tft display contain glass pricelist

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

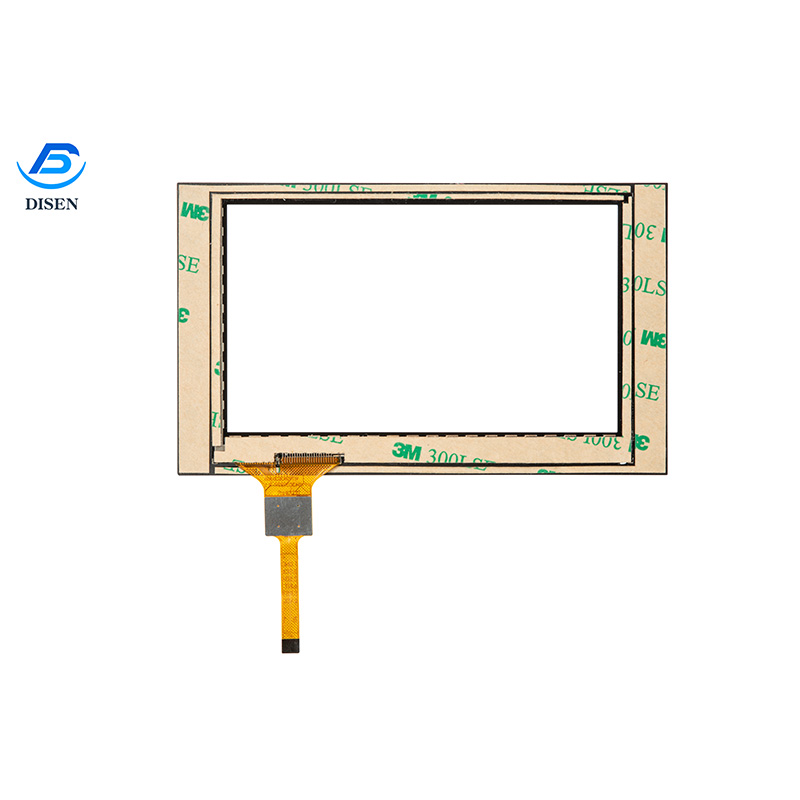

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

In Taiwan. It was formed in 2001 by the merger of Acer Display Technology Inc and Unipac Optoelectronics Corporation. It has G3.5 to G8.5 production lines.

In Korea and China. It is used to be the 2nd biggest TFT LCD manufacturers. LG also planned to stop the production but delayed the plan after the price increased. LG has G7.5 and G8.5 (Guangzhou) production lines.

In Korea. It used to be the biggest TFT LCD manufacturers before it was dethroned by BOE in 2019. Because of tough competition, Samsung planned to stop the production in 2021 but delayed because the price increase during the pandemic. Samsung has G7 and G8.5 production lines.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

Anders have partnered with world leading brand Kastus®to offer a globally patentedantimicrobial & antiviralsurface coating which has a proven kill rate of up to 99.99% against harmful bacteria, fungi and antibiotic-resistant superbugs, which makes it particularly useful for products including glass and ceramics. This year, an independent testing report found Kastus to be effective against human Coronavirus on screens.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

Get started quickly on your new user interface with our HMI development kits. The display, the processor and the OS work together out of the box with optimised QT GUI images. We"ll then optimise the kit to meet exactly your system requirements with our design services.

At Anders we understand that no two customers are the same, which is why we specialise in custom display solutionsand offer unique productstailored to your end application.

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

We aim to offer reliable and long-term solutions to our B2B customers. If you are a business and would like to discuss your display and/or embedded system requirements please contact us below

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

A layer of glass with a matrix of conuctive elements behind that when pressed with another conductive input (ie human finger) registers a touchpoint..

※Price Increase NotificationThe TFT glass cell makers such as Tianma,Hanstar,BOE,Innolux has reduced or stopped the production of small and medium-sized tft glass cell from August-2020 due to the low profit and focus on the size of LCD TV,Tablet PC and Smart Phone .It results the glass cell price in the market is extremely high,and the same situation happens in IC industry.We deeply regret that rapidly rising costs for glass cell and controller IC necessitate our raising the price of tft display.We have made every attempt to avoid the increase, we could accept no profit from the beginning,but the price is going up frequently ,we"re now losing a lot of money. We have no choice if we want to survive. There is no certain answer for when the price would go back to the normal.We guess it will take at least 6 months until these glass cell and semiconductor manufacturing companies recover the production schedule. (Mar-03-2021)

ER-TFTV043A3-3 is 480x272 pixel 4.3 inch color tft lcd display for the Raspberry Pi with optional USB port resistive or capacitive touch panel screen,optional USB cable and HDMI cable. Of course ,it is not limited to the Raspberry Pi ,it can be used for all the universal HDMI port hardwares such as mini PCs, Raspberry Pi, BB Black, Banana Pi, as well as general desktop computers.

![]()

NMLCD-CPT43480272is a colour active matrix LCD module incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of a colour TFT-LCD panel, driver IC, FPC and a back light unit and with/without a Resistive/Capacitive Touch Panel (RTP or CTP), and with/without a Cover Lens Bezel (CLB). The module display area contains 480 x 272 pixels. This product accords with RoHS environmental criterion.

Shenzhen SLS Industrial Co.,ltd established in 2003, is a professional LCD module manufacturer and solution provider. We have 1 full-auto COG assembly line, 2 semi-auto assembly line, backlight assembly line, no dust TP bonding line and manufacturing tech support, we can provide unique, innovative and cost effective LCD module development and manufacturing. Our product range includes: middle-small size TFT LCD, industrial capacitive touch panel... Our LCD products have been widely used in communications, GPS, Equipment, electronic audio-visual, instrumentation, household appliances, PDA and other industries.

We"re one of the leading 4.3 inch CPT glass 480x272 color LCD display LCD TFT display suppliers in China. With advanced technology, we can assure you the high resolution and good performance of our products. Welcome to get the sample and the price list from our factory.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth "unification, determination, tolerance" for Lcd Cog Display, Tft Color Display Monitor, Medical Tft-Lcd Screen, For even more data, please do not be reluctant to call us. All inquiries from you may be highly appreciated.

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for PriceList for Gaming Lcd - 7.0inch 800×480 TFT LCD Display for video door phone – DISEN , The product will supply to all over the world, such as: Korea, Latvia, Norway, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

As a TFT LCD manufacturer, we import mother glass from brands including BOE, INNOLUX, and HANSTAR, Century etc., then cut into small size in house, to assemble with in house produced LCD backlight by semi-automatic and fully-automatic equipment. Those processes contain COF(chip-on-glass), FOG(Flex on Glass) assembling, Backlight design and production, FPC design and production. So our experienced engineers have ability to custom the characters of the TFT LCD screen according to customer demands, LCD panel shape also can custom if you can pay glass mask fee, we can custom high brightness TFT LCD, Flex cable, Interface, with touch and control board are all available.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Tempered Step Lighting Glass, Laminated Flooring Glass, Electrical Wall Switch Plate, We will provide high-quality products and excellent services at competitive prices. Start benefiting from our comprehensive services by contacting us today.

Clear/Ultra Clear Float Glass, Low-e Glass, Frosted Glass(Acid Etched Glass), Tinted glass, Borosilicate Glass, Ceramic Glass, AR glass, AG glass, AF glass, ITO glass, etc.

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for Lowest Price for 8mm Laminated Glass - Custom Flat Glass 0.5mm tempered glass front cover lens for Bar Stretched LCD TFT Display – Saida, The product will supply to all over the world, such as: Lebanon, Holland, UK, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

As you can see in the table above, with chemical strengthening we can make glass even 6 or 8 times mechanically stronger than the regular one. This is a very long process; it can take several hours, and we need hot temperature, 400 or more degrees. Thermally tempered glass is a separate way of strengthening glass. We use hot temperature and very fast cooling to make the glass stronger. We need a higher temperature, 700 degrees in this process, but it is much faster, it takes just several minutes, and we achieve strong glass, 4 to 5 times stronger than regular float glass. Thermally tempered glass is not as strong as chemically strengthened glass. It is cheaper, but we cannot use it for thin glass. The thinnest glass that we can thermally temper is 3-4 millimeter. If the glass is thinner, with hot temperature it starts floating and the surface will not be flat again. So, if we have a thick glass, it would be cheaper to use the thermally tempered solution. That is why it is more popular. For thinner glass we use chemical strengthening, because we cannot use the thermally tempered solution.

Now we will talk about the other difference between these two methods of strengthening glass. On the left side of the picture above, you can see chemically strengthened glass broken, and on the right side there is thermally tempered glass broken. Chemically strengthened glass breaks like regular glass because we do not change the internal part of the glass. We only make the surface stronger, but inside the glass is the same as regular float glass, and it breaks just like it. Thermally tempered glass changes the internal structure of the glass and it breaks into very small pieces. In many cases it is better because it is safer for humans, that is why we normally use thermally tempered glass in cars or in places where broken glass may injure people.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now we know how glass is made, how it is being strengthened, how it breaks and what types of glass, Float and Optiwhite, we have. To continue, we will talk about surface treatments other than strengthening. The other treatments that we use are anti-glare, anti-fingerprint, anti-reflective and anti-bacterial. About anti-reflective treatment we have talked in another video about

On the picture above there are examples of glass. One of them is a little bit blurry, it is anti-glare and the other one is clear – it is anti-reflective. In the past, anti-glare glass was more popular and used in some commercial devices, but later manufacturers have found that devices with anti-glare are being sold less frequently than the glare ones. It is because as humans we think that there is something wrong with a little bit blurry image even if the reflections are lower. When we are in a shop and looking at phones, we do not see the image clearly and we think that there is something wrong and we do not want this device. That is why we do not see any more anti-glare glass in consumer products. Everything is glare in consumer products, it could be anti-reflective or could be only regular without any surface treatment. But in the professional market that we are working on, like medical devices, military devices, we have many projects where we use anti-glare and anti-reflective treatments, both solutions to reduce reflections and increase contrast.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

This scale is about surface hardness – how hard is it to scratch the surface. As you know, even glass with hardness 9 can be scratched, everybody has some scratches on their phone because this hard layer is very thin – 10 micrometers only. If we put enough force and break this barrier, then we have soft glass with hardness 6 or even lower, that is why we have the scratches.

A couple more words about Gorilla glass. Now there is the sixth generation of Gorilla Glass on the market. The goal for Corning company and Gorilla Glass is to make the glass as strong and as light as possible, because most of the cases are handheld devices, where we want the glass to be light, that is why we want to make it very thin. We have also other companies that are making equivalents of Gorilla Glass, like Dragontrail from AGC or Xensation from Shott. They are not so popular but in many mobile phones or tablets on the market you can find these types of glass.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

When we do the Screen Printing, we need a screen for each color, so to minimize cost, we try to reduce the number of colors to 2–4, like the background and the colored logo. Each color is a different process, we need to wait until the previous painting dries and then we need to put another screen and print another color. More colors mean a longer process and of course a higher cost. Of course, we can change the shape of the glass, we can make rounded corners or custom design of the glass, but it is expensive because first it is just the rectangular piece, then you need to go to the CNC machine to make the proper shape of the glass.

Now we will talk about mechanical impact protection. It is different than the surface hardness we talked about before. On the picture above, we have the test and scale to measure the mechanical strength of glass, that means how much energy we can put on the glass before it breaks. It is measured in IK rate. IK rate is a scale where we have different levels and different energy that will boost. For example, if we want to test IK 9, we need to take 5-kilogram mass from 200-millimeter height. The mass is kept above the tested glass using an electromagnet, then we just drop it, and we see if it breaks or not. If not, of course the test is passed.

If the glass has not passed the test, we can try to change the glass type from thermally tempered to chemically strengthened or go to a thicker glass.

The last point in this article is laminated glass. We laminate glass because of a few reasons. First, what is laminated glass. Laminated glass is like putting the film inside two glass sheets. This process is expensive, we need pressure, we need temperature, we need time, and we need an exceptionally clean environment, because when we laminate together two sheets of glass, we need to be sure that no particles get inside. This kind of process needs to be done in a Clean Room, so it is expensive, but as you see on the picture above, even if the glass is broken, it still holds up because of the laminated film inside.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

Deliver exceptionally easy-to-use, advanced glass panels at the lowest price on the market. Choose from the least expensive high-performance basic glass panel VFR PFD or the top-of- the-line EFD1000 Pro PFD.

Not only are Aspen PFDs the most affordable GA glass on the market, your fly-away cost is made even lower because Aspen’s patented retrofit technology delivers substantially lower installation costs. There’s no need for expensive new panel modifications; Evolution Flight Displays (EFDs) uniquely retrofit directly into your aircraft’s six-pack panel holes. The self-contained EFDs also don’t require the installation of heavy remote mount boxes. And since Evolution displays work with the avionics already in your panel - no matter what make - you don’t have to upgrade your GPS or radios.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

MicroLED shows promise as a display technology, potentially offering power savings and a reduced screen thickness when put beside current-generation display panels. Apple has recognized the potential, and has invested heavily into developing the technology over the last few years, with a view to using it in the company"s future products.

To understand fully how MicroLED can benefit Apple, it is worth understanding how the commonly-used display technologies work in the first place, before examining how different MicroLED really is in a comparison.

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

Displays that use collections of LEDs as individual pixels do exist, but it isn"t usually found in consumer products. LED screens are commonly used for billboards, in attractions, and as a large-scale display for events.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

OLED also can be produced on plastic substrates instead of glass, allowing it to be used to create flexible displays. While this is currently embodied in curved and other non-flat screens in some devices, it has the potential to be employed in foldable smartphones or rolled up for storage, an area Apple is also allegedly examining.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

OLED panels are also affected by the presence of water, both in production and in use. Small amounts of water contacting the organic substrate can cause immediate damage to the display, rendering parts of the screen useless.

Thought to be the next big thing in display technology, MicroLED basically takes the idea of using LEDs for pixels in a large stadium-style screen and miniaturizes it all.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED doesn"t use an organic compound to produce light, making it less susceptible to failure compared to OLED. Just like OLED, it can be applied onto a flexible material, allowing it to be used for curved displays or non-stationary components, like a watch strap, and can result in an extremely thin display panel.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

While MicroLED is an attractive proposition for Apple, it is not the only technology under development by the company"s engineers. Apple has previously filed patent applications for a technology described as "Quantum Dot LED and OLED Integration for High Efficiency Displays."

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

Image: Lee, Changhee & BAE, Wanki & KWAK, Jeonghun. (2014). "Quantum Dot LED (QLED) Emerging as a Next-generation Display Technology" in Physics and High Technology

The technology in theory can create an even thinner display than OLED, along with a more streamlined manufacturing process. True QD displays are also capable of high pixel densities of up to 1,000ppi, multiple times the density required to be called a Retina-quality display, and based on Apple"s hybrid invention, will also boast the response times of OLED technology.

The QD patent application certainly shows Apple is thinking about display technology in multiple ways, and how it can be applied to future devices, but short of getting firm supply chain information or an official announcement from Apple directly, it is difficult to confirm which direction it will be heading.

Apple has been interested in using the technology for some time now, with the first notable sign being its acquisition of LuxVue in May 2014, alongside assorted related patents. A MicroLED specialist, LuxVue was rumored to have been the display producer for the ill-fated Google Glass headset, but was also the holder of assorted patents in the LED display field, including MicroLED.

At the time, the acquisition was thought to be an attempt by Apple to bring part of its display technology development in-house, with suggestions the MicroLED technology would be used in another rumored-at-the-time device, the Apple Watch. A more recent report suggests Apple is working with TSMC to make small panels for a future premium Apple Watch, potentially starting mass production by the end of the year.

The facility is also claimed to be sufficient in size to perform small scale manufacturing of display panels, allowing the company to keep development and testing in-house without involving third-parties. Considering Apple"s previous history in developing technologies before issuing information to manufacturing partners, it is possible that Apple is trying to work out the kinks in production before suppliers even attempt to make MicroLED panels.

The rumored small screen production may be for the Apple Watch now, but it may also benefit another often-rumored device, namely the VR or AR headset. This type of hardware relies on light components to keep the weight off the user"s head and neck, as well as displays with a high refresh rate and as close to perfect color reproduction as possible.

Apple is also apparently planning to use the technology in larger displays, said to be bigger in size than those in the MacBook Pro lines. This could be an iMac or iMac Pro, or even an external display, but ultimately there"s no real indication of Apple"s plans at this point, regardless of the scale of the screen.

Reports from last year also suggest Apple"s investment in MicroLED was a cause for concern for Samsung, LG, and other South Korean suppliers who provide display panels for the company"s products. Owning the process for MicroLED manufacturing could allow Apple to migrate away from its existing display suppliers in the coming years, reducing revenues and profits.

Aside from Apple"s development, there has been little in the way of announcements from other firms for products using the technology that could be bought by consumers in the coming months. The exception is Samsung, Apple"s main rival in the mobile marketplace and a major supplier of display panels, but its usage of MicroLED is not aimed at producing smaller screens.

The impending use of the technology in a high-priced consumer product could be considered proof that MicroLED display technology is maturing enough for use in devices. If the reports claiming Apple is getting close to mass producing panels is true, the inclusion of MicroLED in the Apple Watch could end up being the first mainstream usage of the technology.

TFT stands for Thin-Film Transistor. TFT technology is a new standard these days for manufacturing displays, monitors, laptop screens, and other devices. TFT LCD displays can show crisp text, vivid colors, fast animations, and complex graphics.

TFT LCD monitors, also called flat panel displays, are replacing the old style cathode ray tubes (CRTs) as the displays of choice. Almost all LCD monitors today take advantage of the TFT technology.

Each pixel on a TFT display is backed by a tiny transistor. Transistors are so small these days, they need only a very minimal charge to control what they do. TFT displays are much more energy efficient than regular CRT screens that need a powerful light source.

TFT displays also allow for very fast re-drawing of the display, so the image has very little chance to flicker. This was not always the case with flat-panel monitors. Original passive matrix LCD displays were not able to refresh at very high rates and therefore could not keep up with fast moving images. A TFT monitor refresh rate is very high resulting in a display that can be used for video, gaming, and all forms of multimedia.

A TFT monitor delivers crisp text, vibrant colors, and an improved response time for multimedia applications. Today"s standard for response rate in TFT monitors is 16 ms or less.

In general, a LCD display comprises of a layer of LCD material and one or more polarizing layers made of plastic, glass, or some other material. A LCD display has a sandwich-like structure with liquid crystals filled between two glass (or plastic or polycarbonate) plates.

These liquid crystals when stimulated by an external electrical charge can change the properties of light passing through them. When you align two polarizing materials with each other, light passes through. When you align one polarizing agent at a 90° angle to the other, light is blocked. Change the voltage, and the amount of light passing through the display is changed.

A TFT display is an advanced LCD display. A TFT monitor uses so-called thin-film transistor technology to project a picture on the screen. Transistors in a TFT display are used to change the orientation of the polarizing agent.A typical 17-inch TFT monitor has about 1.3 million pixels and 1.3 million transistors. The following text explains TFT in a greater detail...

Passive LCD panels cannot quickly change the orientation of the crystal. Well, it is quick, but not quick enough to display fast-moving graphics. To overcome this slowness, engineers came up with active-LCD technology. Active-LCD displays use transistors to actively change the orientation of crystals. That is where TFT comes from. T in TFT for transistor. This method allows for faster control of the LCD cell but is also more complex.

While passive-LCD displays start to blur with images moving faster than 8 to 15 frames/sec, TFT displays can display full-motion video and graphics because they use fast switching transistors.

Now that we know how a LCD works and what it behind TFT, we can start talking about color. Each pixel in a color TFT LCD is subdivided into three subpixels. One of the subpixels is capable of producing red, the other one green, and the last one blue color. Red, green, and blue are the basic colors. Any other color can be produced by mixing up these three. One set of RGB subpixels is equal to one pixel.

Old TFT displays and the small ones in simple applications such as calculators are reflective TFT. A reflective TFT display has no backlight. The polarizing agent at the rear of the TFT display is simply a mirror layer behind the TFT panel. The agent merely reflects incoming light from the front of the display. You need to be in a well-lit room to be able to read this type of display.

The next step in a TFT LCD design was to add a light source to it. More advanced TFT displays have added sidelights or front lights to these displays. Sidelights and front lights are virtually the same as backlights. The difference is just the position of the light. Front lights sit on the side or slightly in front of the TFT layers. They are designed so that the light they produce shines through the TFT panel and bounces off the reflective polarizing agent back through the display.

A transmissive TFT uses a backlight. Most TFT LCD panels today are designed with a backlight. The source of the light is mounted at the rear side of the LCD panel and shines light towards your eyes through the TFT panel"s polarizing medium (liquid crystal). Small displays, such as cell phones or calculators, use light source that is placed along the sides of the display.

The common TFT-display backlight is the CCFL (cold-cathode fluorescent lamp). CCFLs are similar to fluorescent light tubes that you commonly find in offices and homes. Their advantage is that they are small, inexpensive, replaceable, and cheap.

The polarizing medium in a TFT that transmits or blocks the backlight is clear, so any light shining on the display from the front competes with the backlight. If the light source shining on the front of the TFT display is strong enough, such as sun on a sunny day, it simply overpowers your laptop TFT display"s backlight and the display image is washed out. A reflective TFT display is usually a better choice for applications with high ambient light.

LED technology has only recently achieved the white light necessary to illuminate these panels. LEDs are the choice these days because they are stable over temperature ranges, durable, and very energy efficient. That is why if you buy a laptop with a TFT LED back-lighted display, it is possible that it will go for as much as 8 hours with your battery.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey