of the LCD display. If you decide to hook up your display to different pins then you’ll need to modify this section.

That ends the loop, so we start back at the top of the loop and repeat. The result will be a counter on the second line that counts seconds from the htime the Arduino was last reset.

Load the sketch up to your Arduino and observe your display. If you don’t see anything try adjusting the brightness control that you wired to the display.

The second example we will try isthe Scroll sketch. Scrolling is a useful technique when you can’t get your text to fit on one line of the LCD display.

In the loop the code demonstrates the use of thescrollDisplayLeftandscrollDisplayRightfunctions. As their names imply they move the text in a left or right direction.

Finally the last counter moves the text 16 positions to the left again, which will restore it back to the center of the display. The loop then repeats itself.

Custom characters are useful when you want to display a character that is not part of the standard 127-character ASCII character set. Thi scan be useful for creating custom displays for your project.

A character on the display is formed in a 5 x 8 matrix of blocks so you need to define your custom character within that matrix. To define the character you’ll use thecreateCharfunctionof the LiquidCrystal library. You are limited to defining a maximum of eight characters.

The Custom Character demonstration requires one additional component to be wired to the Arduino, a potentiometer (10K or greater) wired up to deliver a variable voltage to analog input pin A0.

As with the previous sketches we examined this one starts by loading theLiquidCrystallibrary and defining an object calledlcdwith the connection information for the display. It then moves on to define the custom characters.

The last two arrays,amsUpandarmsDowndefine the shape of a little “stickman”, or “stickperson” if you want to be politically correct! This is done to show how we can animate a character on the display.

Finally the setup routine ends by printing a line to the first row of the LCD display. The line makes use of two of the custom characters, the “heart” and the “smiley”.

We begin by reading the value of the voltage on pin A0 using the ArduinoanalogReadfunction. As the Arduino has a 10-bit analog to digital converter this will result in a reading ranging from 0 to 1023.

We then use an Arduinomapfunction to convert this reading into a range from 200 to 1000. This value is then assigned to an integer calleddelayTime, which as its name implies represents a time delay period.

One thing you may have noticed about using the LCD display module with the Arduino is that it consumes a lot of connections. Even in 4-wire mode there are still a total of seven connections made to the Arduino digital I/O pins. As an Arduino Uno has only 14 digital I/O pins that’s half of them used up for the display.

In other cases you would need to resort to using some of the analog pins as digital pins or even moving up to an Arduino Mega which has many more I/O pins.

But there is another solution. Use the I2C bus adapter for the LCD display and connect using I2C. This only consumes two I/O pins and they aren’t even part of the set of digital I/O pins.

The I2C or IIC bus is theInter Integrated Circuitbus. It was developed by Philips Semiconductors in 1982 for use in the television industry. The idea was to allow the integrated circuits in televisions to “talk” to one another using a standard bus.

The bus has evolved to be used as an ideal method of communicating between microcontrollers, integrated circuits, sensors and micro computers. You can use it to allow multiple Arduinos to talk to each other, to interface numerous sensors and output devices or to facilitate communications between a Raspberry Pi and one or more Arduinos.

Power– This can be either 5 Volts or 3.3 volts, depending upon the application. Note that there are many precautions that must be observed if you are interfacing a 3.3 volt and 5 volt I2C device on the same bus.

In I2C communications there is the concept of Master and Slave devices. There can be multiples of each but there can only be one Master at any given moment. In most Arduino applications one Arduino is designated Master permanently while the other Arduinos and peripherals are the Slaves.

The I2C Adapter for the LCD display is a tiny circuit board with 16 male header pins soldered to it. These pins are meant to be connected directly to the 16-pin connection on the LCD1602 display (or onto other displays that use the same connection scheme).

The device also has a 4-pin connector for connection to the I2C bus. In addition there is a small trimpot on the board, this is the LCD display brightness control.

Most Arduino Unos also have some dedicated pins for I2C, these are internally connected to A4 and A5 and are usually located above the 14 digital I/O pins. Some models of the Uno have additional I2C connectors as well.

Note how much easier it is to use the I2C connection, which does not consume any of the Arduino Unos 14 digital I/O pins. Since A4 and A5 are being used for the I2C bus they can’t be used as analog inputs in this configuration.

Load this sketch into your Arduino then open your serial monitor. You’ll see the I2C address of your I2C LCD display adapter. You can then make note of this address and use it in the sketches we’ll be looking at now.

In order to run the subsequent sketches you’ll need to install another library. This is theNewLiquidCrystallibrarywhich, as its name implies, is an improved version of the LiquidCrystal library packaged with your Arduino IDE.

The sketch starts by loading the ArduinoWirelibrary. This is the Arduino library that facilitates communications over I2C and it’s part of your Arduino IDE installation.

On the next line we define the connections to the LCD display module from the I2C Adapter,. Note that these are NOT the connections from the Arduino, they are the connections used by the chip on the adapter itself.

In setup we set the size of the display and then print “Hello world!” on the first line in the first position. After a short delay we print “How are you?” on the second line.

Load the sketch and run it on your Arduino. If you can’t get it to work check out the address and connection information to be sure you have it right.

As you can see the DHT22 is connected with its output tied to pin 7 of the Arduino. The other two connections are 5 volts and ground. Note that pin 3 of the DHT22 is not used.

This sketch also makes use of theDHTlibrary from Adafruit. We used this library in a previous article, “Using the HC-SR04 Ultrasonic Distance Sensor with Arduino” so you may want to take a look at that one in order to get it installed.

The key thing to note is that this library is dependant upon another Adafruit library, theirUnified Sensorlibrary. Both can be installed using the Library Manager in your Arduino IDE.

The sketch is similar to our demo sketch in that it creates an “lcd” object with the I2C and display connection information. It also defines a couple of parameters for the DHT22 sensor, as well as some floating variables to hold the temperature and humidity values.

Note that this displays the temperature in Celsius. If you want to change this to Fahrenheit its a simple matter of using some math. The formula( temp * 1.8 ) + 32will convert the results to Fahrenheit.

So far we have used the LCD1602 display module for all of our experiments. For our final demonstration we’ll switch to a popular Arduino shield that contains a LCD1602 along with some push buttons.

The LCD Keypad Shield is available from several different manufacturers. The device fits onto an Arduino Uno or an Arduino Mega and simplifies adding an LCD display to your project.

The Reset button is simply connected to the Arduino Reset pin and works just like the Reset button on the Arduino itself. This is common on many shields as the shields physically cover the Reset button.

Instead the buttons are connected to a resistor array that acts as a voltage divider. The entire array is connected to the Arduino’s analog A0 pin. One pin for five push buttons.

Note that the LCD is being used in 4-wire mode. The LCD itself is the same one used on the LCD1602 module, so all of the code for that module will work with the LCD Keypad Shield as well.

Now that you know how the LCD Keypad module works and which Arduino pins it uses all that remains is to install it onto your Arduino and load the demo sketch.

One thing – once the shield is installed on the Arduino you won’t have easy access to the unused I/O pins to connect any sensors or output devices you may want to use (although the demo sketch doesn’t need anything else connected). There are a couple of ways to get around this:

Use a shield that exposes the pins for prototyping before you install the LCD Keypad shield. In the video associated with this article I use a “Screw Shield” that brings all of the Arduino I/O pins out to a series of screw connectors. There are other similar shields. Using one of these shields is the easiest way to work with the LCD Keypad shield, as well as other Arduino shields.

The sketch begins by including theLiquidCrystallibrary. You can use the original one or the one includes with theNewLiquidCrystallibrary. We then set up an object with the LCD connections, note that these are just hard-coded as they won’t change.

Next we define a number of constants, one for each of the push buttons. Note that nothing is defined for the Reset button as it simply mimics the Arduino Reset button, however a constant is defined for the “none” condition.

After that we define a function calledread_LCD_buttons(). This function reads the value on analog port A0 and returns an integer corresponding to the button integers we defined earlier. Note that the function adds approximately 50 to each of the manufacturers specified values to account for intolerances in the resistors in the voltage divider.

We start the loop by placing the cursor 9 spaces over on the second line. We then use themillisfunction to display a counter that counts the time since the Arduino was reset. This is to test the Reset button.

We then call ourread_LCD_buttons()function and use it to display the value of the push button, right before the counter. Then we end the loop and do it again.

Load the code onto the Arduino and run it. You should see the value of each button as you press it, along with a counter that increments each second. If you press Reset the counter should reset itself back to zero.

As you can see LCD displays are pretty simple to use thanks to the availability of some excellent libraries for the Arduino. As these displays are also very inexpensive they will make an ideal addition to many of your Arduino projects.

And finally the LCD Keypad Shield is a convenient method of adding both a display and a simple keypad to your project, no wiring or soldering required.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

LCD (Liquid Crystal Displays) have two options or display modes.Positive mode (dark characters on a light colored background) and negative mode (lighter colored characters on a darker background).

Please see Fig.1: Yellow green STN (Super Twisted Nematic) display, the background of yellow green is lighter than dark blue characters. It is a positive mode. Fig. 2 is a blue STN display, its background of blue is darker than the white characters.It is negative mode.

Positive mode displays have the advantage of their lighter background and no backlights are needed. They normally use transflective or reflective polarizers and have lower power consumption. They can be seen with ambient light.

Negative mode displays need backlit in order to be seen. They normally use transmissive polarizers. They have better contrast and wider viewing angles in the indoor dim environment. The readability is much better than positive displays.

But under bright ambient light or even under direct sunlight, the displays will be easily washed out. In order to be seen under the bright surrounding light, the backlight brightness has to be increased to over 800 nits. The sunlight readable displays consume much power.

Of course, we can always use LED backlight in the LCD module with fewer LED chips and turn off LED backlight when not use to save power. When can also add transflective polarizer to some negative LCDs to make it sunlight readable, but the contrast will be compromised.

Positive and negative mode concept is not only limited to monochrome LCD displays (LCD panels, character LCDs, graphic LCDs etc.), it also uses for color displays, or even other display technologies. We will categorize the displays as below,

Character LCD modules (Alphanumeric LCD display modules) with character sets: 8×1 LCD display, 8×2 LCD display, 16×1 LCD display, 16×2 LCD display, 16×4 LCD display, 20×2 LCD display, 20×4 LCD display, 24×2 LCD display, 40×2 LCD display, 40×4 LCD display. COB (Chip on Board) bonded, 4 or 8 bits parallel, SPI, I2C interface

Graphic LCD modules with dot matrix sets 122×32, graphic LCD display, 128×64 graphic LCD display, 192×48 graphic LCD display,192×64 graphic LCD display,240×64 graphic LCD display,240×128 graphic LCD display,240×160 graphic LCD display with different color LED backlights, with COB and COG (Chip on Glass) assembling technologies

Monochrome and Color Graphic OLED modules with dot matrix sets 128×32 graphic OLED display,128×64 graphic OLED display, 128×96 graphic OLED display, 160×128 graphic OLED display, 128×128 graphic OLED display, 256×65 graphic OLED display

Full Color TN and IPS displays with panel sizes: 1.3”IPS display, 1.44” TN display, 1.5” IPS display, 1.77”TN and IPS displays, 2.0” TN and IPS displays, 2.2” IPS display, 2.35” IPS display, 2.4” TN and IPS displays, 2.8” TN and IPS displays, 3.5” TN and IPS displays, 4.3” TN display, 5.0” TN and IPS display, 7.0” TN and IPS display, 10.1” IPS display with medium and high brightness (sunlight readable), with parallel, SPI, RGB, LVDS, MIPI interfaces.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

In addition, there is a jumper on the board that supplies power to the backlight. To control the intensity of the backlight, you can remove the jumper and apply external voltage to the header pin that is marked ‘LED’.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x20. The range of all possible addresses spans from 0x20 to 0x27. Please see the illustration below.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x38. The range of all possible addresses spans from 0x38 to 0x3F. Please see the illustration below.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

Arduino (open-source hardware and software company, project, and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Its hardware products are licensed under a CC BY-SA license, while software is licensed under the GNU Lesser General Public License (LGPL) or the GNU General Public License (GPL),manufacture of Arduino boards and software distribution by anyone. Arduino boards are available commercially from the official website or through authorized distributors.

Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards ("shields") or breadboards (for prototyping) and other circuits. The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the Arduino language, inspired by the Processing language and used with a modified version of the Processing IDE. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go.

The Arduino project began in 2005 as a tool for students at the Interaction Design Institute Ivrea, Italy,sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats and motion detectors.

The name Arduino comes from a bar in Ivrea, Italy, where some of the founders of the project used to meet. The bar was named after Arduin of Ivrea, who was the margrave of the March of Ivrea and King of Italy from 1002 to 1014.

The Arduino project was started at the Interaction Design Institute Ivrea (IDII) in Ivrea, Italy.BASIC Stamp microcontroller at a cost of $50. In 2003 Hernando Barragán created the development platform Casey Reas. Casey Reas is known for co-creating, with Ben Fry, the Processing development platform. The project goal was to create simple, low cost tools for creating digital projects by non-engineers. The Wiring platform consisted of a printed circuit board (PCB) with an ATmega128 microcontroller, an IDE based on Processing and library functions to easily program the microcontroller.Arduino.

Following the completion of the platform, lighter and less expensive versions were distributed in the open-source community. It was estimated in mid-2011 that over 300,000 official Arduinos had been commercially produced,

At the end of 2008, Gianluca Martino"s company, Smart Projects, registered the Arduino trademark in Italy and kept this a secret from the other co-founders for about two years. This was revealed when the Arduino company tried to register the trademark in other areas of the world (they originally registered only in the US), and discovered that it was already registered in Italy. Negotiations with Martino and his firm to bring the trademark under control of the original Arduino company failed. In 2014, Smart Projects began refusing to pay royalties. They then appointed a new CEO, Federico Musto, who renamed the company Arduino SRL and created the website arduino.org, copying the graphics and layout of the original arduino.cc. This resulted in a rift in the Arduino development team.

At the World Maker Faire in New York on 1 October 2016, Arduino LLC co-founder and CEO Massimo Banzi and Arduino SRL CEO Federico Musto announced the merger of the two companies.

In April 2017, Wired reported that Musto had "fabricated his academic record... On his company"s website, personal LinkedIn accounts, and even on Italian business documents, Musto was, until recently, listed as holding a PhD from the Massachusetts Institute of Technology. In some cases, his biography also claimed an MBA from New York University." Wired reported that neither university had any record of Musto"s attendance, and Musto later admitted in an interview with Wired that he had never earned those degrees.open source licenses, schematics, and code from the Arduino website, prompting scrutiny and outcry.

By 2017 Arduino AG owned many Arduino trademarks. In July 2017 BCMI, founded by Massimo Banzi, David Cuartielles, David Mellis and Tom Igoe, acquired Arduino AG and all the Arduino trademarks. Fabio Violante is the new CEO replacing Federico Musto, who no longer works for Arduino AG.

In October 2017, Arduino announced its partnership with ARM Holdings (ARM). The announcement said, in part, "ARM recognized independence as a core value of Arduino ... without any lock-in with the ARM architecture". Arduino intends to continue to work with all technology vendors and architectures.

Under Violante"s guidance, the company started growing again and releasing new designs. The Genuino trademark was dismissed and all products were branded again with the Arduino name. As of February 2020, the Arduino community included about 30 million active users based on the IDE downloads.

In August 2018, Arduino announced its new open source command line tool (arduino-cli), which can be used as a replacement of the IDE to program the boards from a shell.

Arduino is open-source hardware. The hardware reference designs are distributed under a Creative Commons Attribution Share-Alike 2.5 license and are available on the Arduino website. Layout and production files for some versions of the hardware are also available.

Although the hardware and software designs are freely available under copyleft licenses, the developers have requested the name Arduino to be exclusive to the official product and not be used for derived works without permission. The official policy document on use of the Arduino name emphasizes that the project is open to incorporating work by others into the official product.-duino.

An early Arduino boardRS-232 serial interface (upper left) and an Atmel ATmega8 microcontroller chip (black, lower right); the 14 digital I/O pins are at the top, the 6 analog input pins at the lower right, and the power connector at the lower left.

Most Arduino boards consist of an Atmel 8-bit AVR microcontroller (ATmega8,ATmega328, ATmega1280, or ATmega2560) with varying amounts of flash memory, pins, and features.Arduino Due, based on the Atmel SAM3X8E was introduced in 2012.shields. Multiple and possibly stacked shields may be individually addressable via an I2C serial bus. Most boards include a 5 V linear regulator and a 16 MHz crystal oscillator or ceramic resonator. Some designs, such as the LilyPad,

Arduino microcontrollers are pre-programmed with a boot loader that simplifies uploading of programs to the on-chip flash memory. The default bootloader of the Arduino Uno is the Optiboot bootloader.RS-232 logic levels and transistor–transistor logic (TTL) level signals. Current Arduino boards are programmed via Universal Serial Bus (USB), implemented using USB-to-serial adapter chips such as the FTDI FT232. Some boards, such as later-model Uno boards, substitute the FTDI chip with a separate AVR chip containing USB-to-serial firmware, which is reprogrammable via its own ICSP header. Other variants, such as the Arduino Mini and the unofficial Boarduino, use a detachable USB-to-serial adapter board or cable, Bluetooth or other methods. When used with traditional microcontroller tools, instead of the Arduino IDE, standard AVR in-system programming (ISP) programming is used.

The Arduino board exposes most of the microcontroller"s I/O pins for use by other circuits. The Diecimila,Duemilanove,Unopulse-width modulated signals, and six analog inputs, which can also be used as six digital I/O pins. These pins are on the top of the board, via female 0.1-inch (2.54 mm) headers. Several plug-in application shields are also commercially available. The Arduino Nano, and Arduino-compatible Bare Bones Boardbreadboards.

Many Arduino-compatible and Arduino-derived boards exist. Some are functionally equivalent to an Arduino and can be used interchangeably. Many enhance the basic Arduino by adding output drivers, often for use in school-level education,

Arduino and Arduino-compatible boards use printed circuit expansion boards called shields, which plug into the normally supplied Arduino pin headers.3D printing and other applications, GNSS (satellite navigation), Ethernet, liquid crystal display (LCD), or breadboarding (prototyping). Several shields can also be made do it yourself (DIY).

Some shields offer stacking headers which allows multiple shields to be stacked on top of an Arduino board. Here, a prototyping shield is stacked on two Adafruit motor shield V2s.

A program for Arduino hardware may be written in any programming language with compilers that produce binary machine code for the target processor. Atmel provides a development environment for their 8-bit AVR and 32-bit ARM Cortex-M based microcontrollers: AVR Studio (older) and Atmel Studio (newer).

The Arduino integrated development environment (IDE) is a cross-platform application (for Microsoft Windows, macOS, and Linux) that is written in the Java programming language. It originated from the IDE for the languages brace matching, and syntax highlighting, and provides simple one-click mechanisms to compile and upload programs to an Arduino board. It also contains a message area, a text console, a toolbar with buttons for common functions and a hierarchy of operation menus. The source code for the IDE is released under the GNU General Public License, version 2.

The Arduino IDE supports the languages C and C++ using special rules of code structuring. The Arduino IDE supplies a software library from the Wiring project, which provides many common input and output procedures. User-written code only requires two basic functions, for starting the sketch and the main program loop, that are compiled and linked with a program stub main() into an executable cyclic executive program with the GNU toolchain, also included with the IDE distribution. The Arduino IDE employs the program avrdude to convert the executable code into a text file in hexadecimal encoding that is loaded into the Arduino board by a loader program in the board"s firmware.

From version 1.8.12, Arduino IDE windows compiler supports only Windows 7 or newer OS. On Windows Vista or older one gets "Unrecognized Win32 application" error when trying to verify/upload program. To run IDE on older machines, users can either use version 1.8.11, or copy "arduino-builder" executable from version 11 to their current install folder as it"s independent from IDE.

setup(): This function is called once when a sketch starts after power-up or reset. It is used to initialize variables, input and output pin modes, and other libraries needed in the sketch. It is analogous to the function main().

loop(): After setup() function exits (ends), the loop() function is executed repeatedly in the main program. It controls the board until the board is powered off or is reset. It is analogous to the function while(1).

Most Arduino boards contain a light-emitting diode (LED) and a current-limiting resistor connected between pin 13 and ground, which is a convenient feature for many tests and program functions.Hello, World!, is "blink", which repeatedly blinks the on-board LED integrated into the Arduino board. This program uses the functions pinMode(), digitalWrite(), and delay(), which are provided by the internal libraries included in the IDE environment.

The open-source nature of the Arduino project has facilitated the publication of many free software libraries that other developers use to augment their projects.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey