sva tft lcd color tv factory

A loved classic household item – the TV is an essential piece of technology for the modern family. Our wholesale smart sva tv offer great versatility. In addition to watching normal TV, viewers can connect to the internet and browse through programs online for instant streaming. For all of the family, these sva tv can play games, use apps, and are set up for social networking. With built-in voice control and touch screen features, these smart TV"s really are one not to miss. They come in a range of sizes. For those wanting the big screen experience, try the following sizes (inches): 60, 65, 70, 75 80, and 85. For customers who want something smaller, then our range of 24-32-inch sva tv are ideal.

TV definition improves vastly every day with constant new technology. With our wholesale 4k Ultra HD TVs, viewers can watch their favorite programs in ultra-high definition. These sva tv come in the highest resolution for optimal viewing. For customers who want the latest technology at affordable prices, then choose from our range of 4k TVs.

LED TVs are known for their great contrast and lighting, producing stunning clarity and colors. They are more durable than other TVs, so viewers do not have to worry about buying an expensive TV they then have to replace in a year"s time.

Whatever your customer"s preference, we will have the TV for them. Choose from wholesale flat-screen sva tv to curved sva tv. Outdoor TVs are also great for those wanting to install a TV on their terrace or in their back garden. For the full range, then visit our online wholesalers at Alibaba.com.

TN Film panels are the mostly widely used in the desktop display market and have been for many years since LCD monitors became mainstream. Smaller sized screens (15″, 17″ and 19″) are almost exclusively limited to this technology in fact and it has also extended into larger screen sizes over the last 7 years or so, now being a popular choice in the 20 – 28″ bracket as well. The TN Film panels are made by many different manufacturers, with the big names all having a share in the market (Samsung, LG.Display, AU Optronics) and being backed up by the other companies including most notably Innolux and Chunghwa Picture Tubes (CPT). You may see different generations of TN Film being discussed, but over the years the performance characteristics have remained similar overall.

The other main reason for using TN Film is that it is fundamentally a responsive technology in terms of pixel latency, something which has always been a key consideration for LCD buyers. It has long been the choice for gaming screens and response times have long been, and still are today, the lowest out of all the technologies overall. Response times typically reach a limit of around 5ms at the ISO quoted black > white > black transition, and as low as 1ms across grey to grey transitions where Response Time Compensation (overdrive) is used. TN Film has also been incorporated into true 120Hz+ refresh rate desktop displays, pairing low response times with high refresh rates for even better moving picture and gaming experiences, improved frame rates and adding 3D stereoscopic content support. Modern 120Hz+ refresh rate screens normally also support NVIDIA 3D Vision 2 and their LightBoost system which brings about another advantage for gaming. You can use the LightBoost strobed backlight system in 2D gaming to greatly reduce the perceived motion blur which is a significant benefit. Some screens even include a native blur reduction mode instead of having to rely on LightBoost ‘hacks’, providing better support for strobing backlights and improving gaming experiences when it comes to perceived motion blur. As a result, TN Film is still the choice for gamer screens because of the low response times and 120Hz+ refresh rate support.

In MVA panels, the crystals in the domains are oriented differently, so if one domain lets light pass through, the neighboring domain will have the crystals at an angle and will shutter the light (of course, save for the display of white color, in which case all the crystals are placed almost in parallel to the matrix plane).

While some improvements have been made, the color-reproduction properties of these modern MVA technologies can still be problematic in some situations. Such panels give you vivid and bright colors, but due to the peculiarities of the domain technology many subtle color tones (dark tones often) are lost when you are looking at the screen strictly perpendicularly. When you deflect your line of sight just a little, the colors are all there again. This is a characteristic “VA panel contrast shift” (sometimes referred to as ‘black crush’ due to the loss of detail in dark colours) and some users pick up on this and might find it distracting. Thus, MVA matrices are somewhere between IPS and TN technologies as concerns color rendering and viewing angles. On the one hand, they are better than TN matrices in this respect, but on the other hand the above-described shortcoming prevents them from challenging IPS matrices, especially for colour critical work.

AU Optronics have more recently (around 2005) been working on their latest generation of MVA panel technology, termed ‘Advanced Multi Domain Vertical Alignment’ (AMVA). This is still produced today although a lot of their focus has moved to the similarly named, and not to be confused AHVA (Advanced Hyper Viewing Angle, IPS-type) technology. Compared with older MVA generations, AMVA is designed to offer improved performance including reduced colour washout, and the aim to conquer the significant problem of colour distortion with traditional wide viewing angle technology. This technology creates more domains than conventional multi-domain vertical alignment (MVA) LCD’s and reduces the variation of transmittance in oblique angles. It helps improve colour washout and provides better image quality in oblique angles than conventional VA LCD’s. Also, it has been widely recognized worldwide that AMVA technology is one of the few ways to provide optimized image quality through multiple domains.

AMVA still has some limitations however in practice, still suffering from the off-centre contrast shift you see from VA matrices. Viewing angles are therefore not as wide as IPS technology and the technology is often dismissed for colour critical work as a result. As well as this off-centre contrast shift, the wide viewing angles often show more colour and contrast shift than competing IPS-type panels, although some recent AMVA panel generations have shown improvements here (see BenQ GW2760HS for instance with new “Color Shift-free” technology). Responsiveness is better than older MVA offerings certainly, but remains behind TN Film and IPS/PLS in practice. The Anti-Glare (AG) coating used on most panels is light, and sometimes even appears “semi glossy” and so does not produce a grainy image.

AUO developed a series of vertical-alignment (VA) technologies over the years. This is specifically for the TV market although a lot of the changes experienced through these generations applies to monitor panels as well over the years. Most recently, the company developed its AMVA5 technology not only to improve the contrast ratio, but also to enable a liquid crystal transmission improvement of 30% compared to AMVA1 in 2005. This was accomplished by effectively improving the LC disclination line using newly developed polymer-stabilized vertical-alignment (PSA) technology. PSA is a process used to improve cell transmittance, helping to improve brightness, contrast ratio and liquid crystal switching speeds.

The liquid crystals in a PVA matrix have the same structure as in a MVA matrix – domains with varying orientation of the crystals allow keeping the same color, almost irrespective of the user’s line of sight and viewing angle. Viewing angles are not perfect though, as like with MVA matrices when you are looking straight at the screen, the matrix “loses” some shades, which return after you deflect your line of sight from the perpendicular a little. This ‘off-centre’ contrast shift, or ‘black crush’ as it is sometimes called is the reason why some colour enthusiasts prefer IPS-type displays. The overall viewing angles are also not as wide as IPS-type panels, showing more obvious colour and contrast shifts as you change your line or sight.

It is this two-zone structure that differentiates S-PVA from older PVA matrixes which used to have a monolithic sub-pixel divided into four domains. An S-PVA matrix has two zones with four domains in each, for a total of eight domains per each sub-pixel. This helps fight the gamma shift effect which occurs when not only the contrast ratio but also the gamma (i.e. the correlation between the video signal sent to the monitor and the resulting screen brightness) changes when the screen is viewed from a side. The pixel zones of S-PVA matrixes have such shape, position and voltage (in the most expensive matrixes that are installed into some TV-sets, the two zones of one sub-pixel can even be controlled independently) as to mutually compensate the gamma shift effect for each other. Unfortunately, the gamma shift effect is not absolutely eliminated even in S-PVA matrixes. Besides, these matrixes have one more difference from PVA. Their viewing angles are asymmetric: the gamma shift is bigger from one side.

During 2014 Samsung started to label their PVA panels as SVA, although the definition is currently unknown. In fact these are probably the only remaining mass-produced PVA panels on the market. Little information is available regarding any possible changes although we expect some improvements to response times and contrast ratios. We believe PSA has been used for these panels as well, much like AU Optronics have used it for their more recent AMVA generations. PSA is a process used to improve cell transmittance, helping to improve brightness, contrast ratio and liquid crystal switching speeds.

In Plane Switching (IPS – also known as ‘Super TFT’) technology was developed by Hitachi in 1996 to try and solve the two main limitations of TN Film matrices at the time, those being small viewing angles and low-quality color reproduction. The name In-Plane Switching comes from the crystals in the cells of the IPS panel lying always in the same plane and being always parallel to the panel’s plane (if we don’t take into account the minor interference from the electrodes). When voltage is applied to a cell, the crystals of that cell all make a 90-degrees turn. By the way, an IPS panel lets the backlight pass through in its active state and shutters it in its passive state (when no voltage is applied), so if a thin-film transistor crashes, the corresponding pixel will always remain black, unlike with TN matrices.

Since their initial production in 1998 S-IPS panels have gained the widest recognition, mostly due to the efforts of LG.Philips LCD (now known as LG.Display), who were outputting rather inexpensive and high-quality 19″ – 30″ matrices. The response time was among the serious drawbacks of the IPS technology – first panels were as slow as 60ms on the “official” black-to-white-to-back transitions (and even slower on grey-to-grey ones!) Fortunately, the engineers dragged the full response time down to 25 ms and then 16ms later, and this total is equally divided between pixel rise and pixel fall times. Moreover, the response time doesn’t greatly grow up on black-to-gray transitions compared to the specification, so some older S-IPS matrices at the time could challenge TN Film panels in this parameter.

Close inspection of modern IPS panels can show this new H-IPS pixel structure, although not all manufacturers refer to their models as featuring an H-IPS panel. Indeed, LG.Display don’t really make reference to this H-IPS version, although from a technical point of view, most modern IPS panels are H-IPS in format. As an example of someone who has referred to this new generation, NEC have used the H-IPS name in their panel specs for models such as the LCD2690WXUi2 and LCD3090WUXi screens.

The following technical report has feedback from the LG.Philips LCD laboratory workers: “Wedesigned a new pixel layout to improve the aperture ratioof IPS mode TFT-LCD (H-IPS). This H-IPS pixel layout design has reducedthe width of side common electrode used to minimize thecross talk and light leakage which is induced by interferencebetween data bus line and side common electrode of conventionalIPS mode. The side common electrodes of a pixel canbe reduced by horizontal layout of inter-digital electrode pattern whereconventional IPS pixel designs have vertical layout of inter-digital electrodes.We realized 15 inch XGA TFT LCD of H-IPS structurewhich has aperture ratio as much as 1.2 times ofcorresponding conventional IPS pixel design.” ©2004 Society for Information Display.

Some spec sheets from LG.Display give some clues as to the differences. The lines separating the sub-pixels are smaller than with H-IPS and therefore the UH-IPS technology has an 18% higher aperture ratio. The drive for increased LCD panel transmissivity is not for the purpose specifically of increasing on screen brightness, but rather to maintain brightness and reduce backlight lamps, inverters, and optical films in order to lower panel costs. LG have used this terminology with some of their LED backlight monitors.

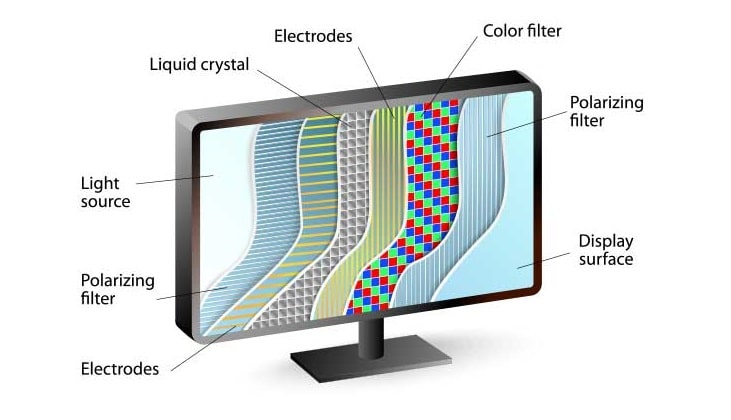

Everyday, we look at LCD display, TV, cell phone, monitor. It becomes a necessity in modern society. LCD panel is the most important part of an LCD display. It determines LCD screen"s performance, e.g. brightness, contrast, color and viewing angle. Therefore, picking the right type of LCD panel is critical to your application.

Vertical Alignment (VA): Also referred to as “super vertical alignment” (SVA) and “advanced multi-domain vertical alignment” (AMVA). They all share similar characteristics.

These names reflect the alignment of crystal molecules inside the LCD, and how they change when they are charged electrically. All liquid crystal displays change the alignment of liquid crystal molecules to work, but the manner in which they do so can drastically affect the image quality and response time. Each panel type has its advantages and disadvantages. The easiest way to choose between them is to decide which attributes are most important to your project. It mainly depends on what you use your LCD display for, and your budget.

TN is the most mature technology in LCD panel manufacturing. When there is no voltage difference between the two transparent electrodes, liquid crystal molecules are twisted 90 degrees, in combination of upper and bottom polarizers, allows light to pass through LCD. As voltage applied, crystal molecules are untwisted and aligned to the same direction, blocking light.

In IPS panel, crystal molecules are parallel to the glass substrates at initial stage, LCD is off. When the in-plane electrodes is charged, crystal molecules are rotated, modifying light"s direction. Which lights up the LCD display.

So in summary, TN panels twist, IPS panels use a parallel alignment and rotate, while VA panels use a perpendicular alignment and tilt. These difference create LCD display with distinctive performance.

IPS LCD is the clear winner in this aspect. It has 178/178 viewing angle ratings. Which means you can look at IPS LCD display from any angle without the image shifting in color and contrast. VA LCD has pretty wide viewing angle, too. But it has contrast shifts at off-center angles. As for TN LCD, viewing angle is its weakest point.

Most TN LCDs have 6-bits colors. Manufacturers use frame rate control (FRC) to enhance its color performance. For IPS and VA panels, you can still find 6-bits entry level LCD. But most of them are 8-bits. And IPS technology can provide natively 10-bits colors.

Color gamut is another part that VA and IPS panels shine at. The best TN LCD can reach sRGB gamut. VA panels typically start with full sRGB coverage, and get to around 90% DCI-P3 coverage. With IPS LCD panel, you could find the best ones full DCI-P3 and Adobe RGB coverage. That is why you see most professional grade LCD displays use IPS panel.

There is no inherent differences among the three panel technologies, because LCD backlight is the main factor here. However, there is a big gap in terms of contrast ratio. TN LCD panel tends to have the lowest value among the three. IPS LCD screen sits in the middle can reach 1500:1. For VA panel, the best one can exceed 4500:1 easily. VA LCD display provides far darker screen than TN & IPS. That is why they are used in vehicle dashboard.

TN panel does have an advantage when it comes to refresh rate. The panel offers the best refresh rate and response time. This is the reason why most gaming LCD monitors are made of TN panel.

TN LCD provides the best refresh rate and economic solution. If your application requires wide viewing angles and good color presentation, VA panel is probably the choice. While IPS has the best overall visual performance, in general it is more expensive than the other two.

The labor cost only accounts for 6% of the total cost, while the cost of raw materials accounts for 70%. To reduce the cost of 17-Inch TFT-LCD panel production, the key is to reduce the cost of raw materials. This is the reason why TFT-LCD panel manufacturers must have perfect the supply chain.

The raw materials cost of 32-inch LCD-TV accounts even higher of 79% of the total cost. TFT-LCD industry is an upstream-dominant industry. On the one hand, only a few manufacturers exist in the upstream market, less than 10 manufacturers in each field of color filter, glass substrate, driver IC, backlight unit, polarized panel and liquid crystal. Moreover, Top 5 in each filed are having about 70% to 100% market shares. On the other hand, the photoresist for color filter, CCFL lamp for BLU and TAC for polarized panel, are monopolized by less than five manufacturers. Therefore, this report mainly focuses on the upstream domain.

The high gross profit was mainly resulted from the good layout on raw materials, but not relying on low labor cost. Except for glass, AUO and CMO can produce all other upstream raw materials. Considering the cost of raw materials accounting for more than 70% of the total cost of LCD panel, manufacturers in Taiwan naturally make more profits than Samsung and LG Philips. Take AUO as an example, the Wellypower, affiliated with AUO, can provide CCFL lamps; the Daxon which was invested by AUO, can produce polarized panel. Moreover, AUO can self-provide color filters, the Corning, locating in the same industrial park with AUO, can provide glass substrate, the Novatek, also affiliated with AUO, is the largest TFT-LCD Driver IC manufacturer in the world.

Compared to AUO and CMO, secondary manufacturers suffer great loss. BOE has a huge deficit of RMB 570 million, and its revenue is the least. SVA Group also suffers a lot. BOE takes 17-inch TFT-LCD panel as its knockout product, while SVA NEC regards 15-inch TFT-LCD panel as its leading product. Nevertheless, the market development of 15-inch TFT-LCD panel is quite limited, only having thin profit margin.

Except for glass substrate, Taiwan manufacturers can produce other raw materials by themselves, whose quality is better than original auxiliary components made by Korean manufacturers. Manufacturers can hold purchase right under the condition of mastering the core technology of TFT-LCD panel, as technical engineers finally decide the purchase of raw materials. As long as manufacturers reserve purchase right, they are able to compete in the upstream market. The technology of BOE comes from Hydis, while SVA"s technology is from NEC. It is well-known that NEC has already completely withdrawn from LCD market. Therefore BOE"s technology is stronger than that of SVA. The most important process for producing TFT-LCD panel is Array, similar with the process of wafer fabrication. What differs is that wafer is put on silicon chip while TFT-LCD on glass substrate. Taiwan manufacturers have rich experience in producing wafer as well as manufacturers in Korea and Japan. But mainland manufacturers pretty lack of experience in manufacturing wafer.

Additionally, establishing industry chain is not simply attracting manufacturers to move into its own industrial park. What the most important is that manufacturers must master its own technology and productivity, and then have power to occupy upstream market. Like AUO in Taiwan, it is the parent company of Daxon and Cando, big shareholder of Wellypower as well as an affiliated company of Novatek. Whereas, even if BOE or SVA NEC attracts overseas providers to move into China, these overseas providers will still transfer their profits to overseas markets. Since price given to BOE or SVA NEC won"t be lower at all, the possibility of loss exists.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey