twisted nematic tn lcd panel technology made in china

![]()

TN stands for twisted nematic. This is a type of LED (a form of LCD) panel display technology. TN panels are characterized as being the fastest and cheapest among the other main types of display panels, VA (vertical alignment)and IPS (in-plane switching). As such, they work great for gaming monitors and gaming laptops. However, TN panels also offer the worst viewing angles and color when compared to VA and IPS panels.

PerformanceFastest: low response times, highest refresh rates, minimal motion blur; Low input lagLongest response times typically; Higher refresh rates possibleSlower response times than TN, faster response times than VA; Gaming-quality refresh rates are rare

DisplayWorst viewing angles;Worst colorViewing angles typically better than TN, worse than IPS; Good color; Best contrast;Best image depthBest viewing angles; Best color

The twisted nematic effect (TN-effect) was a main technology breakthrough that made LCDs practical. Unlike earlier displays, TN-cells did not require a current to flow for operation and used low operating voltages suitable for use with batteries. The introduction of TN-effect displays led to their rapid expansion in the display field, quickly pushing out other common technologies like monolithic LEDs and CRTs for most electronics. By the 1990s, TN-effect LCDs were largely universal in portable electronics, although since then, many applications of LCDs adopted alternatives to the TN-effect such as in-plane switching (IPS) or vertical alignment (VA).

TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display.

The twisted nematic effect is based on the precisely controlled realignment of liquid crystal molecules between different ordered molecular configurations under the action of an applied electric field. This is achieved with little power consumption and at low operating voltages. The underlying phenomenon of alignment of liquid crystal molecules in applied field is called Fréedericksz transition and was discovered by Russian physicist Vsevolod Frederiks in 1927.

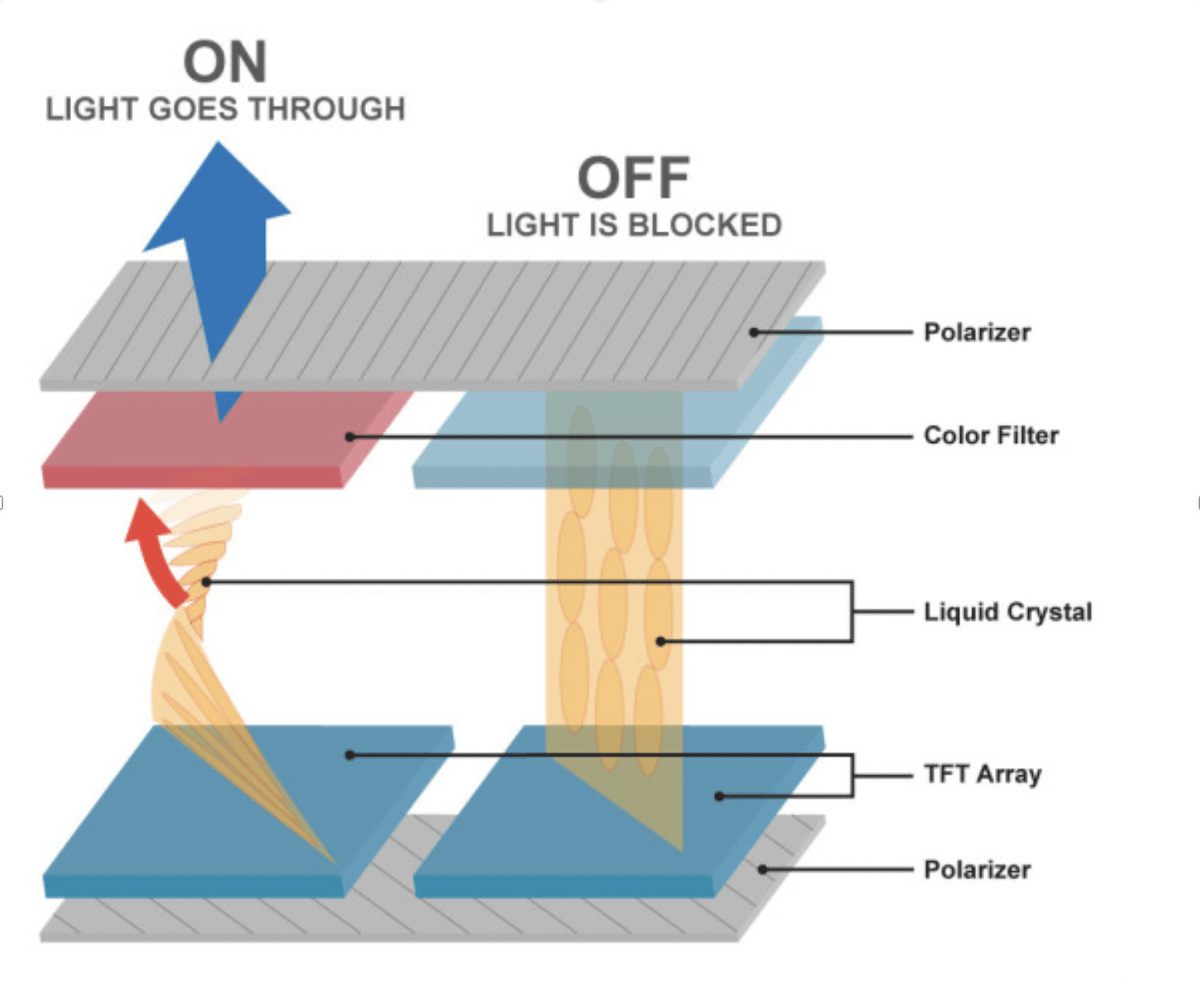

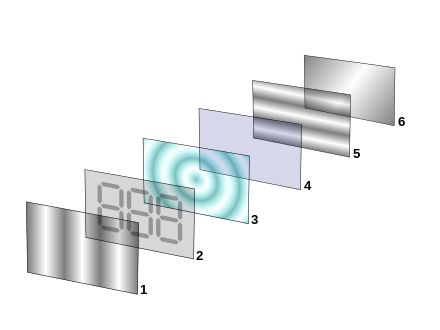

The illustrations to the right show both the OFF and the ON-state of a single picture element (pixel) of a twisted nematic light modulator liquid crystal display operating in the "normally white" mode, i.e., a mode in which light is transmitted when no electrical field is applied to the liquid crystal.

In the OFF state, i.e., when no electrical field is applied, a twisted configuration (aka helical structure or helix) of nematic liquid crystal molecules is formed between two glass plates, G in the figure, which are separated by several spacers and coated with transparent electrodes, E1 and E2. The electrodes themselves are coated with alignment layers (not shown) that precisely twist the liquid crystal by 90° when no external field is present (left diagram). If a light source with the proper polarization (about half) shines on the front of the LCD, the light will pass through the first polarizer, P2 and into the liquid crystal, where it is rotated by the helical structure. The light is then properly polarized to pass through the second polarizer, P1, set at 90° to the first. The light then passes through the back of the cell and the image, I, appears transparent.

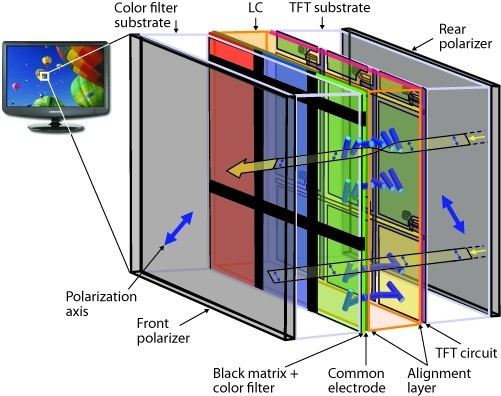

To display information with a twisted nematic liquid crystal, the transparent electrodes are structured by photo-lithography to form a matrix or other pattern of electrodes. Only one of the electrodes has to be patterned in this way, the other can remain continuous (common electrode). For low information content numerical and alpha-numerical TN-LCDs, like digital watches or calculators, segmented electrodes are sufficient. If more complex data or graphics information have to be displayed, a matrix arrangement of electrodes is used. Because of this, voltage-controlled addressing of matrix displays, such as in LCD-screens for computer monitors or flat television screens, is more complex than with segmented electrodes. For a matrix of limited resolution or for a slow-changing display on even a large matrix panel, a passive grid of electrodes is sufficient to implement passive matrix-addressing, provided that there are independent electronic drivers for each row and column. A high-resolution matrix LCD with required fast response (e.g. for animated graphics and/or video) necessitates integration of additional non-linear electronic elements into each picture element (pixel) of the display (e.g., thin-film diodes, TFDs, or thin-film transistors, TFTs) in order to allow active matrix-addressing of individual picture elements without crosstalk (unintended activation of non-addressed pixels).

In 1962, Richard Williams, a physical chemist working at RCA Laboratories, started seeking new physical phenomena that might yield a display technology without vacuum tubes. Aware of the long line of research involving nematic liquid crystals, he started experimenting with the compound p-azoxyanisole which has a melting point of 115 °C (239 °F). Williams set up his experiments on a heated microscope stage, placing samples between transparent tin-oxide electrodes on glass plates held at 125 °C (257 °F). He discovered that a very strong electrical field applied across the stack would cause striped patterns to form. These were later termed "Williams domains".

Although successful, the dynamic scattering display required constant current flow through the device, as well as relatively high voltages. This made them unattractive for low-power situations, where many of these sorts of displays were being used. Not being self-lit, LCDs also required external lighting if they were going to be used in low-light situations, which made existing display technologies even more unattractive in overall power terms. A further limitation was the requirement for a mirror, which limited the viewing angles. The RCA team was aware of these limitations, and continued development of a variety of technologies.

Another potential approach was the twisted-nematic approach, which had first been noticed by French physicist Charles-Victor Mauguin in 1911. Mauguin was experimenting with a variety of semi-solid liquid crystals when he noted that he could align the crystals by pulling a piece of paper across them, causing the crystals to become polarized. He later noticed when he sandwiched the crystal between two aligned polarizers, he could twist them in relation to each other, but the light continued to be transmitted. This was not expected. Normally if two polarizers are aligned at right angles, light will not flow through them. Mauguin concluded that the light was being re-polarized by the twisting of the crystal itself.

Wolfgang Helfrich, a physicist who joined RCA in 1967, became interested in Mauguin"s twisted structure and thought it might be used to create an electronic display. However RCA showed little interest because they felt that any effect that used two polarizers would also have a large amount of light absorption, requiring it to be brightly lit. In 1970, Helfrich left RCA and joined the Central Research Laboratories of Hoffmann-LaRoche in Switzerland, where he teamed up with Martin Schadt, a solid-state physicist. Schadt built a sample with electrodes and a twisted version of a liquid-crystal material called PEBAB (p-ethoxybenzylidene-p"-aminobenzonitrile), which Helfrich had reported in prior studies at RCA, as part of their guest-host experiments.

At this time Brown, Boveri & Cie (BBC) was also working with the devices as part of a prior joint medical research agreement with Hoffmann-LaRoche.James Fergason, an expert in liquid crystals at the Westinghouse Research Laboratories. Fergason was working on the TN-effect for displays, having formed ILIXCO to commercialize developments of the research being carried out in conjunction with Sardari Arora and Alfred Saupe at Kent State University"s Liquid Crystal Institute.

When news of the demonstration reached Hoffmann-LaRoche, Helfrich and Schadt immediately pushed for a patent, which was filed on 4 December 1970. Their formal results were published in Applied Physics Letters on 15 February 1971. In order to demonstrate the feasibility of the new effect for displays, Schadt fabricated a 4-digit display panel in 1972.

This work, in turn, led to the discovery of an entirely different class of nematic crystals by Ludwig Pohl, Rudolf Eidenschink and their colleagues at Merck KGaA in Darmstadt, called cyanophenylcyclohexanes. They quickly became the basis of almost all LCDs, and remain a major part of Merck"s business today.

Gerhard H. Buntz (Patent Attorney, European Patent Attorney, Physicist, Basel), "Twisted Nematic Liquid Crystal Displays (TN-LCDs), an invention from Basel with global effects", Information No. 118, October 2005, issued by Internationale Treuhand AG, Basel, Geneva, Zurich. Published in German

A type of LCD panel technology. In this type of panel, when no electric current is running through the liquid crystal cells, the cells naturally align in a twisted form between two substrate panes of glass which blocks the transmission of light from the backlight. This renders the crystals opaque and results in a black display screen. When an electric current is applied, the liquid crystal cells untwist allowing light to pass through resulting in a white display screen. TN panels have relatively narrow viewing angles especially in the vertical direction and color reproduction is poor; however, they are economical and suitable for a wide-range of general uses, particularly with office tasks (e.g. word processing).

Liquid crystal displays mainly use electro-optic effects, including dynamic scattering, distortion effects, phase change effects, guest-host effects, and electrically controlled birefringence effects. From the perspective of technological development, the liquid crystal display device (Liquid Crystal Display device, LCD) has mainly experienced four development stages.

In 1968, G.H. Heilmeier of the Princeton Institute of Radio Corporation of America (RCA) discovered the dynamic scattering phenomenon of liquid crystals. In the same year, the company successfully developed the world"s first dynamic scattering liquid crystal display (Dynamic Scattering LCD, DS-LCD). From 1971 to 1972, the first watch using DS-LCD was developed, marking the practical stage of LCD technology. Since the movement of ions in dynamic scattering easily destroys liquid crystal molecules, this display mode is quickly eliminated.

In 1971, Swiss M. Schadt et al. disclosed the twisting effect of nematic liquid crystals for the first time. In 1973, Japan"s Shengbao Company developed the Twisted Nematic-Liquid Crystal Display (TN-LCD), which was used to make digital displays for electronic calculators. Due to the low manufacturing cost and low price, TN-LCD was mass-produced in the 1970s and 1980s, mainly used for pen-segment digital display and simple character display.

In 1984, T. Scheffer discovered the super twisted birefringence effect and invented the super twisted nematic liquid crystal display (Su per Twisted Nematic-LCD, STN-LCD) technology. Compared with TN-LCD, STN-LCD has greatly improved display capacity and viewing angle. Because STN-LCD has the characteristics of high resolution, wide viewing angle and good contrast, it will soon be widely used in notebook computers, graphics processors and other office and communication equipment with large information capacity display, and become the mainstream product of this era.

In the late 1980s, Japanese manufacturers mastered the production technology of Thin Film Transistor LCD (TFT-LCD) and began mass production. In 1988, 10.4in TFT-LCD was born; in 1990, notebook computers using TFT-LCD were mass-produced; in 1998, liquid crystal display technology entered the application field of desktop displays, and reflective TFT-LCD began production. Based on the rapid development of active-matrix liquid crystal displays, LCD technology has begun to enter the stage of high-quality liquid crystal displays. With the further development of technology, the production cost of TFT-LCD has dropped significantly, eventually surpassing the market share of CRT. After entering the 21st century, with the development of TFT-LCD production lines from the 8.5th generation line to the 10th generation line, the increasing popularity of large-screen LCD TVs has fundamentally changed the face of the display industry. The liquid crystal display industry has developed into a new industry with an annual output value of hundreds of billions of dollars, occupying a leading position in the field of information display.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

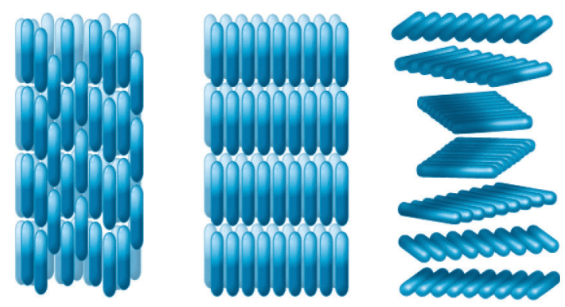

Nematic refers to one of the common phases of liquid crystals (LC). In this phase, rod-like molecules tend to self-align more or less parallel to each other.

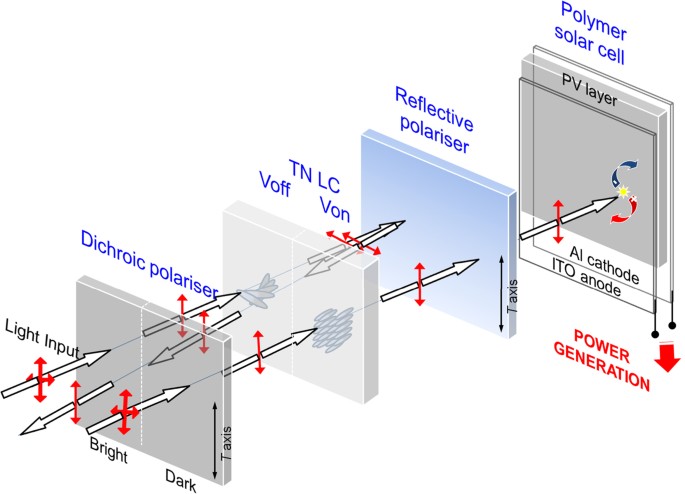

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Here, each color sub-pixel is further divided into zones (called domains) having a different direction of the molecular movement when voltage is applied. Again, the purpose is a much wider and more symmetric viewing performance and the elimination of color shifts and contrast inversion at shallow angles. MVA technology achieves that with carefully designed protrusions on the inside surfaces of the display, while PVA uses fine patterning of the electrodes on both substrates.

ASV is a version of MVA where instead of two or four domains per pixel the liquid crystal switches in radial directions all around the center of the pixel. This technology was developed and used exclusively by Sharp and is no longer in production.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

Low Voltage Differential Signaling (LVDS) is an interface to the display, not a display technology itself. This technology is not specific to displays, as it’s used in many other applications as well. It’s a high-speed signal that provides some noise immunity for the display. It also allows for longer distances compared to parallel interfaces.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

Everyday, we look at LCD display, TV, cell phone, monitor. It becomes a necessity in modern society. LCD panel is the most important part of an LCD display. It determines LCD screen"s performance, e.g. brightness, contrast, color and viewing angle. Therefore, picking the right type of LCD panel is critical to your application.

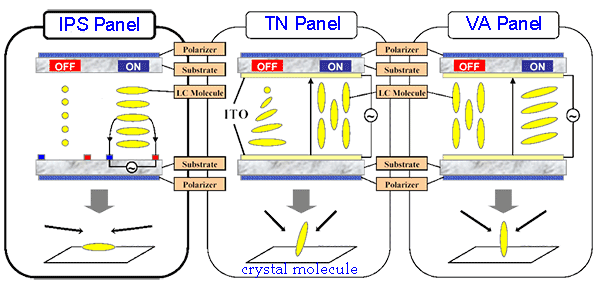

These names reflect the alignment of crystal molecules inside the LCD, and how they change when they are charged electrically. All liquid crystal displays change the alignment of liquid crystal molecules to work, but the manner in which they do so can drastically affect the image quality and response time. Each panel type has its advantages and disadvantages. The easiest way to choose between them is to decide which attributes are most important to your project. It mainly depends on what you use your LCD display for, and your budget.

TN is the most mature technology in LCD panel manufacturing. When there is no voltage difference between the two transparent electrodes, liquid crystal molecules are twisted 90 degrees, in combination of upper and bottom polarizers, allows light to pass through LCD. As voltage applied, crystal molecules are untwisted and aligned to the same direction, blocking light.

In IPS panel, crystal molecules are parallel to the glass substrates at initial stage, LCD is off. When the in-plane electrodes is charged, crystal molecules are rotated, modifying light"s direction. Which lights up the LCD display.

As its name suggests, VA panel"s liquid crystals are aligned vertically without charged. When a voltage is applied, the molecules tilt and modifying light direction.

So in summary, TN panels twist, IPS panels use a parallel alignment and rotate, while VA panels use a perpendicular alignment and tilt. These difference create LCD display with distinctive performance.

IPS LCD is the clear winner in this aspect. It has 178/178 viewing angle ratings. Which means you can look at IPS LCD display from any angle without the image shifting in color and contrast. VA LCD has pretty wide viewing angle, too. But it has contrast shifts at off-center angles. As for TN LCD, viewing angle is its weakest point.

Most TN LCDs have 6-bits colors. Manufacturers use frame rate control (FRC) to enhance its color performance. For IPS and VA panels, you can still find 6-bits entry level LCD. But most of them are 8-bits. And IPS technology can provide natively 10-bits colors.

Color gamut is another part that VA and IPS panels shine at. The best TN LCD can reach sRGB gamut. VA panels typically start with full sRGB coverage, and get to around 90% DCI-P3 coverage. With IPS LCD panel, you could find the best ones full DCI-P3 and Adobe RGB coverage. That is why you see most professional grade LCD displays use IPS panel.

There is no inherent differences among the three panel technologies, because LCD backlight is the main factor here. However, there is a big gap in terms of contrast ratio. TN LCD panel tends to have the lowest value among the three. IPS LCD screen sits in the middle can reach 1500:1. For VA panel, the best one can exceed 4500:1 easily. VA LCD display provides far darker screen than TN & IPS. That is why they are used in vehicle dashboard.

TN panel does have an advantage when it comes to refresh rate. The panel offers the best refresh rate and response time. This is the reason why most gaming LCD monitors are made of TN panel.

TN LCD provides the best refresh rate and economic solution. If your application requires wide viewing angles and good color presentation, VA panel is probably the choice. While IPS has the best overall visual performance, in general it is more expensive than the other two.

The quality of a LCD depends first on its panel, because the panel directly affects the viewing effect of the screen, and LCD TV panel accounts for more than half of the total cost of the whole machine, which is the main factor affecting the cost of LCD TV, so to choose a good LCD, the first thing is to choose its panel. LCD panel can largely determine the brightness, contrast, color, visual angle and other very important parameters of LCD. LCD panelsare developing rapidly from three generations in previous years to four and five generations, then skipping six generations to seven generations, and renewing the eighth generation of panels is also under planning. At present, the main manufacturers of LCD panels are Samsung, LG-Philips, Youda and so on. Due to the difference of technical level of each country, the LCD panels produced can be roughly divided into different types of machines. Common are TN panel, MVA panel and PVA panel, IPS panel and CPA panel.

TN is called Twisted Nematic (Twisted Nematic) panel. The low cost of production makes TN the most widely used entry-level LCD panel. It is widely used in the mainstream low and medium-end LCD in the current market. At present, most of the TN panels we see are improved TN+film, film is compensation film, which is used to compensate for the deficiency of the visual angle of TN panels. At present, the visual angle of the improved TN panels reaches 160 degrees. Of course, this is the limit value measured by the manufacturer when the contrast is 10:1. In fact, when the contrast is reduced to 100:1, the image has been distorted or even biased.

As a 6Bit panel, TN panel can only display 64 colors of red/green/blue, and only 262.144 kinds of maximum actual colors. Through the "jitter" technology, it can obtain more than 16 million colors, and can only display three primary colors of 0 to 252 gray scales. Therefore, the final color display information is 16.2 M color, not the true color 16.7 M color as we usually call it; plus TN panel. It is difficult to improve contrast. The problems directly exposed are thin color, poor restoring ability and unnatural transition.

The advantage of TN panel is that it has fewer gray class output, fast deflection speed of liquid crystal molecules and easy to improve response time. At present, TN panel is basically used in liquid crystal products below 8ms on the market. In addition, Samsung has developed a B-TN (Best-TN) panel, which is actually an improved type of TN panel. In order to balance the high-speed response of TN panel, the contradiction of quality must be sacrificed. At the same time, the contrast can reach 700:1, which is close to the panel of MVA or early PVA. Many panel manufacturers in Taiwan produce TN panels. TN panels belong to soft screens. Similar water marks will appear when you gently scratch them with your hands. In addition, if you look closely at the screen, it is roughly like this:

Class VA panels are widely used in high-end liquid crystals nowadays, and belong to wide-view panels. Compared with TN panel, 8 bit panel can provide 16.7M color and large visual angle, which is the capital of positioning high-end panel, but the price is also more expensive than TN panel. VA panel can be divided into MVA panel dominated by Fujitsu and PVA panel developed by Samsung. The latter is the inheritance and improvement of the former. The front (face-to-face) contrast of the VA panel is the highest, but the uniformity of the screen is not good enough, and color drift often occurs. Sharp text is its killer mace, black and white contrast is quite high.

Fujitsu MVA technology (multi-domain Vertical Alignment, multi-quadrant vertical alignment technology) can be said to be the earliest wide-view LCD panel technology. This kind of panel can provide a larger visual angle, usually up to 170 degrees. Through technical authorization, Chimei Electronics (Chimei Optoelectronics), Youda Optoelectronics and other panel enterprises in Taiwan Province of China have adopted this panel technology. The visual angle of the improved P-MVA panel can reach 178 degrees close to the level, and the gray scale response time can reach less than 8 ms.

Samsung Samsung Electronics PVA (Patterned Vertical Alignment) technology also belongs to the category of VA technology, it is the successor and developer of MVA technology. Its comprehensive quality has surpassed the latter in an all-round way, and the improved S-PVA has been able to keep pace with P-MVA to obtain a wide visual angle and faster response time. PVA uses transparent ITO electrodes instead of liquid crystal protrusions in MVA. Transparent electrodes can obtain better opening ratio and minimize the waste of backlight. This mode greatly reduces the possibility of "bright spots" in LCD panels, and its status in the era of LCD TV is equivalent to the "long tube" in the era of CRT TV. Samsung"s wide-view technology of PVA mode is widely used by Japanese and American manufacturers because of its strong capacity and stable quality control system. At present, PVA technology is widely used in high-end LCD or LCD TV. The VA panel also belongs to the soft screen. The similar water marks will appear when you gently scratch it with your hands. Look closely at the screen roughly as follows:

IPS (In-Plane Switching) technology is a liquid crystal panel technology launched by Hitachi in 2001, commonly known as "Super TFT". The IPS camp, headed by Hitachi, has gathered a number of manufacturers, such as LG-Philips,Topfoison,Hanyu Caijing, IDTech (Chimei Electronics and Japan"s IBM joint venture), but not many models can be seen in the market. IPS panel"s biggest characteristic is that its two poles are on the same surface, unlike other liquid crystal mode"s electrodes are on the upper and lower sides, three-dimensional arrangement. Because the electrodes are on the same plane, the liquid crystal molecules are always parallel to the screen in any state, which will cause the opening rate.

CPA (Continuous Pinwheel Alignment) mode wide-angle technology (soft screen), CPA mode wide-angle technology strictly belongs to the VA camp, the liquid crystal molecules radiate toward the central electrode in a firework-like arrangement. Because the electric field on the pixel electrodes varies continuously, this wide-angle mode is called "continuous pyrotechnic arrangement" mode. CPA is mainly promoted by Sharp, the father of LCD. What we need to pay attention to here is that the ASV that Sharp has always advocated does not refer to a specific wide-view technology. It refers to the products that have used TN+Film, VA, CPA wide-view technology as ASV. In fact, only CPA mode is Sharp"s own Broadview technology. The products of this mode are basically the same as MVA and PVA. That is to say, Sharp brand LCD TV may not use Sharp"s own CPA mode LCD panel. It may use Taiwan"s VA mode panel or other manufacturers"LCD panel. Sharp"s CPA panel color restoration is real, visual angle is excellent, image is delicate, the price is relatively expensive, and Sharp seldom sells CPA panel to other manufacturers. CPA panel also belongs to the soft screen, with the hand gently strokes will appear similar watermarks, carefully look at the screen is roughly like this:

In addition, some other manufacturers also have their own LCD panel technology, such as NEC ExtraView technology, Panasonic OCB technology, modern FFS technology, etc. These technologies are improvements to the old TFT panel, providing visual angle and response time, usually only used in their own brand LCD display or LCD TV. In fact, these panels belong to TFT panels, but now various panels have their own technology and name, so the name TFT is not often used.

The so-called black-and-white response time is the speed at which each pixel of the LCD reacts to the input signal, that is, the time required for the pixel to turn dark or light to dark (the principle is to apply voltage in the liquid crystal molecule to make the liquid crystal molecule twist and recover). The commonly used 25ms and 16ms refer to the response time. The shorter the response time, the less the user will feel the tail shadow dragging when looking at the dynamic picture. In general, the black-and-white response time is divided into two parts: Rise time and Fall time, and the representation is based on the sum of the two.

In CRT display, as long as the electron beam strikes the phosphor, it can emit light immediately, and the glow residue time is very short, so the response time of traditional CRT display is only 1-3 Ms. Therefore, response time is generally not mentioned in CRT monitors. Because LCD controls the turn-off of light by twisting liquid crystal molecules, and the twisting of liquid crystal molecules requires a process, the response time of LCD is obviously longer than that of CRT.

From the early 25 ms to the well-known 16 ms to the recent 12 ms or even 8 ms, the response time has been constantly shortened, and the old idea that LCD is not suitable for entertainment is being challenged. A simple conversion can be made: 30 milliseconds = 1/0.030 = 33 frames per second; 25 milliseconds = 1/0.025 = 40 frames per second; 16 milliseconds = 1/0.016 = 63 frames per second; 12 milliseconds = 1/0.012 = 83 frames per second. It can be seen that the birth of 12ms means a great progress in liquid crystal manufacturing.

However, it should be noted that LCD has a scanning frequency limit, especially for the field frequency (also known as refresh rate), many of which are limited to less than 75Hz. In general, 75Hz means 75 frames per second refresh, so that it does not seem to reach 83 frames per second corresponding to 12ms.

In fact, the 12ms response time mentioned above is the time needed for switching between full black and full white pictures. The driving voltage required for switching between full white and full black pictures is relatively high, so the switching speed is relatively fast, which can reach 12ms. In practical applications, most of them are gray-scale pictures switching (in essence, liquid crystal is not completely twisted, not fully transparent). The required driving voltage is relatively low, so the switching speed is relatively slow. Since 2005, many manufacturers have begun to emphasize the importance of gray-scale response time, but gray-scale response time can be improved by special methods, so there is no clear correspondence between black-and-white response time, which is equivalent to a new parameter describing response time.

When it comes to gray scale response time, let"s first look at what gray scale is. We can see that every point on the LCD screen, that is, a pixel, is composed of three sub-pixels: red, green and blue (RGB). In order to change the color of the screen, we must control the brightness of the three sub-pixels of RGB separately, so as to "mix" different colors. The more layers of light and shade in the middle, the more delicate the effect of the picture can be presented. Take the 8 bit panel as an example, it can show 256 brightness levels (the 8th power of 2), which we call 256 gray levels.

Because of the rotation of liquid crystal molecules, each point on the LCD screen transits from the former color to the latter color change, which will have a time process, which is what we usually call response time. Because the conversion process between different gray scales of each pixel is complex and varied in length, it is difficult to express it by an objective scale. Therefore, the traditional definition of liquid crystal response time tries to take the conversion speed of liquid crystal molecules from all black to all white as the response time of liquid crystal panel. Because the conversion speed of liquid crystal molecules from black to white is not exactly the same as that from white to black, in order to show the reaction speed of liquid crystal panel as meaningfully as possible, the traditional definition of response time basically takes the whole response time of "black-white-black" as the standard.

It should be noted that although the grey scale response is more difficult to control and takes longer time, the actual situation may be quite the opposite. Because manufacturers can greatly improve the gray scale response time through special technology, which in turn is much shorter than the traditional black-and-white response time. For example, using response time acceleration chip, the product with 25 ms black-and-white response time can have 8 ms gray-scale response time. Grey-scale response time differs greatly from the original black-and-white response time in meaning and properties. There is no clear correspondence between them, but both are descriptions of liquid crystal response time.

Grey scale response has been used by many manufacturers since 2005. Generally speaking, these products usually use better response time control methods, such as the response time of each pixel is more stable and uniform. The products with short gray-scale response time have fewer shadows and better picture quality, especially when playing moving images. Therefore, game players or video users can consider this parameter of LCD more.

Also known as refresh rate, is the number of times the display refreshes the screen per second in Hz. The lower the field frequency is, the more flickering and jittering the image is. But the scanning frequency of LCD display screen is different from CRT. It refers to the number of times that the display receives signals in unit time and updates the picture. Because the status of LCD display pixels changes only when the content of the picture changes, so even if the scanning frequency is very low, it can ensure stable display. Generally, 60 Hz is enough. But in some industry applications such as medical treatment and monitoring, the refresh rate of LCD is required to reach 70 Hz or even 85 Hz. The main requirement is to be able to read and display data at a faster frequency.

FFS technology is a TFT-LCD technology mastered by Korea HYDIS (which was stripped from BOE in 2006 and acquired by PVI-Taiwanese Yuantai in 2007). It is called Fringe Field Switching (FFS). FFS is a wide-view technology developed by LCD industry to solve large-scale, high-definition desktop display and LCD TV applications, which is now commonly known as hard-screen technology. FFS technology generates edge electric field between the electrodes in the same plane, so that orientational liquid crystal molecules can rotate in the plane direction (parallel to the substrate) between the electrodes and above the electrodes, thus improving the transparency efficiency of the liquid crystal layer. FFS technology overcomes the conventional IPS (In-Plane-Switching, plane side)

Lcd technology is from the TN-LCD technology that the pen section shows that is applied to of beginning; Develop into the STN-LCD technology that medium information capacity shows that is used for; Arrive the super large information capacity again; The TFT-LCD technology that the LCD TV of high resolving power rate adopted etc., along with infotech is constantly deepened and the development of the amusement trend of society now, what touching technique was also successful at present develops; Particularly capacitive touch screen begins to become new bright spot in the recent period, and beginning begins to popularize in mobile phone and game machine.Capacitance technology touch-screen CTP (Capacity Touch Panel) utilizes the induction by current of human body to carry out work; Capacitance plate is four layers of compound glass screen; The inside surface of glass screen and interlayer respectively are coated with one deck ITO (nano indium tin metal oxide), and outermost layer is the silicon soil glassivation that has only 0.0015mm thick, and interlayer ITO coating is made workplace; Four electrodes are drawn at four angles, and internal layer ITO is for shielding layer to guarantee working environment.When the user touches capacitance plate; Because people"s bulk electric field, user"s finger and workplace form a coupling capacitance, because be connected to high-frequency signal on the workplace; So finger is walked a very little electric current; This electric current flows out the electrode from four angles of screen respectively, and the electric current of four electrodes of flowing through in theory and finger are proportional to four jiaos distance, and controller calculates the position through the precision to four current ratios.

Existing market adopts separate type touch LCD screen basically, and promptly touch panel is assembled into after the liquid crystal panel produced by separation.For reducing the thickness of liquid crystal touch screen; Market has also been released and has been merged touch panel and liquid crystal panel characteristic in the novel touch LCDs of one; At present both incorporate implementations of bibliographical information comprise mainly that " In-cell " method and " On-cell " method: In-cell are meant touch panel are embedded into the method in the liquid crystal pixel; But this complex process need be through repeatedly plated film and photoetching process could be accomplished; On-cell is meant that this mode has increased the thickness of screen, has increased the technology of capacitance plate and display screen assembling with the method for configuration touch sensor on the touch panel, thereby brings the assembling contraposition a series of problems such as to be forbidden, so cost is than higher.

Lcd technology is from the TN-LCD technology that the pen section shows that is applied to of beginning; Develop into the STN-LCD technology that medium information capacity shows that is used for; Arrive the super large information capacity again; The TFT-LCD technology that the LCD TV of high resolving power rate adopted etc., along with infotech is constantly deepened and the development of the amusement trend of society now, what touching technique was also successful at present develops; Particularly capacitive touch screen begins to become new bright spot in the recent period, and beginning begins to popularize in mobile phone and game machine.Capacitance technology touch-screen CTP (Capacity Touch Panel) utilizes the induction by current of human body to carry out work; Capacitance plate is four layers of compound glass screen; The inside surface of glass screen and interlayer respectively are coated with one deck ITO (nano indium tin metal oxide), and outermost layer is the silicon soil glassivation that has only 0.0015mm thick, and interlayer ITO coating is made workplace; Four electrodes are drawn at four angles, and internal layer ITO is for shielding layer to guarantee working environment.When the user touches capacitance plate; Because people"s bulk electric field, user"s finger and workplace form a coupling capacitance, because be connected to high-frequency signal on the workplace; So finger is walked a very little electric current; This electric current flows out the electrode from four angles of screen respectively, and the electric current of four electrodes of flowing through in theory and finger are proportional to four jiaos distance, and controller calculates the position through the precision to four current ratios.

Existing market adopts separate type touch LCD screen basically, and promptly touch panel is assembled into after the liquid crystal panel produced by separation.For reducing the thickness of liquid crystal touch screen; Market has also been released and has been merged touch panel and liquid crystal panel characteristic in the novel touch LCDs of one; At present both incorporate implementations of bibliographical information comprise mainly that " In-cell " method and " On-cell " method: In-cell are meant touch panel are embedded into the method in the liquid crystal pixel; But this complex process need be through repeatedly plated film and photoetching process could be accomplished; On-cell is meant that this mode has increased the thickness of screen, has increased the technology of capacitance plate and display screen assembling with the method for configuration touch sensor on the touch panel, thereby brings the assembling contraposition a series of problems such as to be forbidden, so cost is than higher.

The Nematic liquid crystal state is a unique state not included in the above 3 states. It is a state between the crystalline (solid) and isotropic (liquid) states. Even in the state of liquid crystals, there are several types of liquid crystal states, as below.

The nematic liquid crystal phase is characterized by molecules maintain the general order of tending to point in the same direction. It has one dimensional order. See Fig.1

In smectic phase, molecules show two-dimensional order not present in the nematic. The molecules maintain the general orientationally of nematic, but also tend to align themselves in layers or planes. It is the state between nematic (one-dimensional order) and solid state (three-dimensional order). See Fig.1.

The cholesteric (or chiral nematic) liquid crystal phase is typically the molecules are directionally oriented and stacked in a helical pattern, with each layer rotated at a slight angle to the ones above and below it. See Fig.1.

When searching for monitors, consumers inevitably come across terms like twisted nematic (TN), vertical alignment (VA), or in-plane switching (IPS) when referring to the panel types. All three panel types come in at different price points and have pros and cons. Gaming monitors often use TN panels because of their high speed and low cost.

TN panels are based on liquid crystal technology. The first person to note the color generation properties of liquid crystal was a man called Friedrich Reinitzer. In 1888 he discovered that certain types of extracted cholesterol from carrots have two melting points. At the first melting point, it becomes a nontransparent liquid, and at the second melting point, it becomes transparent. This phenomenon is the basis of what eventually become LCDs.

In 1911, a French physicist called Charles-Victor Mauguin first noticed the twisted nematic effect. He found that if he positioned liquid crystals between two aligned polarizers, a light would still pass through them. Knowing that light doesn’t usually pass through two aligned polarizers, he surmised that the crystals repolarized the light.

It was only in 1972 when the first real TN device was created. While working in Switzerland, two physicists named Martin Schadt and Wolfgang Helfrich found that applying voltage to liquid crystals could redirect light due to their structure twisting. They developed the first four-digit LCD screen.

Their discovery paved the way for devices with digital displays and was widely adopted for use in watches and calculators. The first color LCD TV only came out in 1988 and had a tiny, two-inch screen. Since then, TN technology has evolved at a rapid pace and now serves as the basis for many LCD screens, including TVs and monitors.

TN panels contain liquid crystals positioned between two polarizing filters. Each filter is the same size but orientated at 90-degree angles to each other with one placed vertically and the other horizontally. In its standard form, no light can pass through the filters because of their orientation. When voltage is applied to the liquid crystals, their molecules twist to 90 degrees allowing light to pass through the filters.

There are many advantages to using TN panels for gaming monitors. A couple of the main reasons why they are favored for gaming is their high refresh rates and response times which make them ideal for fast-paced competitive gaming.

Another reason why TN panels are popular is their price. They are inexpensive compared to the other panel types, making them ideal for budget gaming monitors like the LG Ultragear 24GL600F-B and the Asus VP28UQG.

Despite their high speeds, TN panels have some drawbacks. They can’t compete with IPS or VA panels when it comes to color accuracy. Many TN panels also have narrower viewing angles compared to the other monitor types.

While these are the general characteristics of TN panels, real-world performance varies depending on the screen itself, and there is often overlap between the different display types.

When it comes todisplay technologies such asprojectorsand panels, factors such as resolution and refresh rate are often discussed. But the underlying technology is equally, if not more, important. There are tons of different types of screens, from OLED and LED to TN, VA, and IPS. Learn about the various monitor and television types, from operation to pros and cons!

The most common form of monitor or TV on the market is LCD or Liquid Crystal Display. As the name suggests, LCDs use liquid crystals that alter the light to generate a specific colour. So some form of backlighting is necessary. Often, it’s LED lighting. But there are multiple forms of backlighting.

LCDs have utilized CCFLs or cold cathode fluorescent lamps. An LCD panel lit with CCFL backlighting benefits from extremely uniform illumination for a pretty even level of brightness across the entire screen. However, this comes at the expense of picture quality. Unlike an LED TV, cold cathode fluorescent lamp LCD monitors lack dimming capabilities. Since the brightness level is even throughout the entire array, a darker portion of scenes might look overly lit or washed out. While that might not be as obvious in a room filled with ambient light, under ideal movie-watching conditions, or in a dark room, it’s noticeable. LED TVs have mostly replaced CCFL.

An LCD panel is transmissive rather than emissive. Composition depends on the specific form of LCD being used, but generally, pixels are made up of subpixel layers that comprise the RGB (red-green-blue) colour spectrum and control the light that passes through. A backlight is needed, and it’s usually LED for modern monitors.

Please note that some of the mentioned types may be considered a sub-category of LCD TVs; therefore, some of the names may vary depending on the manufacturer and the market.

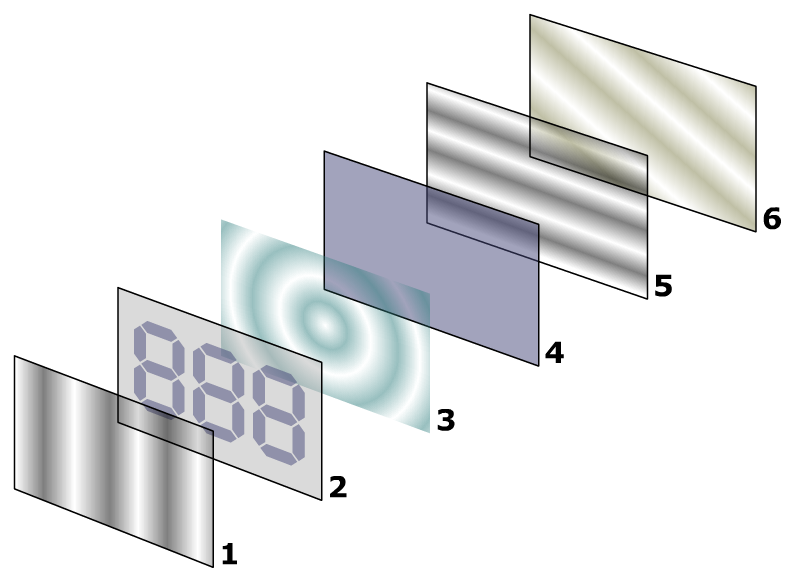

1)Film layer that polarizes light entering2)glass substrate that dictates the dark shapes when the LCD screen is on3)Liquid crystal layer4)glass substrate that lines up with the horizontal filter5)Horizontal film filter letting light through or blocking it6)Reflective surface transmitting an image to the viewer

While many newer TVs and monitors are marketed as LED TVs, it’s sort of the same as an LCD TV. Whereas LCD refers to a display type, LED points to the backlighting in liquid crystal display instead. As such, LED TV is a subset of LCD. Rather than CCFLs, LEDs are light-emitting diodes or semiconductor light sources which generate light when a current passes through.

LED TVs boast several different benefits. Physically, LED television tends to be slimmer than CCFL-based LCD panels, and viewing angles are generally better than on non-LED LCD monitors. So if you’re at an angle, the picture remains relatively clear nonetheless. LEDs are alsoextremely long-lasting as well as more energy-efficient. As such, you can expect a lengthy lifespan and low power draw. Chances are you’ll upgrade to a new telly, or an internal part will go out far before any LEDs cease functioning.

Ultimately, the choice between LED vs VA or any other display technology will depend on your specific needs and preferences, including things like size, resolution, brightness, and colour accuracy.

Further segmenting LED TVs down, you"ll find TN panels. A TN or twisted nematic display is a type of LED TV that offers a low-cost solution with a low response time and low input lag.

These displays are known for their high refresh rates, ranging from 100Hz to 144Hz or higher. As a result, many monitors marketed towards gamers feature TN technology. The fast response time and low input lag make them ideal for fast-paced action and gaming. However, TN panels have some limitations.

Overall, while TN panels are an affordable and fast option, they may not be the best choice for those looking for accurate colour reproduction and wide viewing angles.

Like TN, IPS or In-plane Switching displays are a subset of LED panels. IPS monitors tend to boast accurate colour reproduction and great viewing angles. Price is higher than on TN monitors, but in-plane switching TVs generally feature a better picture when compared with twisted nematic sets. Latency and response time can be higher on IPS monitors meaning not all are ideal for gaming.

An IPS display aligns liquid crystals in parallel for lush colours. Polarizing filters have transmission axes aligned in the same direction. Because the electrode alignment differs from TN panels, black levels, viewing angles, and colour accuracy is much better. TN liquid crystals are perpendicular.

A VA or vertical alignment monitor is a type of LED monitor that features excellent contrast ratios, colour reproduction, and viewing angles. This is achieved by using crystals that are perpendicular to the polarizers at right angles, similar to the technology used in TN monitors. VA monitors are known for their deep blacks and vibrant colours, making them popular for media consumption and gaming.

They also have better viewing angles than TN monitors, meaning that the picture quality remains consistent when viewed from different angles. However, the response time of a VA monitor is not as fast as that of a TN monitor, which can be a concern for those looking to use the monitor for fast-paced action or gaming.

The pricing of VA monitors varies, but they are typically more expensive than TN monitors and less costly than IPS or OLED monitors. Overall, VA monitors are an excellent option for those looking for a balance between good picture quality and affordability.

A quantum dot LED TV or QLED is yet another form of LED television. But it’s drastically different from other LED variants. Whereas most LED panels use a white backlight, quantum dot televisions opt for blue lights. In front of these blue LEDs sits a thin layer of quantum dots. These quantum dots in a screen glow at specific wavelengths of colour, either red, green, or blue, therefore comprising the entire RGB (red-green-blue) colour spectrum required to create a colour TV image.

Please note that some of the mentioned types may be considered a sub-category of Quantum Dot TVs; therefore, some of the names may vary depending on the manufacturer and the market. Also, it"s worth mentioning that not all brands use the same technology. Some are using QD films or QD-LEDs, others are using QD-OLEDs, and the list could go on.

An OLED or organic light-emitting diode display isn’t another variation of LED. OLEDs use negatively and positively charged ions for illuminating individual pixels. By contrast, LCD/LED TVs use a backlight that can make an unwanted glow. In OLED display, there are several layers, including a substrate, an anode, a hole injection layer, a hole transport layer, an emissive layer, a blocking layer, an electron transport layer, and a cathode. The emissive layer, comprised of an electroluminescent layer of film, is nestled between an electron-injecting cathode and an electron removal layer, the anode. OLEDs benefit from darker blacks and eschew any unwanted screen glow. Because OLED panels are made up of millions of individual subpixels, the pixels themselves emit light, and it’s, therefore, an emissive display as opposed to a transmissive technology like LCD/LED panels where a backlight is required behind the pixels themselves.

The image quality is top-notch. OLED TVs feature superb local dimming capabilities. The contrast ratio is unrivalled, even by the best of QLEDs, since pixels not used may be turned off. There’s no light bleed, black levels are incredible, excellent screen uniformity, and viewing angles don’t degrade the picture. Unfortunately, this comes at a cost. OLEDs are pricey, and the image isn’t as bright overall when compared to LED panels. For viewing in a darkened room, that’s fine, but ambient lighting isn’t ideal for OLED use.

OLED:Organic light-emitting diode display, non-LED. Emissive technology is where negatively and positively charged ions illuminate individual pixels in a display.

Please note that OLED technology can be applied to various displays and devices, and the list mentioned above may not be exhaustive. Also, some types may be considered a sub-category of OLED.

As you can see, a wide variety of displays are available on the market today, each with their unique advantages and disadvantages. While many monitors and TVs are referred to by various names, such as LED, IPS, VA, TN, or QLED, many are variations of LCD panels. The specific technology used in a display, such as the colour of backlighting and the alignment of pixels, plays a major role in determining the overall picture quality.

On March 2, the second phase production line of TAC (cellulose triacetate) film for LCD and the third production line of solar cell back film invested by lucky group started construction in the company headquarters. After the two projects are put into operation, they will break the monopoly of foreign countries on the important raw material market of China"s flat panel display and photovoltaic industry.

TAC thin film is an important raw material for making the core component of LCD - polarizer. At present, domestic high-end product manufacturing technology is monopolized by foreign enterprises. Lekai group increased R & D investment on the basis of the original TAC membrane production line, produced high-end TAC membrane and passed the application performance test. The market places high hopes on Lekai"s products. After the completion of the project, the domestic TAC film will gradually replace the imported medium and high-grade optical TAC film, so as to reduce the operation cost of China"s flat panel display industry.

At present, all kinds of new flat panel display devices led by LCD (liquid crystal display) have developed rapidly, especially thin film transistor liquid crystal display (TFT-LCD) has become the mainstream development direction of new thin display technology, and it is also the core force for the growth of electronic information industry in the next 20 years. Domestic polarizers are in a state of serious shortage of supply and basically rely on imports. The raw material of high-end optical TAC film also depends on imports. At present, lucky has a certain share in the domestic TN / STN (twisted nematic / super twisted nematic) polarizer market, and has made some progress in the research and development of TAC film for TFT polarizer.

Compared with the existing TAC membrane production line in the first phase, many process technologies of the second phase production line have been improved. Based on the production of medium and high-end products, the project is expected to break the foreign monopoly and further improve Lekai"s position in the LCD industry chain to meet the development needs of China"s flat panel display industry.

At the same time, the construction of the third production line of solar cell back film will produce important materials for solar cell modules, which are used for solar photovoltaic panel packaging, mainly serving the photovoltaic industry in China. At present, TPT (poly (ethylene terephthalate) and TPE (poly (ethylene terephthalate), ethylene vinyl acetate and poly (ethylene fluoride)) are the common back films of solar cells in the market, and the back films with multi-layer pet (poly (ethylene terephthalate) structure in Japan. Lekai solar cell back film has independent intellectual property rights, and its cost performance is better than that of foreign similar products, and is gradually breaking the market monopoly of foreign companies.

The advance in technology implies incrementation in the number of devices, machines as well as systems which, require electrical energy to operate. Therefore,

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey