difference between tft lcd and resistive touchscreen factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Touchscreens have changed the way people expect to interact with their devices. When it comes to smartphones and tablets, touch is the way to go. Even handheld game consoles, laptops, and car navigation systems are moving towards touch. Manufacturers of these devices need to give their respective consumers the responsiveness these consumers are looking for. Selecting the right TFT-LCD display to use for different devices is important.

For touch-sensitive displays, two types of technologies are used: resistive and capacitive. The main difference is in how they respond to touch. Mobile phone comparison site Omio indicates that resistive technology is more accurate but capacitive technology is more responsive.

To elaborate on that, resistive touchscreens allow input from fingers and non-finger objects, like a stylus. A stylus has a smaller point than a finger and makes interaction on a resistive screen more accurate. This makes the technology suitable for devices whose applications require high accuracy, like sketching and pinpoint games. Mobile devices that use a stylus typically have resistive touchscreens.

Capacitive touchscreens, on the other hand, offer more responsiveness with better optical clarity and multi-touch performance. They detect more complex finger gestures. These qualities are shown to be more important for general interaction so it’s more dominant in smartphones and tablets, as well as in other devices with small to medium screen sizes.

As you can see, capacitive screens get general usage while resistive screens cater to more specific applications. With this, TFT-LCD module manufacturers, like Microtips Technology, focus on continuously improving capacitive screen technology.

Electronic Design states that many technological advances can be used to integrate touch sensors directly into the display. In some, manufacturers stack-up the touch sensors and integrate the controller with the display driver ICs. These advances allowed thinner and smarter capacitive touchscreens – a trend that you see in many devices today. For example, Windows phones originally worked exclusively with resistive touchscreen technology but later on moved over to capacitive. If the continuous development of capacitive touchscreen technology becomes successful, these screens may soon have abilities they don’t possess at the moment, such as hover support, non-finger support, and many more.

Capacitive touch panels are the more modern and advanced touchscreen option because of their advanced capabilities. They are commonly found in consumer products like smartphones, tablets, appliances, and monitors.

A capacitive touchscreen detects and responds to changes in capacitance caused by the screen"s electrostatic field when the screen"s surface is touched.

Capacitive touchscreen displays allow for touch gestures and respond to multi-touch inputs. You’ll typically be able to enter one to five touch inputs simultaneously, but some capacitive touchscreens can process even more.

Capacitive touchscreens deliver brighter, higher contrast images due to the makeup of their panels. Displays with capacitive touch screens are more durable than resistive touch screens because they are designed with cover glass on their top layer. In fact, all of our capacitive TFT displays have standard 0.7mm thick built-in cover glass and can be further

While the cost is currently higher than resistive touchscreens, capacitive touchscreens are quickly becoming the industry standard in touchscreen technology.

The enhanced responsiveness can be a downside depending on how and where the display is used. For example, a capacitive touchscreen would not easily respond to the user while wearing certain types of gloves. Although capacitive touchscreens don’t respond to inorganic inputs, they can still be accidentally activated by other conductive elements. One of the the most common elements that causes interruptions is water.

Rain, humidity, and condensation on the surface of capacitive touchscreens will often cause accidental inputs and reduced accuracy until the water is removed. This is one of the main reasons why a resistive touchscreen would be chosen over a capacitive touchscreen in certain situations.

Any device that utilizes touch gestures like swiping, pinching, or multi-touch will require a capacitive touchscreen. These features often help make capacitive touchscreen displays more intuitive and user-friendly than resistive touchscreens. Capacitive touchscreens are best suited for applications requiring improved touch responsiveness with better image brightness and contrast.

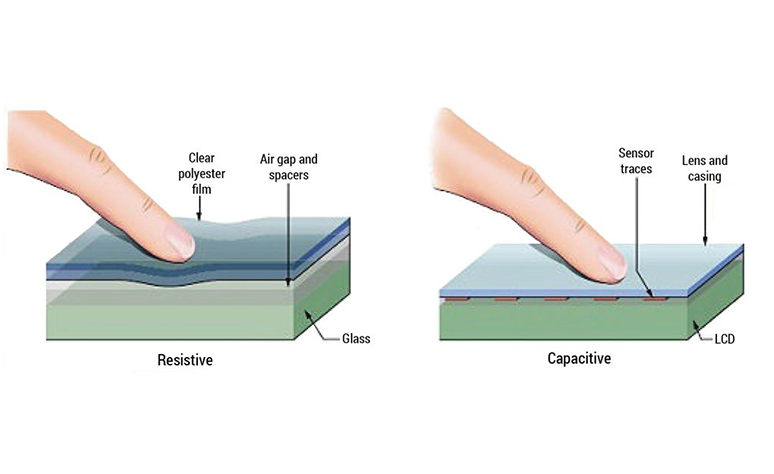

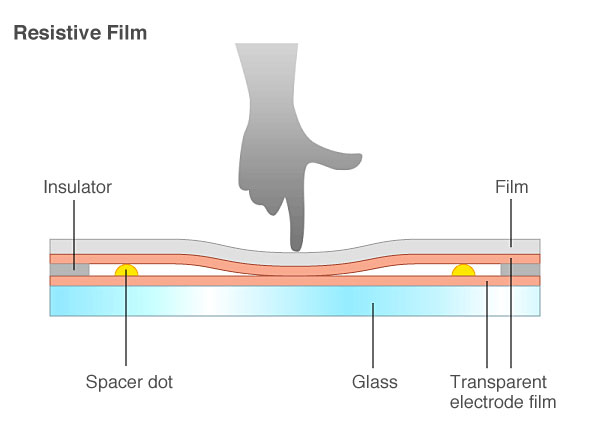

sense pressure on the display"s top layer and send a signal to the circuit layer to activate the touchscreen functionality. Because they use pressure to activate the touch inputs, resistive touchscreen displays can be used with a stylus, gloves, and other items. Resistive touchscreens are built without cover glass and made of plastic, making them more susceptible to dents and scratches.

"touch event" occurs when these two layers make contact with each other (closing the circuit) by the user"s action of pressing into the soft, semi-flexible top layer. Each layer consists of horizontal and vertical lines (x,y matrix) that detects the exact location of the touch.

The gap or space layer typically consists of air or inert gas and some spacers whose only purpose is to separate the soft top layer from the bottom layer.

Resistive touchscreens are often seen as the less advanced variety of touch panel compared to capacitive touch panels. However, being able to interact with non-organic inputs keeps these touchscreens relevant in specific industries.

Resistive touchscreen displays are less sensitive than capacitive touchscreen displays. This is considered an advantage in some cases and is why they’re chosen for specific applications. Resistive touchscreens will not respond to accidental inputs from the environment, so they won’t be interrupted by things like water spills or lightweight debris landing on the screen.

This type of touchscreen requires more intentional inputs from the user, making them more reliable in rugged and unstable environments. For example, a resistive touchscreen is the perfect solution on a construction site where water or debris might land on the screen. They’re also the best touchscreen display option for situations where the user is wearing gloves.

Resistive touchscreen panels are unfortunately more susceptible to dents and scratches. Their poor visibility in direct sunlight does not make them ideal for outdoor applications. Their inability to respond to multi-touch inputs can be a disadvantage in fast-paced applications requiring such. Because resistive touchscreens rely on the pressure applied to the top layer, they tend to be abused and mishandled, which makes them less durable over time than capacitive touchscreens.

Resistive touchscreen technology is ideal for low-cost applications involving rugged environments, indirect sunlight, and simple touch features. Fewer accidental touch inputs, better resistance to heat and moisture, and the ability to be operated with pretty much anything (stylus, pen, gloves, fingers, etc.) make this touchscreen technology a more reliable solution when user input is crucial.

While it’s clear that capacitive touchscreens are dominating the consumer electronics market, resistive touchscreens still have an advantage in some ways.

If you’re looking for a cost-effective touchscreen that can operate with simple tap inputs in rugged environments, resistive is the way to go. For more advanced and intuitive touchscreen technology with higher quality applications, choose capacitive touchscreens.

There are many types of touch panel technologies available in the market, the popular types are we are going to discuss the two most widely used types, and compare resistive vs capacitive touch screen

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

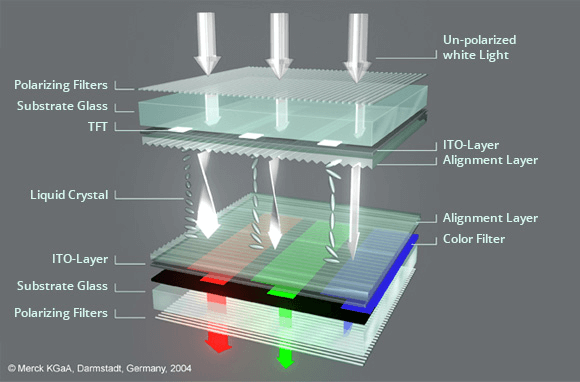

Projected capacitive touchscreen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

Projected capacitive supports multiple touches (Multi-touch), so it supports a lot of gestures: Zoom in and out (pinch/spread), scroll, swipe, drag, slide, hold/press, rotate, tap etc.

With the new development, projected capacitive touch panels can support gloved hand touch with different glove materials and touch with water or even with salt water.

Before 2007, resistive technology was the most popular touch panel market. From its name, we know that the technology relies on resistance. A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

With the fast development of projected capacitive, resistive touchscreen devices market is shrinking rapidly but it is still widely used in some industrial applications because of the following advantages.

The following table shows the comparison of resistive and capacitive touch screens. It is up to your application to select the types of technology to use.

Projected capacitive touch screen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

Resistive touch screens still reign in cost-sensitive applications. They also prevail in point-of-sale terminals, industrial, automotive, and medical applications.

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

There are a variety of touch technologies available today, with each working in different ways, such as using infrared light, pressure or even sound waves. However, there are two touchscreen technologies that surpass all others - resistive touch and capacitive touch.

There are advantages to both capacitive and resistive touchscreens, and either can be suited for a variety of applications dependent on specific requirements for your market sector.

Resistive touchscreens use pressure as input. Made up of several layers of flexible plastic and glass, the front layer is scratch resistant plastic and the second layer is (usually) glass. These are both coated with conductive material. When someone applies pressure to the panel, the resistance is measured between the two layers highlighting where the point of contact is on the screen.

Some of the benefits of resistive touch panels include the minimal production cost, flexibility when it comes to touch (gloves and styluses can be used) and its durability – strong resistance to water and dust.

In contrast to resistive touchscreens, capacitive touchscreens use the electrical properties of the human body as input. When touched with a finger, a small electrical charge is drawn to the point of contact, which allows the display to detect where it has received an input. The result is a display that can detect lighter touches and with greater accuracy than with a resistive touchscren.

If you want increased screen contrast and clarity, capacitive touch screens are the preferred option over resistive screens, which have more reflections due to their number of layers. Capacitive screens are also far more sensitive and can work with multi-point inputs, known as ‘multi-touch’. However, because of these advantages, they are sometimes less cost-effective than resistive touch panels.

Although capacitive touchscreen technology was invented long before resistive touchscreens, capacitive technology has seen more rapid evolution in recent years. Thanks to consumer electronics, particularly mobile technology, capacitive touchscreens are swiftly improving in both performance and cost.

At GTK, we find ourselves recommending capacitive touchscreens more regularly than resitive ones. Our customers almost always find capacitive touchscreens more pleasant to work with and appreciate the vibrancy of image that cap touch TFTs can produce. With constant advancements in capacitive sensors, including new fine-tuned sensors that work with heavy duty gloves, if we had to pick just one, it would be the capacitive touchscreen.

The biggest difference a user will notice between a resistive and a capacitive touch screen is that a resistive touch screen can only detect one touch at a time.

There are many other differences between a resistive and a capacitive touch screens– let’s compare some touch screen properties, and how they are different between resistive touch screens and capacitive touch screens.

Works with glovesYesNoA capacitive touch screen depends on a conductive contact. Your finger works well, or the end of a wrench you are holding . . . but non-conductive objects like a gloved finger or the plastic handle of a screwdriver will not be detected.

InterfaceAnalogDigitalThe interface to a resistive touch screen is typically accomplished with two digital ports and two analog ports of your microcontroller, along with a few lines of code. Typically this interface adds zero incremental cost to the project.

Projected Capacitance takes orders of magnitude more finesse to read it, and so most capacitive touch screens have a dedicated IC bonded to their flexible printed circuit (FPC) to handle the added complexity.

Typically you read of a bank of registers on the IC, one register contains the number of points touched, and others registers follow with X and Y coordinate pairs of each point.

As capacitive touch screen functionality increases and costs continue to come down, you can expect to see many more embedded displays available with touch screens in the near future.

The Crystalfontz tech team is here to help and can assist you in finding the best display for your project. Please contact our friendly sales and support team — ready to answer any questions that you may have about these touch display modules or any the displays in the Crystalfontz catalog.

Take your product to the next level with a capacitive touch screen LCD by Displaytech. Our PCAP (projected capacitive) touch screen technology is a premium alternative to a resistive touchscreen. We offer capacitive touchscreens for our 2.8-inch, 3.5-inch, 4.3-inch, 5-inch and 7-inch TFT LCD displays.

Capacitive touch technology allows for an enhanced product user interface since it supports gestures and proximity sensing. Unlike resistive touch screens which rely on pressure, capacitive touch responds to an electric current and can handle multi-finger touch points. This means that capacitive touchscreens can be used with your bare finger and it supports gestures such as pinch-to-zoom or swipe.

The construction of a capacitive touch screen,mainly to plate a transparent film conductor layer on the glass screen,then add a protective glass to the outside of the conductor layer,plate narrow electrodes on all four sides of the touch screen,a low voltage alternating electric field is formed in the electrical conductor.When you touch the screen,due to the existence of the human body electric field,a coupling capacitor is formed between the finger and the conductor layer,the current from the four electrodes will flow to the contacts,the current strength is proportional to the distance from the finger to the electrode,the controller behind the touch screen can calculate the ratio and strength of the current,then can accurately calculate the location of the touch point.

Compared with the resistive touch screens that are common in the market at that time,capacitive touch screen has obvious advantages,no pressure is needed to generate the signal,while the resistive touch screen is activated by pressure.Second,the capacitive touch screen has a long average life.Third,for the resistive touch screen, the upper film needs to be thin enough to be elastic so as to be bent downward to contact the underlying film, so it is easily damaged.And the covers of capacitive touch screen can be thicker, also have glass protection and have good scratch resistance, which can better protect conductors and sensors.In addition, capacitive touch screen is more durable, not easy to aging, high temperature resistance.Moreover, the double-glass design of capacitive touch screen can effectively prevent the impact of external environmental factors on the touch screen,even if the screen is stained with dirt, dust or oil stains, the capacitive touch screen can still accurately calculate the touch position.the more important thing is,at this time, the touch screen has evolved from an early analog touch screen to a digital touch screen, can achieve multi-touch.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Raystar ‘s Resistive Touch Screen TFT Display uses 4- wire type of resistive touch screen with advantages of low-power consumption, fast response time and stable quality. With full ranges from small to medium sizes, we set low MOQ in standard products. Comparing to TFT Capacitive Touch screen Display, the Resistive Touch Screen TFT is more competitive.

The resistive structure is sensed by pressure so there is no limitation of contacting forms. Resistive touch screens work smoothly even using a pen or with gloves. TFT display with resistive touch screen can be used on consumer electrical products, such as POS system, security system, control monitors and GPS devices.

Capacitive touch screens and resistive touch screens are mainly different in touch sensitivity, precision, cost, multi-touch feasibility, damage resistance, cleaning, and visual effect under sunlight.

1. Resistive touch screen: all layers of the screen are in contact with pressure. Fingers (even with gloves on), fingernails, and stylus can be used for the operation. Stylus support is important in The Asian market, where gesture and word recognition are valued.

2. Capacitive touch: The slightest touch from the surface of a charged finger activates the capacitive sensing system at the bottom of the screen. Inanimate objects, fingernails, and gloves are invalid. Handwriting recognition is more difficult.

1. Resistive touch screen: the accuracy is at least as high as a single display pixel, which can be seen with a stylus.Easy handwriting recognition and easy to operate in an interface that USES small control elements.

2. Capacitive touch: Capacitor screens from different manufacturers are 10% to 50% more expensive than resistive screens. This extra cost is fine for flagship products, but maybe prohibitive for mid-priced phones.

1. Resistive touch screen: The fundamental characteristics of the resistive screen determine that the top is soft and can be pressed down. This makes the screen very easy to scratch. Resistance screens require protective film and relatively frequent calibration. On the plus side, resistive touchscreen devices that use plastic are generally less vulnerable to breakage.

2. Capacitive touch screen: glass can be used for the outer layer. While not indestructible and likely to break under severe impact, glass is better for everyday scratches and smudges.

1. Resistive touch screen: It is less likely to leave fingerprints, oil stains, and bacteria on the screen because it can be operated with a stylus or fingernail.

1. Resistance touch screen: the specific value is unknown. But there is evidence that the Nokia5800, which USES resistive screens, can operate normally at temperatures from -15°C to +45°C, with little requirement for humidity.

2. The capacitive touch screen utilizes the human body’s current induction to work. The capacitive touch screen is a four-layer composite glass screen. The inner surface and interlayer of the glass screen are each coated with a layer of ITO(coated conductive glass). The outermost layer is a thin layer of silica glass protective layer.

When the finger touches the metal layer, the electric field of the human body, the user, and the surface of the touch screen form a coupling capacitance. For high-frequency currents, the capacitance is a direct conductor, so the finger draws a small amount of current from the contact point. The current flows from the electrodes at the four corners of the touch screen, and the current flowing through the four electrodes is proportional to the distance between the fingers and the four corners. The controller calculates the exact proportion of these four currents to obtain the position information of the touchpoints.

For now, you can choose the right screen for your application scenario. Both resistive and capacitive screens are very delicate, so we need to take good care of them.

Beijing STONE Technology Co., Ltd. focuses on the industrial display screen, Industrial touch screen product development and manufacturing, products are widely used in medical equipment, industrial equipment, automation, civil equipment and smart home, and other application fields.

Capacitive touch screen technologyUSES the human body’s current induction to work. The capacitive touch screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with one layer of ITO respectively. The outermost layer is a thin layer of silica soil glass protective layer. When the finger touches the metal layer, the user and the touch screen surface form a coupling capacitor due to the electric field in the human body.

The capacitor is a direct conductor to the high-frequency current, so the finger sucks a small current away from the contact point. The current flows from the electrodes at the four corners of the touch screen respectively, and the current flowing through the four electrodes is proportional to the distance from the fingers to the four corners. The controller calculates the precise proportion of the four currents to get the position of the touchpoint.

In order to realize multi-touch on a capacitive screen, it is necessary to add electrodes of mutual capacitance. In a simple words, it is to divide the screen into blocks and set a group of mutual capacitance modules in each area to work independently. Therefore, the capacitive screen can independently detect the touch situation of each area and simply realize multi-touch after processing.

Capacity Touch Panel USES the current induction of the human body to work. The capacitive screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with ITO (indium sikgold oxide nano). The outermost layer is a protective layer of silica glass with a thickness of 0.0015mm.

Whena user capacitive touch screen, the electric field due to the human body, your fingers and face form a coupling capacitance, because the working plane to have a high-frequency signal, so the fingers on a very small current, respectively from the current screen in the four corners of the electrode, and theoretically through the four electrodes with the finger to the four corners of the current is proportional to the distance, the controller through the precise calculation of the four current ratio, it is concluded that location. It can achieve 99% accuracy, with a response speed of less than 3ms.

Projective capacitive touch screens etch different ITO conductive circuit modules on two layers of ITO conductive glass coatings. The etched patterns on the two modules are perpendicular to each other and can be thought of as sliders with continuous changes in X and Y directions. As the X and Y architectures are on different surfaces, their intersection forms a capacitor node. One slider can be used as the drive wire and the other as the detection wire. When a current passes through one of the wires in the drive wire, if there is a signal of a change in the capacitance outside, it will cause a change in the capacitance node on the other layer of wire. The change in capacitance can be detected by measuring the electrical circuit connected to it, and then converted to A digital signal by A/D controller, which can be processed by A computer to obtain the (X, Y) axis position, so as to achieve the positioning target.

During operation, the controller successively supplies power to the driving wire, thus forming a specific electric field between each node and the wire. Then scan the sensor line one by one to measure the capacitance change between the electrodes so as to achieve multi-point positioning. When the finger or touch medium is close, the controller can quickly detect the change of capacitance between the touch node and the wire, and then confirm the position of the touch.

One axis is driven by a set of AC signals, and the response across the touch screen is measured by electrodes on the other axis. Users call this’ transversal ‘sensing or projective sensing. The sensor is plated with the ITO pattern of the X and Y-axis. When the finger touches the touch screen surface, the capacitance under the touchpoint increases according to the distance of the touchpoint. The continuous scanning on the sensor detects the change of capacitance value, and the control chip calculates the touchpoint and returns it to the processor.

Projective capacitive touch screens are multi-finger touch. These two capacitive touch screens have the advantages of high light transmittance, fast response speed, and long life, etc. The disadvantages are: with the change of temperature and humidity, the capacitance value will change, resulting in poor work stability, often drift phenomenon, need to frequently proofread the screen, and can not wear ordinary gloves for touch positioning.

The projected capacitive touch screen can be divided into the capacitance and mutual capacitance screen two types, one of the more common mutual capacitance screen as an example, the internal electrode and receiving electrode by the driver, drive electrode signal low voltage high frequency projected onto the receiving electrode form stable current, when human exposure to the capacitance screen, earth due to the human body, fingers and capacitance screen to form an equivalent capacitance, and the high-frequency signal by the equivalent capacitance into the ground, in this way, the receiver receives charge is reduced, when fingers near the transmitter, electric charge, the more significant, according to the receiving end receives the current strength of to determine the touchpoint.

Arrays of transverse and longitudinal electrodes are made from ITO on the surface of the glass. These transverse and longitudinal electrodes form capacitors with the ground respectively. This capacitor is commonly referred to as self-capacitance, that is, the capacitance of the electrode to the ground. When the finger touches the capacitive screen, the capacitance of the finger will be superimposed on the capacitance of the screen, thus increasing the capacitance of the screen.

During touch detection, the horizontal and longitudinal electrode arrays are respectively detected from the capacitive screen. According to the changes of capacitance before and aftertouch, the horizontal coordinates and longitudinal coordinates are determined respectively, and then the touch coordinates of the plane are combined. The scanning method of self-capacitance is equivalent to projecting the touchpoints on the touch screen to the X-axis and Y-axis directions respectively, and then calculating the coordinates in the X-axis and Y-axis directions respectively, and finally combining them into the coordinates of the touchpoints.

If it is a single touch, the projection in the X and Y direction is unique, and the combined coordinates are unique. If there are two touches on the touch screen and the two touches are not in the same X direction or the same Y direction, then there are two projections in the X and Y direction respectively, and the combined coordinates are 4.Apparently, only two of the coordinates are real, and the other two are known as ghost points. Therefore, self – the capacitive screen can not achieve true multi-touch.

The mutual capacitor screen also USES ITO to make the transverse electrode and the longitudinal electrode on the glass surface. The difference between it and the self-capacitor screen is that the place where the two groups of electrodes cross will form a capacitor, that is, the two groups of electrodes form the electrodes of the capacitor respectively. When a finger touches a capacitive screen, the coupling between two electrodes near the touchpoint is affected, thus changing the capacitance between the two electrodes.

When the mutual capacitance is detected, the transverse electrode will send out excitation signals successively, and all the longitudinal electrodes will receive signals at the same time. In this way, the capacitance value of all the intersection points of the transverse and longitudinal electrodes can be obtained, that is, the capacitance value of the entire two-dimensional surface of the touch screen. The coordinates of each touchpoint can be calculated according to the two-dimensional capacitance variation data of the touch screen. Therefore, even if there are multiple touchpoints on the screen, the actual coordinates of each touchpoint can be calculated.

The advantage of the mutual capacitive screen is less wiring, and can simultaneously identify and distinguish the difference between multiple contacts since the capacitive screen can also sense multiple contacts, but because the signal itself is fuzzy, so can’t distinguish. In addition, the induction scheme of the mutual capacitive screen has the advantages of fast speed and low power consumption, because it can measure all the nodes in a driveline at the same time, thus reducing the number of acquisition cycles by 50%. The dual-electrode structure has the function of self-shielding external noise and can improve signal stability at a certain power level.

In any case, the touch position is determined by measuring the distribution of signal changes between the X and Y electrodes, and a mathematical algorithm is then used to process the changed signal levels to determine the XY coordinates of the touchpoint.

• Capacitive schemes last longer because the components in the capacitive touch screen do not need to move at all. In a resistive touch screen, the top layer of the ITO film needs to be thin enough to be elastic so that it bends down and touches the bottom layer of the ITO film.

• The choice of capacitor or resistor depends largely on the object touching the screen. If it is a finger touch, the capacitive touch screen is a better choice. If a stylus is needed, whether plastic or metal, a resistive touch screen will do. A capacitive touch screen can also use a stylus but requires a special stylus to work with it.

• Surface capacitances can be used for large touch screens and are relatively low, but they currently do not support gesture recognition: inductive capacitances are mainly used for small and medium-sized touch screens and can support gesture recognition.

• Capacitive technology is wear-resistant, has a long service life, and has low maintenance costs when users use it, so the overall operating costs of manufacturers can be further reduced.

• Capacitive touch screens are designed to support multi-touch technology and are less responsive and less prone to wear and tear than resistive touch screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

In an analogue configuration, the electrodes are placed on opposite sides of the layers without any specific patterning. Regardless, pressing or touching the surface of a lcd touch screen panel allows the two layers to make contact, and when the electrodes touch each other, it triggers a touch command.

Though with the fast development of projected capacitive, resistive touchscreen devices market is shrinking rapidly, but it is still the first choice for specified applications, like underwater usage devices,

printers, digital cameras, automotive, medical etc. One main advantage is no false touch, as the name suggested, it works by physical pressure, not sensitive to water or electromagnetic interference, so it can obey the instruction precisely. Secondly, lower-cost especially for a bigger size, normally 10 inches above screens, we choose Resistive touchscreen.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

A resistive touch screen is made of several layers. A capacitive touch screen consists of an insulator coated with a transparent conductor. Use the table below to determining which type of touch suits your project best.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey