tft display contain glass factory

In Taiwan. It was formed in 2001 by the merger of Acer Display Technology Inc and Unipac Optoelectronics Corporation. It has G3.5 to G8.5 production lines.

In Korea and China. It is used to be the 2nd biggest TFT LCD manufacturers. LG also planned to stop the production but delayed the plan after the price increased. LG has G7.5 and G8.5 (Guangzhou) production lines.

In Korea. It used to be the biggest TFT LCD manufacturers before it was dethroned by BOE in 2019. Because of tough competition, Samsung planned to stop the production in 2021 but delayed because the price increase during the pandemic. Samsung has G7 and G8.5 production lines.

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

As you can see in the table above, with chemical strengthening we can make glass even 6 or 8 times mechanically stronger than the regular one. This is a very long process; it can take several hours, and we need hot temperature, 400 or more degrees. Thermally tempered glass is a separate way of strengthening glass. We use hot temperature and very fast cooling to make the glass stronger. We need a higher temperature, 700 degrees in this process, but it is much faster, it takes just several minutes, and we achieve strong glass, 4 to 5 times stronger than regular float glass. Thermally tempered glass is not as strong as chemically strengthened glass. It is cheaper, but we cannot use it for thin glass. The thinnest glass that we can thermally temper is 3-4 millimeter. If the glass is thinner, with hot temperature it starts floating and the surface will not be flat again. So, if we have a thick glass, it would be cheaper to use the thermally tempered solution. That is why it is more popular. For thinner glass we use chemical strengthening, because we cannot use the thermally tempered solution.

Now we will talk about the other difference between these two methods of strengthening glass. On the left side of the picture above, you can see chemically strengthened glass broken, and on the right side there is thermally tempered glass broken. Chemically strengthened glass breaks like regular glass because we do not change the internal part of the glass. We only make the surface stronger, but inside the glass is the same as regular float glass, and it breaks just like it. Thermally tempered glass changes the internal structure of the glass and it breaks into very small pieces. In many cases it is better because it is safer for humans, that is why we normally use thermally tempered glass in cars or in places where broken glass may injure people.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now we know how glass is made, how it is being strengthened, how it breaks and what types of glass, Float and Optiwhite, we have. To continue, we will talk about surface treatments other than strengthening. The other treatments that we use are anti-glare, anti-fingerprint, anti-reflective and anti-bacterial. About anti-reflective treatment we have talked in another video about

On the picture above there are examples of glass. One of them is a little bit blurry, it is anti-glare and the other one is clear – it is anti-reflective. In the past, anti-glare glass was more popular and used in some commercial devices, but later manufacturers have found that devices with anti-glare are being sold less frequently than the glare ones. It is because as humans we think that there is something wrong with a little bit blurry image even if the reflections are lower. When we are in a shop and looking at phones, we do not see the image clearly and we think that there is something wrong and we do not want this device. That is why we do not see any more anti-glare glass in consumer products. Everything is glare in consumer products, it could be anti-reflective or could be only regular without any surface treatment. But in the professional market that we are working on, like medical devices, military devices, we have many projects where we use anti-glare and anti-reflective treatments, both solutions to reduce reflections and increase contrast.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

This scale is about surface hardness – how hard is it to scratch the surface. As you know, even glass with hardness 9 can be scratched, everybody has some scratches on their phone because this hard layer is very thin – 10 micrometers only. If we put enough force and break this barrier, then we have soft glass with hardness 6 or even lower, that is why we have the scratches.

A couple more words about Gorilla glass. Now there is the sixth generation of Gorilla Glass on the market. The goal for Corning company and Gorilla Glass is to make the glass as strong and as light as possible, because most of the cases are handheld devices, where we want the glass to be light, that is why we want to make it very thin. We have also other companies that are making equivalents of Gorilla Glass, like Dragontrail from AGC or Xensation from Shott. They are not so popular but in many mobile phones or tablets on the market you can find these types of glass.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

When we do the Screen Printing, we need a screen for each color, so to minimize cost, we try to reduce the number of colors to 2–4, like the background and the colored logo. Each color is a different process, we need to wait until the previous painting dries and then we need to put another screen and print another color. More colors mean a longer process and of course a higher cost. Of course, we can change the shape of the glass, we can make rounded corners or custom design of the glass, but it is expensive because first it is just the rectangular piece, then you need to go to the CNC machine to make the proper shape of the glass.

Now we will talk about mechanical impact protection. It is different than the surface hardness we talked about before. On the picture above, we have the test and scale to measure the mechanical strength of glass, that means how much energy we can put on the glass before it breaks. It is measured in IK rate. IK rate is a scale where we have different levels and different energy that will boost. For example, if we want to test IK 9, we need to take 5-kilogram mass from 200-millimeter height. The mass is kept above the tested glass using an electromagnet, then we just drop it, and we see if it breaks or not. If not, of course the test is passed.

If the glass has not passed the test, we can try to change the glass type from thermally tempered to chemically strengthened or go to a thicker glass.

The last point in this article is laminated glass. We laminate glass because of a few reasons. First, what is laminated glass. Laminated glass is like putting the film inside two glass sheets. This process is expensive, we need pressure, we need temperature, we need time, and we need an exceptionally clean environment, because when we laminate together two sheets of glass, we need to be sure that no particles get inside. This kind of process needs to be done in a Clean Room, so it is expensive, but as you see on the picture above, even if the glass is broken, it still holds up because of the laminated film inside.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

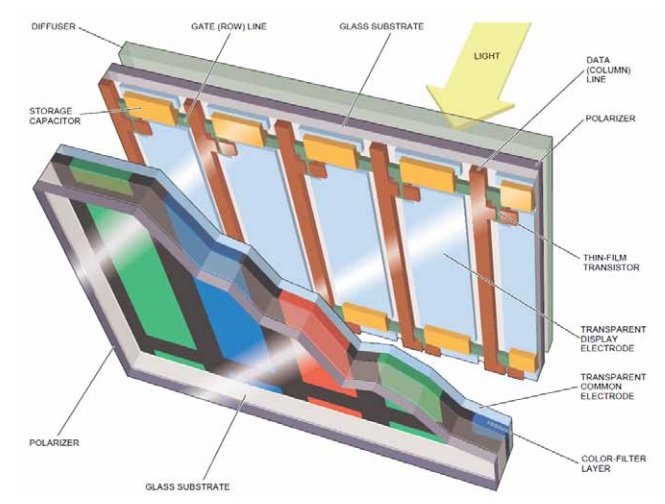

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

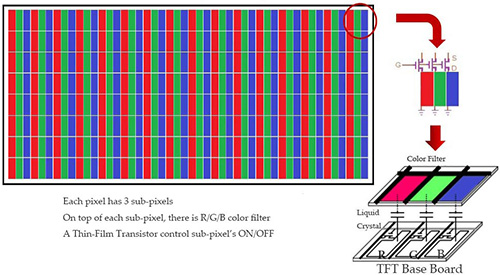

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

![]()

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

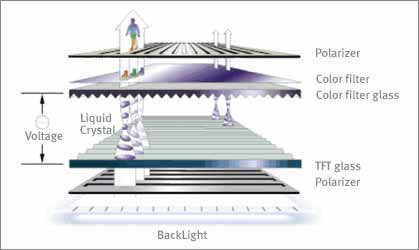

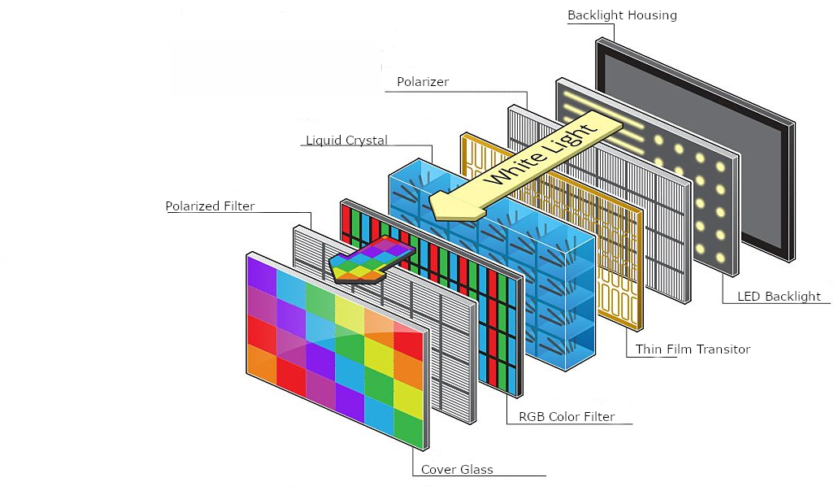

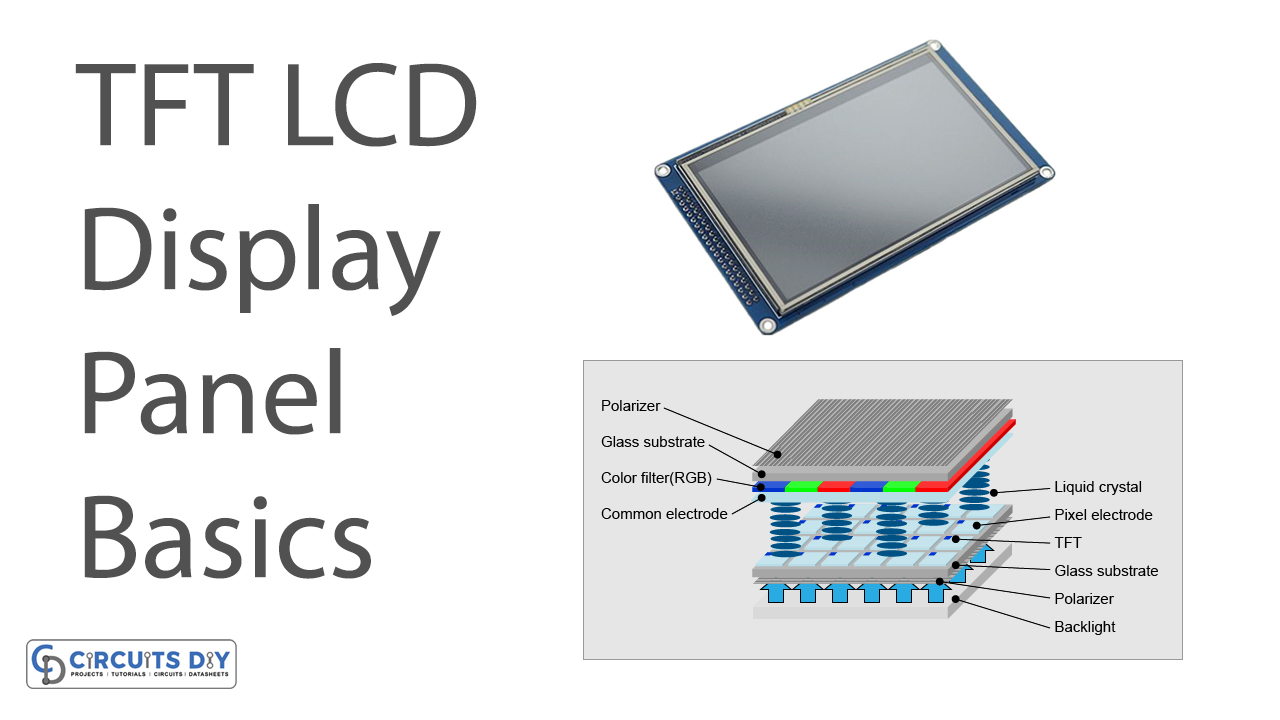

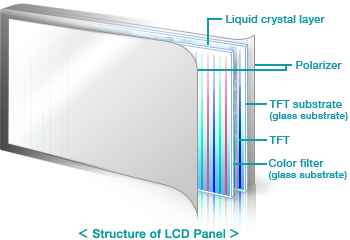

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

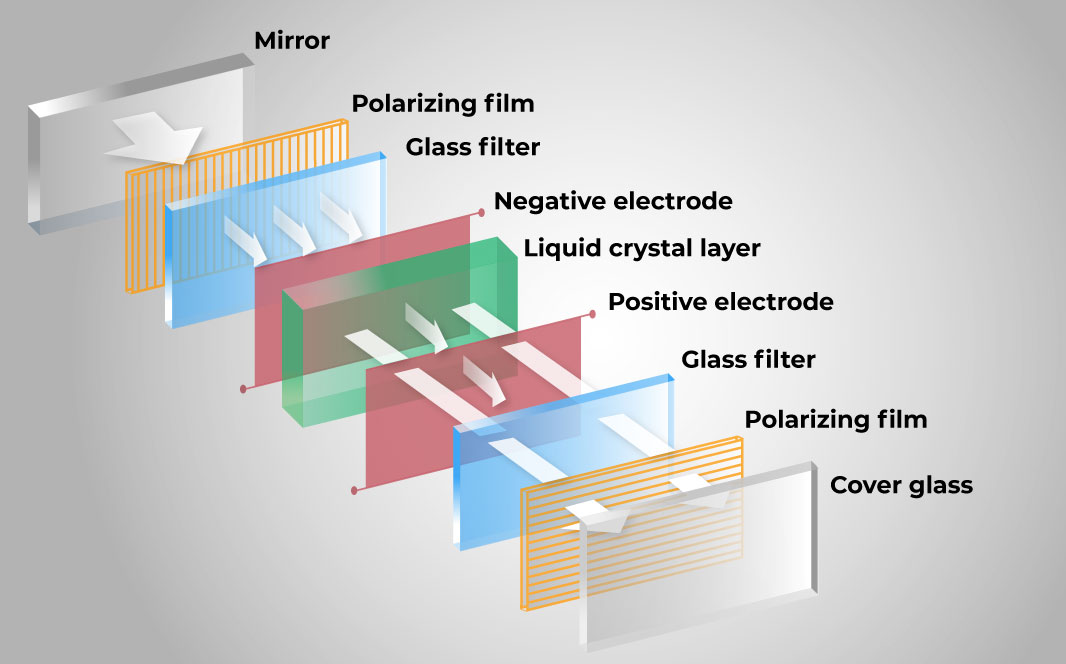

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

– The Array process in the front segment is similar to the semiconductor process, except that thin-film transistors are made on glass rather than silicon wafers.

– The middle Cell is based on the glass substrate of the front segment Array, which is combined with the glass substrate of the color filter, and liquid crystal (LC) is injected between the two glass substrates.

-The rear module assembly process is the production operation of assembling the glass after the Cell process with other components such as backlight plate, circuit, frame, etc.

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

Polysilicon is a silicon-based material about 0.1 to several um in size, composed of many silicon particles. In the semiconductor manufacturing industry, polysilicon should normally be treated by Low-Pressure Chemical Vapor Deposition. If the annealing process is higher than 900C, this method is known as SPC. Solid Phase Deposition. However, this method does not work in the flat display industry because the maximum temperature of the glass is only 650C. Therefore, LTPS technology is specifically applied to the manufacture of flat displays.

A method for direct deposition of Poly-film without vapor extraction. The sedimentation temperature may be below 300C. Growth mechanisms contain catalytic cracking reactions of SiH4-H2 mixtures.

This method is currently the most widely used. The Excimer laser is used for heating and melting A-SI. It contains low amounts of hydrogen and recrystallizes to Poly-film.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

2. Vehicle for OLED: High mobility means that the OLED Device can provide a large driving current, so it is more suitable for an active OLED display substrate.

3. Compact module: As part of the drive circuit can be made on the glass substrate, the circuit on the PCB is relatively simple, thus saving the PCB area.

The “reflective” architecture USES an external light source to display the image via a reflector, which saves electricity but is harder to see in the absence of an external light source.

Different from the traditional manufacturing process, COG technology directly assumes the drive IC on the glass substrate. The advantages of this technology include:

(Yicai Global) June 19 -- China National Building Material has built the country"s first production line capable of producing 8.5th-generation TFT-LCD glass substrates, making China one of few nations to master the technology.

The central state-owned firm"s Bengbu Glass Industry Design and Research built the facility after three years of research, Science and Technology Daily reported. The plant aims to obtain certifications that will allow it to manufacture for domestic display makers.

TFT-LCD, or thin-film-transistor liquid-crystal displays, are classified by the size of their glass substrate. Sixth-generation displays are now widely considered out-dated while 8.5th-gen tech is the most advanced. The newer technologies use larger substrates, which are more efficient to make and can be used in larger screens.

Demand for glass substrates in China reached 260 million square meters in 2018, with demand for 8.5th-gen components making up 233 million, according to the China Optics & Optoelectronics Manufacturers Association. But domestic production is only about 40 million square meters and all below 6th-gen. American and Japanese companies mostly dominate the more advanced segment of the market.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

In order to enhance productivity, in this step we’ll do a series of procedure on a large glass, which will be cut into smaller pieces in the following step.

First, let me introduce a crucial material, ITO, to you. ITO, abbreviation of Indium tin oxide, has the characteristic of electrical conductivity and optical transparency, as well as can be easily deposited as a thin film. Thus it’s widely used to create circuit on glass.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

◇ Use glue to build a boundary for LC on both glass. And on CF glass, apply one more layer of conductive adhesive. This enable LC molecule link to the control circuit.

Asahi Glass, Co., Ltd. (Headquarters: Tokyo; President: Shinya Ishizu) decided to increase its manufacturing capacity of glass substrates used for TFT-LCD (Thin Film Transistor Liquid Crystal Display). With this increase the company will install new furnace of glass substrate at its Kansai factory and augment its glass panel polishing line in Taiwan. Engineering will commence from August of this year and is expected to be completed in October, 2003. Total funds to be injected into the project are estimated at 17 billion yen. The total production capacity as a result of this increase is estimated to be 10 million square meters annually, using four furnaces of glass substrates.

The demand for TFT-LCD displays is predicted to increase at a rate of 30% annually through the year 2005, since a steady increase is predicted not only for their use in notebook PCs, but even more so for their use in PC monitors. Their use in TVs is also expected to sky rocket. In addition, TFT-LCD substrate panel manufacturers announce they plan to use the large substrates to reduce their cost, and that in the future the "5th Generation Size" of glass substrates with a surface are exceeding one square meter, will be the industry mainstay.

Unlike many competitors, Asahi Glass incorporates floating method in manufacturing process of the glass substrates, which is suited to the mass production of large size. The company decided to increase the manufacturing capacity of its TFT-LCD glass substrates because it felt that the increasing demand for TFT-LCD displays and calls for larger glass substrates for TFT-LCD displays presented a great opportunity to further expand this business area and become the global leader in the impending. Details of the future capacity increase are as follows:

We will install the fourth furnace of TFT-LCD glass substrate at the Kansai Factory (Amagasaki City, Hyogo Prefecture). The new furnace will enable highly efficient multi-line production of ultra-large-sized substrates, primarily ultra-large glass substrates larger than one square meter, making possible the manufacture of glass substrates of approximately four meters in width. The manufacturing capacity of this furnace is four million square meters annually, nearly twice that of our existing furnaces, and requires a capital investment of roughly 12 billion yen.

We will augment the TFT-LCD glass panel polishing line, which is targeted for the fifth generation size glass substrate, at Asahi Glass Fine Techno Taiwan Co., Ltd. (a fully owned subsidiary of Asahi Glass, Co., Ltd., located in Douliu City, Taiwan), which has been operating a polishing line since 2001. Capital investment for the new line is roughly five billion yen. Although Asahi Glass Fine Techno in Japan (a fully owned subsidiary of Asahi Glass, Co., Ltd., located in Yonezawa City, Yamagata Prefecture) also conducts polishing of TFT-LCD glass substrates, the line addition will be made in Taiwan, since future production volumes of TFT-LCD substrates will greatly increase there and since it is expected that Taiwanese TFT-LCD panel manufacturers will employ the 5th generation size of glass substrate before manufacturers in Japan do.

We will fully leverage the features of the float method, which is especially suited for larger glass substrates, to address increasing demand and proceed with the expansion of the TFT-LCD glass substrate business.

We are the only glass manufacturer in the world employing the float method in the manufacturing process of TFT-LCD glass substrates. Produced using this method and brought to market in 1998, our "AN100" product exhibits the following major features:

The "AN100" comes fully equipped with the qualities sought after in the future TFT-LCD industry"s 5th generation line of large glass substrate (one square meter or larger), and is very highly regarded by our customers.

Our "AN100" is an environmental friendly product. In fact, it is the only non-alkaline glass substrate used in TFT-LCD displays that does not use the harmful substances known as Arsenious Acid (As2O3) and Antimony (Sb2O3) in the manufacturing process.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

We TFT screen manufacturers generally buy back the glass panel belongs to the big board, and the big board glass needs to be cut into the corresponding size to be cut into the substrate, cut into 5-inch TFT screen, 7-inch TFT screen, 8-inch TFT screen, and so on. And the cut TFT screen panel will be cleaned. After cleaning on the Cell Test test, speaking of poor TFT screen panel selected out, this step is very critical.

Put the two glass substrates according to the fixed interval, seal the two glass edges with frame glue and conductive glue and leave one or two notches, put the liquid crystal panel into the vacuum chamber, pump out the air from the liquid crystal panel through the notches reserved, then fill the liquid crystal with the help of atmospheric pressure (liquid crystal is a kind of compound material between solid and liquid), and then use UV glue to close the mouth of the crystal filling to complete the liquid crystal filling process.

Polarizer lamination is also called POL, which refers to the TFT screen panel on both sides of the polarizer, the angle of the two polarizers and color filters, TFT"s PI directional film friction angle parallel, stick polarizer production completed. TFT screen imaging to use polarized light. TFT screen panel before and after each a polarized light film affixed to the LCD glass above and below, the composition of the total thickness of about 1mm LCD film. If any of the polarizers is missing, the liquid crystal sheet is unable to display images.

The chip on glass is directly bonded to the glass by the COG (Chip on Glass). and then this pressure. Use ACF to crimp the endpoints together as required, and then seal with sealing glue.

The wiring also called the flex circuit, is mainly responsible for connecting the circuits and is responsible for energizing them. Through ACF bonding, hot pressing at a certain temperature, pressure, and time, the FPC flexible circuit board is connected to the TFT screen panel to achieve the connection of the external driver circuit. The manufacturing process mainly includes ACF pre-paste, pre-bonding, main bonding, testing, and other steps. After assembly and wiring are called FOG.

This is the complete TFT screen production process, although it is relatively simple, the details of this all test the production level of TFT screen manufacturers.

TFT LCD is Thin Film Transistor Liquid Crystal Display, which has a sandwich-like structure with liquid crystal filled between two glass plates. It has as many TFTs as the number of pixels displayed, while a Color Filter Glass has color filter which generates color.

TFT display is the most popular display device among all kinds of notebooks and desktops, with high responsiveness, high brightness, high contrast ratio and other advantages. It is one of the best LCD color display

Actually, the top cover glass works a very important role to protect the display against from external damage and destructions. Even it used in strict working environments, especially for industrial devices which are often exposed to dust and dirt surroundings. When adding anti-fingerprint coating & etched anti-glare, the glass panel becomes non-glare under strong light and fingerprints-free. For a 6mm thickness glass panel, it can even bear 10J without breakage.

For glass solutions, special shapes and surface treatment in various thicknesses is available, chemical toughened or safety glass minimizes the risk of injury in public areas.

If you are in the market of color TFT LCD displays and you haven’t already been affected by the recent changes in the global market, then it’s just a matter of time. If you have recently asked, ‘What is going on with TFT-LCD panel prices lately?’, you are not alone. Here at Phoenix Display we have had a lot of questions regarding the TFT-LCD panel price increase that the market is seeing. We want to help explain what is happening, why it’s happening, and what to expect in the near future so that you can be aware of the effects and adjust accordingly.

In recent months there has developed a fair amount of uncertainty in regards to manufacturing conditions for TFT panels at the TFT glass fab level. This has caused a lot of fluctuation and volatility in both the supply and price of TFT panels. We are seeing that the price of TFTs has increased from 25% to 70% on average, and have seen some instances of a 2.5 times increase for the less common configurations. Combined with the fact that lead time is now only confirmed upon placing an actual order with payment in advance, in makes planning and producing around your color display product even more challenging.

One of the important things to realize with regards to TFT market conditions is that flat TFT panels in almost every size are currently in short supply. This is the first time this has happened in almost 20 years.

Some of the larger panel manufactures are exiting TN TFT manufacturing to focus on newer, more profitable technologies. The market has seen a trend towards low-temperature polysilicon (LTPS) TFT LCD panels, which provide customers lower power consumption along with higher resolution, along with a big shift into OLED to support wearables, the latest smart phone designs, and even the flat panel Television market as well.

In 2016 there has been a rise in the proportion of LTPS/Oxide TFT smartphone panel shipment production, rising to 34.6% market share compared to 29.8% in 2015. In the coming year we expect to see a variety of panel makers including CSOT, Taiwanese AUO, Chinese Tianma, and Japanese JDI, roll out new LTPS capacities eclipsing and impacting conventional TFT manufacturing. In May the industry had a shortage of television panels which was followed by a similar supply-demand dynamic for notebook and smartphone small panels. This was largely due to JDI, LG Display Co. and Samsung Display Inc., shutting down their production lines in these verticals.

In the last 5 months the TFT cell glass cost has been rapidly increasing, largely due to the influence of upstream LCD panel maker’s supply. As a result of these market fluctuations almost all TFT mother glass suppliers have increased their pricing across the board. Due to these new market impacts, we highly doubt that any of the major TFT mother glass manufacturers will reopen lines that have previously been closed. In fact, current trends lend us to believe that if these lines were ever reopened, they would be used for OLED production rather than TFT. We believe that the capacities problems the market is seeing is not a short-term problem, and will likely not ease until the second quarter of 2017, at the earliest. This leaves the current state of the market in a fair amount of turmoil as the suppliers battle the glass shortage and while offloading the increased cost to manufacturers.

While there is a trend at the manufacturing level to diversify away from traditional color TN TFT LCD display, the positive is there is still be a strong market for this product for years to come due to TN TFTs lower cost advantage and availability. In short, we don’t see TFT displays going away any time soon, but we will be impacted by higher costs and longer lead times for the near future.

You’ve already taken the first step by educating yourself on the issue. By preparing your business and supply chain for the increase in price and decrease in supply which lead to longer lead-times, you can mitigate potential delays and issues in your production. If you have any additional questions about TFT panels or any other standard or custom display needs, please

This 10.1 inch TFT LCD display has a 1024x600 resolution screen with IPS technology, which delivers sunlight readable brightness, better color reproduction, better image consistency, and better optical characteristics at any angle. For extra protection, this 24-bit true color TFT also includes an EMI filter on the input power supply line. This 10.1" display is RoHS compliant with RGB interface, and does not include a touchscreen. This 10.1" IPS display has been designed with the same mechanical footprint and pinout and includes the same HX8282 driver IC as the TN display, making this a compatible replacement option for the TN models.

Enhance your user experience with capacitive or resistive touch screen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

TFT displays are now used in a wide range of products, including TVs, computers, appliances, medical equipment, instruments, mobile, and other gadgets. The utilization of LCDs in all market segments was significantly enhanced by incorporating thin film transistors into LCD architecture.

The liquid crystal display (LCD) uses TFT (thin-film transistor) technology and contains a transistor for each pixel (that is, for each of the tiny elements that control the illumination of your display). Since each pixel has a transistor, the current that initiates pixel lighting may be reduced and turned on and off more quickly. The active matrix display technology is another name for TFT (and contrasts with the "passive matrix," which does not have a transistor at each pixel).

The materials required to make a TFT display include ITO glass, liquid crystal, polarizer, sealing glue, and intermediate powder. These components themselves are simple enough, but the manufacturing process can often involve heavy investment in tooling, sourcing, and research. Each step of the process requires a unique line and space in the factory, along with dedicated design, engineering, and manufacturing staffing.

A custom sized TFT display will likely need to be designed such that each component fits into an appropriately sized housing that the project will require; this will often require experimentation and creative resources.

Regarding engineering support, the bespoke panels will need to be designed to function reliably and with the performance required for the use. This process will also require sourcing the tooling or suppliers for individual parts in order to manufacture the custom display. Finally, manufacturing the custom display will require a dedicated assembly line with the training to create the bespoke display configuration. Depending on the use case, this may require custom or unique processes that will require an investment in training and quality assurance. The quality assurance process for devices that are not mass-produced can be difficult and time-consuming. Because there are usually tight deadlines to follow and a limited number of samples, it can be difficult to reliably assess samples and understand the breadth of limitations surrounding a design.

Therefore, it may not make sense for a small project scope if you need a small number of TFTs with custom sizes. While the overall cost may be lower due to unit price reductions as the number of displays purchased leads to a decreased cost per unit, this price reduction will not be feasible with a smaller purchase size of custom-size displays. Additionally, when considering the tooling cost, this is not able to be spread over a smaller number of custom displays purchased, leading to limited cost savings on small purchase orders. Custom can be cheaper if your project falls within mid-range volumes, but this is not the case for small projects.

Consequently, due to design, sourcing of materials, manufacturing considerations, and cost and time of quality assessment, it can be impractical to order a custom TFT configuration for smaller projects. Fortunately, FocusLCDs offers a wide variety of mass-produced screen sizes that allows you to benefit from economies of scale and may even be a perfect fit for your specific project.

Display Search, “Quarterly LCD Glass Substrate Report,” http://www.displaysearch.com/cps/rde/xchg/displaysearch/hs.xsl/quarterly_lcd_glass_substrate_report.asp (Accessed 24 SEP 2015)

Chen, G., Lee, H., Young, K. L., Yue, P. L., Wong, A., et al., “Glass Recycling in Cement Production-An Innovative Approach,” Waste Management, Vol. 22, No. 7, pp. 747–753, 2002.

Terro, M. J., “Properties of Concrete Made with Recycled Crushed Glass at Elevated Temperatures,” Building and Environment, Vol. 41, No. 5, pp. 633–639, 2006.

Wang, H. Y., Zeng, X. X., and Lin, X. H., “A Study on Strength and Durability of Waste LCD Glass Concrete,” Green Builds Technology Seminar, A1-2-1-6, 2006.

Shayan, A. and Xu, A., “Performance of Glass Powder as a Pozzolanic Material in Concrete: A Field Trial on Concrete Slabs,” Cement and Concrete Research, Vol. 36, No. 3, pp. 457–468, 2006.

Zhu, H.-y. and Byars, E. A., “Alkali-Silica Reaction of Recycles Glass in Concrete,” Proc. of the 12th International Conference on Alkali-Aggregate Reaction in Concrete, pp. 811–820, 2004.

Meyer, C., Baxter, S., and Jin, W., “Alkali-Silica Reaction: Concrete with Waste Glass as Aggregate,” Proc. of ASCE Materials Engineering Conference on Materials for the New Millennium, pp. 1388–1394, 1996.

Byars, E. A., Morales-Hernandez, B., and Huiying, Z., “Waste Glass as Concrete Aggregate and Pozzolan Laboratory and Industrial Projects,” Concrete, Vol. 38, No. 1, pp. 41–44, 2004.

Shi, C., Wu, Y., Riefler, C., and Wang, H., “Characteristics and Pozzolanic Reactivity of Glass Powders,” Cement and Concrete Research, Vol. 35, No. 5, pp. 987–993, 2005.

Xie, Z. and Xi, Y., “Use of Recycled Glass as a Raw Material in the Manufacture of Portland Cement,” Materials and Structures, Vol. 35, No. 8, pp. 510–515, 2002.

Corinaldesi, V., Gnappi, G., Moriconi, G., and Montenero, A., “Reuse of Ground Waste Glass as Aggregate for Mortars,” Waste Management, Vol. 25, No. 2, pp. 197–201, 2005.

Shao, Y., Lefort, T., Moras, S., and Rodriguez, D., “Studies on Concrete Containing Ground Waste Glass,” Cement and Concrete Research, Vol. 30, No. 1, pp. 91–100, 2000.

Dyer, T. D. and Dhir, R. K., “Chemical Reactions of Glass Cullet Used as Cement Component,” Journal of Materials in Civil Engineering, Vol. 13, No. 6, pp. 412–417, 2001.

Wang, H.-Y., “The Effect of the Proportion of Thin Film Transistor–Liquid Crystal Display (TFT-LCD) Optical Waste Glass as a Partial Substitute for Cement in Cement Mortar,” Construction and Building Materials, Vol. 25, No. 2, pp. 791–797, 2011.

Wang, H.-Y. and Huang, W.-L., “Durability of Self-Consolidating Concrete using Waste LCD Glass,” Construction and Building Materials, Vol. 24, No. 6, pp. 1008–1013, 2010.

Sobolev, K., Türker, P., Soboleva, S., and Iscioglu, G., “Utilization of Waste Glass in Eco-Cement: Strength Properties and Microstructural Observations,” Waste Management, Vol. 27, No. 7, pp. 971–976, 2007.

Taha, B. and Nounu, G., “Using Lithium Nitrate and Pozzolanic Glass Powder in Concrete as ASR Suppressors,” Cement and Concrete Composites, Vol. 30, No. 6, pp. 497–505, 2008.

“LCD glass substrate” is a generic term for the special glass used for thin-film transistor (TFT) LCDs which form the display area of products including LCD televisions, personal computers and mobile phones. An LCD panel consists of various components stacked in a number of layers. These components include a polarizer, a color filter and a liquid crystal layer, with the glass substrate being the most important. Glass substrates are extremely thin – typically about 0.3-0.7 mm – and 8th-generation glass substrates (2,200 x 2,500 mm) are as large as three tatami mats in size.

In order to accurately display beautiful, high-definition images, LCD glass substrates must have super-smooth surfaces with irregularities reduced to the nano-level. It is also necessary to avoid the formation of internal bubbles and the intrusion of foreign matter (dust) too minute for the naked eye. Smooth and scratch-free glass substrates with the ultimate precision represent the maximum quality AvanStrate aims for.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey