nanotechnology display screens free sample

Since Charles Wheatstone first invented stereoscopy, the research interest in three-dimensional (3D) displays has extended for 150 years, and its history is as long as that of photography (Charles, 1838). As a more natural way to present virtual data, glasses-free 3D displays show great prospects in various fields including education, military, medical, entertainment, automobile, etc. According to a survey, people spend an average of 5 h every day watching display panel screens. The visualization of 3D images will have a huge impact on improving work efficiency. Therefore, glasses-free 3D displays are regarded as next-generation display technology.

Generally, we assign glasses-free 3D displays into three main categories: holographic 3D displays, volumetric 3D displays and autostereoscopic 3D displays (Geng, 2013). A holographic 3D display is a technology that records both the amplitude and phase information of a real object and reproduces it through specific mediums (e.g., photorefractive polymers) (Tay et al., 2008; Blanche et al., 2010). Furthermore, by using a spatial light modulator that directly modulates the coherent wave, computer-generated hologram systems can be implemented via numerical simulation. (Hahn et al., 2008; Sasaki et al., 2014). Currently, powerful acceleration chips or video processors have enabled the reproduction of high-quality 3D holograms at video rates (An et al., 2020; Shi et al., 2021). In the future, real-time holographic 3D displays will have wide applications in mobile displays and AR displays (Peng et al., 2021; Lee et al., 2022). Volumetric 3D display is another technology that generates luminous image points (i.e., voxels) in space via special media, such as trapped particles and fluorescent screens. These image points form 3D graphics that can be observed within 360° (Kumagai et al., 2015; Kumagai et al., 2018; Smalley et al., 2018; Hirayama et al., 2019). Both the holographic 3D display and volumetric 3D display require a large amount of data to provide 3D content, which brings challenges to data processing and transportation.

In contrast, autostereoscopic 3D displays reduce computing costs by discretizing a continuously distributed light field of 3D objects into multiple “views”. The properly arranged perspective views can approximate the 3D images with motion parallax and stereo parallax. Moreover, by modulating the irradiance pattern of each view, only a small number of views are required to reconstruct the light field. A typical autostereoscopic 3D display only needs to integrate two components: an optical element and an off-the-shelf refreshable display panel (e.g., liquid crystal display, organic light-emitting diode display, light-emitting diode display) (Dodgson, 2005). With the advantages of a compact form factor, ease of integration with flat display devices, ease of modulation, and low cost, autostereoscopic 3D displays can be applied in portable electronics and redefine human-computer interfaces. The function of the optical element in an autostereoscopic 3D display is to manipulate the incident light and generate a finite number of views. To improve the display effect, the optical elements also need to modulate the views and angular separation between views, which is called the “view modulator” in this paper. View modulators represent a special class of optical elements that are used in glass-free 3D displays for view modulation, such as parallax barriers, lenticular lens arrays, and metagratings.

One of the most critical issues in autostereoscopic 3D displays is how to design view modulators. When we design view modulators, several essential problems need to be considered that are directly related to 3D display performance (Figure 1): 1) To minimize crosstalk and ghost images, the view modulators should confine the emerging light within a well-defined region; 2) To address the vergence-accommodation conflict, the view modulators need to provide both correct vergence and accommodation cues. Vergence-accommodation conflict occurs when the depth of 3D images induced by binocular parallax lies in front of or behind the display screen, whereas the depth recognized by a single eye is fixed at the apparent location of the physical display panel because the image observed by a single eye is 2D (Zou et al., 2015; Koulieris et al., 2017); 3) To achieve a large field of view (FOV), the view modulators need to precisely manipulate light over a large steering angle; 4) For an energy-efficient system, the light efficiency of the view modulators needs to be adequate. In addition to these four important factors that affect the optical performance of 3D displays, there are some additional features that should be addressed in applications; 5) To maintain a thin form factor and be lightweight for portable electronics, the design of view modulators should be elegant with as few layers or components as possible; 6) To solve the tradeoff between spatial resolution, angular resolution, and FOV, the view modulators should manipulate the shape of view for variant information density. 7) In window display applications, the view modulators should be transparent to combine virtual 3D images with physical objects for glasses-free augmented reality display.

Depending on the types of adopted view modulators, autostereoscopic 3D displays can be divided into geometrical optics-based and planar optics-based systems. With regard to geometrical optics-based 3D displays, the most representative architectures are parallax barrier or lenticular lens array-based, microlens array-based and layer-based systems (Ma et al., 2019). The parallax barrier or lenticular lens array was first integrated with flat panels and applied in 3D mobile electronic devices because of the advantages of utilizing existing 2D screen fabrication infrastructure (Ives, 1902; Kim et al., 2016; Yoon et al., 2016; Lv et al., 2017; Huang et al., 2019). For improved display performance, aperture stops were inserted into the system to reduce the crosstalk by decreasing the aperture ratio; however, this strategy comes at the expense of light efficiency (Wang et al., 2010; Liang et al., 2014; Lv et al., 2014). Microlens array-based 3D display, i.e., integral imaging display generates stereoscopic images by recording and reproducing the rays from 3D objects (Lippmann, 1908; Martínez-Corral and Javidi, 2018; Javidi et al., 2020). It can present full motion parallax by adding light manipulating power in a different direction. Recently, a bionic compound eye structure was proposed to enhance the performance of integral imaging 3D display systems. With proper design based on geometric optics, the 3D display prototype can be used to obtain a 28° horizontal, 22° vertical viewing angle, approximately two times that of a normal integral imaging display (Zhao et al., 2020). In another work, an integral imaging 3D display system that can enhance both the pixel density and viewing angle was proposed, with parallel projection of ultrahigh-definition elemental images (Watanabe et al., 2020). This prototype display system reproduced 3D images with a horizontal pixel density of 63.5 ppi and viewing angles of 32.8° and 26.5° in the horizontal and vertical directions, respectively. Furthermore, with three groups of directional backlight and a fast-switching liquid crystal display (LCD) panel, a time-multiplexed integral imaging 3D display with a 120° wide viewing angle was demonstrated (Liu et al., 2019). The layer-based 3D display invented by Lanman and Wetzstein (Lanman et al., 2010; Lanman et al., 2011; Wetzstein et al., 2011; Wetzstein et al., 2012) used multiple LCD screen layers to modulate the light field of 3D objects. This display can provide both vergence and accommodation cues for viewers with limited fatigue and dizziness (Maimone et al., 2013). Nevertheless, its FOV is limited by the effective size of the display panel. Moreover, layer-based 3D displays also suffer from a trade-off between the depth of field and the complexity of the system (i.e., the layer number for the display devices). In general, geometrical optics-based autostereoscopic 3D displays have the advantages of low cost and thin form factors that are compatible with 2D flat display panels. However, we still have a fair way to go due to the tradeoffs among the resolution, FOV, depth cues, depth of field and form factor (Qiao et al., 2020). Alleviating these tradeoffs and improving the image quality to provide more realistic stereoscopic vision has opened up an intriguing avenue for developing next-generation 3D display technology.

Fast-growing planar optics have attracted wide attention in various fields because of their outstanding capability for light control (Genevet et al., 2017; Zhang and Fang, 2019; Chen and Segev, 2021; Tabiryan et al., 2021; Xiong and Wu, 2021). In the field of glasses-free 3D displays, planar optical elements, such as diffraction gratings, diffractive lenses and metasurfaces, can be used to modulate the light field of 3D objects at the pixel level. With proper design, planar optical elements at the micro or nano scale provide superior light manipulation capability in terms of light intensity, phase, and polarization. Therefore, planar optics-based glass-free 3D displays have several merits, such as reduced crosstalk, no vergence-accommodation conflict, enhanced light efficiency, and an enlarged FOV. Figure 2 shows the developing trend for 3D display technologies with regard to the revolution of view modulators. Planar optics are becoming the “next-generation 3D display technology” because of outstanding view modulation flexibility.

FIGURE 2. Schematic of the development of glasses-free 3D displays with regard to the revolution of view modulators. LLA: Lenticular lens array; MLA: Microlens array.

In this review, the critical challenges for glasses-free 3D displays are analyzed. Planar optics-based 3D displays suggest a variety of solutions for 3D displays, which will be reviewed in the section Glasses-Free 3D Display Based on Planar Optical Elements. As a specific application and an appealing feature, augmented reality (AR) 3D displays enabled by planar optics will be comprehensively introduced in the section Glasses-Free augmented reality 3D display based on planar optical elements. In addition to the design of view modulators, the fabrication of view modulators is another challenge that hinders the development of 3D displays. Therefore, in the section Fabrication of Large-Scale Micro/Nanostructures on View Modulators for 3D Displays, we will highlight multiple micro/nanofabrication methods for view modulators in 3D displays. In the section Conclusions and Outlook, the current status for glasses-free 3D displays and glasses-free AR 3D displays will be summarized. Finally, future directions and potential applications are suggested in the section Conclusions and Outlook.

Diffraction gratings are unique components that can split incident light into many spatial directions simultaneously and have been widely used in steering devices, such as spectrometers, optical waveguides and laser resonators (Zola et al., 2019; Cao et al., 2020; Görrn et al., 2011; Zhang et al., 2019; Liu et al., 2020). Fattal et al. employed diffraction gratings in a 3D display and proposed a directional diffractive backlight to produce full parallax views within a wide FOV (Fattal et al., 2013). The key elements in the backlight were pixelated grating patterns fabricated by electron-beam lithography. Both passive and active prototypes provided 64-view images within a FOV of 90°. The diffractive wide-angle backlight is regarded as a revolutionary 3D display (https://www.technologyreview.com/innovator/david-fattal). It has opened up rich opportunities for planar optics-based glasses-free 3D displays.

On this basis, a holographic sampling 3D display was proposed by combining a phase plate with a thin film transistor-LCD panel (Wan et al., 2017) (Figure 3A). The phase plate modulates the phase information, while the LCD panel provides refreshable amplitude information for the light field. Notably, the period and orientation of the diffraction gratings in each pixel are calculated to form converged beams instead of (semi)parallel beams in a geometrical optics-based 3D display. As a result, the angular divergence of target viewpoints (1.02°) is confined close to the diffraction limit (0.94°), leading to significantly reduced crosstalk and ghost images (Figures 3B,C). The researchers further presented a holographic sampling 3D display based on metagratings and demonstrated a video rate full-color 3D display prototype with sizes ranging from 5 to 32 inches (Figure 3D) (Wan et al., 2020). The metagratings on the view modulator were designed to operate at the R/G/B wavelength to reconstruct the wavefront at sampling viewpoints with the correct white balance (Figure 3E). By combining the view modulator, a LCD panel and a color filter, virtual 3D whales were presented, as shown in Figure 3F. To address the vergence-accommodation conflict in 3D displays, a super multiview display was also proposed based on pixelated gratings. Closely packaged views with an angular separation of 0.9° provide a depth cue for the accommodation process of the human eye (Wan et al., 2020).

FIGURE 3. (A) Schematic of the proposed holographic sampling 3D display. (B) Photograph of 4 views and the light intensity distribution at 4 views. (C) 3D images of a car running through trees. (D) Schematic of the full-color video rate holographic sampling 3D display. (E) The radiation pattern measured from a 16-view point view modulator. (F) 3D images of whales and logos. [(A–C) Reproduced from Wan et al. (2013). Copyright (2021) with permission from Optica Publishing Group. (D–F) Reproduced from Wan et al. (2020). Copyright (2021) with permission from Elsevier B.V.].

To summarize, diffraction grating-based 3D displays have the advantages of minimum crosstalk, reduced vergence-accommodation conflict, tailorable view arrangement, continuous motion parallax and a wide FOV. Nevertheless, the experimental diffraction efficiency of binary gratings is approximately 20%, leading to inevitable high-power consumption. On this basis, diffractive lenses and metasurfaces are employed for 3D displays.

Light efficiency is a crucial parameter in glass-free 3D display systems. Diffractive lenses with blazed structures can be used to focus light together, thereby showing higher light efficiency in 3D displays than diffraction gratings. As shown in Figures 4A,B, pixelated blazed diffractive lenses are introduced in a 3D display to form four independent convergent views, while the amplitude plate provides the images at these views. The system has the following benefits. First, each structured pixel on the view modulator is calculated by the relative position relationship between the pixel and viewing points. These accurately calculated aperiodic structures can improve the precision of light manipulation, thereby eliminating crosstalk and ghost images. Second, the 4-level blazed diffractive lens greatly increases the diffraction efficiency of the grating-based 3D display from 20 to 60% (Zhou et al., 2020). In another work, a view modulator covered with a blazed diffractive lenticular lens was proposed in a multiview holographic 3D display (Hua et al., 2020). This system redirected the diverging rays to shape four extended views with a vertical FOV of 17.8°. In addition, the diffraction efficiency of the view modulator was increased to 46.9% using the blazed phase structures. Most recently, a vector light field display with a large depth of focus was proposed based on an intertwined flat lens, as shown in Figures 4C,D. A grayscale achromatic diffractive lens was designed to extend the depth of focus by 1.8 × 104 times. By integrating the intertwined diffractive lens with a liquid crystal display, a 3D display with a crosstalk below 26% was realized over a viewing distance ranging from 24 to 90 cm (Zhou et al., 2022).

FIGURE 4. (A) Schematic of a glass-free 3D display based on a multilevel diffractive lens. (B) 3D images of letters or thoracic cages in a blazed diffractive lens-based 3D display. (C) Schematic of a vector light field display based on a grayscale achromatic diffractive lens. (D) Full color 3D images of letters and the thoracic cage produced by the intertwined diffractive lens-based 3D display. [(A,B) Reproduced from Zhou et al. (2020). Copyright (2021), with permission from IEEE. (C,D) Reproduced from Zhou et al. (2022). Copyright (2022), with permission from Optica Publishing Group.].

In summary, coupled with various design approaches, an optimized diffractive lens can enable the realization of a high-quality full spectrum in imaging applications (Peng et al., 2015; Heide et al., 2016; Peng et al., 2016; Peng et al., 2019). The design of diffractive lenses in 3D displays bears similarities to the design in imaging. This solves the problem of light efficiency in diffractive grating-based 3D displays. The optimized lens features a high light efficiency, wide spectrum response and large depth of focus, which benefits glasses-free 3D displays in terms of brightness, color fidelity, and viewing depth. However, the minimum feature size of diffractive lenses is generally larger than that of nanogratings due to the fabrication limit, resulting in a reduced viewing angle.

We believe that metasurfaces can be used in 3D displays because of their unprecedented capability to manipulate light fields. In 2013, 3D computer-generated holography image reconstruction was demonstrated in the visible and near-infrared range by a plasmonic metasurface composed of pixelated gold nanorods (Huang et al., 2013) (Figures 5A,B). The pixel size of the metasurface hologram was only 500 nm, which is much smaller than the size of the hologram pixels generated by spatial light modulators or diffractive optical elements. As a result, a FOV as large as 40° was demonstrated. To correct chromatic aberration in integral imaging 3D displays, a single polarization-insensitive broadband achromatic metalens using silicon nitride was proposed (Fan et al., 2019) (Figures 5C,D). Each achromatic metalens has a diameter of 14 µm and was fabricated via the electron beam lithography technique. The focusing efficiency was 47% on average. By composing a 60 × 60 metalens in a rectangular lattice, a broadband achromatic integral imaging display was demonstrated under white light illumination. To address the tradeoff between spatial resolution, angular resolution, and FOV, a general approach for foveated glasses-free 3D displays using the two-dimensional metagrating complex was proposed recently (Figure 5E) (Hua et al., 2021). The dot/linear/rectangular hybrid views, which are shaped by a two-dimensional metagrating complex, form spatially variant information density. By combining the two-dimensional metagrating complex film and a LCD panel, a video rate full-color foveated 3D display system with an unprecedented FOV up to 160° was demonstrated (Figure 5F). Compared with prior work, the proposed system makes two breakthroughs: First, the irradiance pattern of each view can be tailored carefully to avoid both crosstalk and discontinuity between views. Second, the tradeoffs between the angular resolution, spatial resolution and FOV in 3D displays are alleviated.

FIGURE 5. (A) Schematic of a plasmonic metasurface for 3D CGH image reconstruction. (B) Experimental hologram images for different focusing positions along the z direction. (C) Schematic of the broadband achromatic metalens array for a white-light achromatic integral imaging display. (D) Reconstructed images for the cases that “3” and “D” lie on the same depth plane or on different depth planes, respectively. Scale bar, 100 µm. (E) Schematic of a foveated glasses-free 3D display using the two-dimensional metagrating complex. (F) “Albert Einstein” images in the foveated 3D display system. [(A,B) Reproduced from Huang et al. (2013). Copyright (2021), with permission from Springer Nature. (C,D) Reproduced from Fan et al. (2019). Copyright (2021), with permission from Springer Nature. (E,F) Reproduced from Hua et al. (2021). Copyright (2021), with permission from Springer Nature.].

To summarize, metasurfaces provide a solution that maintains both a large FOV and reasonable light efficiency. Moreover, the superior light manipulation capability provides an inspiring foveated glasses-free 3D display solution for an intrinsic tradeoff between resolution and viewing angle in 3D displays. Like all metamaterial-based photonic devices, the mass fabrication of metasurfaces is the major issue that prevents industrial application of this technology.

As mentioned above, we have reviewed the research progress for planar optics-based glass-free 3D displays: diffraction grating-based, diffractive lens-based and metasurface-based. Compared with geometric optics-based 3D displays, these displays all have common advantages, such as high precision control at the pixel level, high degrees of freedom in design, and compact form factors. On the other hand, they have their own properties in terms of light efficiency, FOV, viewing distance, and fabrication scaling, as listed in Table 1. The diffraction grating-based method has both a large FOV with continuous motion parallax and large fabrication scaling. Although the bandwidth of the diffraction grating is limited, a full-color display can still be realized by integrating a color filter. As a result, the problem of selective bandwidth operation is trivial in 3D displays. However, the low light efficiency of binary gratings can be problematic because of the increased power consumption, especially in portable electronics. The diffractive lens-based approach greatly improves the light efficiency. Moreover, through proper design, an intertwined diffractive lens can be used to realize a large viewing distance and broadband spectrum manipulation. Nevertheless, the viewing angle of a diffractive lens-based 3D display is limited by the numerical aperture. The metasurface-based technique has the advantages of medium light efficiency, a large FOV and broadband spectrum response. Therefore, metasurfaces can provide better 3D display performance in terms of color fidelity. Furthermore, the subwavelength dimensions of metasurfaces ensure their flexibility for view manipulation. However, the complexity and difficulty in nanofabrication hinders the application of metasurfaces in large-scale displays.

Most recently, augmented reality (AR), as an interactive display that fuses the virtual world with reality, has become an aggressive research field that attracts broad attention from researchers, investors and scientists (Chang et al., 2020; Xiong et al., 2021). Glasses-free AR 3D displays are of special interest because of the huge demand in many applications, such as head-up displays in vehicles, education, and exhibitions. Although near-to-eye displays for AR technologies based on wearable devices can be implemented by various methods, including free-form optics, holographic optical elements, surface relief gratings, or metasurfaces, the realization of glasses-free AR 3D displays is a much harder task because of the uncertain spatial relationship between the display screen and observers. Glasses-free AR 3D displays can be assigned to either reflection-type and optical see-through type displays. Li et al. adopted a mirror-based pinhole array to demonstrate a reflective AR 3D display system based on an integral imaging display (Li et al., 2019). Recently, they improved the performance of the reflection-type AR 3D system with high definition and high brightness based on the use of a reflective polarizer (Li et al., 2021). However, in the reflection-type AR 3D display, virtual images are fused with mirror images of the real scene rather than the real scene itself.

The optical see-through glasses-free AR 3D display permits people to perceive real scenes directly through a transparent optical combiner (Hong et al., 2016; Mu et al., 2020). Generally, it occupies the mainstream for various AR 3D display technologies and can be realized by using geometric optical elements, holographic optical elements (HOE) and metagratings. In 2020, a lenticular lens-based light field 3D display system with continuous depth was proposed and integrated into AR head up display optics (Lee et al., 2020). This integrated system can generate stereoscopic virtual images with a FOV of 10° × 5°.

The HOE is an optical component that can be used to produce holographic images using principles of diffraction, which is commonly used in transparent displays, 3D imaging, and certain scanning technologies. HOEs share the same optical functions as conventional optical elements, such as mirrors, microlenses, and lenticular lenses. On the other hand, they also have unique advantages of high transparency and high diffraction efficiency. On this basis, the integral imaging display can be integrated with an AR display based on a lenticular lens or microlens-array HOE (Li et al., 2016; Wakunami et al., 2016). Moreover, the HOE can be recorded by wavelength multiplexing for full-color imaging (Hong et al., 2014; Deng et al., 2019) (Figure 6A). A high transmittance was achieved at all wavelengths (Figures 6B,C). A 2D/3D convertible AR 3D display was further proposed based on a lens-array holographic optical element, a polymer dispersed liquid crystal film, and a projector (Zhang et al., 2019). Controlled by voltage, the film can switch the display mode from a 2D display to an optical see-through 3D display.

FIGURE 6. (A) Work principles for a lens-array HOE used in the OST AR 3D display system. (B) Transmittance and reflectance of the recorded lens-array HOE. (C) 3D virtual image of the lens-array HOE-based full color AR 3D display system. (D) Schematic for spatial multiplexing metagratings for a full-color glasses-free AR 3D display. (E) Transmittance of the holographic combiner based on pixelated metagratings. (F) 3D virtual image of the metagratings-based glasses-free AR 3D display system. (G) Schematic of the pixelated multilevel blazed gratings for a glass-free AR 3D display. (H) Principles of the pixelated multilevel blazed gratings array that form viewpoints in different focal planes. (I) 3D virtual image of the blazed gratings-based glasses-free AR 3D display system. [(A–C) Reproduced from Hong et al. (2014). Copyright (2021), with permission from Optica Publishing Group. (D–F) Reproduced from Shi et al. (2020). Copyright (2021), with permission from De Gruyter. (G–I) Reproduced from Shi et al. (2021). Copyright (2021), with permission from MDPI.].

In fact, AR 3D displays based on lens arrays form self-repeating views. Thus, both motion parallax and FOV are limited. Moreover, false depth cues for 3D virtual images can be generated due to the image flip effect. Correct depth cues are particularly important for AR 3D displays when virtual images fuse with natural objects. On this basis, a holographic combiner composed of spatial multiplexing metagratings was proposed to realize a 32-inch full-color glass-free AR 3D display, as shown in Figure 6D (Shi et al., 2020). The irradiance pattern for each view is formed as a super Gaussian function to reduce crosstalk. A FOV as large as 47° was achieved in the horizontal direction. For the sake of correct white balance, three layers of metagratings are stacked for spatial multiplexing. The whole system contains only two components: a projector and a metagrating-based holographic combiner. Moreover, the transmittance is higher than 75% over the visible spectrum (Figures 6E,F), but the light efficiency of metagrating is relatively low (40% in theory and 12% in experiment). To improve the light efficiency, pixelated multilevel blazed gratings were introduced for glasses-free AR 3D displays with a 20 inch format (Figures 6G,H) (Shi et al., 2021). The measured diffraction efficiency was improved to a value of ∼53%. The viewing distance for motion parallax was extended to more than 5 m, benefiting from the multiorder diffraction light according to harmonic diffraction theory (Figure 6I).

We introduce a summary of various methods for realizing glasses-free AR 3D displays. As shown in Table 2, the optical see-through combiner outweighs the reflection type method for a more natural fusion with the physical world. In all optical see-through combiners, holographic optical element-based combiners have the advantages of high diffraction efficiency and high transparency. However, they suffer from a limited FOV and motion parallax. The metagrating-based combiner offers an accurate depth cue over a large FOV. The multilevel blazed grating-based method further improves the light efficiency and viewing depth due to multiorder diffraction.

The development of high-throughput micro/nanofabrication methods is essential for large view modulators. To fabricate the diffraction gratings or metagratings at a high throughput, a flexible lithography system was proposed (Figure 7A) (Wan et al., 2016). The nanogratings in this system were fabricated pixel by pixel. Through one exposure, a nanograting pixel with a size on the scale of tens of microns was formed. Therefore, the throughput can be much faster than that obtained by an electron beam lithography system that works via a sequential writing process. In addition, the periodic tuning accuracy of the fabricated gratings can be less than 1 nm. Using the proposed lithography system, a 32-inch view modulator with a minimum feature size of 300 nm was successfully prepared for a glass-free 3D display (Figures 7B,C). This view modulator has a total of 24,883,200 pixelated metagratings.

To efficiently fabricate multilevel microstructures, a grayscale laser direct writing system can be employed, as shown in Figure 7D. The system mainly contains a laser, an electronically programmable spatial light modulator device and an objective lens. The spatial light modulator device loads the hologram patterns that are refreshed synchronously with the movement of the 2D sample stage. The objective lens reduces the pixel size of the spatial light modulator device by 20 times or 50 times. Furthermore, the proposed laser direct writing system has a high throughput of 25 mm2/min, which supports the fabrication of a large-scale view modulator for display purposes. It took only 30 min to fabricate a 40 mm2 view modulator fully covered with a four-level blazed diffractive lens (Figures 7E,F).

In this paper, we mainly focused on the exciting achievements of planar optics-based glass-free 3D displays and glass-free AR 3D displays (as summarized in Figure 8). Planar optics opens up the possibility to manipulate the beam steering pixel by pixel, rather than an image with many pixels as in a microlens array-based architecture. There are several benefits to modulating individual pixels. First, the views can be arranged freely either in a line for horizontal parallax, a curve for table-top 3D displays, or a matrix for full parallax. As a result, the views can be arranged according to the application. Second, when imaging with many pixels, many pixels are wasted, especially at large viewing angles. Therefore, severe resolution degradation is always criticized. In the pixel-to-pixel steering strategy, however, every pixel contributes to the virtual 3D image. Third, planar optics offers superior light steering capability for a large FOV. Fourth, the light distribution of each view can be tuned from a Gaussian distribution to a super-Gaussian distribution to minimize crosstalk and ghost images. Fifth, the view shape can be tuned to dots/linear/rectangular shapes for information density variant 3D displays. The tradeoff between resolution and viewing angle can be alleviated. Sixth, a super multiview display can be realized with closely packaged views to address vergence-accommodation conflict problems. Seventh, multilevel structures, such as blazed gratings, diffractive lenses, and metasurfaces, offer solutions for high light efficiency and reduced chromatic aberration. Eighth, planar optics possess the features of a thin form factor and light weight, which are compatible with portable electronics. Finally, a glass-free AR 3D display can be achieved with a large FOV, enhanced light efficiency and reduced crosstalk for window displays.

FIGURE 8. Schematic of the emerging planar optical elements applied in glasses-free 3D displays and glasses-free AR 3D displays. There are various merits for planar optical elements compared with geometric optical elements. DG: Diffraction gratings.

To summarize, planar optics-based 3D displays have the advantages of a thin form factor, light weight, flexible design, and precise light manipulation. They hold great promise to tackle the critical challenges for geometric-based 3D displays, especially for the applications of portable electronics and transparent displays.

Future research in planar optics-based 3D displays should focus on the improvement of display performance and enhancement of practicality. From the system level, some strategies can be used to further improve display performance. First, a time-multiplexed strategy enabled by a high refresh rate monitor can be used to increase the resolution by exploiting the redundant time information (Hwang et al., 2014; Ting et al., 2016; Liu et al., 2019). For example, a projector array and a liquid crystal-based steering screen has been used to implement a time-multiplexed multiview 3D display. An angular steering screen was used to control the light direction to generate more continual viewpoints, thereby increasing the angular resolution (Xia et al., 2018). In another work, a time sequential directional beam splitter array was introduced in a multiview 3D display to increase the spatial resolution (Feng et al., 2017). When equipped with eye-tracking systems, a time-multiplexed 3D display can provide both high spatial resolution and angular resolution for single-user applications. Second, a foveated vision strategy can be utilized to compress the image processing load and improve the optical performance of the imaging system and near-eye display (Phillips et al., 2017; Chang et al., 2020). For instance, a multiresolution foveated display using two display panels and an optical combiner was proposed for virtual reality applications (Tan et al., 2018). The first display panel provides a wide FOV, and the second display panel improves spatial resolution for the central fovea region. This system effectively reduces the screen-door effect in near-eye displays. Moreover, a foveated glasses-free 3D display was also demonstrated with spatially variant information density. This strategy offers potential solutions to solve the trade-off between resolution and FOV (Hua et al., 2021). For foveated display systems, liquid crystal lens technology is also significant (Chen et al., 2015; Lin et al., 2017; Yuan et al., 2021). Under polarization control, liquid crystal lenses with tunable focal lengths are able to provide active switching of the FOV. This technology was demonstrated in a foveated near-eye display to create multiresolution images with a single display module (Yoo et al., 2020). The system maintains both a wide FOV and high resolution with compressed data. Third, the development of artificial intelligence algorithms can improve the optical performance of planar optical elements (Chang et al., 2018; Sitzmann et al., 2018; Tseng et al., 2021; Zeng et al., 2021). For example, an end-to-end optimization algorithm was introduced to design a diffractive achromatic lens. By jointly learning the lens and an image recovery neural network, this method can be used to realize superior high-fidelity imaging (Dun et al., 2020). Therefore, in planar optics-based 3D displays, algorithms such as deep learning can be incorporated with hardware for aberration reduction and image precalibration.

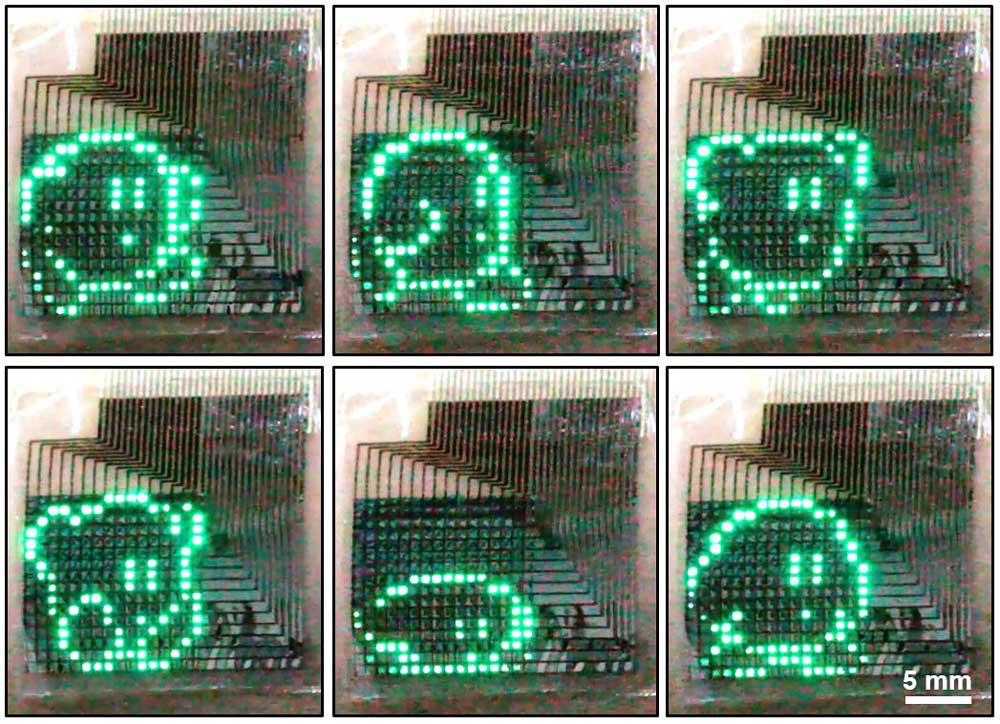

In addition to the aforementioned improvement in display performance, several techniques need to be implemented that can promote the practical application of 3D displays. First, a directional backlight system with low divergence and high uniformity should be integrated into planar optics-based glass-free 3D displays (Yoon et al., 2011; Fan et al., 2015; Teng and Tseng, 2015; Zhan et al., 2016; Krebs et al., 2017). The angular divergence of the illumination greatly affects the display performance in terms of crosstalk and ghost images. An edge-lit directional backlight based on a waveguide with pixelated nanogratings was proposed (Zhang et al., 2020). The directional backlight module provides an angular divergence of ±6.17° and a uniformity of 95.7 and 86.8% in the x- and y-directions, respectively, at a wavelength of 532 nm. In another work, a steering-backlight was introduced into a slim panel holographic video display (An et al., 2020). The overall system thickness is < 10 cm. Nevertheless, the design and fabrication of a directional backlight is still a difficult task. Second, several challenges in nanofabrication should be overcome for planar optics-based 3D displays (Manfrinato et al., 2013; Manfrinato et al., 2014; Chen et al., 2015; Qiao et al., 2016; Wu et al., 2021). For example, the patterning of nanostructures over a large size, the fabrication of multilevel micro/nanostructures with a high aspect ratio, and the realization of high-fidelity batch copies of micro/nanostructures remains challenging. We believe that numerous micro/nanomanufacturing techniques and instruments will be developed to meet the specific needs of 3D displays. Last but not least, planar optics-based 3D displays will benefit from the rapid development of advanced display panels. To enhance the brightness while ensuring low system power consumption, a spontaneous emission source can be introduced into planar optics-based 3D displays (Fang et al., 2006; Hoang et al., 2015; Pelton, 2015). By constructing plasmonic nanoantennas, large spontaneous emission enhancements were realized with increased spontaneous emission rates (Tsakmakidis et al., 2016). As a result, light-emitting diodes can possess a faster modulation speed than typical semiconductor lasers, providing a solution with high brightness and a high refresh rate. Ideally, the space-bandwidth product needs to be larger than 50 K for glasses-free 3D displays. MicroLED and nanoLED displays can effectively expand space-bandwidth products and fundamentally solve the problem of resolution degradation in the future (Huang et al., 2020; Liu et al., 2020). We believe that advances in directional backlights, nanofabrication, spontaneous emission sources, and microLED displays will lead to innovative and ecological development of the 3D display industry.

An, J., Won, K., Kim, Y., Hong, J.-Y., Kim, H., Kim, Y., et al. (2020). Slim-panel Holographic Video Display. Nat. Commun. 11 (1), 1–7. doi:10.1038/s41467-020-19298-4

Chang, C., Bang, K., Wetzstein, G., Lee, B., and Gao, L. (2020). Toward the Next-Generation VR/AR Optics: a Review of Holographic Near-Eye Displays from a Human-Centric Perspective. Optica 7 (11), 1563–1578. doi:10.1364/OPTICA.406004

Deng, H., Chen, C., He, M.-Y., Li, J.-J., Zhang, H.-L., and Wang, Q.-H. (2019). High-resolution Augmented Reality 3D Display with Use of a Lenticular Lens Array Holographic Optical Element. J. Opt. Soc. Am. A. 36 (4), 588–593. doi:10.1364/JOSAA.36.000588

Fan, H., Zhou, Y., Wang, J., Liang, H., Krebs, P., Su, J., et al. (2015). Full Resolution, Low Crosstalk, and Wide Viewing Angle Auto-Stereoscopic Display with a Hybrid Spatial-Temporal Control Using Free-form Surface Backlight Unit. J. Display Technol. 11 (7), 620–624. doi:10.1109/JDT.2015.2425432

Fattal, D., Peng, Z., Tran, T., Vo, S., Fiorentino, M., Brug, J., et al. (2013). A Multi-Directional Backlight for a Wide-Angle, Glasses-free Three-Dimensional Display. Nature 495 (7441), 348–351. doi:10.1038/nature11972

Feng, J.-L., Wang, Y.-J., Liu, S.-Y., Hu, D.-C., and Lu, J.-G. (2017). Three-dimensional Display with Directional Beam Splitter Array. Opt. Express 25 (2), 1564. doi:10.1364/OE.25.001564

Hirayama, R., Martinez Plasencia, D., Masuda, N., and Subramanian, S. (2019). A Volumetric Display for Visual, Tactile and Audio Presentation Using Acoustic Trapping. Nature 575 (7782), 320–323. doi:10.1038/s41586-019-1739-5

Hong, J.-Y., Park, S.-G., Lee, C.-K., Moon, S., Kim, S.-J., Hong, J., et al. (2016). See-through Multi-Projection Three-Dimensional Display Using Transparent Anisotropic Diffuser. Opt. Express 24 (13), 14138–14151. doi:10.1364/OE.24.014138

Hua, J., Hua, E., Zhou, F., Shi, J., Wang, C., Duan, H., et al. (2021). Foveated Glasses-free 3D Display with Ultrawide Field of View via a Large-Scale 2D-Metagrating Complex. Light Sci. Appl. 10 (1), 1–9. doi:10.1038/s41377-021-00651-1

Hua, J., Yi, D., Qiao, W., and Chen, L. (2020). Multiview Holographic 3D Display Based on Blazed Fresnel DOE. Opt. Commun. 472, 125829. doi:10.1016/j.optcom.2020.125829

Huang, T., Han, B., Zhang, X., and Liao, H. (2019). High-performance Autostereoscopic Display Based on the Lenticular Tracking Method. Opt. Express 27 (15), 20421–20434. doi:10.1364/OE.27.020421

Huang, Y., Hsiang, E.-L., Deng, M.-Y., and Wu, S.-T. (2020). Mini-LED, Micro-LED and OLED Displays: Present Status and Future Perspectives. Light Sci. Appl. 9 (1), 1–16. doi:10.1038/s41377-020-0341-9

Hwang, Y. S., Bruder, F.-K., Fäcke, T., Kim, S.-C., Walze, G., Hagen, R., et al. (2014). Time-sequential Autostereoscopic 3-D Display with a Novel Directional Backlight System Based on Volume-Holographic Optical Elements. Opt. Express 22 (8), 9820–9838. doi:10.1364/OE.22.009820

Javidi, B., Carnicer, A., Arai, J., Fujii, T., Hua, H., Liao, H., et al. (2020). Roadmap on 3D Integral Imaging: Sensing, Processing, and Display. Opt. Express 28 (22), 32266–32293. doi:10.1364/OE.402193

Kim, S.-U., Kim, J., Suh, J.-H., Na, J.-H., and Lee, S.-D. (2016). Concept of Active Parallax Barrier on Polarizing Interlayer for Near-Viewing Autostereoscopic Displays. Opt. Express 24 (22), 25010–25018. doi:10.1364/OE.24.025010

Koulieris, G.-A., Bui, B., Banks, M. S., and Drettakis, G. (2017). Accommodation and comfort in Head-Mounted Displays. ACM Trans. Graph. 36 (4), 1–11. doi:10.1145/3072959.3073622

Krebs, P., Liang, H., Fan, H., Zhang, A., Zhou, Y., Chen, J., et al. (2017). Homogeneous Free-form Directional Backlight for 3D Display. Opt. Commun. 397, 112–117. doi:10.1016/j.optcom.2017.04.002

Kumagai, K., Suzuki, D., Hasegawa, S., and Hayasaki, Y. (2015). Volumetric Display with Holographic Parallel Optical Access and Multilayer Fluorescent Screen. Opt. Lett. 40 (14), 3356–3359. doi:10.1364/OL.40.003356

Kumagai, K., Yamaguchi, I., and Hayasaki, Y. (2018). Three-dimensionally Structured Voxels for Volumetric Display. Opt. Lett. 43 (14), 3341–3344. doi:10.1364/OL.43.003341

Lee, J.-h., Yanusik, I., Choi, Y., Kang, B., Hwang, C., Park, J., et al. (2020). Automotive Augmented Reality 3D Head-Up Display Based on Light-Field Rendering with Eye-Tracking. Opt. Express 28 (20), 29788–29804. doi:10.1364/OE.404318

Li, G., Lee, D., Jeong, Y., Cho, J., and Lee, B. (2016). Holographic Display for See-Through Augmented Reality Using Mirror-Lens Holographic Optical Element. Opt. Lett. 41 (11), 2486–2489. doi:10.1364/OL.41.002486

Li, Q., Deng, H., Pang, S., Jiang, W., and Wang, Q. (2019). A Reflective Augmented Reality Integral Imaging 3D Display by Using a Mirror-Based Pinhole Array. Appl. Sci. 9 (15), 3124. doi:10.3390/app9153124

Li, Q., He, W., Deng, H., Zhong, F.-Y., and Chen, Y. (2021). High-performance Reflection-type Augmented Reality 3D Display Using a Reflective Polarizer. Opt. Express 29 (6), 9446–9453. doi:10.1364/OE.421879

Liang, H., An, S., Wang, J., Zhou, Y., Fan, H., Krebs, P., et al. (2014). Optimizing Time-Multiplexing Auto-Stereoscopic Displays with a Genetic Algorithm. J. Display Technol. 10 (8), 695–699. doi:10.1109/JDT.2014.2314138

Liu, B., Sang, X., Yu, X., Gao, X., Liu, L., Gao, C., et al. (2019). Time-multiplexed Light Field Display with 120-degree Wide Viewing Angle. Opt. Express 27 (24), 35728–35739. doi:10.1364/OE.27.035728

Liu, Z., Cui, Q., Huang, Z., and Guo, L. J. (2020). Transparent Colored Display Enabled by Flat Glass Waveguide and Nanoimprinted Multilayer Gratings. ACS Photon. 7 (6), 1418–1424. doi:10.1021/acsphotonics.9b01803

Liu, Z., Lin, C.-H., Hyun, B.-R., Sher, C.-W., Lv, Z., Luo, B., et al. (2020). Micro-light-emitting Diodes with Quantum Dots in Display Technology. Light Sci. Appl. 9 (1), 1–23. doi:10.1038/s41377-020-0268-1

Lv, G.-J., Wang, Q.-H., Zhao, W.-X., Wang, J., Deng, H., and Wu, F. (2015). Glasses-free Three-Dimensional Display Based on Microsphere-Lens Array. J. Display Technol. 11 (3), 292–295. doi:10.1109/JDT.2014.2385098

Lv, G.-J., Zhao, B.-C., Wu, F., Zhao, W.-X., Yang, Y.-Z., and Wang, Q.-H. (2017). Autostereoscopic 3D Display with High Brightness and Low Crosstalk. Appl. Opt. 56 (10), 2792–2795. doi:10.1364/AO.56.002792

Ma, Q., Cao, L., He, Z., and Zhang, S. (2019). Progress of Three-Dimensional Light-Field Display [Invited]. 中国光学快报 17 (11), 111001. doi:10.3788/COL201917.111001

Martínez-Corral, M., and Javidi, B. (2018). Fundamentals of 3D Imaging and Displays: a Tutorial on Integral Imaging, Light-Field, and Plenoptic Systems. Adv. Opt. Photon. 10 (3), 512–566. doi:10.1364/AOP.10.000512

Mu, C.-T., Tseng, S.-H., and Chen, C.-H. (2020). See-through Holographic Display with Randomly Distributed Partial Computer Generated Holograms. Opt. Express 28 (24), 35674–35681. doi:10.1364/OE.405203

Shi, J., Hua, J., Zhou, F., Yang, M., and Qiao, W. (2021). Augmented Reality Vector Light Field Display with Large Viewing Distance Based on Pixelated Multilevel Blazed Gratings. Photonics 8 (8), 337. doi:10.3390/photonics8080337

Smalley, D. E., Nygaard, E., Squire, K., Van Wagoner, J., Rasmussen, J., Gneiting, S., et al. (2018). A Photophoretic-Trap Volumetric Display. Nature 553 (7689), 486–490. doi:10.1038/nature25176

Tan, G., Lee, Y.-H., Zhan, T., Yang, J., Liu, S., Zhao, D., et al. (2018). Foveated Imaging for Near-Eye Displays. Opt. Express 26 (19), 25076–25085. doi:10.1364/OE.26.025076

Tay, S., Blanche, P.-A., Voorakaranam, R., Tunç, A. V., Lin, W., Rokutanda, S., et al. (2008). An Updatable Holographic Three-Dimensional Display. Nature 451 (7179), 694–698. doi:10.1038/nature06596

Teng, T.-C., and Tseng, L.-W. (2015). Design of a Bidirectional Backlight Using a Pair of Stacked Light Guide Plates for Large Dual-View and 3D Displays. Appl. Opt. 54 (3), 509–516. doi:10.1364/AO.54.000509

Wakunami, K., Hsieh, P.-Y., Oi, R., Senoh, T., Sasaki, H., Ichihashi, Y., et al. (2016). Projection-type See-Through Holographic Three-Dimensional Display. Nat. Commun. 7 (1), 1–7. doi:10.1038/ncomms12954

Wan, W., Qiao, W., Huang, W., Zhu, M., Fang, Z., Pu, D., et al. (2016). Efficient Fabrication Method of Nano-Grating for 3D Holographic Display with Full Parallax Views. Opt. Express 24 (6), 6203–6212. doi:10.1364/OE.24.006203

Wan, W., Qiao, W., Huang, W., Zhu, M., Ye, Y., Chen, X., et al. (2017). Multiview Holographic 3D Dynamic Display by Combining a Nano-Grating Patterned Phase Plate and LCD. Opt. Express 25 (2), 1114–1122. doi:10.1364/OE.25.001114

Wan, W., Qiao, W., Pu, D., and Chen, L. (2020). Super Multi-View Display Based on Pixelated Nanogratings under an Illumination of a point Light Source. Opt. Lasers Eng. 134, 106258. doi:10.1016/j.optlaseng.2020.106258

Wan, W., Qiao, W., Pu, D., Li, R., Wang, C., Hu, Y., et al. (2020). Holographic Sampling Display Based on Metagratings. iScience 23, 100773. doi:10.1016/j.isci.2019.100773

Wang, Q. H., Pan, D. D., Li, D. H., Li, X. F., and Zhao, R. L. (2010). Stereoscopic Image Crosstalk Factor for Auto-Stereoscopic Display Based on Parallax Barrier. J. Optoelectron. Laser 21, 1058–1061. doi:10.16136/j.joe.l.2010.07.027

Watanabe, H., Okaichi, N., Sasaki, H., and Kawakita, M. (2020). Pixel-density and Viewing-Angle Enhanced Integral 3D Display with Parallel Projection of Multiple UHD Elemental Images. Opt. Express 28 (17), 24731–24746. doi:10.1364/OE.397647

Wen Qiao, 乔., Fengbin Zhou, 周., and Linsen Chen, 陈. (2020). Towards Application of mobile Devices: the Status and Future of Glasses-free 3D Display. 红外与激光工程 49 (3), 303002. doi:10.3788/IRLA202049.0303002

Xia, X., Zhang, X., Zhang, L., Surman, P., and Zheng, Y. (2018). Time-multiplexed Multi-View Three-Dimensional Display with Projector Array and Steering Screen. Opt. Express 26 (12), 15528–15538. doi:10.1364/OE.26.015528

Xiong, J., Hsiang, E.-L., He, Z., Zhan, T., and Wu, S.-T. (2021). Augmented Reality and Virtual Reality Displays: Emerging Technologies and Future Perspectives. Light Sci. Appl. 10 (1), 1–30. doi:10.1038/s41377-021-00658-8

Yoo, C., Xiong, J., Moon, S., Yoo, D., Lee, C.-K., Wu, S.-T., et al. (2020). Foveated Display System Based on a Doublet Geometric Phase Lens. Opt. Express 28 (16), 23690–23702. doi:10.1364/OE.399808

Yoon, H., Oh, S.-G., Kang, D. S., Park, J. M., Choi, S. J., Suh, K. Y., et al. (2011). Arrays of Lucius Microprisms for Directional Allocation of Light and Autostereoscopic Three-Dimensional Displays. Nat. Commun. 2 (1), 1–5. doi:10.1038/ncomms1456

Yoon, S. K., Khym, S., Kim, H.-W., and Kim, S.-K. (2016). Variable Parallax Barrier Spacing in Autostereoscopic Displays. Opt. Commun. 370, 319–326. doi:10.1016/j.optcom.2016.03.028

Zhan, L., Xu, B., Hu, J., Wang, Y., Li, M., Cao, L., et al. (2016). Directional Backlight 3D Display System with Wide-Dynamic-Range View Zone, High Brightness and Switchable 2D/3D. J. Display Technol. 12 (12), 1. doi:10.1109/JDT.2016.2609198

Zhang, H.-L., Deng, H., Li, J.-J., He, M.-Y., Li, D.-H., and Wang, Q.-H. (2019). Integral Imaging-Based 2D/3D Convertible Display System by Using Holographic Optical Element and Polymer Dispersed Liquid crystal. Opt. Lett. 44 (2), 387–390. doi:10.1364/OL.44.000387

Zhang, Y., and Fang, F. (2019). Development of Planar Diffractive Waveguides in Optical See-Through Head-Mounted Displays. Precision Eng. 60, 482–496. doi:10.1016/j.precisioneng.2019.09.009

Zhao, Z.-F., Liu, J., Zhang, Z.-Q., and Xu, L.-F. (2020). Bionic-compound-eye Structure for Realizing a Compact Integral Imaging 3D Display in a Cell Phone with Enhanced Performance. Opt. Lett. 45 (6), 1491–1494. doi:10.1364/OL.384182

Zhou, F., Hua, J., Shi, J., Qiao, W., and Chen, L. (2020). Pixelated Blazed Gratings for High Brightness Multiview Holographic 3D Display. IEEE Photon. Technol. Lett. 32 (5), 283–286. doi:10.1109/LPT.2020.2971147

Zhou, F., Zhou, F., Chen, Y., Hua, J., Qiao, W., and Chen, L. (2022). Vector Light Field Display Based on an Intertwined Flat Lens with Large Depth of Focus. Optica 9 (3). doi:10.1364/OPTICA.439613

Zou, B., Liu, Y., Guo, M., and Wang, Y. (2015). EEG-based Assessment of Stereoscopic 3D Visual Fatigue Caused by Vergence-Accommodation Conflict. J. Display Technol. 11 (12), 1076–1083. doi:10.1109/JDT.2015.2451087

There are endless technical arguments for determining which screens are the best, but if you set price aside, the deciding factor usually comes down to which screen produces the best visuals — the most accurate depiction of the world as we see it with our own eyes.

Leading screen manufacturers like Samsung have turned to nanotechnology that, ironically, can’t even be seen by the naked eye but produces jaw-droppingly rich, vibrant displays. An emerging technology called Quantum Dot enhances flat-panel LED displays, commercial TVs and curved widescreen monitors, revealing many more colors and adding the necessary brightness to take full advantage of technologies like High Dynamic Range (HDR).

Quantum Dots are essentially nanoparticles that manufacturers add to the layers of films, filters, glass and electronics — sometimes called the sandwich — that comprise a Liquid Crystal Display (LCD). When these Quantum Dots are illuminated, they re-emit light of a certain color. Developing the technology for the primary QLED colors (red, blue and green) has been a technological feat, and one Samsung has overcome with its R&D hub Samsung Advanced Institute of Technology (SAIT). The team successfully developed blue QLED technology in 2020.

Because of its investment in R&D, Samsung is, by far, the market leader in Quantum Dots development and display products, with a category it calls Quantum LED (QLED). Other display manufacturers using Quantum Dots technology often include “Q” or “Quantum” in product names to make the distinction from conventional LCDs.

Quantum Dots-enhanced displays compare favorably with super-premium Organic LED displays (OLEDs), but usually at less cost, and with none of the technical issues and limitations that OLED introduces (more on that later). Quantum Dots technology first found its way into the premium TV market, and is now increasingly being used by image-sensitive brands for commercial applications such as digital signage, where the depth and accuracy of color is critically important.

Quantum Dots are usually applied to a sheet of film that sits as a layer in that “sandwich” in front of the LED backlight that’s used to illuminate an LCD. The light passes through the LCD display stack, with the Quantum Dot color filter layer enhancing and enabling the LCD to reveal a wider and more saturated range of colors than would otherwise be possible.

Many consumer and B2B brands place heavy importance on how their products look to the marketplace. Their brands’ colors are not just blue and red — they are very specific blues and reds. Brand owners often have rigorous guidelines that mandate how these colors are reproduced, and in the case of digital displays, Quantum Dots technology provides the level of accuracy they want. Samsung’s QLED displays, for example, enable more than a billion colors.

By one estimate, Quantum Dots increase the color gamut on LCD displays by up to 50 percent. That broad range of colors also enables more saturated colors — the vivid, intense color levels that “pop” on screens and draw viewer attention.

Using Quantum Dots means the range of colors and their accuracy is maintained even at peak brightness, while other display technologies like OLED might wash out colors when scenes require full brightness. The result with QLED is accurate, rich and detailed colors on displays, in any light.

Quantum Dots LCD displays are often compared to OLED flat panel displays, with both billed as premium visual experiences. To a casual observer, they can look very similar, but there are distinct differences.

Both technologies offer a huge range of colors, delivering eye-popping visuals. But while Quantum Dots can reproduce that full range of colors even at peak brightness, when the image on an OLED display becomes too bright, its color capabilities are compromised, and diminishing the available spectrum. Samsung QLEDs have peak brightness levels as high as 4,000 nits, which is brighter than what’s needed for outdoor displays to overpower the glare of direct sunlight.

When flat panel displays first came into the marketplace, much of the marketing story and buyer interest focused on their shape and scale. Then the focus turned to resolution, shifting from 720p to 1080p HD and then to 4K and even 8K.

Size and pixel counts are important, but in many respects the real determining factors for brands and business users is visual quality. The real benefits of Full HD, Ultra HD and beyond come when a display can deliver that volume of detail with an exceptional depth of color, no matter the visuals. Samsung’s QLED technology is supported by AI-powered machine learning, which can scale 4K UHD and Full HD content to 8K resolution without compromising quality.

Quantum Dots may seem like a term that could only excite nerds, but one look at a QLED display will generate admiration even from people who don’t want to know all the technical details.

Explore Samsung’s full lineup ofQLED displays, designed deliver realistic detail and vibrant color to showcase your business in the best light. Looking for more buying advice? You can find everything you need to know about choosing your LED displays for optimal viewing indoors and out in thisfree, comprehensive guide.

Nanotechnology involves the understanding and control of matter at the nanometer-scale. The so-called nanoscale deals with dimensions between approximately 1 and 100 nanometers.

Nanotechnology can increase the surface area of a material. This allows more atoms to interact with other materials. An increased surface area is one of the chief reasons nanometer-scale materials can be stronger, more durable, and more conductive than their larger-scale (called bulk) counterparts.

Nanotechnology is not microscopy. "Nanotechnology is not simply working at ever smaller dimensions," the National Nanotechnology Initiative says. "Rather, working at the nanoscale enables scientists to utilize the unique physical, chemical, mechanical, and optical properties of materials that naturally occur at that scale."

Scientists and engineers working at the nanometer-scale need special microscopes. The atomic force microscope (AFM) and the scanning tunneling microscope (STM) are essential in the study of nanotechnology. These powerful tools allow scientists and engineers to see and manipulate individual atoms.

American physicist Richard Feynman is considered the father of nanotechnology. He introduced the ideas and concepts behind nanotech in a 1959 talk titled "There’s Plenty of Room at the Bottom." Feynman did not use the term "nanotechnology," but described a process in which scientists would be able to manipulate and control individual atoms and molecules.

Modern nanotechnology truly began in 1981, when the scanning tunneling microscope allowed scientists and engineers to see and manipulate individual atoms. IBM scientists Gerd Binnig and Heinrich Rohrer won the 1986 Nobel Prize in Physics for inventing the scanning tunneling microscope. The Binnig and Rohrer Nanotechnology Center in Zurich, Switzerland, continues to build on the work of these pioneering scientists by conducting research and developing new applications for nanotechnology.

By the end of the 20th century, many companies and governments were investing in nanotechnology. Major nanotech discoveries, such as carbon nanotubes, were made throughout the 1990s. By the early 2000s, nanomaterials were being used in consumer products from sports equipment to digital cameras.

Many governments, scientists, and engineers are researching the potential of nanotechnology to bring affordable, high-tech, and energy-efficient products to millions of people around the world. Nanotechnology has improved the design of products such as light bulbs, paints, computer screens, and fuels.

Nanotechnology is helping inform the development of alternative energy sources, such as solar and wind power. Solar cells, for instance, turn sunlight into electric currents. Nanotechnology could change the way solar cells are used, making them more efficient and affordable.

Solar cells, also called photovoltaic cells, are usually assembled as a series of large, flat panels. These solar panels are big and bulky. They are also expensive and often difficult to install. Using nanotechnology, scientists and engineers have been able to experiment with print-like development processes, which reduces manufacturing costs. Some experimental solar panels have been made in flexible rolls rather than rigid panels. In the future, panels might even be "painted" with photovoltaic technology.

Researchers are also experimenting with using nanotechnology to safely, affordably, and efficiently turn saltwater into freshwater, a process called desalination. In one experiment, nano-sized electrodes are being used to reduce the cost and energy requirements of removing salts from water.

Scientists and engineers are experimenting with nanotechnology to help isolate and remove oil spilled from offshore oil platforms and container ships.

Scientists and engineers are using nanotechnology to enhance clothing. By coating fabrics with a thin layer of zinc oxide nanoparticles, for instance, manufacturers can create clothes that give better protection from ultraviolet radiation, like that from the sun. Some clothes have nanoparticles in the form of little hairs or whiskers that help repel water and other materials, making fabric more stain-resistant.

Some researchers are experimenting with nanotechnology for "personal climate control." Nanofiber jackets allow the wearer to control the jacket’s warmth using a small set of batteries.

Nanotechnology may also provide better "delivery systems" for cosmetic ingredients. Nanomaterials may be able to penetrate a skin’s cell membranes to augment the cell’s features, such as elasticity or moisture.

Engineers and chemists use nanotechnology to adapt the texture and flavor of foods. Nanomaterials’ greater surface area may improve the "spreadability" of foods such as mayonnaise, for instance.

Nanotechnology has revolutionized the realm of electronics. It provides faster and more portable systems that can manage and store larger and larger amounts of data.

Nanotech has improved display screens on electronic devices. This involves reducing power consumption while decreasing the weight and thickness of the screens.

Nanotechnology has allowed glass to be more consumer-friendly. One glass uses nanomaterials to clean itself, for example. As ultraviolet light hits the glass, nanoparticles become energized and begin to break down and loosen organic molecules—dirt—on the glass. Rain cleanly washes the dirt away. Similar technology could be applied to touch-screen devices to resist sweat.

Nanotechnology can help medical tools and procedures be more personalized, portable, cheaper, safer, and easier to administer. Silver nanoparticles incorporated into bandages, for example, smother and kill harmful microbes. This can be especially useful in healing burns.

Unregulated pursuit of nanotechnology is controversial. In 1986, Eric Drexler wrote a book called Engines of Creation, which painted a vision of the future of nanotech, but also warned of the dangers. The book’s apocalyptic vision included self-replicating nanometer-scale robots that malfunctioned, duplicating themselves a trillion times over. These nano-bots rapidly consumed the entire world as they pulled carbon from the environment to replicate themselves.

Another concern about nanotechnology is the price. Nanotech is an expensive area of research, and largely confined to developed nations with strong infrastructure. Many social scientists are concerned that underdeveloped countries will fall further behind as they cannot afford to develop a nanotechnology industry.

(a) Physico-chemical properties of phospholipids. Phospholipids are composed of a hydrophilic head group and hydrophobic tails (N = 1–6). PC: phosphatidylcholine, LPC: LysoPC, CL: cardiolipin, LPS: lipopolysaccharide. The head group may carry a positive or negative charge. It may also be neutral but possess a significant electric dipole which enforces particular arrangements in the monolayer and bilayer assemblies. Self assembly of phospholipids results in bilayers or monolayers. Bilayers are birefringent [28], thermally conductive (energy transfer on sub-picosecond time scales; κ~several Watt/mK [20]), behave as insulators perpendicular to the membrane and in the core part whereas they are electrically conductive within the plane of the

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey