crt to lcd monitors manufacturer

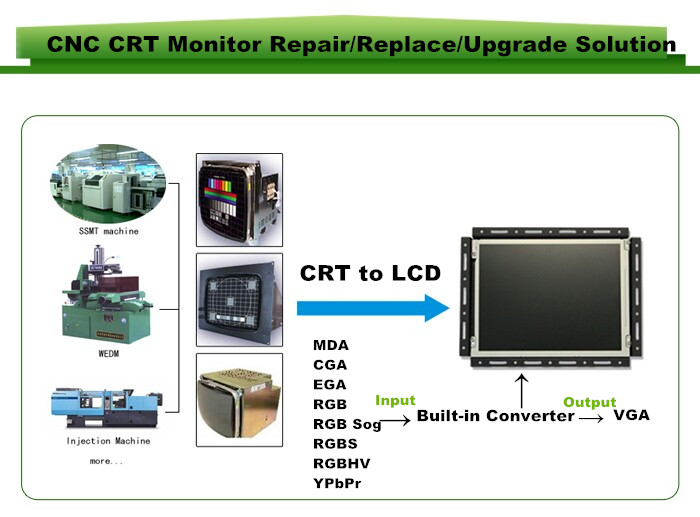

In today"s fast-changing environment, it"s becoming more and more difficult for many companies to find replacement display monitors for their costly industrial equipment. Often, the CRT monitor originally installed in an older CNC Machine tool or Industrial Lathe control has become obsolete and is no longer supported by the original manufacturer. In some cases, the original monitor manufacturer may even be out of business.

In today"s market, repairing a failed CRT display may be impossible, and replacements can be costly and hard (if not impossible) to come by. Indeed, most modern LCD monitors simply will not function properly when used to replace a CRT monitor in a legacy control system.

To make matters worse, most monitor manufacturers don"t want to be "bothered" with supporting legacy systems that are not their own. Even if they agree to look at your problem, they are often very expensive.

Industrial Panels can help you find an affordable solution to replace your display monitor. For years, we have specialized in modifying our LCD display monitors to meet our customer"s Legacy Monitor needs. We now provide affordabledrop-in CRT replacement LCD Monitorsfor a wide variety of industrial legacy computer monitor applications that require special timing or unique packaging, and the list keeps growing. To find a suitable replacement LCD monitor, please click the following link to our latest Replacement Monitor Cross-Reference listing of new LCD replacements for your old CRT monitors. There you can search by OEM system or CRT manufacture"s model number for the appropriate LCD replacement.

If you are having trouble sourcing a video display for one of the following older machines, our engineering staff will be happy to customize a rugged LCD display to meet the unique computer monitor specifications required and extend the life of your production equipment.

If we don"t have a standard replacement LCD display for your particular CRT monitor model, we"ll be glad to work with you to arrive at a cost-effective solution. Often, all that we need you to provide us with is basic pin-out and/or timing information and mounting information and we"ll do the rest.

It may be possible for you to send us your old monitor chassis or enclosure and we"ll install our electronics, or design a chassis that will mount in the same location as the original CRT monitor. Occasionally, more information may be required, but we"ll be happy to work with you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Manufacturer of standard & custom cathode ray tube & electroluminescent displays. Features include 17 in. to 23 in. LCD, rugged steel & aluminum construction, optional resistive or capacitive touch-screens, light textured powder coated black color, contrast filters, transmissive daylight modification, hard coated vandal shields, 16.7 million display colors, anti-glare hard coating, analog RGB input, weight ranging 13 lbs to 24 lbs & 1280 x 1024 SXGA or 1600 x 1200 UXGA or 920 x 1200 maximum resolution. Applications include use for rack, wall, panel or kiosk installations in commercial, military & broadcast industries. One year limited warranty. RoHS compliant. Meet NEMA & Military Spec.

With today’s ever-changing technology, many companies are finding it difficult to support their legacy monitor product lines. Dynamic Displays can help. Over the past 18 years, we have developed a number of stable product lines ideally suited to meet your legacy monitor needs.

With this in mind, Dynamic Displays now offers a variety of Slow Scan compatible legacy CRT and LCD monitor replacements that are specifically customized to interface with older industrial control equipment made by CNC machine control manufacturers like GE Fanuc, Allen Bradley, Mitsushita, Mazak, Hitachi, Toshiba, and others. This compatibility is made possible by DDI’s proprietary A/D converter and our extensive library of industrial video signal formats, compiled over many years of manufacturing CRT displays for some of industries largest OEMs. A short list of the OEM systems that we support includes; ABB, Westinghouse, Fisher, Bailey, Allen-Bradley, Foxboro, Honeywell, Moore, Siemens, Forney, Harris, Fanuc, Giddings and Lewis, Walter Grinders and Berger.

Looking for wholesale crt monitor manufacturers? Look no further than Alibaba.com, one of the largest collections of wholesale shipment suppliers in the world. We have a huge range of lcd computer monitor options and lcd display screen options to choose from. Whether you need a small lcd screen or a large one, we have you covered.

These crt monitor manufacturers products have become the go to display types for computers today. With tft color monitors slowly being phased out, lcd computer monitor displays are the standard in the industry. All customers need a flat screen computer monitor to interact with their personal computers. For ardent gamers that require high refresh rates to minimize lagging and make use of high performance computers there are a range of lcd gaming monitors available.

We also have more specialised products like rack mounted monitors for IT administrators and network administrators working in commercial settings. These monitors are used to oversee large server rooms and network infrastructure. New transparent lcd screen options are also coming on the market that are futuristic and allow for a sleek look to fit modern aesthetics.

So, start ordering your shipment of crt monitor manufacturers today from our suppliers. They are ready and willing to answer any questions you may have about their products and get you started today!

By connecting with the best crt monitor manufacturers and suppliers you can grow your business and satisfy your clients with top-notch products and services. At ExportHub you’ll find global crt monitor suppliers and manufacturers ready to serve your demands. Regardless of where you are located, you can get your products manufactured easily without setting foot out of your national border. As a leading B2B platform, we highlight the following attributes of the listed manufacturers and suppliers.

Still wondering where to start? Allow us to help you out! Call us at +1-214-306-7737 or fill out a short form on our Contact us page and a representative will get back to you in no time.

Are you a seller or a supplier of CRT monitor? Or are you willing to sell your used one? eWorldtrade is the best place to sell your product. There are buyers here who are looking for the product that you are offering. We have now made a great name in the trading world as well as in the minds of the consumers and sellers. We are the name that flashes in the mind of sellers and buyers around the world when they talk about trading. Our aim to make the trading business easy has helped many people reach their goals and to go to the perfect seller to buy the best stuff. You can always be sure to get a response from your target customer ones you get registered with us and share what you’re offering and what price and quality do you offer. Selling the items that you are offering to your customers around the world has never been so easy before.

Also, setup and key adjustments are more complicated with LCDs—and much more necessary—than they are with CRTs. To be sure, all displays can benefit from proper tuning and adjustment. But LCDs are more likely to experience clarity or viewability issues if they"re not tuned and tweaked to optimum conditions.

In this Recipe, we"ll tackle the system-building differences between LCDs and CRTs. We"ll also describe the kinds of usage situations best suited to one kind of display over the other. Finally, we"ll describe some important tools you can use to make sure your customers get the most from their LCD choices.

We"ll start with the pros and cons of CRT displays, and then do likewise for LCDs. After that, we"ll make some comparisons and explain which type of display is best-suited for specific, identifiable usage scenarios.

Our comparison of the pros, cons, and differences between CRT and LCD displays hinges on the differences between analog and digital technologies. CRTs are analog; therefore, they support continuous values, smooth scaling, and arbitrarily high resolutions (within reason or the limits of technology). LCDs are digital and therefore work like an array of individual, discrete pixels with individual, discrete color and gray-scale values, and a fixed, native resolution. In mathematical terms, it"s the difference between a continuous integral versus a stair-step function. Here"s how they line up:

Motion artifacts: The faster images move on a display, the more past display values can affect current display contents; these leftovers are called motion artifacts. CRTs offer fast response times with no motion artifacts. For this reason, CRTs are the best choice for fast-moving or ever-changing images.

Resolution: CRTs operate at any resolution, geometry, and aspect ratio with no need to rescale images shown. CRTs also run at the highest resolutions graphics cards support.

Emissions: CRTs emit electrical, magnetic, and electromagnetic fields, where magnetic fields are often believed to pose health hazards (although no available scientific evidence supports this belief).

Geometric distortion: CRTs are subject to geometric distortion and generally include adjustments to counter same. But they may also be affected by magnetic fields from other devices.

Interference: CRTs produce visual distortions known as Moire patterns. While many monitors offer Moire reduction, this doesn"t entirely eliminate this problem.

Sharpness: CRTs use electron beams to activate pixels on their screens. This results in softer images than an LCD operating at its native resolution. (But a CRT is usually sharper than an LCD not operating at its native resolutions.)

Size, weight, and power consumption: CRTs are big and bulky. They consume more power—and give off more heat—than most other display technologies.

Size, weight, and power consumption:LCDs are thin-profile devices that are generally lighter than CRTs. LCDs also consume less electricity—and give off less heat—than CRTs.

Aspect ratio: Any LCD has a fixed resolution and aspect ratio. For panels with a resolution of 1280 x 1024 (common for 17- and 19-inch models), the aspect ratio is 5:4 or 1.25, smaller than the 4:3 or 1.33 ratio common for other displays. This may require letterboxing to a 1280 x 960 resolution to get a standard 4:3 ratio.

Bad pixels and screen uniformity: LCDs may include malfunctioning pixels that are weak, or stuck in on or off modes. They are also subject to variations in backlighting, owing to the use of light sources at the top or bottom edges of the display.

Black-level, contract, color saturation: LCDs are poor at producing deep blacks and dark grays. This results in lower contrast and reduced color saturation for low intensity colors, which makes LCDs a poor choice for dimly lit or dark environments.

Color and gray scale accuracy: Internal gamma and gray-scale on an LCD varies by location on the display surface. LCDs normally produce only a limited number—fewer than 256—of discrete intensity levels. This leads to image-accuracy issues with black level, gray-scale, and gamma, and it isn"t suitable for professional color balancing.

Interference: LCDs using analog input require painstaking adjustment of pixel tracking and phase to minimize digital noise in image display. Automatic controls seldom produce optimum outputs, and it may be impossible to eliminate all digital noise completely.

Motion artifacts: The slower an LCD"s pixel refresh rate—often called response time, though this term is more appropriate for CRTs—the more likely it is that motion artifacts will appear. For continuous or very fast motion, some artifacts are inevitable on an LCD.

Resolution: Native resolution is set by the manufacturer and cannot be altered. All other resolutions require re-scaling and leads to image degradation, especially where fine text and graphics are concerned.

White saturation: White levels on LCDs are easily overloaded, and maximum brightness occurs before gray-scale values peak. This phenomenon is best managed by careful contrast-setting adjustments.

When it comes to picking one kind of display over the other, here"s what you should advise your customers on a number of criteria, including needs, pocketbooks, and working environments:

Color or gray-scale accuracy: Users who need or want higher color or gray-scale accuracy, and more viewable deep blacks or dark grays, will be better served by CRTs. Professional color balancing demands a high-quality CRT.

Contrast: CRTs produce the brightest contrast levels available, LCDs fare somewhat more poorly, especially with black and dark colors. Contrast ratio numbers published for LCD displays cannot always be taken literally.

Environmental concerns:CRTs, especially the picture tube itself, are chock-full of heavy metals of several varieties and pose more challenges for recycling than do LCDs. Also, smaller size and weight means less waste to manage. Also, LCDs emit less heat and other forms of energy—electrical, electromagnetic and magnetic—than do CRTs.

Lighting: Users who work in bright light are bound to prefer an LCD. Users who work in lower-light conditions will increasingly prefer a CRT as ambient light decreases.

Motion and artifacts: Users who need or want to work with fast or constantly moving images are best served by CRTs. But this also limits diagonal sizes to no more than 24 inches.

Operating costs: Those concerned about energy consumption will favor LCDs, as these monitors consume at least 40 percent less electricity than CRTs with the same rated diagonal measurements. (And standby mode savings are about 40 percent.) In theory, users can also get away with less office space by using LCDs, translating into lower rent.

Purchase cost: Those with smaller budgets should consider CRTs, as they cost 50 percent or less than LCDs with the same reported diagonal measurements.

Resolution: If a user doesn"t like an LCD at its native resolution, this spells trouble. Native resolution for an LCD is equivalent to maximum resolution on a CRT; it represents the upper limit of picture quality for a given model. So if a user needs a monitor to run at multiple resolutions, especially if they also need fine text and graphics for all resolutions, this virtually mandates a CRT.

With more customers switching to LCDs, system builders should understand how to set up these monitors and configure them properly once they"re in place. A system builder should also know how to get the best-looking text on the screen. To help, we"ll now describe some great tools for system builders working with LCD displays.

ClearType is a Microsoft technology specifically designed to improve text readability on LCD screens, including laptop screens, mobile device displays, and flat-panel monitors. ClearType technology can access individual color elements in each pixel on an LCD display. Prior to its introduction, the level of detail operated at the pixel level. But with ClearType running on an LCD monitor, features of text as small as a fraction of a pixel in width can be displayed, according to Microsoft. This leads to a visible improvement in the sharpness of tiny text details. It not only improves readability, but also is easier on the eyes, especially over extended periods of time.

ClearType is included with Windows XP. But to tweak text settings on individual LCD displays, you must download a Windows PowerToy called ClearType Tuner.

Once downloaded and installed, ClearType Tuner appears as a control panel widget named ClearType Tuning. Its users work with a wizard that asks them to select among multiple on-screen displays that look the best, in much the same way an optometrist works with patients to help determine a new prescription for corrective lenses.

Using the ClearType Tuning widget is fast and easy, and a bit of practice makes working with it a snap. You"ll also see noticeable improvements to text on LCD screens as a consequence of its use, as toggling the check box for "Turn on ClearType" in the widget itself will show.

DisplayMate Technologies is a small and highly-regarded company that offers a family of powerful tools of great interest to system builders and consultants. The company offers a $89 (download only) or $99 (CD and manual shipped to buyer) product called DisplayMate for Windows Video Edition, which we highly recommend. It not only supports both CRT and LCD displays, but also other display types, including liquid crystal on silicon (LCoS), digital light processing (DLP), TV, HDTV, Plasma, and multi-media displays. Though this product aims primarily at end-users and consumers, system builders and consultants on a tight budget can get plenty of value from this product.

System builders who work with lots of displays and really want to get the most out of them will probably prefer the higher end DisplayMate Multimedia Edition, which sells for $495. It not only handles the same kinds of displays as the aforementioned Windows Video Edition, but also includes many more test patterns and command scripts to perform customized display testing and tuning.

This scaffolding around the consumer-level DisplayMate for Windows program provides users with a set of detailed descriptive text screens that precede each of the monitor test sequences under two general headings: Set-Up Program and Tune-Up Program.

The Set-Up program helps familiarize users with graphics and display capabilities on the systems under test, and to establish initial configuration. The Tune-Up Program provides quick checks on specific display capabilities, with opportunities to tweak and tune them for optimal display output.

Introduction: A lead-in screen for the program that briefly describes its capabilities and (more important) provides the option to toggle the Novice Option on or off. Beginners will appreciate its information and instructions, while experienced users can ignore this.

Set-Up Display: A stepwise procedure that leads users through all available user controls on their display and graphics card, each of which is associated with a test pattern and an explanation of how to use its appearance on screen to achieve settings that are visually optimal. First, an initial explanation appears on screen. Then, users click through a sequence of 22 test-pattern screens that include checks on brightness and contrast, intensity range, black-level, and gray scale checks, numerous standard test patterns and color gauges, and numerous geometry checks. The whole sequence takes at least 30 minutes to traverse the first few times through, especially if you read all the preliminary text that precedes each individual test (and if our experience is any guide, you definitely should).

Video Obstacle Course: A set of demanding and difficult images designed to stress test displays and show settings in need of adjustment or improvement. The software also provides information about what users will see during these 24 tests, and how to remedy any potential problems or issues they may expose. About a third of the tests repeat from the previous Set-Up Display sequence, but others deal with important checks related to Moire patterns, color registration, screen and local display regulation, and more. Expect to spend at least 30 minutes working through this series of test patterns and checks.

Master Test Pattern: As the name suggests, this one has a little bit of everything: Geometry, focus and resolution checks, gray-scale and color levels and saturation, and more. You"ll learn to use this to take a quick look at a display and see if it needs some (or more) work.

Video System Information: Shows what information from your display and graphics card DisplayMate can read, including native resolution, screen colors, gray levels, screen and pixel aspect ratios, pixel shape (square or not), color depth, palette, and planes, as well as system font and display driver information. Useful to make sure everything is as it should be.

The DisplayMate Tune-Up Program includes the following elements, whose organization indicates that this tool takes a functional view of the various activities involved in display tuning and tweaking:

Screen Pixel Resolution: Shows a series of 15 visually interesting test patterns to check screen resolution, fineness of detail, and accuracy in a series of complex line and pattern traces. This is some of the coolest looking stuff in the program.

Miscellaneous Effects: A series of 14 tests and checks that let you fool around with colors and gray scales on the display. Be sure to toggle through color selections where you can; click the right mouse button to toggle through such options where available.

In our test lab, we have a number of LCD screens ranging in size from 17 inches (diagonal) to 30 inches. We found the DisplayMate program"s ability to help us properly set brightness, contrast, and pixel timing to be of greatest use. Those are the aspects of our LCDs that suffer the most when left at factory-default settings. System builders and consultants will find these tools useful in making sure that their customers and users have the best possible experiences when they upgrade or switch to LCD displays.

ED TITTEL is a freelance writer and trainer in Austin, TX, who specializes in Windows topics and tools, especially networking and security related matters. JUSTIN KORELC is a long-time Linux hacker and Windows maven who concentrates on hardware and software security topics. Ed and Justin are also co-authors of Build the Ultimate Home Theater PC (John Wiley, 2005).

At ACS, most monitors cost a fraction of what you would pay for a brand new one. You will be very satisfied with ACS Monitor Repair Services – Guaranteed!

LCD, CRT, Touch Screen, CNC, and many other monitors are expertly repaired and serviced. Video driver and controller repair, replacement of screens, back light assemblies, power supplies are just a few of the monitor services provided by ACS Industrial.

ACS also repairs Security Monitors, Hospital Monitors, Medical Monitors, Touch Screen Operator Control Stations, POS (Point of Sale) Terminals, and more...

Thomas Electronics has acquired the CRT magnetic coil assets of Syntronic Instruments and Thomson Genlis S.A. We now offer a full range of electromagnetic design & manufacturing services, from initial design & prototyping to manufacturing & comprehensive testing. We can customize our process & our products at every step to ensure full compatibility with your unique specifications.

We are committed to maintaining a high level of quality & look forward to providing all products & services traditionally offered by Syntronic Instruments and Thomson Genlis S.A., including convergence correction magnets & coils, electromagnetic & permanent magnet astigmators, focus coils, & more.

CRT stands for Cathode Ray Tube and LCD stands for Liquid Crystal Display area unit the kinds of display devices wherever CRT is employed as standard display devices whereas LCD is more modern technology. These area unit primarily differentiated supported the fabric they’re made from and dealing mechanism, however, each area unit alleged to perform identical perform of providing a visible variety of electronic media. Here, the crucial operational distinction is that the CRT integrates the 2 processes lightweight generation and lightweight modulation and it’s additionally managed by one set of elements. Conversely, the LCD isolates the 2 processes kind one another that’s lightweight generation and modulation.

/is2.ecplaza.com/ecplaza1/offers/6/62/62e/153126764/crt-and-lcd.jpg)

A cathode-ray tube (CRT) is a vacuum tube containing one or more electron guns, which emit electron beams that are manipulated to display images on a phosphorescent screen.waveforms (oscilloscope), pictures (television set, computer monitor), radar targets, or other phenomena. A CRT on a television set is commonly called a picture tube. CRTs have also been used as memory devices, in which case the screen is not intended to be visible to an observer. The term

In CRT television sets and computer monitors, the entire front area of the tube is scanned repeatedly and systematically in a fixed pattern called a raster. In color devices, an image is produced by controlling the intensity of each of three electron beams, one for each additive primary color (red, green, and blue) with a video signal as a reference.magnetic deflection, using a deflection yoke. Electrostatic deflection is commonly used in oscilloscopes.

A CRT is a glass envelope which is deep (i.e., long from front screen face to rear end), heavy, and fragile. The interior is evacuated to 0.01 pascals (1×10−7 atm)×10−12 atm) or less,implosion that can hurl glass at great velocity. The face is typically made of thick lead glass or special barium-strontium glass to be shatter-resistant and to block most X-ray emissions. CRTs make up most of the weight of CRT TVs and computer monitors.

Since the mid-late 2000"s, CRTs have been superseded by flat-panel display technologies such as LCD, plasma display, and OLED displays which are cheaper to manufacture and run, as well as significantly lighter and less bulky. Flat-panel displays can also be made in very large sizes whereas 40 in (100 cm) to 45 in (110 cm)

Cathode rays were discovered by Julius Plücker and Johann Wilhelm Hittorf.cathode (negative electrode) which could cast shadows on the glowing wall of the tube, indicating the rays were traveling in straight lines. In 1890, Arthur Schuster demonstrated cathode rays could be deflected by electric fields, and William Crookes showed they could be deflected by magnetic fields. In 1897, J. J. Thomson succeeded in measuring the charge-mass-ratio of cathode rays, showing that they consisted of negatively charged particles smaller than atoms, the first "subatomic particles", which had already been named George Johnstone Stoney in 1891. The earliest version of the CRT was known as the "Braun tube", invented by the German physicist Ferdinand Braun in 1897.cold-cathode diode, a modification of the Crookes tube with a phosphor-coated screen. Braun was the first to conceive the use of a CRT as a display device.

The first cathode-ray tube to use a hot cathode was developed by John Bertrand Johnson (who gave his name to the term Johnson noise) and Harry Weiner Weinhart of Western Electric, and became a commercial product in 1922.

In 1926, Kenjiro Takayanagi demonstrated a CRT television receiver with a mechanical video camera that received images with a 40-line resolution.Philo Farnsworth created a television prototype.Vladimir K. Zworykin.: 84 RCA was granted a trademark for the term (for its cathode-ray tube) in 1932; it voluntarily released the term to the public domain in 1950.

In the 1930s, Allen B. DuMont made the first CRTs to last 1,000 hours of use, which was one of the factors that led to the widespread adoption of television.

In 1947, the cathode-ray tube amusement device, the earliest known interactive electronic game as well as the first to incorporate a cathode-ray tube screen, was created.

From 1949 to the early 1960s, there was a shift from circular CRTs to rectangular CRTs, although the first rectangular CRTs were made in 1938 by Telefunken.

1968 marks the release of Sony Trinitron brand with the model KV-1310, which was based on Aperture Grille technology. It was acclaimed to have improved the output brightness. The Trinitron screen was identical with its upright cylindrical shape due to its unique triple cathode single gun construction.

In 1987, flat-screen CRTs were developed by Zenith for computer monitors, reducing reflections and helping increase image contrast and brightness.float glass.

In the mid-2000s, Canon and Sony presented the surface-conduction electron-emitter display and field-emission displays, respectively. They both were flat-panel displays that had one (SED) or several (FED) electron emitters per subpixel in place of electron guns. The electron emitters were placed on a sheet of glass and the electrons were accelerated to a nearby sheet of glass with phosphors using an anode voltage. The electrons were not focused, making each subpixel essentially a flood beam CRT. They were never put into mass production as LCD technology was significantly cheaper, eliminating the market for such displays.

Beginning in the late 90s to the early 2000s, CRTs began to be replaced with LCDs, starting first with computer monitors smaller than 15 inches in size,Hitachi in 2001,Flat-panel displays dropped in price and started significantly displacing cathode-ray tubes in the 2000s. LCD monitor sales began exceeding those of CRTs in 2003–2004

Despite being a mainstay of display technology for decades, CRT-based computer monitors and televisions are now virtually a dead technology. Demand for CRT screens dropped in the late 2000s.

Some industries still use CRTs because it is either too much effort, downtime, and/or cost to replace them, or there is no substitute available; a notable example is the airline industry. Planes such as the Boeing 747-400 and the Airbus A320 used CRT instruments in their glass cockpits instead of mechanical instruments.Lufthansa still use CRT technology, which also uses floppy disks for navigation updates.

A popular consumer usage of CRTs is for retrogaming. Some games are impossible to play without CRT display hardware, and some games play better. Reasons for this include:

The size of the screen of a CRT is measured in two ways: the size of the screen or the face diagonal, and the viewable image size/area or viewable screen diagonal, which is the part of the screen with phosphor. The size of the screen is the viewable image size plus its black edges which are not coated with phosphor.

Small CRTs below 3 inches were made for handheld televisions such as the MTV-1 and viewfinders in camcorders. In these, there may be no black edges, that are however truly flat.

Most of the weight of a CRT comes from the thick glass screen, which comprises 65% of the total weight of a CRT. The funnel and neck glass comprise the remaining 30% and 5% respectively. The glass in the funnel is thinner than on the screen.

The outer conductive coating is connected to ground while the inner conductive coating is connected using the anode button/cap through a series of capacitors and diodes (a Cockcroft–Walton generator) to the high voltage flyback transformer; the inner coating is the anode of the CRT,voltage multiplier for the current delivered by the flyback.

The anode is used to accelerate the electrons towards the screen and also collects the secondary electrons that are emitted by the phosphor particles in the vacuum of the CRT.

The anode cap connection in modern CRTs must be able to handle up to 55–60 kV depending on the size and brightness of the CRT. Higher voltages allow for larger CRTs, higher image brightness, or a tradeoff between the two.corona discharge.

The anode button must be specially shaped to establish a hermetic seal between the button and funnel. X-rays may leak through the anode button, although that may not be the case in newer CRTs starting from the late 1970s to early 1980s, thanks to a new button and clip design.

The flyback transformer is also known as an IHVT (Integrated High Voltage Transformer) if it includes a voltage multiplier. The flyback uses a ceramic or powdered iron core to enable efficient operation at high frequencies. The flyback contains one primary and many secondary windings that provide several different voltages. The main secondary winding supplies the voltage multiplier with voltage pulses to ultimately supply the CRT with the high anode voltage it uses, while the remaining windings supply the CRT"s filament voltage, keying pulses, focus voltage and voltages derived from the scan raster. When the transformer is turned off, the flyback"s magnetic field quickly collapses which induces high voltage in its windings. The speed at which the magnetic field collapses determines the voltage that is induced, so the voltage increases alongside its speed. A capacitor (Retrace Timing Capacitor) or series of capacitors (to provide redundancy) is used to slow the collapse of the magnetic field.

The design of the high voltage power supply in a product using a CRT has an influence in the amount of x-rays emitted by the CRT. The amount of emitted x-rays increases with both higher voltages and currents. If the product such as a TV set uses an unregulated high voltage power supply, meaning that anode and focus voltage go down with increasing electron current when displaying a bright image, the amount of emitted x-rays is as its highest when the CRT is displaying a moderately bright images, since when displaying dark or bright images, the higher anode voltage counteracts the lower electron beam current and vice versa respectively. The high voltage regulator and rectifier vacuum tubes in some old CRT TV sets may also emit x-rays.

The electron gun emits the electrons that ultimately hit the phosphors on the screen of the CRT. The electron gun contains a heater, which heats a cathode, which generates electrons that, using grids, are focused and ultimately accelerated into the screen of the CRT. The acceleration occurs in conjunction with the inner aluminum or aquadag coating of the CRT. The electron gun is positioned so that it aims at the center of the screen.

It has a hot cathode that is heated by a tungsten filament heating element; the heater may draw 0.5 to 2 A of current depending on the CRT. The voltage applied to the heater can affect the life of the CRT.

There are several shortcircuits that can occur in a CRT electron gun. One is a heater-to-cathode short, that causes the cathode to permanently emit electrons which may cause an image with a bright red, green or blue tint with retrace lines, depending on the cathode (s) affected. Alternatively, the cathode may short to the control grid, possibly causing similar effects, or, the control grid and screen grid (G2)sputtering.

Since it is a hot cathode, it is prone to cathode poisoning, which is the formation of a positive ion layer that prevents the cathode from emitting electrons, reducing image brightness significantly or completely and causing focus and intensity to be affected by the frequency of the video signal preventing detailed images from being displayed by the CRT. The positive ions come from leftover air molecules inside the CRT or from the cathode itself

The amount of electrons generated by the cathodes is related to their surface area. A cathode with more surface area creates more electrons, in a larger electron cloud, which makes focusing the electron cloud into an electron beam more difficult.

The second (screen) grid of the gun (G2) accelerates the electrons towards the screen using several hundred DC volts. A negative currentWehnelt cylinder.

However, electrostatic focusing cannot be accomplished near the final anode of the CRT due to its high voltage in the dozens of Kilovolts, so a high voltage (≈600

There is a voltage called cutoff voltage which is the voltage that creates black on the screen since it causes the image on the screen created by the electron beam to disappear, the voltage is applied to G1. In a color CRT with three guns, the guns have different cutoff voltages. Many CRTs share grid G1 and G2 across all three guns, increasing image brightness and simplifying adjustment since on such CRTs there is a single cutoff voltage for all three guns (since G1 is shared across all guns).

During retracing of the electron beam, the preamplifier that feeds the video amplifier is disabled and the video amplifier is biased to a voltage higher than the cutoff voltage to prevent retrace lines from showing, or G1 can have a large negative voltage applied to it to prevent electrons from getting out of the cathode.Vertical blanking interval and Horizontal blanking interval.) Incorrect biasing can lead to visible retrace lines on one or more colors, creating retrace lines that are tinted or white (for example, tinted red if the red color is affected, tinted magenta if the red and blue colors are affected, and white if all colors are affected).

The electron beam may be affected by the earth"s magnetic field, causing it to normally enter the focusing lens off-center; this can be corrected using astigmation controls. Astigmation controls are both magnetic and electronic (dynamic); magnetic does most of the work while electronic is used for fine adjustments.

Some electron guns have a quadrupole lens with dynamic focus to alter the shape and adjust the focus of the electron beam, varying the focus voltage depending on the position of the electron beam to maintain image sharpness across the entire screen, specially at the corners.

The electron guns in color CRTs are driven by a video amplifier which takes a signal per color channel and amplifies it to 40-170v per channel, to be fed into the electron gun"s cathodes;

CRTs have a pronounced triode characteristic, which results in significant gamma (a nonlinear relationship in an electron gun between applied video voltage and beam intensity).

There are two types of deflection: magnetic and electrostatic. Magnetic is usually used in TVs and monitors as it allows for higher deflection angles (and hence shallower CRTs) and deflection power (which allows for higher electron beam current and hence brighter images)

The deflection coils are driven by sawtooth signalsHorizontal scan rate) of 15 to 240 kHz depending on the refresh rate of the CRT and the number of horizontal lines to be drawn (the vertical resolution of the CRT). The higher frequency makes it more susceptible to interference, so an automatic frequency control (AFC) circuit may be used to lock the phase of the horizontal deflection signal to that of a sync signal, to prevent the image from becoming distorted diagonally. The vertical frequency varies according to the refresh rate of the CRT. So a CRT with a 60 Hz refresh rate has a vertical deflection circuit running at 60 Hz. The horizontal and vertical deflection signals may be generated using two circuits that work differently; the horizontal deflection signal may be generated using a voltage controlled oscillator (VCO) while the vertical signal may be generated using a triggered relaxation oscillator. In many TVs, the frequencies at which the deflection coils run is in part determined by the inductance value of the coils.

Due to the high frequency at which the horizontal deflection coils operate, the energy in the deflection coils must be recycled to reduce heat dissipation. Recycling is done by transferring the energy in the deflection coils" magnetic field to a set of capacitors.

Mostly used in oscilloscopes. Deflection is carried out by applying a voltage across two pairs of plates, one for horizontal, and the other for vertical deflection. The electron beam is steered by varying the voltage difference across plates in a pair; For example, applying a voltage to the upper plate of the vertical deflection pair, while keeping the voltage in the bottom plate at 0 volts, will cause the electron beam to be deflected towards the upper part of the screen; increasing the voltage in the upper plate while keeping the bottom plate at 0 will cause the electron beam to be deflected to a higher point in the screen (will cause the beam to be deflected at a higher deflection angle). The same applies with the horizontal deflection plates. Increasing the length and proximity between plates in a pair can also increase the deflection angle.

Burn-in is when images are physically "burned" into the screen of the CRT; this occurs due to degradation of the phosphors due to prolonged electron bombardment of the phosphors, and happens when a fixed image or logo is left for too long on the screen, causing it to appear as a "ghost" image or, in severe cases, also when the CRT is off. To counter this, screensavers were used in computers to minimize burn-in.

CRTs are evacuated or exhausted (a vacuum is formed) inside an oven at approx. 375–475 °C, in a process called baking or bake-out.turbomolecular pump or a diffusion pump.getter is then fired using an RF (induction) coil. The getter is usually in the funnel or in the neck of the CRT.

CRTs used to be rebuilt; repaired or refurbished. The rebuilding process included the disassembly of the CRT, the disassembly and repair or replacement of the electron gun(s), the removal and redeposition of phosphors and aquadag, etc. Rebuilding was popular until the 1960s because CRTs were expensive and wore out quickly, making repair worth it.

Also known as rejuvenation, the goal is to temporarily restore the brightness of a worn CRT. This is often done by carefully increasing the voltage on the cathode heater and the current and voltage on the control grids of the electron gun manually

Phosphors in CRTs emit secondary electrons due to them being inside the vacuum of the CRT. The secondary electrons are collected by the anode of the CRT.

SMPTE-C phosphors have properties defined by the SMPTE-C standard, which defines a color space of the same name. The standard prioritizes accurate color reproduction, which was made difficult by the different phosphors and color spaces used in the NTSC and PAL color systems. PAL TV sets have subjectively better color reproduction due to the use of saturated green phosphors, which have relatively long decay times that are tolerated in PAL since there is more time in PAL for phosphors to decay, due to its lower framerate. SMPTE-C phosphors were used in professional video monitors.

The phosphor coating on monochrome and color CRTs may have an aluminum coating on its rear side used to reflect light forward, provide protection against ions to prevent ion burn by negative ions on the phosphor, manage heat generated by electrons colliding against the phosphor,

Various phosphors are available depending upon the needs of the measurement or display application. The brightness, color, and persistence of the illumination depends upon the type of phosphor used on the CRT screen. Phosphors are available with persistences ranging from less than one microsecond to several seconds.

Variations in anode voltage can lead to variations in brightness in parts or all of the image, in addition to blooming, shrinkage or the image getting zoomed in or out. Lower voltages lead to blooming and zooming in, while higher voltages do the opposite.

Doming is a phenomenon found on some CRT televisions in which parts of the shadow mask become heated. In televisions that exhibit this behavior, it tends to occur in high-contrast scenes in which there is a largely dark scene with one or more localized bright spots. As the electron beam hits the shadow mask in these areas it heats unevenly. The shadow mask warps due to the heat differences, which causes the electron gun to hit the wrong colored phosphors and incorrect colors to be displayed in the affected area.

Bimetal springs may be used in CRTs used in TVs to compensate for warping that occurs as the electron beam heats the shadow mask, causing thermal expansion.

Aperture grille screens are brighter since they allow more electrons through, but they require support wires. They are also more resistant to warping.

Size is limited by anode voltage, as it would require a higher dielectric strength to prevent arcing (corona discharge) and the electrical losses and ozone generation it causes, without sacrificing image brightness. The weight of the CRT, which originates from the thick glass needed to safely sustain a vacuum, imposes a practical limit on the size of a CRT.

At high deflection angles, resolutions and refresh rates (since higher resolutions and refresh rates require significantly higher frequencies to be applied to the horizontal deflection coils), the deflection yoke starts to produce large amounts of heat, due to the need to move the electron beam at a higher angle, which in turn requires exponentially larger amounts of power. As an example, to increase the deflection angle from 90 to 120°, power consumption of the yoke must also go up from 40 watts to 80 watts, and to increase it further from 120 to 150°, deflection power must again go up from 80 watts to 160 watts. This normally makes CRTs that go beyond certain deflection angles, resolutions and refresh rates impractical, since the coils would generate too much heat due to resistance caused by the skin effect, surface and eddy current losses, and/or possibly causing the glass underneath the coil to become conductive (as the electrical conductivity of glass decreases with increasing temperature). Some deflection yokes are designed to dissipate the heat that comes from their operation.

On CRTs, refresh rate depends on resolution, both of which are ultimately limited by the maximum horizontal scanning frequency of the CRT. Motion blur also depends on the decay time of the phosphors. Phosphors that decay too slowly for a given refresh rate may cause smearing or motion blur on the image. In practice, CRTs are limited to a refresh rate of 160 Hz.quantum dot LCDs (QLEDs) are available in high refresh rates (up to 144 Hz)

CRT monitors can still outperform LCD and OLED monitors in input lag, as there is no signal processing between the CRT and the display connector of the monitor, since CRT monitors often use VGA which provides an analog signal that can be fed to a CRT directly. Video cards designed for use with CRTs may have a RAMDAC to generate the analog signals needed by the CRT.multisyncing.

Picture tube CRTs have overscan, meaning the actual edges of the image are not shown; this is deliberate to allow for adjustment variations between CRT TVs, preventing the ragged edges (due to blooming) of the image from being shown on screen. The shadow mask may have grooves that reflect away the electrons that do not hit the screen due to overscan.

If the CRT is a black and white (B&W or monochrome) CRT, there is a single electron gun in the neck and the funnel is coated on the inside with aluminum that has been applied by evaporation; the aluminum is evaporated in a vacuum and allowed to condense on the inside of the CRT.ion traps, necessary to prevent ion burn on the phosphor, while also reflecting light generated by the phosphor towards the screen, managing heat and absorbing electrons providing a return path for them; previously funnels were coated on the inside with aquadag, used because it can be applied like paint;

The screen, funnel and neck are fused together into a single envelope, possibly using lead enamel seals, a hole is made in the funnel onto which the anode cap is installed and the phosphor, aquadag and aluminum are applied afterwards.

The interior aquadag or aluminum coating was the anode and served to accelerate the electrons towards the screen, collect them after hitting the screen while serving as a capacitor together with the outer aquadag coating. The screen has a single uniform phosphor coating and no shadow mask, technically having no resolution limit.

Monochrome CRTs may use ring magnets to adjust the centering of the electron beam and magnets around the deflection yoke to adjust the geometry of the image.

Color CRTs use three different phosphors which emit red, green, and blue light respectively. They are packed together in stripes (as in aperture grille designs) or clusters called "triads" (as in shadow mask CRTs).

Color CRTs have three electron guns, one for each primary color, (red, green and blue) arranged either in a straight line (in-line) or in an equilateral triangular configuration (the guns are usually constructed as a single unit).

A shadow mask tube uses a metal plate with tiny holes, typically in a delta configuration, placed so that the electron beam only illuminates the correct phosphors on the face of the tube;aperture grille of tensioned vertical wires to achieve the same result.

Trinitron CRTs were different from other color CRTs in that they had a single electron gun with three cathodes, an aperture grille which lets more electrons through, increasing image brightness (since the aperture grille does not block as many electrons), and a vertically cylindrical screen, rather than a curved screen.

The three electron guns are in the neck (except for Trinitrons) and the red, green and blue phosphors on the screen may be separated by a black grid or matrix (called black stripe by Toshiba).

Shadow masks were replaced in TVs by slot masks in the 1970s, since slot masks let more electrons through, increasing image brightness. Shadow masks may be connected electrically to the anode of the CRT.Cromaclear; Trinitron and Diamondtron use aperture grilles while Cromaclear uses a slot mask. Some shadow mask CRTs have color phosphors that are smaller in diameter than the electron beams used to light them,

Several methods were used to create the black matrix. One method coated the screen in photoresist such as dichromate-sensitized polyvinyl alcohol photoresist which was then dried and exposed; the unexposed areas were removed and the entire screen was coated in colloidal graphite to create a carbon film, and then hydrogen peroxide was used to remove the remaining photoresist alongside the carbon that was on top of it, creating holes that in turn created the black matrix. The photoresist had to be of the correct thickness to ensure sufficient adhesion to the screen, while the exposure step had to be controlled to avoid holes that were too small or large with ragged edges caused by light diffraction, ultimately limiting the maximum resolution of large color CRTs.

After the screen is coated with phosphor and aluminum and the shadow mask installed onto it the screen is bonded to the funnel using a glass frit that may contain 65 to 88% of lead oxide by weight. The lead oxide is necessary for the glass frit to have a low melting temperature. Boron oxide (III) may also present to stabilize the frit, with alumina powder as filler powder to control the thermal expansion of the frit.amyl acetate or in a polymer with an alkyl methacrylate monomer together with an organic solvent to dissolve the polymer and monomer.

Due to limitations in the dimensional precision with which CRTs can be manufactured economically, it has not been practically possible to build color CRTs in which three electron beams could be aligned to hit phosphors of respective color in acceptable coordination, solely on the basis of the geometric configuration of the electron gun axes and gun aperture positions, shadow mask apertures, etc. The shadow mask ensures that one beam will only hit spots of certain colors of phosphors, but minute variations in physical alignment of the internal parts among individual CRTs will cause variations in the exact alignment of the beams through the shadow mask, allowing some electrons from, for example, the red beam to hit, say, blue phosphors, unless some individual compensation is made for the variance among individual tubes.

Color convergence and color purity are two aspects of this single problem. Firstly, for correct color rendering it is necessary that regardless of where the beams are deflected on the screen, all three hit the same spot (and nominally pass through the same hole or slot) on the shadow mask.intaglio printed with poor registration. Poor purity causes objects on the screen to appear off-color while their edges remain sharp. Purity and convergence problems can occur at the same time, in the same or different areas of the screen or both over the whole screen, and either uniformly or to greater or lesser degrees over different parts of the screen.

The solution to the static convergence and purity problems is a set of color alignment ring magnets installed around the neck of the CRT.magnetic fields parallel to the planes of the magnets, which are perpendicular to the electron gun axes. Often, one ring has two poles, another has 4, and the remaining ring has 6 poles.vector can be fully and freely adjusted (in both direction and magnitude). By rotating a pair of magnets relative to each other, their relative field alignment can be varied, adjusting the effective field strength of the pair. (As they rotate relative to each other, each magnet"s field can be considered to have two opposing components at right angles, and these four components [two each for two magnets] form two pairs, one pair reinforcing each other and the other pair opposing and canceling each other. Rotating away from alignment, the magnets" mutually reinforcing field components decrease as they are traded for increasing opposed, mutually cancelling components.) By rotating a pair of magnets together, preserving the relative angle between them, the direction of their collective magnetic field can be varied. Overall, adjusting all of the convergence/purity magnets allows a finely tuned slight electron beam deflection or lateral offset to be applied, which compensates for minor static convergence and purity errors intrinsic to the uncalibrated tube. Once set, these magnets are usually glued in place, but normally they can be freed and readjusted in the field (e.g. by a TV repair shop) if necessary.

On some CRTs, additional fixed adjustable magnets are added for dynamic convergence or dynamic purity at specific points on the screen, typically near the corners or edges. Further adjustment of dynamic convergence and purity typically cannot be done passively, but requires active compensation circuits, one to correct convergence horizontally and another to correct it vertically. The deflection yoke contains convergence coils, a set of two per color, wound on the same core, to which the convergence signals are applied. That means 6 convergence coils in groups of 3, with 2 coils per group, with one coil for horizontal convergence correction and another for vertical convergence correction, with each group sharing a core. The groups are separated 120° from one another. Dynamic convergence is necessary because the front of the CRT and the shadow mask aren"t spherical, compensating for electron beam defocusing and astigmatism. The fact that the CRT screen isn"t spherical

The convergence signal may instead be a sawtooth signal with a slight sine wave appearance, the sine wave part is created using a capacitor in series with each deflection coil. In this case, the convergence signal is used to drive the deflection coils. The sine wave part of the signal causes the electron beam to move more slowly near the edges of the screen. The capacitors used to create the convergence signal are known as the s-capacitors. This type of convergence is necessary due to the high deflection angles and flat screens of many CRT computer monitors. The value of the s-capacitors must be chosen based on the scan rate of the CRT, so multi-syncing monitors must have different sets of s-capacitors, one for each refresh rate.

Dynamic convergence may instead be accomplished in some CRTs using only the ring magnets, magnets glued to the CRT, and by varying the position of the deflection yoke, whose position may be maintained using set screws, a clamp and rubber wedges.

Dynamic color convergence and purity are one of the main reasons why until late in their history, CRTs were long-necked (deep) and had biaxially curved faces; these geometric design characteristics are necessary for intrinsic passive dynamic color convergence and purity. Only starting around the 1990s did sophisticated active dynamic convergence compensation circuits become available that made short-necked and flat-faced CRTs workable. These active compensation circuits use the deflection yoke to finely adjust beam deflection according to the beam target location. The same techniques (and major circuit components) also make possible the adjustment of display image rotation, skew, and other complex raster geometry parameters through electronics under user control.

The guns are aligned with one another (converged) using convergence rings placed right outside the neck; there is one ring per gun. The rings have north and south poles. There are 4 sets of rings, one to adjust RGB convergence, a second to adjust Red and Blue convergence, a third to adjust vertical raster shift, and a fourth to adjust purity. The vertical raster shift adjusts the straightness of the scan line. CRTs may also employ dynamic convergence circuits, which ensure correct convergence at the edges of the CRT. Permalloy magnets may also be used to correct the convergence at the edges. Convergence is carried out with the help of a crosshatch (grid) pattern.

If the shadow mask or aperture grille becomes magnetized, its magnetic field alters the paths of the electron beams. This causes errors of "color purity" as the electrons no longer follow only their intended paths, and some will hit some phosphors of colors other than the one intended. For example, some electrons from the red beam may hit blue or green phosphors, imposing a magenta or yellow tint to parts of the image that are supposed to be pure red. (This effect is localized to a specific area of the screen if the magnetization is localized.) Therefore, it is important that the shadow mask or aperture grille not be magnetized. The earth"s magnetic field may have an effect on the color purity of the CRT.

Color CRT displays in television sets and computer monitors often have a built-in degaussing (demagnetizing) coil mounted around the perimeter of the CRT face. Upon power-up of the CRT display, the degaussing circuit produces a brief, alternating current through the coil which fades to zero over a few seconds, producing a decaying alternating magnetic field from the coil. This degaussing field is strong enough to remove shadow mask magnetization in most cases, maintaining color purity.deform (bend) the shadow mask, causing a permanent color distortion on the display which looks very similar to a magnetization effect.

Dot pitch defines the maximum resolution of the display, assuming delta-gun CRTs. In these, as the scanned resolution approaches the dot pitch resolution, moiré appears, as the detail being displayed is finer than what the shadow mask can render.

Projector CRTs were available with electrostatic and electromagnetic focusing, the latter being more expensive. Electrostatic focusing used electronics to focus the electron beam, together with focusing magnets around the neck of the CRT for fine focusing adjustments. This type of focusing degraded over time. Electromagnetic focusing was introduced in the early 1990s and included an electromagnetic focusing coil in addition to the already existing focusing magnets. Electromagnetic focusing was much more stable over the lifetime of the CRT, retaining 95% of its sharpness by the end of life of the CRT.

Beam-index tubes, also known as Uniray, Apple CRT or Indextron,Philco to create a color CRT without a shadow mask, eliminating convergence and purity problems, and allowing for shallower CRTs with higher deflection angles.

Flat CRTs are those with a flat screen. Despite having a flat screen, they may not be completely flat, especially on the inside, instead having a greatly increased curvature. A notable exception is the LG Flatron (made by LG.Philips Displays, later LP Displays) which is truly flat on the outside and inside, but has a bonded glass pane on the screen with a tensioned rim band to provide implosion protection. Such completely flat CRTs were first introduced by Zenith in 1986, and used

flat tensioned shadow masks, where the shadow mask is held under tension, providing increased resistance to blooming.TV80, and in many Sony Watchmans were flat in that they were not deep and their front screens were flat, but their electron guns were put to a side of the screen.

Radar CRTs such as the 7JP4 had a circular screen and scanned the beam from the center outwards. The screen often had two colors, often a bright short persistence color that only appeared as the beam scanned the display and a long persistence phosphor afterglow. When the beam strikes the phosphor, the phosphor brightly illuminates, and when the beam leaves, the dimmer long persistence afterglow would remain lit where the beam struck the phosphor, alongside the radar targets that were "written" by the beam, until the beam re-struck the phosphor.

In oscilloscope CRTs, electrostatic deflection is used, rather than the magnetic deflection commonly used with television and other large CRTs. The beam is deflected horizontally by applying an electric field between a pair of plates to its left and right, and vertically by applying an electric field to plates above and below. Televisions use magnetic rather than electrostatic deflection because the deflection plates obstruct the beam when the deflection angle is as large as is required for tubes that are relatively short for their size. Some Oscilloscope CRTs incorporate post deflection anodes (PDAs) that are spiral-shaped to ensure even anode potential across the CRT and operate at up to 15,000 volts. In PDA CRTs the electron beam is deflected before it is accelerated, improving sensitivity and legibility, specially when analyzing voltage pulses with short duty cycles.

When displaying fast one-shot events, the electron beam must deflect very quickly, with few electrons impinging on the screen, leading to a faint or invisib

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey