low-power color tft lcd display for handheld embedded systems made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

※Price Increase NotificationThe TFT glass cell makers such as Tianma,Hanstar,BOE,Innolux has reduced or stopped the production of small and medium-sized tft glass cell from August-2020 due to the low profit and focus on the size of LCD TV,Tablet PC and Smart Phone .It results the glass cell price in the market is extremely high,and the same situation happens in IC industry.We deeply regret that rapidly rising costs for glass cell and controller IC necessitate our raising the price of tft display.We have made every attempt to avoid the increase, we could accept no profit from the beginning,but the price is going up frequently ,we"re now losing a lot of money. We have no choice if we want to survive. There is no certain answer for when the price would go back to the normal.We guess it will take at least 6 months until these glass cell and semiconductor manufacturing companies recover the production schedule. (Mar-03-2021)

Impact: ER-TFT043-7 is the same with ER-TFT043A1-7 in mechanical dimension and electrical spec in our testing.As old customer,we recommend you test samples before mass order.

ER-TFT043A1-7 is 4.3 inch IPS TFT LCD 800x480 dots display, with driver IC ST7262E43 and optional capacitive touch panel or resistive touch panel,superior display quality,full view angle and easily controlled by MCU such as PIC, AVR, ARDUINO,ARM and Raspberry portable or handheld device.PI.

It can be used in any embedded systems,car,mp4,gps,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports rgb interface. FPC with zif connector is easily to assemble or remove.Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for 4.3"TFT Touch Shield with Libraries, Examples.Schematic Diagram for Arduino Due,Mega 2560,Uno and 8051 Microcontroller Development Board&Kit.

Display brilliant colors on theEnrich9inch TFT LCD module!The active display area is 8.95 inches diagonally measured and the native resolution is 1024*RGB*600. It can be used in any embedded systems, car, GPS, industrial device, security and hand-held equipment which requires display in high quality and colorful image. It supports RGB interface.

EnrichTFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

Last week, Sharp announced that it will expand its alliance with CEC (China Electronics Corp.), the parent company of CEC-Panda, a Chinese TFT LCD panel maker. Sharp sold its Gen 6 line to CEC-Panda back in 2011, and now has decided to play an important role in CEC-Panda’s planned Gen 8 TFT LCD fab in Nanjing. Nanjing CEC-Panda LCD Technology Co., with 17.5 billion RMB ($2.9 billion) in capital, will be a joint venture between CEC Group (92 percent) and Sharp (8 percent), the first joint Chinese-Japanese TFT LCD fab. This follows Samsung and LG Display’s efforts to build Gen 8 fabs in China through joint ventures with TCL and Skyworth, respectively.

With smart handheld devices (smartphones and tablet PCs) growing faster than LCD TV, CEC-Panda is planning to shift its business focus from TV to smart handheld device panels, which require high resolution, slim form factor, low color shift, high color saturation and low power consumption. This shift requires high performance technologies and processes, which Sharp can provide.

Sharp will benefit from the cash flow coming from royalty and technology transfer income, and will have first priority for the allocation of the output of the Gen 8 fab.

Sharp is the first to implement oxide TFT (in particular IGZO) technology for handheld devices, in order to achieve low power consumption and high resolution. Sharp may implement IGZO technology in Nanjing, not only to help the joint venture company to ramp up high resolution panels, but also to collect royalties from any IGZO production.

As we have analyzed, by 2015, there will be 8 Gen 8 fabs in China, at which point China will have the most Gen 8 capacity; one of these will be the CEC-Panda/Sharp line. As the LCD TV market matures, some of these fabs will start to produce high-resolution smart handheld device panels.

Taiwanese panel makers might be further marginalized and forced to reshape their strategy toward the China market. Taiwan panel makers are the largest suppliers to China at present, with LCD TV panels supplied by AUO and Innolux, and smartphone and tablet PC panels supplied by HannStar and CPT. However, with Korean and Japanese makers invested in China, Taiwanese panel makers will be the only ones facing import duties. Taiwan panel makers will be forced to make additional panel cost reductions or somehow create a unique offering in China (such as new TV sizes, or large but lower resolution smart handheld panels).

CEC-Panda is not recognized as a leading panel maker due to its limited product mix (monitor panels and 32” in Gen 6) and lagging technology. The company has no experience in high resolution (like 4Kx2K) TV panels or smart device panels. However, with help from Sharp, CEC-Panda may become a competitor for high-end panels.

Foxconn had intended to get closer to Sharp to access to high-resolution and low-power technologies, but has not been able to strike an agreement with Sharp, and the relationship is so far limited to the Sakai Gen 10 joint venture and TV business.

Sharp Imaging and Information Company of America (SIICA), a division of Sharp Electronics Corporation (SEC), today announced the debut of the Synappx collaboration hub experience. Combining the power of Synappx Go and Synappx Meeting, the Synappx collaboration hub creates a mobile-first experience, enabling participants to start a scheduled or ad hoc meeting on a meeting […]

Sharp Imaging and Information Company of America (SIICA) and Sharp NEC Display Solutions of America (SNDSA) introduced the PN-HC and PN-HE 4K Ultra-HD LCD professional display series. The large-format monitors complement the existing Sharp lineup of monitors for commercial and professional environments, which launched in February 2022 with the PN-HS and PN-HY displays. Offering “vivid, […]

Sharp NEC Display Solutions just launched the PE456USL entry-level installation projector today. This new model is made to accommodate tight rooms, specifically in museums, golf simulators, corporate offices and higher education classrooms. The new projector, which will be part of Sharp/NEC’s PE Series, provides a short-throw, 4,500-lumen projection in areas where space is limited or where casting […]

The widest range of microprocessor cores for almost all application markets. Explore ARM. Performance, power & cost requirements for almost all application markets, processors are crucial. The system performance depends heavily on its hardware; this article will guide you through a study of the ARM Processor and be of great assistance in your decision-making.

Before 2003, there are classic ARM Processors which are including ARM7(ARMv4 Architecture), ARM9(ARMv5 Architecture), ARM11(ARMv6 Architecture). ARM7 has no MMU (memory management unit), cannot run multi-user multi-process system such as Linux and WinCE. Only can run system such as ucOS and ucLinux which do not need MMU. ARM9 and ARM11 are embedded CPUs with MMU, which can run Linux.

Simply put, Cortex-A series are suitable for applications that have high computing requirements, run rich operating systems, and provide interactive media and graphics experience. Cortex-R are suitable for that require reliability, high availability, fault tolerance, maintainability and real-time response. Cortex-M series are aimed at cost and power-sensitive MCUs and end applications.

The set of common features for A-processors includes a media processing engine (NEON), a tool for security purposes (Trustzone), and various supported instruction sets (ARM, Thumb, DSP etc.)

The main features of Cortex-A processors are top performance and brilliant power efficiency closely bundled to provide users with the best service possible

Cortex-A5: The Cortex A5 is the smallest and lowest power member of the Cortex A series, but it can still demonstrate multicore performance, it is compatible with A9 and A15 processors.

Cortex-A7: The power consumption of A7 is nearly the same as A5, But the performance provided by the A7 is 20% higher than A5 as well as full architectural compatibility with Cortex-A15 and Cortex-A17. The Cortex-A7 is an ideal choice for cost -sensitive smartphone and tablet implementations.

Contrex-A15:The Cortex-A15 is the highest performance member of this series, providing twice the performance than A9. A15 finds its application in high-end devices, low-power servers, and wireless infrastructure. This is the first processor support for data management and virtual environment solutions.

Contrex-A50: Contrex-A50, latest series, are built on the ARMv8 architecture and bring with them support for Arch64-bit an energy-efficient system. An obvious reason for the move to 64-bit is the support of more than 4GB of physical memory, which is already achieved on Cortex-A15 and Cortex-A7.

Cortex-R processors target high-performance real-time applications such as hard disk controllers, networking equipment media players, and other similar devices, Furthermore, it also great support for the automotive industry such as airbags, braking systems and engine management.

Cortex-R4: Cortex-R4 is well suited for automotive applications. It can be clocked up to 600 MHz, has an 8-stage pipeline with dual-issue, pre-fetch and a low latency interrupt system making it ideal for safety critical systems.

Cortex-R5: Cortex-R5 extends features offered by R4 and adding increased efficiency, reliability and enhance error management. The dual-core implementation makes it possible to build very powerful, flexible systems with real-time responses.

Cortex-R7:The Cortex-R7 significantly extends the performance. They feature an 11-stage pipeline and enable both out-of-order execution and high-level branch prediction. Tools can be implemented for lock-step, symmetric, and asymmetric multiprocessing. The generic interrupt controller is another significant feature that should be mentioned.

Cortex-M designed specifically to target MCU market. The Cortex-M series is built on the ARMv7-M architecture (used for Cortex-M3 and Cortex-M4), and the smaller Cortex-M0+ is built on the ARMv6-M architecture. It is safe to say that the Cortex-M has become for the 32-bit world what the 8051 is for the 8-bit – an industry-standard core supplied by many vendors. The Cortex-M series can be implemented as a soft core in an FPGA, for example, but it is much more common to find them implemented as MCU with integrated memories, clocks and peripherals. Some are optimized for energy efficiency, some for high performance and some are tailored to a specific market segment such as smart metering

For applications that are particularly cost sensitive or are migrating from 8-bit to 32-bit, the smallest member of the Cortex-M series might be the best choice.

Cortex-M0:The Cortex-M0+ uses the Thumb-2 instruction set and has a 2-stage pipeline. Significant features are the bus for single-cycle GPIO and the micro trace buffer.

Cortex-M3&M4: The Cortex-M3 and Cortex-M4 are very similar cores. Each offers a 3-stage pipeline, multiple 32-bit busses, clock speeds up to 200 MHz and very efficient debug options. The significant difference is the Cortex-M4 core’s capability for DSP. The Cortex-M3 and Cortex-M4 share the same architecture and instruction set (Thumb-2). If your application requires floating point math, you will get this done considerably faster on a Cortex-M4 than you will on a Cortex-M3. That said, for an application that is not using the DSP or FPU capabilities of the Cortex-M4, you will see the same level of performance and power consumption on a Cortex-M3. In other words, if you need DSP functionality, go with a Cortex-M4. Otherwise, the Cortex-M3 will do the job.

ARM processors offer a variety of capabilities for different purposes. With a little bit of thought and investigation, you will be able to find the right processor that suits your application needs. whether it’s for a high-end tablet or an ultra-low-cost wireless sensor node.

Orient Display has focused on ARM processor-related technologies for many years, and has accumulated rich experience in the development and implementation of ARM architecture products. While continuously launching development platforms and core board that meet the general needs of the market, it also addresses the individual project needs of customers. Provide customized services.

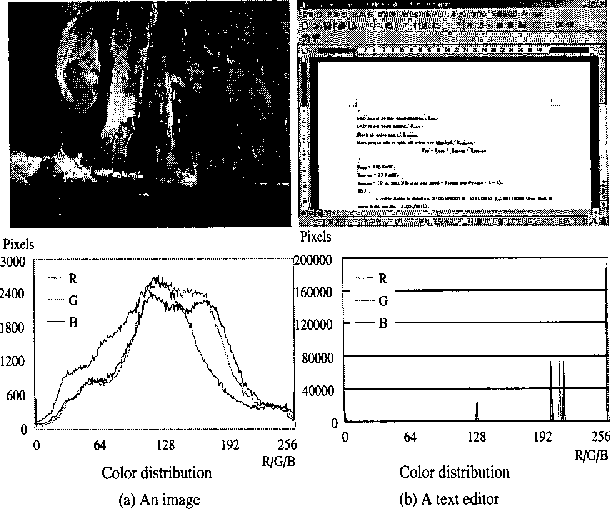

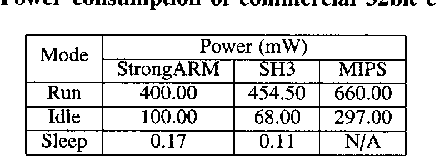

An LCD (Liquid Crystal Display) is a standard display device for hand-held embedded systems. Today, color TFT (Thin-Film Transistor) LCDs are common even in cost-effective equipments. An LCD display system is composed of an LCD panel, a frame buffer memory, an LCD and frame buffer controller, and a backlight inverter and lamp. All of them are heavy power consumers, and their portion becomes much more dominant when running interactive applications. This is because interactive applications are often triggered by human inputs and thus result in a lot of slack time in the CPU and memory system, which can be effectively used for dynamic power management. In this paper, we introduce low-power LCD display schemes as a system-level approach. We accurately characterize the energy consumption at the component level and minimize energy consumption of each component without appreciable display quality degradation. We develop several techniques such as variable-duty-ratio refresh, dynamic-color-depth control and backlight luminance dimming with brightness compensation or contrast enhancement.

The STM32L4R5xx, STM32L4R7xx and STM32L4R9xx devices are an ultra-low-power microcontrollers family (STM32L4+ Series) based on the high-performance Arm® Cortex®-M4 32-bit RISC core. They operate at a frequency of up to 120 MHz.

These devices embed high-speed memories (2 Mbytes of Flash memory and 640 Kbytes of SRAM), a flexible external memory controller (FSMC) for static memories (for devices with packages of 100 pins and more), two OctoSPI Flash memories interface (available on all packages) and an extensive range of enhanced I/Os and peripherals connected to two APB buses, two AHB buses and a 32-bit multi-AHB bus matrix.

The STM32L4Rxxx devices embed several protection mechanisms for embedded Flash memory and SRAM: readout protection, write protection, proprietary code readout protection and a firewall.

These devices offer a fast 12-bit ADC (5 Msps), two comparators, two operational amplifiers, two DAC channels, an internal voltage reference buffer, a low-power RTC, two general-purpose 32-bit timer, two 16-bit PWM timers dedicated to motor control, seven general-purpose 16-bit timers, and two 16-bit low-power timers. The devices support four digital filters for external sigma delta modulators (DFSDM). In addition, up to 24 capacitive sensing channels are available.

They also feature standard and advanced communication interfaces such as: four I2Cs, three SPIs, three USARTs, two UARTs and one low-power UART, two SAIs, one SDMMC, one CAN, one USB OTG full-speed, one camera interface and one DMA2D controller.

The devices operate in the -40 to +85 °C (+105 °C junction) and -40 to +125 °C (+130 °C junction) temperature ranges from a 1.71 to 3.6 V for VDD power supply when using internal LDO regulator and a 1.05 to 1.32 V VDD12 power supply when using external SMPS supply. A comprehensive set of power-saving modes allows the design of low-power applications.

Some independent power supplies are supported like an analog independent supply input for ADC, DAC, OPAMPs and comparators, a 3.3 V dedicated supply input for USB and up to 14 I/Os, which can be supplied independently down to 1.08 V. A VBAT input allows to backup the RTC and backup the registers. Dedicated VDD12 power supplies can be used to bypass the internal LDO regulator when connected to an external SMPS.

The STM32L4R5xx, STM32L4R7xx and STM32L4R9xx devices are an ultra-low-power microcontrollers family (STM32L4+ Series) based on the high-performance Arm® Cortex®-M4 32-bit RISC core. They operate at a frequency of up to 120 MHz.

These devices embed high-speed memories (2 Mbytes of Flash memory and 640 Kbytes of SRAM), a flexible external memory controller (FSMC) for static memories (for devices with packages of 100 pins and more), two OctoSPI Flash memories interface (available on all packages) and an extensive range of enhanced I/Os and peripherals connected to two APB buses, two AHB buses and a 32-bit multi-AHB bus matrix.

The STM32L4Rxxx devices embed several protection mechanisms for embedded Flash memory and SRAM: readout protection, write protection, proprietary code readout protection and a firewall.

These devices offer a fast 12-bit ADC (5 Msps), two comparators, two operational amplifiers, two DAC channels, an internal voltage reference buffer, a low-power RTC, two general-purpose 32-bit timer, two 16-bit PWM timers dedicated to motor control, seven general-purpose 16-bit timers, and two 16-bit low-power timers. The devices support four digital filters for external sigma delta modulators (DFSDM). In addition, up to 24 capacitive sensing channels are available.

They also feature standard and advanced communication interfaces such as: four I2Cs, three SPIs, three USARTs, two UARTs and one low-power UART, two SAIs, one SDMMC, one CAN, one USB OTG full-speed, one camera interface and one DMA2D controller.

The devices operate in the -40 to +85 °C (+105 °C junction) and -40 to +125 °C (+130 °C junction) temperature ranges from a 1.71 to 3.6 V for VDD power supply when using internal LDO regulator and a 1.05 to 1.32 V VDD12 power supply when using external SMPS supply. A comprehensive set of power-saving modes allows the design of low-power applications.

Some independent power supplies are supported like an analog independent supply input for ADC, DAC, OPAMPs and comparators, a 3.3 V dedicated supply input for USB and up to 14 I/Os, which can be supplied independently down to 1.08 V. A VBAT input allows to backup the RTC and backup the registers. Dedicated VDD12 power supplies can be used to bypass the internal LDO regulator when connected to an external SMPS.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In order to study the influence of driving waveforms on the reflectivity of an active matrix EWD, a driving system was designed for active matrix EWDs, and the reflectivity range of the traditional PWM waveform and the dynamic reset waveform proposed in this paper were tested. The TFT substrate used in active matrix EWDs was co-developed by South China Normal University and Tianma Microelectronics Co. Ltd. (Shanghai, China). Its resolution is 1024 × 768. The pixel voltage is charged by the source chip. The gate of TFTs is controlled by the gate chip. Then, the precise voltage control of each pixel can be realized in the active matrix EWD. The source and gate functions are integrated into an IST7109 chip, which can control a 512 × 384 active matrix. Its source function includes a 512 bit long, 2 bit wide serial input register and a 2 bit encoder. The 2 bit encoder is used to choose the output voltage between 20, 0, and −20 V. IST7108 has the same function as IST7109. The IST7108 is the cascade chip of IST7109. The two chips are bound to a TFT substrate by chip on glass (COG) technology. The connection between the chip and the driving circuit board is completed through a flexible cable.

The driving system structure used in this study is shown in Figure 5. A filed program gate array (FPGA) in the system is mainly responsible for the output of the driving waveform and the dynamic reset waveform. The dynamic reset waveform and grayscale waveform are output independently so the driving time of the grayscale waveform is shortened. Then, movement of oil in the pixel can be controlled more precisely by the grayscale waveform. The joint test action group (JTAG) interface of FPGAs is used to download the complied code with a USB blaster cable. The image data are stored in an erasable, programmable flash chip. a synchronous dynamic random-access memory (SDRAM) is responsible for image data caches. A {"type":"entrez-protein","attrs":{"text":"TPS65186","term_id":"1694062029","term_text":"TPS65186"}}TPS65186 (Texas Instruments, American) is used as a power supply IC to generate all 0 V, −15 V, +15 V, −20 V, and +20 V voltages in one chip as a power management solution for EWDs. The gate is responsible for controlling the pixel switch of each column, and the source provides voltage for each row of pixels in the pixel matrix. A timing controller (TCON) is used to control the cooperative work of gate and source chips. Since the driving voltage, which is required for oil movement, is 30 V, the liquid crystal driver chip cannot meet the requirements for controlling EWDs. Therefore, IST7109 was chosen as the source chip; it can output 0 V, +15 V and −15 V. In order to achieve the driving voltage required by EWDs, the top plate is connected to +15 V, which can output driving voltages of 0 V, 15 V, and 30 V.

The block diagram of the driving board and the function module of a FPGA. After the system is powered on, RGB image data are read from FLASH to SDRAM and the image data are converted into gray tone data by the RGB2GRAY module. Then, the gray tone data are used to find the waveform in the waveform table and output it to a FPGA internal module. Finally, the source and gate chips are controlled for display. Pixels can be driven by the final waveform with the control of the source and gate chips. The data frame buffer in SDRAM is detected by the frame detection module to control the dynamic output of the reset waveform.

Related materials of TFT substrates that are used in our system are shown in Table 1. To enable comparison with the traditional PWM method, an optical colorimeter arg-45, developed by Admesy in the Netherlands, was used to obtain the reflected luminance of the EWD and a camera was used to record the video and image. The driving system was powered by a power adapter. The specifications of EWDs are shown in Table 2.

The colorimeter can emit light at an angle of 45° to irradiate pixels in an area. After the light is transmitted by the EWD panel, it can be reflected by the reflective panel and passed through the EWD panel again. Then, the intensity of the reflected light can be obtained by the colorimeter. In this experiment, the influence of different reset waveforms on oil backflow was compared, as shown in Figure 6. An EWD was driven by the same voltage (30 V) with a different reset waveform. Based on the experimental data, the proposed reset waveform more effectively maintains the oil state.

The influence of three different reset waveforms on oil backflow. A negative voltage (−5 V) is contained in the reverse reset waveform. A zero voltage is contained in the PWM reset waveform.

The influence of grayscale driven by the reset waveform is shown in Figure 7. The luminance of grayscales G1′, G2′, G3′, and G4′ cannot be maintained without the reset waveform. After 30 s, four grayscales are decreased to three gray scales G1, G2, and G3. However, the grayscales of G1r, G2r, G3r, and G4r can be maintained by the reset waveform. The fluctuation of brightness was controlled within 4%.

Grayscales affected by oil backflow. The luminance of four grayscales decreased after 30 s. After 30 s, the luminance of G3′ was the same as G4′. The initial luminance of grayscales was G1′, G2′, G3′, and G4′. After 30 s, the grayscales without the reset waveform ere changed to G1, G2, and G3, and grayscales with the reset waveform changed to G1r, G2r, G3r, and G4r.

In the reset waveform and the PWM waveform, the reflected brightness curves are shown in Figure 8. When there is no reset waveform, the oil state in a pixel cannot be maintained beyond oil backflow time. The oil backflow start time is the time when the reflectivity decreases from the maximum value to 90% of the maximum value. The oil backflow start time without the reset waveform was 31.28 s. When the reset waveform was used, the response curve is with reset. The reflected brightness oscillated periodically, and the oscillation period was about 24 s.

The relationship between the reflected brightness and time for different driving methods. The “with reset” curve is the brightness data, which are driven with the reset waveform. The “without reset” curve is the brightness data, which are driven with the traditional driving waveform. The linear backflow is used to evaluate the oil backflow speed.

In order to analyze the influence of oil backflow, we used the method of numerical fitting for statistical analysis. First, the maximum points in each oscillation period were extracted as the local maximum data in the with reset curve. Second, the maximum point (44.39, 7.07007) and minimum point (196.19, 6.98932) were found in the local maximum data. Third, the maximum point and minimum point were used to represent the worst-case oil backflow percentage (1.14%) after a reset waveform; a straight line was used to simply predict the oil backflow situation. Finally, according to the calculation of the straight line, the oil backflow start time was 23,616 s. The oil backflow time was extended by 761 times compared with PWM driving.

The static image effect comparison among different driving waveforms is shown in Figure 9. When the EWD was switched on, a camera was used to record the EWD screen. After 30 s, the camera was used to take another recording. The defect line on the screen is a chip bonding defect. As a result, the display quality was improved intuitively by the reset waveform.

Comparison of static images with different driving waveforms. The ordinate indicates the driving waveform used in the experiment, and the abscissa indicates time. At 0 s, image (A) was recorded with the reset waveform and image (C) was recorded without the reset waveform. After 30 s, image (B) was recorded with the reset waveform and image (D) was recorded without the reset waveform. There is an uncontrollable line in the middle of the screen, which is a defect in the gate chip binding.

The system successfully realizes the reset function of EWDs with 1024 × 768 resolution. The oil backflow of the static display is effectively suppressed, and the frame loss and obvious flicker caused by the insertion of the reset waveform are avoided at the same time, providing a new driving technology foundation for EWDs.

Until about a year ago, active-matrix organic light-emitting diode (AMOLED)–based smartphones remained Samsung’s niche. Almost all the AMOLEDs Samsung was making went into Galaxy products. AMOLED prices were relatively high compared to equivalent liquid crystal displays (LCDs). Samsung’s AMOLED fab utilization was low, and it was struggling to ramp up its A3 flexible AMOLED dedicated fab. Its AMOLED business was challenged to raise profits.

What a difference a year makes! Now in June 2016, the outlook for AMOLED smartphones has dramatically shifted in a positive direction. Samsung’s AMOLED fab utilization is high, prices for external customers are on par with LCDs, and the company’s AMOLED business is profitable. Over the same period, it has become evident that Apple plans to transition the iPhone display from rigid LCDs to flexible AMOLEDs in the next couple of years. Meanwhile, more and more people are talking about the coming flexible or foldable OLED displays that will bring revolutionary change to the form factor of handheld devices.

These shifts in market outlook have created an unprecedented wave of new flexible AMOLED fab investment plans for makers in Korea, China, and Japan. Competitors are trying to replicate Samsung’s success, hoping to escape the commoditization and low profitability of LCDs—and chasing after potential Apple business. A large number of new fabs are now being built, and they are the most expensive ever made relative to glass size and input capacity.

Although Samsung’s AMOLED process to date has used a simplified p-channel metal-oxide-semiconductor (PMOS) thin-film transistor (TFT) for the back plane, other makers and new lines targeting Apple demand appear to be preparing for processes that use up to 50% more mask steps. Low temperature polysilicon and oxide (LTPO) is one of the candidates. This drives significantly more TFT equipment, automation, and other spending. Furthermore, all the new AMOLED fabs will be designed to produce flexible AMOLEDs or will be hybrid rigid/flexible lines. Flexible capability adds costs to the TFT backplane process by requiring flexible substrate coating, curing, and encapsulation steps. Flexible capability adds cost to the front plane process by requiring thin-film encapsulation (TFE), laser lift-off (LLO), and a variety of other steps necessary to handle flexible panels. As shown below, the new flexible AMOLED fabs for mobile display production have a total costs that is almost 1.4x higher than previous rigid AMOLED lines, according to the IHS Technology Display Supply Demand & Equipment Tracker report.

In other words, pushed by a complex TFT process and flexible display requirements, the new AMOLED fabs are the most expensive flat-panel display (FPD) factories ever built, nearly 1.4x that of previously constructed rigid AMOLED lines.

Capital equipment markets tend to be highly cyclical, but the high cost of flexible AMOLED fabs is pushing the equipment market in 2016 and 2017 to near-historic two-year highs. Some concerns have been raised that equipment supply bottlenecks will restrict panel makers’ ability to build fabs according to schedule. Most of these concerns have focused on high-resolution photolithography machines, RGB evaporators, and some high-performance vacuum tools.

According to the IHS Technology Display Supply Demand & Equipment Tracker report, the large number of new flexible AMOLED investments, along with the high costs of these lines, is pushing the FPD equipment market to near-record two-year highs of $12.6 billion in 2016 and $12.3 billion in 2017.

All the new capacity in the pipeline may be creating a fantastic opportunity for equipment makers, but the ever-increasing scope of investments is now starting to raise questions about whether so many new players will actually be able to ramp up their fabs—and even if they do, will there be enough demand to keep those fabs running at high utilization and even moderate profitability?

Forecasting the supply and demand of flexible AMOLEDs in 2018 is a challenging task, not only due to the assumptions that must be made about both capacity and demand, but also the questions about yield rates, how long it will take fabs to ramp and begin commercial production, and the price competitiveness of these new fabs. Building rational forecasts of capacity is possible based on panel maker plans because new factories have lead times of up to two years.

In order to test supply and demand under the more optimistic scenario of faster adoption by Apple, the IHS forecast for total AMOLED smartphones was increased to 503 million units in 2017 and 653 million in 2018. This includes Samsung Galaxy phones, other brands such as Chinese cell phone makers, and a reasonable adoption forecast for Apple. Other mobile applications are also counted in demand. Relatively long ramp-up times and low yield rates for all makers, except Samsung, were assumed. Prices were presumed to be competitive and not directly tested in this analysis.

Analyzing all panel makers’ capacity plans and the comparatively aggressive demand forecast, the glut level is projected to increase from 2016 through 2018, suggesting a trend of growing oversupply.

As the graph below implies, Samsung Display alone is expected to add enough capacity to keep up with the accelerated demand forecast and maintain a glut similar to the current level. Samsung Display is presently very busy running its AMOLED fabs near maximum utilization. Supply is tight, but sufficient.

Samsung’s strategy likely involves adding enough capacity to enable it to continue—for as long as possible and almost exclusively—to dominate the AMOLED market for mobile applications. Samsung Display has a substantial technology and cost lead over even its closest competitors. It controls much of its own process know-how, and it will be a difficult path for followers to catch up in the near- or even mid-term. According to our analysis, Samsung could potentially maintain its AMOLED monopoly through 2018 or longer, even when taking into consideration the large increase in demand as the iPhone transitions from LCD to AMOLED.

The shift from rigid LCD to flexible AMOLED is the most significant change in FPD process technology since the start of the LCD era almost 20 years ago. All panel makers are now scrambling to avoid being left behind during this technology revolution.

However, as supply/demand analysis suggests, all the capacity being added by new AMOLED players may well get ahead of how much the market can absorb. Demand could grow faster than the accelerated forecast; however, it is not clear by how much. In 2018 and 2019 the market for both rigid and flexible AMOLED may be restricted by prices. It is unlikely that many makers will be able to compete on price and performance with Samsung or even with low-cost, high-end LCDs without incurring financial losses.

In other words, even in a high-demand scenario, the supply glut is forecast to increase through 2018—a time during which Samsung Display alone would be able to fulfill all market demand. This high-glut level is a risk factor for low utilization and low profitability in the short- to mid-term.

In the long run, all the investment in AMOLED capacity will help reduce material prices, strengthen the equipment supply chain, and allow the market to trend towards balance. However, it would also not be surprising for new AMOLED entrants to struggle to ramp up new fabs in 2018 and 2019, and suffer from low utilization and profitability as the industry works through the currently forecast flexible AMOLED supply glut.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey