comparison of crt and lcd monitors made in china

The general quality of Chinese CCTV monitors gets much improved. Three major Chinese monitor manufacturers are Skyworth, Stonesonic and Satow. The industry started export quite earlier compared to other security vendors in China. Now, LCD monitors, monitors for surveillance in commercial setting and LCD multiple screen combination panel wall are their main products.

The general quality of Chinese CCTV monitors gets much improved. Three major Chinese monitor manufacturers are Skyworth, Stonesonic and Satow. The industry started export quite earlier compared to other security vendors in China. Now, LCD monitors, monitors for surveillance in commercial setting and LCD multiple screen combination panel wall are their main products.

According to some industry expert, the ratio of global LCD to CRT production is roughly about 6:4. LCD monitors, in the past, had some defeats in certain aspects, such as brightness, contrast, visual angle, response time, lifespan and production. Along with the technical improvement, current LCD monitors are better performed in color, brightness, contrast, nearly 180-degree visual angle and response time. Plus, it has advantages in thin design, environmental friendly, and energy-saved (because of lead in the components of CRT monitors). LCD monitors have gradually replaced the CRT.

Many users might confuse LCD monitors with LCD display or LCD TV. However, the basic requirements for LCD monitors are quite different from them. For one LCD monitor, it is usually required to have higher standards on visual angle, brightness and contrast, color display ability, response time, resolution and the stability to operate continuously 24/7. Therefore, the safe electric performance and good heat emission design should be taken into the consideration for the design of one LCD monitor.

For one LCD monitor, a much broader visual angle and higher brightness and contrast are required for watching the fixed video picture at long distances. For PC display, the ideal pictures can be showed if it meets the required brightness and contrast of 200 cd/m2 and 300:1 respectively. But for monitors, the brightness and contrast should be not less than 300 cd/m2 and 450:1. The quality of picture is not only related to the brightness and contrast but also the definition, color reducibility, and SNR (signal to noise ratio) specifications. In addition, the response time is also quite important for LCD monitors. Manufacturers recently have taken a lot of efforts on increasing the response speed from the early 60 ms, 30 ms and 25 ms to current 16 ms, 12 ms and 8 ms; the tailing phenomenon has been almost disappeared and has little difference with response time for CRT.

One of Satow"s latest launch--42" Color LCD monitor, ML-4200TM1. It features 3-dimension image processing to reduce the noise and avoid the interference from the bright, making the picture display more sophisticated with PAL/NTSC. Its unique DNX technology makes the image more stable while displaying the moving pictures and video. The resolution is about 1920 x 1080; brightness is 500 cd/m2 and the contrast ratio is 2000:1. The response time can be 6.5 ms. Power supply is AC 100-240V.

Many LCD display"s power is often DC 12 V, using the external AC power adapter 220V AC/12V DC; however, it could not meet the requirements of electromagnetism interference (EMI) and electromagnetism compatible electron agnetic compatibility (E-MC) for professional monitors working at factories. Take Stonesonic. It adopted the reliable built-in switch power instead that can meet the requirements of electromagnetism compatible and interference standard. So it ensures the constant working of the machine no matter under what kind of environments and its much more coordinated appear once design is also more convenient for project mounting and operation. Skyworth also highlights its internal power supply with low consumption, and its screen service expectancy exceeds 60,000 hours. The latest I2C controlling circuits, the high reliability of whole system.

The luminescence of LCD panel is realized through several lamp tubes (cathode vacuum tube). Because some of the tubers are fixed at the fringe of the panel, it is normal that the frame becomes heated when being used for a certain period. In the design of LCD monitors, Stonesonic applied the hydrodynamics theory to make the air whirlpool inside the space of the machine form the convection, and operate the heat emission through those metal parts inside at the same time, which all ensure the reliable and constant working of the machine. So it will not affect the lifespan of the monitor if the frame of the LCD feels a little heated by hand.

Stonesonic recently launched one 19"color LCD monitor built-in DVR--SCM-1980MR. It is one kind of 8-channel monitoring and recording all-in-one monitor, adopting top-quality 19" TFT LCD panel and has functions of 4-8 channels composite video simultaneous input, real-time monitoring and recording, network remote monitoring, recording backup and alarm pan/tilt controlling.

Satow Eletronic also has one 17" LCD with built-in 4-channel MPEG-4 DVR system-BL-1700T4/CP-5714CB. Adopting the latest DSP hardware compression for each channel, the resolution is quite high. It can remote monitor via network, viewing with IE Browser or client-end software. For the LCD monitor, its contrast ratio is 800:1, brightness ratio of 300 cd/m2, display color in 16.2 M.

Stonesonic and Skywor th also developed their latest products of LCD combination panel wall. For Stonesonic, its LCD combination panel wall has already been registered and approved for six patents. The hardware basic is FPG A array, using parallel high speed image processing technology. It implements multiple high speed video signal"s unify processing technology. It totally replaces the insert card combination controller and solves the problem of quantity limitation of VGA input. It possesses all the excellent DID display technology, embedded hardware combination technology, multiple image processing technology, signal switching technology. This advanced LCD combination panel wall display system has benefits of high brightness and high definition, low power consumption and long lifespan.

Stonesonic monitor is used in many different applications such as security, broadcast, industry and multi-media. Their application in security accounts for 60 to 70 percent. Its strengths are high definition in image quality; more natural color in display. Its LCD export accounts for 50 percent of their total market. Till now, Stonesonic has had sales points in over 80 countries. It targets more at European and US markets. The latest products also includes one big IP screen monitor; very easy to install within one single IP cable. It also differentiated others in self-developed chipsets for monitors. Other vendors might adopt AV chips for LCD monitor so the 3D image may be worse in quality.

:max_bytes(150000):strip_icc()/CRT-vs-LCD-monitor-cfe0b6f375b542928baf22a0478a57a3.jpg)

First, we will provide a brief technical overview of functional principles as they relate to visual stimulus presentation. Detailed descriptions and parameter measurements are already available from the existing literature; however, our intention here is to equip readers with limited technical expertise with the necessary knowledge to set up computer experiments with LCD monitors. Thus, we keep our explanations relatively short and simplified.

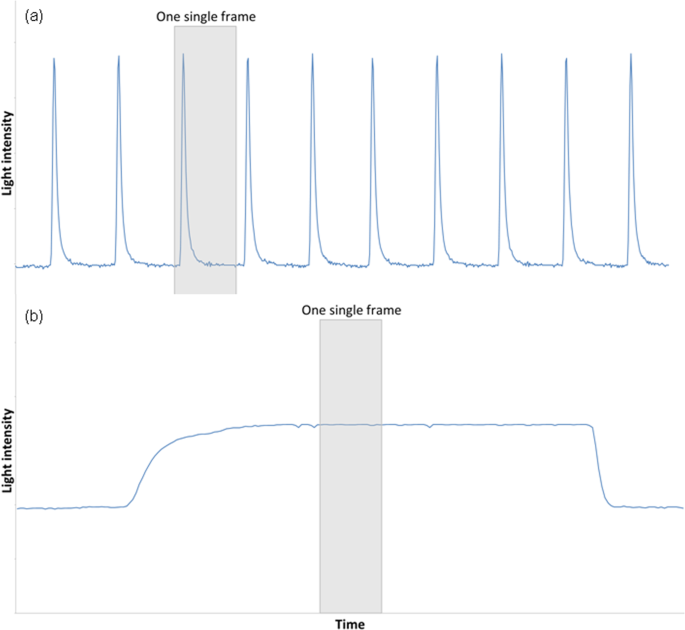

LCD monitors work differently: Each pixel consists of liquid crystal threads that can be twisted or arranged in parallel by an electrical current applied to them. This leads to a polarization effect that either allows or prevents light passing through. A white light source located behind this crystal array uniformly and constantly illuminates the array. To display a black pixel, the crystal threads are twisted by 90° such that no light will pass through. A white pixel is achieved by aligning the crystals such that maximum light is allowed to pass through, until a different, non-white color needs to be displayed (see the lower panel of Fig. 1 for an LCD pixel’s brightness over time). This is a static process, not a pulsed one as in CRTs.

In theory, the difference in presentation methods, namely a strobing versus a static image, should be of no consequence if the light energy that falls onto the retina remains the same over the time period of one single frame. As the Talbot-Plateau law states2 is equally well detectable as a light flash presented for 60 ms at 40 cd/m2. This suggests that temporal integration can be easily described by energy summation”. Thus, in principle, LCD and CRT monitors should be able to yield comparable results.

However, due to the differences in technology, the visual signals produced by the two display types have different shapes (i.e., a different light energy-over-time-curve; see Fig. 1). Moreover, default luminance as well as visual-signal response times (in addition to other parameters, see below) differ between most CRT and LCD monitors

Table 1 reports the parameters we considered in setting up the CRT and LCD monitors. Certainly, most of them are commonly considered when setting up a computer experiment; nevertheless we deemed it important to mention them here explicitly, as their neglect might have unintended consequences. We used a 17” Fujitsu Siemens Scenicview P796-2 CRT color monitor previously used in several published studies including studies with masked presentation conditions

We tested various monitor user settings, refresh rates, resolutions and luminance settings (see materials available at https://osf.io/g842s/) with regard to the emitted light energy–over-time-curve and therefore response characteristics (i.e., onset and offset of full screen and centrally presented stimuli). Measurements were conducted with a photodiode setup, using both an oscilloscope (model “Agilent MSOX 3012 A”) and a self-developed microcontroller setup as measurement devices. Stimuli were black and white squares.

Our measurements revealed several interesting characteristics: First, luminance of the LCD monitor at default setting (i.e., maximum brightness) exceeded the CRT luminance at a ratio of 3.25:1. However, comparable average luminance can be (and was) achieved by downregulating the LCD monitor (the older CRT technology emits less energy even at maximum settings, see Table 2), without participants perceiving it as unnaturally dark. If one plans to upgrade from CRT to LCD monitors in an experimental laboratory, we therefore recommend measuring the CRT monitors’ brightness levels and matching them in the new LCD monitors’ user setup, if comparability with the old setup is needed. This will minimize hardware-dependent variability, thus contributing to better replicability. Please note that a brightness adaption is not a necessary precondition when employing LCD monitors; researchers should simply be aware that the brightness level can have an influence onto the resulting effects, especially in time-critical experiments with short and/or masked presentation. Thus, we recommend the adaptation for time-critical experiments in which researchers orient on existing empirical evidence gathered with CRT monitors. Furthermore, gray-to-gray response times varied slightly depending on the employed brightness levels2), so we suggest that researchers can rely on this more efficient method as an approximation.

For the empirical comparison of human performance with CRT and LCD monitors, we relied on these results and set the monitor settings accordingly (see Method section below).

Participants were administered a masked number priming task and a subsequent forced-choice prime discrimination task using both a CRT and an LCD monitor. In this well-established paradigm

Of central interest was the question whether both monitors would yield comparable masked priming effects. Monitors were set according to the parameters described in the previous section (see also Method section below). In order to obtain conclusive evidence, we decided for sequential hypothesis testing using Bayes factorshttps://osf.io/g842s/.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Direct exposure of bare skin to strong light after PDT can cause severe skin phototoxicity although the superficial light irradiation has a limited tissue penetration depth. Therefore, the patient is advised to avoid direct light exposure to the skin after the administration of the photosensitizer. The length of light avoidance after PDT depends on the retention time of photosensitizer in the normal skin, which can be affected by the nature and dose of photosensitizer and its administration route, and body site [

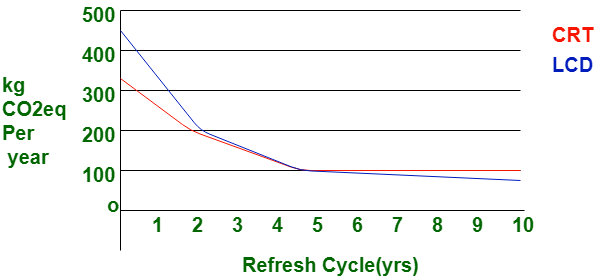

Incidences of post-PDT skin phototoxicity are often associated with patients who fail to heed the advice of strict light avoidance. Rather than indoor light, sunlight exposure shortly after receiving an exogenous photosensitizer or prodrug presents a major risk factor for skin phototoxicity. Although rare, exposure to CRT or LCD monitor emissions after PDT can also cause cutaneous phototoxicity on bare skin [

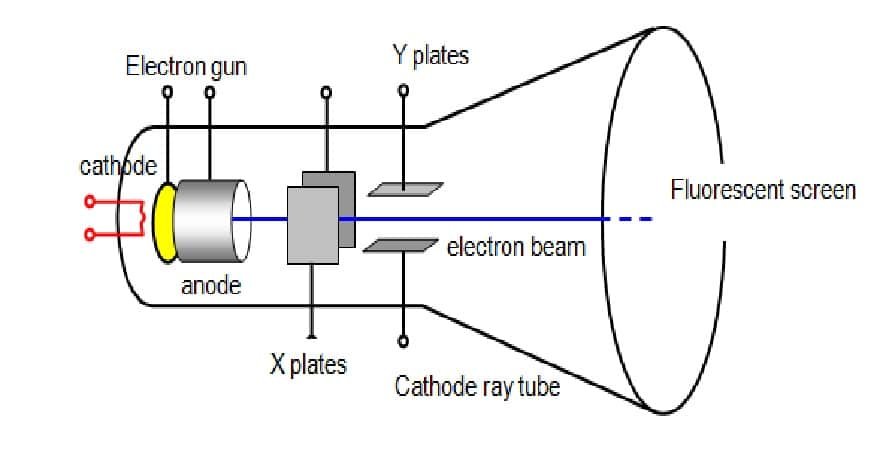

Color CRT monitors use a phosphor-coated screen. Phosphors are arranged in strips and emit visible light when exposed to an electron beam generated within the CRT. Three beams are used in CRT monitors to excite red, green, and blue color in combinations needed to create the various hues that form the picture. CRT monitors are gradually being replaced by LCD flat panel monitors in households and offices. The light emitting mechanism of LCD monitors is different than that of CRTs. LCD displays use two basic techniques for producing color: passive matrix or thin film transistor. Basically, LCD monitors utilize two sheets of polarizing material with a segmented liquid crystal solution between them. An electric current passes through the liquid causing the crystals to align so that the light emission of individual pixels can be controlled. LCD monitors are typically backlit by a white light fluorescent (fluorescent-backlit) or LED light (LED-backlit) source since the liquid crystals generate no light of their own.

This study examined the light emission profiles of common CRT, LCD, and LED monitors utilizing simulated movie and video game streams. The range of optical irradiance generated from the movie stream was broader than that from the game stream (see Fig. 2). The 50% points of the cumulative ratio for the game were slightly higher than that of the movie (see Fig. 3). Using a representative figure of 1 μW/cm2 as an example, it can be estimated that 10 min exposure to a monitor at a distance of 18 in. can deliver a total fluence of 0.6 mJ/cm2, i.e., 60 μJ/cm2/min to the skin surface. This estimated fluence rate is considerably lower than that of sunlight or PDT light, which are typically at 101–102 mW/cm2 range. The moderate monitor settings (e.g., the total emission intensity of 6:5 μW/cm2 at the measurement point), randomly selected video streams, and longer sensor-to-monitor distance (e.g., 18 in.) might cause an underestimate of the fluence rate. It should be noted that the actual light emission profiles depend on several factors, including the size and configuration of monitor screen, program being played back on the screen, and its duration. The light fluence received by the skin is also affected by the screen-to-face distance and their alignment. Furthermore, the light fluence inside the skin of a multilayered geometry can be significantly affected not only by light source but also by tissue optical properties [

For 10 min of the movie or game the integrated fluence from the CRT’s visible emission (467.5–800 nm) measured by the spectrometer at the same face position (i.e., 18 in. from the monitor) was approximately 1 mJ/cm2. This value was higher than that estimated from the optical irradiance (0.6 mJ/cm2) measured by the Si photodiode. It needs to be pointed out that the Si photodiode used in this study is wavelength dependent. As the wavelength was set up at 635 nm, it might underestimate the actual total optical irradiance. Interestingly, under the same condition, the integrated fluence from the LCD or LED was 40% or 80% higher than that of the CRT. The active diagonal screen size of the CRT, LCD, and LED was 16, 15, and 17.2 in., respectively. Under the white screen mode, the relative fluence of visible emission from the LCD or LED was 40% or 60% higher than that of the CRT when the total emission intensity was set up at the same level (see Fig. 1). Although the difference in the screen size might contribute to some variation, this finding suggests that the common assumption that LCD and LED monitors might be safer than older CRT monitors is incorrect in terms of potential risk of skin phototoxicity.

In some cases, the back of the hands can be exposed to monitor light while working on the keyboard. A recent report indicated that mild phototoxicity could occur on the back of both hands after PDT when the hands were exposed to an LCD monitor for a few hours [

It has been a concern that overexposure to UV and visible radiation in the presence and absence of photosensitizer might be also detrimental to the eye and subsequently to vision [

In summary, our results suggest that the optical and spectral profiles of emissions from color monitors are clinically relevant. Therefore, prolonged exposure to monitor emissions at a close distance might pose as a potential risk to the face, eyes, and hands. Future guidelines on post-PDT care and patient warnings should include the avoidance of overexposure to common light sources, such as computers, video games, and TV monitors after receiving a topical and systemic administration of a photosensitizer. This should be emphasized to certain high-risk patient populations, e.g., teenagers who may play video games for extended periods of time and people who receive repeated topical application of a photosensitizer or prodrug at a short period of time or work long hours in front of a large and bright monitor screen. The same caution is also applicable to patients who take drugs known to cause photoallergic, photosensitive, and phototoxic reactions.

Are LED monitors better than their LCD predecessors? How are the two technologies differ in terms of functionality and performance? All these questions will be answered by the LED vs. LCD comparison presented in here.

The age of CRT (cathode ray tube) displays is over and LCD displays are already being replaced with LED screens. Technology is evolving at an exponential pace, pushing existing technologies into obsolescence. Just when we thought LCD screens will be the default choice for some time to come, they were supplanted by LED monitors, with their superior power efficiency and rich picture quality.

Considering that we spend a major amount of our lifetime in front of screens these days and eyes are not a replaceable commodity, a discerning consumer must opt for technology that is soft on the eyes, while providing a rich visual experience.

There seems to be a lot of confusion about the differences between LED (Light Emitting Diode) and LCD (Liquid Crystal Display) monitors that need clarification. Here"s a succinct analysis of the similarities and differences between the two models.

LED and LCD monitors are based on the same basic technology for image display but differ in the kind of backlighting used. While LCD monitors use CCFL (cold cathode fluorescent lamps) for backlighting, the latter use light-emitting diodes. This is the prime difference between the two display technologies. So LED monitors are in actuality, a type of LCD monitors or an improvement over them.

Unlike CRT monitors that generate their own light through cathode ray incidence on fluorescent materials, LCD displays have to rely on external lighting, as their display is created through manipulation of light, passing through polarized liquid crystals. Backlighting affects picture quality substantially and light shed by LEDs offers superior picture quality compared to LCDs.

This is because LEDs offer much more gradation in intensity and a larger light wavelength spectrum, providing a truer color quality. These types of monitors offer a better dynamic contrast ratio as well. So if you compare LED and LCD monitors from a gaming perspective and for use in intensive graphic applications, LED monitors are surely better choices. They provide vivid and more lifelike colors, with better gradation.

In this type of monitor, the white LEDs are placed along the edge of the screen, taking up less space overall, making the entire monitor slimmer, as well as cheaper. This is the most common type of LED screen available in the market.

LED monitors cure one of the basic problems with LCD TVs, which is the inability to display true black colors. They can produce true black hues, by switching off LEDs entirely, increasing the blackness quotient of the screen, and providing better contrast in the process.

LED monitors are a very recently introduced technology and they are preferred over LCD monitors because of the amazingly rich picture quality and viewing comfort. One more advantage that LED monitors to have over LCD ones is the power consumption factor. LED monitors require a lot less power to operate than cold cathode fluorescent lamps. This property can be attributed to the inherently low energy required by an LED to function. Their power consumption is as much as 40% lesser than conventional LCD monitors.

LED monitors are also a lot softer on the eyes than LCD monitors, making them popular choices for people who work for long hours on their desktop computers. They are also a lot more eco-friendly because mercury is not used in their production. LEDs last longer than cold cathode fluorescent lamps, with little reduction in their power output over time, which makes these monitors long-lasting.

To conclude this LCD vs. LED monitor comparison, let us compare the price ranges. One major factor that has been holding back LED technology from reaching the masses is the high price factor. The manufacturing of these devices is a bit costlier currently, compared to LCD displays which have raised their overall price. However, the cost gap is slowly lowering with time, as the demand for superior LED back-lit displays is on the rise all over the world. Even laptop computers and now smartphones come equipped with LED displays. While some of the best LCD monitors are available for a price of around $100, the best LED monitors fall in the $150 to $200+ range.

The temporal and spatial luminance characteristics of a CRT monitor and two LCD monitors were tested. The CRT monitor (P1230, Dell Inc. TX, USA, referred to as “CRT”) had maintained an excellent working condition after 10 years of use. The first LCD monitor (ASUS PG278Q) was tested in two different modes: once in the ULMB mode, which was our candidate and is referred to here as “LCD1-ULMB,” and once in Overdrive (OD) mode, which we refer to as “LCD1-OD.” The second monitor was an ASUS VG278 tested in the standard mode (LCD2). All the tested monitors were driven by an NVIDIA GeForce GTX 960 graphics card.

The monitors’ configurations and basic luminance characteristics are shown in Table 1. The contrast was set to 50%, 80%, and 100% for LCD1, LCD2, and CRT, respectively. The luminance was set to 90% for LCD1 and CRT, and to 100% for LCD2. The resolution of the CRT was set to 1,024 × 768 pixels, and the LCDs were set to their native resolutions, which were 2,560 × 1,440 for LCD1 and 1,920 × 1,080 for LCD2. A refresh rate of 120 Hz was used for all monitors. The user-mode and the default-mode color temperatures were used for the LCDs and CRT, respectively. These settings were kept constant throughout the test.

Luminance was measured in two ways. First, a photodiode (BPW21R, Vishay Intertechnology, Inc. ShangHai, China) with a switch time below 1 μs was placed in the centers of different areas of the monitor to measure their temporal and spatial characteristics. Voltages, proportional to luminance changes, were amplified and recorded by an electrophysiology (EEG) recording system (Synamps II, Compumedics NeuroScan, Charlotte, USA) at a sampling rate of 10 kHz and were used to characterize the luminance properties of each monitor. The second method was to use a ColorCal MKII photometer (Cambridge Research Systems Ltd., Cambridge, UK) to measure the dependence of luminance on pixel location and viewing angle.

All measurements were taken in a dark room after the monitors had been turned on for at least 60 min, to minimize variation due to warming up (Klein, Zlatkova, Lauritzen, & Pierscionek, 2013). The study was approved by the Academic Committee of the College of Education, Soochow University. All of the Matlab code to analyze the data is available at https://github.com/yangzhangpsy/monitorTestForPsy.

To measure the spatial homogeneity of luminance, the whole display of each monitor was divided evenly into nine rectangular areas (appearing as a 3 × 3 grid). The centers of the nine areas were measured one by one in a random order. Test images were generated and displayed over these nine areas using Matlab (2011b; MathWorks Inc., Natick, USA) with Psychtoolbox (3.0.14; Pelli, 1997b).

Three series of tests were carried out using two different types of images. The first series tested the luminance dependence on pixel location and time (Pelli, 1997a). The test was based on presentation of a solid white ellipse fitting the inside of each rectangular area of the display, and measurements were made using the photodiode placed in the center of the ellipse over each area. Each location was tested for 50 trials, each of which consisted of a black display (100 ms) and an image (33.3 ms). A trigger was sent to the EEG amplifiers by the photodiode via a parallel port when the image appeared on the screen.

In addition to location dependence, the second test series also addressed the luminance’s dependence on orientation. A full-contrast grating filling the whole display with a spatial frequency of two pixels per cycle was used. The stripes of the grating were oriented vertically, horizontally, or at an angle of 45° to the right. The luminance of the grating in each orientation at each of the nine locations was measured ten times with the photometer. The grating remained on the monitor for each measurement until the luminance readout became stable.

The luminance dependence on viewing angle was measured in the third test series for the CRT and LCD1-ULMB (the candidate monitor). The luminance at the center of the screen was measured with the photometer 28.5 cm away from the screen center at seven viewing angles (– 45°, – 30°, – 15°, 0°, 15°, 30°, and 45°) along the horizontal meridian. The luminance at each viewing angle was measured five times and then normalized to the maximum luminance of each monitor measured at 0°.

To understand the spatial and temporal characteristics of the monitors, two parameters—initial latency and relative maximum luminance of the first frame (RML1st)—were calculated from luminance values measured with the photodiode for each trial at each location. Because the luminance was recorded with the EEG system at a digitizing rate of 10 kHz, the temporal resolution was 0.1 ms. To calculate the initial latency, the stimulus onset time was detected as the time point at which the luminance first reached or exceeded 40% of the maximum luminance (with the restriction that the eight consecutive bins just before the onset time bin should be less than 44% of the maximum potential). The initial latency was then calculated as the interval between the stimulus trigger and stimulus onset.

RML1st was defined as the percentage of the maximum luminance of the first frame relative to the maximum luminance over the second and third frames. The maximum luminance was defined differently for different monitors, since the images were displayed continuously for LCD1-OD and LCD2 but displayed in a flash style for CRT and LCD1-ULMB. For the continuously displaying monitors (LCD1-OD and LCD2), the maximum luminance for the first frame was defined as the mean luminance over the first 8.2 ms (corresponding to the duration of a single frame at a 120-Hz refresh rate), whereas the maximum luminance over the next two frames was defined as the mean luminance from 8.3 to 24.9 ms. For the CRT, the maximum luminance was defined as the mean luminance around peaks (0.1 to 0.6 ms, 8.4 to 8.9 ms, and 16.8 to 17.3 for the first, second, and third frames, respectively). For LCD1-ULMB, the maximum luminance was defined as the mean luminance around plateaus (0 to 1.6 ms, 8.3 to 9.9 ms, and 16.7 to 18.3 ms for the first three frames, respectively).

SINGAPORE--The adoption of liquid-crystal displays in the Asia-Pacific region will increase fivefold this year, driven primarily by recent price reductions.

"Given the current tough PC market conditions, many vendors throughout the region are looking to differentiate themselves from their competitors. And with the recent price drops in LCDs, bundling these monitors with PCs is an effective way to make their products more attractive."

About 19.8 million CRTs shipped last year, IDC said, and 20 million will ship this year. That"s because of the many "price-sensitive" buyers in the region, including in China, India

CRT stands for Cathode Ray Tube and LCD stands for Liquid Crystal Display area unit the kinds of display devices wherever CRT is employed as standard display devices whereas LCD is more modern technology. These area unit primarily differentiated supported the fabric they’re made from and dealing mechanism, however, each area unit alleged to perform identical perform of providing a visible variety of electronic media. Here, the crucial operational distinction is that the CRT integrates the 2 processes lightweight generation and lightweight modulation and it’s additionally managed by one set of elements. Conversely, the LCD isolates the 2 processes kind one another that’s lightweight generation and modulation.

Advantages: thin body and space saving. Compared with the more bulky CRT display, the liquid crystal display only needs one third of the space of the former; it saves electricity and does not produce high temperature. It is a low power consumption product, which can be achieved compared to CRT displays. No heat at all; no radiation, which is good for health, and the liquid crystal display is completely free of radiation.

The screen is soft and does not hurt the eyes. Unlike CRT technology, the LCD screen will not flicker, which can reduce the damage of the display to the eyes and make the eyes less fatigued.

Disadvantages: The visual deflection angle is small; it is easy to cause image tailing phenomenon (such as the rapid shaking of the mouse pointer). This is because the ordinary LCD screen is mostly 60Hz (60 frames per second), but this problem mainly occurs when the LCD is just popular The brightness and contrast of the LCD monitor is not very good.

LCD "dead pixels" problem; life is limited; when the resolution is lower than the default resolution of the monitor, the picture will be blurred; when the resolution is greater than the default resolution of the monitor (mandatory setting by software is required), the color of the details Will be lost.

Advantages: OLED is a self-luminous material, no backlight is required, at the same time, wide viewing angle, uniform picture quality, fast response speed, easier colorization, light emission can be achieved with a simple driving circuit, simple manufacturing process, and flexible The panel conforms to the principle of lightness, thinness and shortness, and its application range belongs to small and medium size panels.

Active light emission, wide viewing angle range; fast response speed, stable image; high brightness, rich colors, and high resolution. Low driving voltage, low energy consumption, and can be matched with solar cells, integrated circuits, etc.

Disadvantages: It is difficult to increase the size. In order to maintain the brightness of the entire panel, it is necessary to increase the brightness of each Pixel and increase the operating current, which will reduce the life of the OLED Device. Current Drive control is not easy. The manufacturing process is more complicated and the variability of TFT is higher.

Every aspect of your day involves interacting with an LCD Display Touch Screen. They are used in numerous places, including mobile phones, automated teller machines, kiosks, ticket vending machines, and factories. LCD display touch screens have dominated the market for years, and their dominance shows no signs of abating any time soon. Mechanical engineers are always working to enhance their hardware and software algorithms to render traditional input devices like keyboards and mice unnecessary.

An LCD display touch screen"s adaptability means it may be used in almost any setting, including those that are noisy, chaotic, or even dirty because of the high volume of traffic expected. This has numerous positive implications for many different types of businesses.

Because of their intended use in commercial and industrial settings, these displays are equipped with safeguards to prevent damage over time. Touchscreens used in commercial and industrial settings are made to last for years, even when subjected to extreme temperatures, humidity, and pressure. LCD touch screen displays can be configured to the precise characteristics required by a wide variety of applications, making them ideal for supermarkets, restaurants, stores, warehouses, distribution centers, hospitals, and even military and maritime activities.

LCD display touch screen ultra-compact and lightweight design. The liquid crystal display takes up only a third as much room as the bulkier CRT display, uses less power, and stays cool under pressure. When compared to cathode ray tube (CRT) displays, this device has a significantly lower power usage. The liquid crystal display generates zero thermal energy and emits zero harmful radiation, making it a safe and healthy choice. The display is gentle on the eyes. The lack of flickering on an LCD panel means less strain on the eyes and a more comfortable viewing experience than with CRT technology.

Therefore, it is crucial that these multipurpose systems can continue functioning normally and at peak efficiency even in the harshest environmental conditions, with as little system failure and hardware damage as possible. They might be responsible for saving someone"s life.

One of your least tech-savvy employees should be able to set up these devices with ease. You can save yourself a ton of time and money by not having to hire a computer professional to set up your portable industrial computer monitor because it is very similar to setting up a personal or office computer.

A-TOPS Electronics Co., Ltd., founded in 1998, is an industry leader in LCD display R&D and production. We have a distinct competitive advantage when it comes to producing individualized and specially designed products for our clients in addition to the more commonplace industrial displays.

When it comes to meeting the unique requirements of our customers, A-TOPS is always looking for new methods to improve and broaden our product offerings. We contribute to the value plus quality and service that our customers need to flourish in today"s competitive market by offering expert solutions at a fair price and prompt, helpful customer service.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

In Topway, we work side by side to help you overcome any technical and none technical challenges that may arise during product design, manufacture or installation. We can even take care of component sourcing and manufacturing for you.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

The origins and the complex history of liquid-crystal displays from the perspective of an insider during the early days were described by Joseph A. Castellano in Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry.IEEE History Center.Peter J. Wild, can be found at the Engineering and Technology History Wiki.

In 1888,Friedrich Reinitzer (1858–1927) discovered the liquid crystalline nature of cholesterol extracted from carrots (that is, two melting points and generation of colors) and published his findings at a meeting of the Vienna Chemical Society on May 3, 1888 (F. Reinitzer: Beiträge zur Kenntniss des Cholesterins, Monatshefte für Chemie (Wien) 9, 421–441 (1888)).Otto Lehmann published his work "Flüssige Kristalle" (Liquid Crystals). In 1911, Charles Mauguin first experimented with liquid crystals confined between plates in thin layers.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In 1964, George H. Heilmeier, then working at the RCA laboratories on the effect discovered by Williams achieved the switching of colors by field-induced realignment of dichroic dyes in a homeotropically oriented liquid crystal. Practical problems with this new electro-optical effect made Heilmeier continue to work on scattering effects in liquid crystals and finally the achievement of the first operational liquid-crystal display based on what he called the George H. Heilmeier was inducted in the National Inventors Hall of FameIEEE Milestone.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humidity) or on the color filter of the LCD, replacing the resists that are normally used.

WLED array: The LCD panel is lit by a full array of white LEDs placed behind a diffuser behind the panel. LCDs that use this implementation will usually have the ability to dim or completely turn off the LEDs in the dark areas of the image being displayed, effectively increasing the contrast ratio of the display. The precision with which this can be done will depend on the number of dimming zones of the display. The more dimming zones, the more precise the dimming, with less obvious blooming artifacts which are visible as dark grey patches surrounded by the unlit areas of the LCD. As of 2012, this design gets most of its use from upscale, larger-screen LCD televisions.

RGB-LED array: Similar to the WLED array, except the panel is lit by a full array of RGB LEDs. While displays lit with white LEDs usually have a poorer color gamut than CCFL lit displays, panels lit with RGB LEDs have very wide color gamuts. This implementation is most popular on professional graphics editing LCDs. As of 2012, LCDs in this category usually cost more than $1000. As of 2016 the cost of this category has drastically reduced and such LCD televisions obtained same price levels as the former 28" (71 cm) CRT based categories.

Monochrome LEDs: such as red, green, yellow or blue LEDs are used in the small passive monochrome LCDs typically used in clocks, watches and small appliances.

Mini-LED: Backlighting with Mini-LEDs can support over a thousand of Full-area Local Area Dimming (FLAD) zones. This allows deeper blacks and higher contrast ratio.

Today, most LCD screens are being designed with an LED backlight instead of the traditional CCFL backlight, while that backlight is dynamically controlled with the video information (dynamic backlight control). The combination with the dynamic backlight control, invented by Philips researchers Douglas Stanton, Martinus Stroomer and Adrianus de Vaan, simultaneously increases the dynamic range of the display system (also marketed as HDR, high dynamic range television or FLAD, full-area local area dimming).

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure (prism sheet) to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

A pink elastomeric connector mating an LCD panel to circuit board traces, shown next to a centimeter-scale ruler. The conductive and insulating layers in the black stripe are very small.

A standard television receiver screen, a modern LCD panel, has over six million pixels, and they are all individually powered by a wire network embedded in the screen. The fine wires, or pathways, form a grid with vertical wires across the whole screen on one side of the screen and horizontal wires across the whole screen on the other side of the screen. To this grid each pixel has a positive connection on one side and a negative connection on the other side. So the total amount of wires needed for a 1080p display is 3 x 1920 going vertically and 1080 going horizontally for a total of 6840 wires horizontally and vertically. That"s three for red, green and blue and 1920 columns of pixels for each color for a total of 5760 wires going vertically and 1080 rows of wires going horizontally. For a panel that is 28.8 inches (73 centimeters) wide, that means a wire density of 200 wires per inch along the horizontal edge.

The LCD panel is powered by LCD drivers that are carefully matched up with the edge of the LCD panel at the factory level. The drivers may be installed using several methods, the most common of which are COG (Chip-On-Glass) and TAB (Tape-automated bonding) These same principles apply also for smartphone screens that are much smaller than TV screens.anisotropic conductive film or, for lower densities, elastomeric connectors.

Monochrome and later color passive-matrix LCDs were standard in most early laptops (although a few used plasma displaysGame Boyactive-matrix became standard on all laptops. The commercially unsuccessful Macintosh Portable (released in 1989) was one of the first to use an active-matrix display (though still monochrome). Passive-matrix LCDs are still used in the 2010s for applications less demanding than laptop computers and TVs, such as inexpensive calculators. In particular, these are used on portable devices where less information content needs to be displayed, lowest power consumption (no backlight) and low cost are desired or readability in direct sunlight is needed.

A comparison between a blank passive-matrix display (top) and a blank active-matrix display (bottom). A passive-matrix display can be identified when the blank background is more grey in appearance than the crisper active-matrix display, fog appears on all edges of the screen, and while pictures appear to be fading on the screen.

Displays having a passive-matrix structure are employing Crosstalk between activated and non-activated pixels has to be handled properly by keeping the RMS voltage of non-activated pixels below the

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey