graphic segment lcd module quotation

Graphic LCD displays are available in many resolution sizes, backlight colors, and display modes including transflective and transmissive. Some of our graphic LCD displays are available with a built-in Sitronix ST7066U, NT7108C, RA6963, ST7920, or S1D13700 controller.

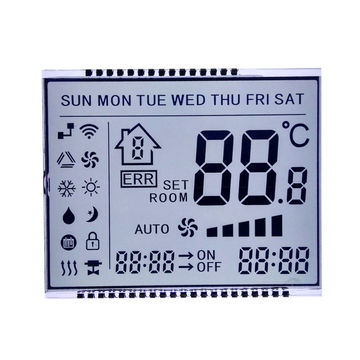

Dr Pan: Hello, Greg. Segment LCD screen can only be used for simple display content of numbers and characters at a specified position. For example, the display on clock, landline, calculator, etc.

It is supposed to be a replacement for LED segment display. If we compare it with LED segment display, it is more stylish and high class, but more expensive. If we compare it with dot matrix LCD, the display content is very simple and absence of variation, but much cheaper. It is widely used in monochrome LCD screen: TN, HTN, STN, FSTN and VA because of relatively low cost.

The 128240D is our largest standard monochrome graphic LCD. The viewing area is 92 x 53 mm and offers grey-scale performance. This LCD module is most commonly paired with a white LED backlight.

The ST7529 is a driver & controller LSI for 32 gray scale graphic dot-matrix liquid crystal display systems. It generates 255 Segment and 160 Common driver circuits. This chip is connected directly to a microprocessor, accepts Serial Peripheral Interface (SPI), 8-bit/16-bit parallel or IIC display data and stores in an on-chip display data RAM. It performs display data RAM read/write operation with no external operating clock to minimize power consumption. In addition, because it contains power supply circuits necessary to drive liquid crystal, it is possible to make a display system with the fewest components.

The 64128N uses our 64128K LCD module which has a viewing area of 50 x 25 mm and the ST7565R COG IC. The backlight uses a single LED for low power consumption.The PCB allows for easy mounting and assembly.

The ST7565R is a single-chip dot matrix LCD driver that can be connected directly to a microprocessor bus. 8-bit parallel or 4-line SPI display data sent from the microprocessor is stored in the internal display data RAM and the chip generates a LCD drive signal independent of the microprocessor. Because the chips in the ST7565R contain 65x132 bits of display data RAM and there is a 1-to-1 correspondence between the LCD panel pixels and the internal RAM bits, these chips enable displays with a high degree of freedom. The ST7565R chips contain 65 common output circuits and 132 segment output circuits, so that a single chip can drive a 65x132 dot display (capable of displaying 8 columns x4 rows of a 16x16 dot kanji font).

128x64 Dot Matrix COG, FSTN Gray background with White LED backlight, bottom (or 6:00) viewing angle, Transflective (positive), 3.0V LCD, 3.0V LED, RoHS Compliant. This LCD glass display has a wide temperature range: -20° Celcius to +70° Celcius which equates to (-4° Fahrenheit to +158° Fahrenheit).

FSTN (Film-compensated Super-twisted Nematic) provides a sharper contrast than STN by adding a film. The cost is approximately 5% higher than STN. FSTN works great for indoor and outdoor applications and is mainly used in graphic displays and higher end products. The Transflective polarizer is a mixture of Reflective and Transmissive. It provides the ability to read the LCD with or without the backlight on. It will work for all lighting conditions from dark with backlight to direct sunlight which makes it the most common choice. There is no cost difference between Transflective, Transmissive and Reflective.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

In Layman’s language, when an electric current is applied to the electrodes, i.e. to the segment line and common line, it twists the Liquid Crystals w.r.t to the polarizing filter, obstructing the light in that particular area as shown in the figure below. Hence, that area becomes darker and prominent.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Finding and choosing the right seven segment display can be very difficult and time-consuming. There are several technologies out there, with vastly different specifications, advantages, and disadvantages. Reading this article, will provide you new insights on what seven segment displays that will suit your project or product.

This post aims to give you a better understanding of what different 7 segment display technologies are available on the market and how they can be applied in various use-cases. We will cover the following seven segment display options:

Good appearance if designed right. Low-cost versions typically have a poor appearance with clearly visible segments in the off state. Good for dark & indoor environment

* 2x2 cm^2 outer dimension of a 1x7 segment display, approximately equivalent to 1 cm2 active display area. The calculations are based on 100 display updates per day. The presented figures are the average energy consumption from multiple datasheets available online.

In this seven segment display comparison, we include both emissive displays and reflective displays. An emissive display versus a reflective display are significantly different when comparing factors such as energy consumption and optical performance. For instance, a reflective display cannot be used without ambient light, but an emissive display is close to impossible to read in direct sunlight. Additional factors that will be covered in this article include cost, form factor, electrical driving, connector options.

If you’re looking for an ultra-low-powered display technology, a segmented LED display is ruled out, and most likely, so is a backlit LCD display. What you need is a reflective display. This leaves us with three choices; reflective LCD, the E Ink display, and the Rdot display.

Reflective LCDs are less complex in terms of energy consumption. Our research indicates that the average power consumption for one square centimeter active display area will consume around 6.6 µW. This figure will not be significantly affected depending on the number of display updates you perform.

The Rdot display has similar bistability characteristics as E Ink, but the screen will not retain the image as long as an E Ink display. The image retention time can be anywhere from 0 minutes up to 24 hours, depending on the use-case. For this example, we use a display with 15 minutes of image retention time. At 100 display updates per day, the Rdot display will consume around 1.2µW/cm2. One noteworthy feature to remember is that if the display is no longer powered, the current number on the seven segment display will naturally fade out during the next hour or so - you don’t have to actively turn it off.

The cost per unit will always influence the decision regarding which seven segment display technology to use. Before writing this article, a lot of work went into requesting offers from manufacturers worldwide to generate an average cost for all identified display technologies. The vast number of available variations, such as different types of liquid crystals, different connector types, different LED options, etc., makes it nearly impossible to end up at one generalized and representative number. For small one-digit seven segment displays in approximately 100 000 units per year, we are however able to draw the following conclusions:

The Rdot display is the only seven segment display that is bendable. The screen choice will therefore become very easy if your project requires a flexible display. The Rdot display is printed on a transparent plastic substrate that is bendable. The bend radius can be optimized to match your requirements simply through choosing the right thickness of the plastic substrate on which the display stack is printed upon.

Our preferred approach to evaluate the optical performance of various seven segment display types is to request samples from the producers. Seeing is believing. The very standard LCD and LED technologies will be easily accessible through multiple vendors. E Ink and Rdot have

My personal opinion is that the visual appearance of backlit and reflective LCDs, as well as segment LED displays, is not that appealing. One particular factor is that the segments in the unpowered state are still very visible in relation to the background. Another parameter is the viewing angle dependency. Most low-cost LCDs and LEDs are far from being perfectly non-angle dependent. Some are even impossible to read if you observe from only a 30° angle or more.

Both E Ink and the Rdot displays have close to no viewing angle dependency. E Ink has also managed to create very good black in the dark state, but still only 40% white reflection in the bright state which makes it fairly dark in poor light. The seven segment displays from Rdot will fade into the background color perfectly with accurate driving, which makes the Rdot display together with the E Ink display more visually appealing than the other options.

A robust display solution that can reliably work at least throughout the entire product lifetime is apparently a critical factor. From our perspective, the robustness can be broken down into three subparameters; lifetime, operating conditions, and ruggedness. We all know that seven segment displays have been around for a long time. Segment LCDs and LEDs are very mature and optimized. Typical operating conditions range from at least -40 °C to +85 °C, and the display lifetime will exceed almost all expected product lifetimes. Put simply, they are extremely robust. However, they do have one problem. They are fabricated on glass, meaning that they can crack or shatter. The typical solution to make them more rugged is through making the substrates thicker and also to add other safety measures in the display-device integration. This is the reason why there’s often a significant distance from the surface of the device to the display.

The Rdot display is fabricated on a flexible substrate that will not crack or shatter. E Ink also offers some flexible displays with similar properties. Both E Ink and Rdot will not yet compete on robustness in all environments. The operating temperature range spans from 0 °C to 50 °C for the majority of E Ink films, while the Rdot can guarantee -5 °C to 40 °C to this date. Lifetime is also slightly limited for the two seven segment technologies. The lifetime will depend on the number of display updates that are performed. E Ink suppliers communicate a lifetime number ranging from 1 million up to 10 million display updates. The Rdot display has a lifetime that is currently below 1 million updates.

Even though said to be low cost, if people need different requirements for the LCD, the price will still be high. For example, -30 to 80 degrees temperature range, DFSTN modes, with RGB backlights and silk printing, also need to be made into a COG module. Specialists say the greatness of LCD screens is predominantly because of the low yield rate in the assembling cycle, bringing about an expense that can’t be diminished.

As of now, just Some makers in Japan and Taiwan can deliver LCD screens, the innovation has not spread, there has not been a cutthroat circumstance of large-scale manufacturing, and the quality is additionally altogether different. The value distinction between various grades can be just about tens to many dollars in the global market.

Advanced interfaces for LCD shows (LCDs) are desolate at the top. Right off the bat, the sign misfortune and impedance can be decreased during the time spent in simple-to-computerized transformation. Decrease the relating change circuits and segments; secondly, there is no compelling reason to change the clock recurrence and vector.

In any case, a large portion of the low-evaluated LCDs available utilize simple interfaces, which have issues like weak sign transmission impedance, the need to add simple-to-computerized transformation circuits inside the showcase, and the powerlessness to move up to advanced interfaces. Additionally, to stay away from the event of pixel glint, the clock recurrence, vector, and simple sign should be reliable.

What’s more, LCD advanced interfaces have not yet been normalized, and CARDS with computerized yield are uncommonly available. Come in this way, the vital benefit of the LCD show is brought into full play hard, in any case. For the time being, the aftereffect of early utilization is an expensive showcase.

Early LCDs had a visual redirection Angle of just 90 degrees and must be seen from the front, with more prominent brilliance and shading bending when seen from the side. LCD shows now available ordinarily have a visual avoidance Angle of around 140 degrees, which is sufficient for individual use; however, if few individuals are watching simultaneously, the issue of mutilation becomes obvious.

Reaction time is an exceptional marker of LCD. The reaction season of the LCD show alludes to the reaction speed of every pixel of the presentation to the information signal. On the off chance that the reaction time is short, there will be no picture following while showing the moving picture. This is significant when messing around and watching a quick video.

A quick enough reaction time guarantees a steady picture. As of now, the reaction season of standard LCD shows available has made an incredible advancement in contrast to the past ones, which is by and large about 40ms. Yet, it neglects to satisfy the need for 3D games and great DVD films.

Do you need an electric lamp? The joke is about the brilliance and differentiation of LCD screens. Since fluid gem atoms can’t discharge light without anyone else, LCD shows need to depend on outside light sources to help with transmitting light. As a rule, 140 lumens for each square meter is sufficient. There is as yet a hole between the boundary guidelines of certain makers and the genuine principles. It ought to be noticed that some little LCD used to be chiefly utilized in PCs, two lights change, so their splendor and differentiation are not excellent.

The material of the LCD, for the most part, is made of glass, which is easy to break. So when we produce LCD modules, and deliver them, also when customers make the installation we should be careful. And it’s easy to leave some finger print on the screens. So we need to wear finger cots when taking or installing the LCD screen.

A seven-segment display is a form of electronic display device for displaying decimal numerals that is an alternative to the more complex dot matrix displays.

Seven-segment displays are widely used in digital clocks, electronic meters, basic calculators, and other electronic devices that display numerical information.

Some early seven-segment displays used incandescent filaments in an evacuated bulb; they are also known as numitrons.potted box. Minitrons are filament segment displays that are housed in DIP packages like modern LED segment displays. They may have up to 16 segments.

Many early (c. 1970s) LED seven-segment displays had each digit built on a single die. This made the digits very small. Some included magnifying lenses onto the design in an attempt to make the digits more legible.

The seven-segment pattern is sometimes used in posters or tags, where the user either applies color to pre-printed segments, or applies color through a seven-segment digit template, to compose figures such as product prices or telephone numbers.

For many applications, dot-matrix LCDs have largely superseded LED displays in general, though even in LCDs, seven-segment displays are common. Unlike LEDs, the shapes of elements in an LCD panel are arbitrary since they are formed on the display by photolithography. In contrast, the shapes of LED segments tend to be simple rectangles, reflecting the fact that they have to be physically moulded to shape, which makes it difficult to form more complex shapes than the segments of 7-segment displays. However, the high recognition factor of seven-segment displays, and the comparatively high visual contrast obtained by such displays relative to dot-matrix digits, makes seven-segment multiple-digit LCD screens very common on basic calculators.

The seven-segment display has inspired type designers to produce typefaces reminiscent of that display (but more legible), such as New Alphabet, "DB LCD Temp", "ION B", etc.

Using a restricted range of letters that look like (upside-down) digits, seven-segment displays are commonly used by school children to form words and phrases using a technique known as "calculator spelling".

Seven-segment displays may use a liquid crystal display (LCD), a light-emitting diode (LED) for each segment, an electrochromic display, or other light-generating or controlling techniques such as cold cathode gas discharge (Panaplex), vacuum fluorescent (VFD), incandescent filaments (Numitron), and others. For gasoline price totems and other large signs, vane displays made up of electromagnetically flipped light-reflecting segments (or "vanes") are still commonly used. A precursor to the 7-segment display in the 1950s through the 1970s was the cold-cathode, neon-lamp-like nixie tube. Starting in 1970, RCA sold a display device known as the Numitron that used incandescent filaments arranged into a seven-segment display.electroluminescent display.

In a simple LED package, typically all of the cathodes (negative terminals) or all of the anodes (positive terminals) of the segment LEDs are connected and brought out to a common pin; this is referred to as a "common cathode" or "common anode" device.IC sockets. Integrated displays also exist, with single or multiple digits. Some of these integrated displays incorporate their own internal decoder, though most do not: each individual LED is brought out to a connecting pin as described.

Multiple-digit LED displays as used in pocket calculators and similar devices used multiplexed displays to reduce the number of I/O pins required to control the display. For example, all the anodes of the A segments of each digit position would be connected together and to a driver circuit pin, while the cathodes of all segments for each digit would be connected. To operate any particular segment of any digit, the controlling integrated circuit would turn on the cathode driver for the selected digit, and the anode drivers for the desired segments; then after a short blanking interval the next digit would be selected and new segments lit, in a sequential fashion. In this manner an eight digit display with seven segments and a decimal point would require only 8 cathode drivers and 8 anode drivers, instead of sixty-four drivers and IC pins.

The seven segments are arranged as a rectangle of two vertical segments on each side with one horizontal segment on the top, middle, and bottom. Often the rectangle is hexagons, though trapezoids and rectangles can also be used), though in the case of adding machines, the vertical segments are longer and more oddly shaped at the ends in an effort to further enhance readability. The seven elements of the display can be lit in different combinations to represent the Arabic numerals.

The segments are referred to by the letters A to G, where the optional decimal point (an "eighth segment", referred to as DP) is used for the display of non-integer numbers.gfedcba and abcdefg. In the gfedcba representation, a byte value of 0x06 would turn on segments "c" and "b", which would display a "1".

Alternate patterns: The numeral 1 may be represented with the left segments, the numerals 6 and 9 may be represented without a "tail", and the numeral 7 represented with a "tail":

In Unicode 13.0, 10 codepoints had been given for segmented digits 0–9 in the Symbols for Legacy Computing block, to replicate early computer fonts that included seven-segment versions of the digits.

Most letters of the Latin alphabet can be reasonably implemented using seven segments. Though not every letter is available, it is possible to create many useful words. By choosing better synonyms, it is possible to work around many shortcomings of seven-segment alphabet encodings. Some uppercase letters ("I", "O", "S", "Z") look identical to numerical digits ("1", "0", "5", "2"), though it is possible to use lower-case "o" and "i", or putting "I" on the left. Lowercase letters "b" and "q" are identical to the alternate numerical digits "6" and "9". Depending on the situation, some of these problem characters can be used when no numeric values are used in the same word/phrase, see examples below.

Short messages giving status information (e.g. "no dISC" on a CD player) are also commonly represented on 7-segment displays. In the case of such messages it is not necessary for every letter to be unambiguous, merely for the words as a whole to be readable.

There are enough patterns to show all the letters but few representations are unambiguous and intuitive at the same time.sixteen-segment and dot matrix displays are better choices than seven-segment displays.

There are also fourteen- and sixteen-segment displays (for full alphanumerics); however, these have mostly been replaced by dot matrix displays. Twenty-two-segment displays capable of displaying the full ASCII character set

"Application Note 3210 – Quick-Start: Driving 7-Segment Displays with the MAX6954" (PDF) (Application note) (3 ed.). Maxim Integrated. March 2008 [2004-06-25]. Archived (PDF) from the original on 2017-03-20. Retrieved 2013-05-06.

"DL-3422 4-digit 22-segment alphanumeric Intelligent Display preliminary data sheet". Internet Archive. Litronix 1982 Optoelectronics Catalog. p. 82. Retrieved 2016-09-03.

Alibaba.com offers 10158 segmented lcd display products. About 54% % of these are lcd modules, 14%% are segment displays, and 1%% are lcd touch screen.

A wide variety of segmented lcd display options are available to you, such as original manufacturer, odm and retailer.You can also choose from tn, standard and tft segmented lcd display,

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey