nanotechnology display screens made in china

“Nanosys is the innovative leader in Quantum Dot technology – always providing the best quantum dot performance, material reliability, most competitive price and a solid IP foundation for Exciton and our customers,” said Dr. John Zhang, chief executive officer, Exciton Technology. “We have already secured orders from display makers and will begin shipping QDEF in mass production volumes during the first half of 2017.”

“Exciton is a world-leading manufacturer of optical films for displays, and has an execution-focused culture that moves fast, with a proven ability to thrive in this highly competitive market,” said Russell Kempt, vice president of global sales and marketing, Nanosys, Inc. “This new, China-based supply of high quality and cost competitive QDEF will further accelerate the utilization of Quantum Dot technology in UltraHD televisions.”

Nanosys QDEF Quantum Dot technology makes displays more vivid by enabling pure colors with lifelike brightness using cutting-edge nanotechnology. QDEF is a drop-in film that LCD manufacturers can integrate with existing production processes. It utilizes the light emitting properties of Quantum Dots to create an ideal backlight for LCDs -- one of the most critical factors in the color and efficiency performance of displays.

The company, based on the most advanced production technology and materials science, has a development goal to become the world"s largest, most profitable and most respected optical film company. The company is committed to providing its customers with the best quality and service, and to supply best-in-class optical film solutions to the flat panel display, solar cell and LED lighting industries. Since it was established, the company has been focused on liquid crystal display with optical film production technology and production process upgrades and innovation, independent of the optical diffusion film, prism film, reflective film and other optical film product development, production and sales.

The company is in the State Ministry of Science and Technology Torch high-tech industry development center identified with the national Torch Program focused on high-tech enterprises, post-doctoral research platform enterprises, with rich technical level and research and development capabilities. The company has a number of patents granted in the area of display optical films. The company"s products are in the Samsung, LGD, Sharp, AUO, Foxconn, TPL, TCL, Hisense, Haier, Changhong, Skyworth, BOE, Tianma and many other international and domestic consumer electronics brands. The company is the leader in the field of optical film for display globally.

The company built up the R&D center in Suzhou Industrial Park, marketing office in Beijing and manufacturing facilities in Nanjing. Halation has developed its unique Whiteon® Technology applied to E-book/paper screen, Electronic Shelf Label and information board; the Priview® Technology applied to privacy glass/film in Auto and Construction Industries; and the Silkink®Technology applied to the application of Full Color Static Display in In/outdoor advertising billboard, Street window display, as well as Transportation/ Station Information Board industries.

Halation Photonics has raised funds from world leading VC firms and strategic investors of Fortune 500 companies, build up diversified collaborations for those applications that include ESL(electronic shelf label), E-book screen, new generation trans-reflective full color static display, and privacy glass (smart window).

Foldable tablets, electronic charts and bridge displays should become a reality after innovation in nanotechnology screen films. The first foldable smartphones are set to be introduced in Q1 2019, when consumers can test the technology.

Manufacturers have made great strides in developing folding displays for phones. But, an invention was required in conductive materials that would enable touchscreens to function reliably. This is vital if this technology is to be adopted in a maritime environment.

Heraeus Electronic Chemicals has made this technological step with its Clevios HY E material for touchscreens. It unveiled this material in November for folding, or rollable, touchscreen devices that need to be robust, flexible and elastic.

Heraeus head of technical service display Armin Sautter said its Clevios HY E material has the requisite electronic and mechanical properties, combined with a flexible binding agent that allows for a smaller bending radius.

This material has demonstrated the high conductivity needed for large displays, while its bending tests mean it could be used for tablets with multiple folds. Touch-sensitive sensors can then be inserted into the display film so they are undetectable.

Improvements in organic light-emitting diode (OLED) technology has enabled foldable and rolling displays. OLED displays can be mounted on a hyper-elastic material, such as silicone rubber, enabling the screen to be folded 180˚ with a bending radius of 1 mm.

Samsung has been developing folding screen technology for nearly a decade, which culminated in it revealing the Infinity Flex Display earlier this month. Samsung is expected to introduce its Galaxy X smartphone in Q1 or Q2 2019, which would include a screen that can be folded inwards in half.

Chinese technology company Royole has demonstrated the FlexPai smartphone with a display that can be folded outwards. It could be available to purchase in December 2018 and could be scaled up to tablets.

There are questions over the quality of flexible material, the clarity of these displays and their durability. However, these are first-generation products and further development work could improve quality and reduce these concerns.

LG has demonstrated its foldable screen technology for larger displays with an 18-in display that could be rolled up like a newspaper or magazine. This could be adapted into a commercial product.

Foldable display technology is an important development of bridge digitalisation as it has several potential applications. For example, rollable and foldable displays could revolutionise electronic chart and voyage planning processes.

Bridge teams could open electronic charts with optimised routes and navigation warnings superimposed on any surface, like a roadmap or a rolled paper chart. Displays could be curved around bridge workstations or around ship interiors.

Foldable tablets could be used by vessel officers to review operations, or by pilots already familiar with portable navigation units. Captains could have a portable foldable screen to display navigation and automation aids, such as radar, ECDIS, conning and alarm monitoring, around the ship.

Larger displays could be easily stored and transported. This would enable training simulators to be transferred between ships for teaching seamanship and engineering skills, or assessing competencies, such as navigation and ship handling.

The company is dedicated to the development of low cost, high performance, environmentally benign perovskite quantum dots for their applications in lighting and display. Adapting its patented technology, the company has developed the worldâs first PQD/polymer based optical film (PQDF). LCD displays equipped with PQDF reportedly exhibit a color gamut of 110% NTSC and brightness of 600 nits. Zhijing Nanotech is also applying its advanced perovskite technology to a wider range of applications, such as seperator membrane for Li ion battery, UV converter for Si solar cell, etc.

Zhijing Nanotech is now working closely with several world-leading industrial partners to integrate its PQDF product into various commercial display products. The company can also produce patented PQD coating materials in large quantity. PQDF samples made from PQD coating material are being tested by end customers. Zhijing Nanotech is able to offer PQDF samples with size range from A4 to 65 inch (16:9).

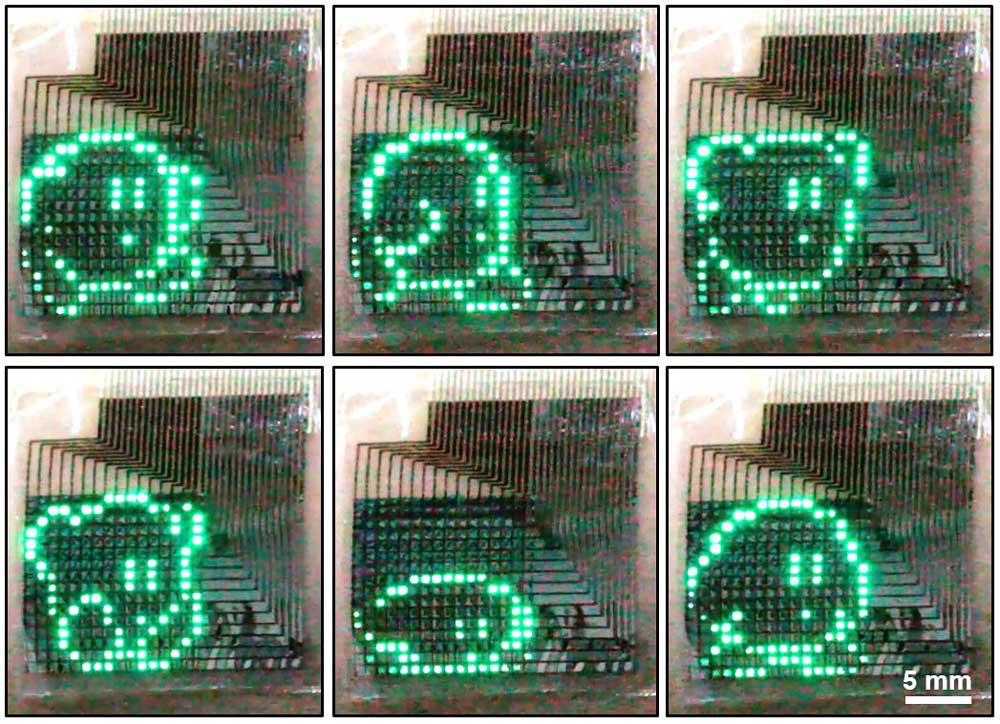

Researchers from Zhejiang University in China have used silver nanowires to fabricate transparent and flexible LED screens. The technique is both cost-effective and simple and can be applied when more opaque screens are not suitable. Additionally, in some situations existing screens can be too brittle when attached to a flexible surface.

For many years, researchers have been looking at ways to make more flexible screens. Most studies looked at ways to adapt glass or clear plastic and involved networks of highly transparent electrical circuits that connected different LED parts together. The circuits on larger screens were made with eitherindium tin oxide (ITO) or fluorine-doped tin oxide (FTO). However, this is a complex and costly process, using expensive raw materials, and results in screens that are still relatively rigid and prone to cracking.

The team have now published their results in the journal Optical Materials Express, where they state their belief that this newnanowire method could replace tin oxide-based circuits in transparent display applications.

Ultimately, silver nanowiresmake an ideal raw materialfor next generation screens, using their properties of strength, flexibility, electrical conductivity, and optical transference, all provided at a relatively low-cost.

“Because of our very simple and low-cost fabrication method and the inherent flexibility of silver nanowires, these new transparent conductive circuits could lower the cost and expand the applications of the transparent LED screens to ever more flexible and large-angle curved areas.”

China has grown a substantial nanotechnology research infrastructure and commercialization base in less than a decade. From a low base, China has established itself as one of the leading countries in nanotechnology. Over the past decade, the Chinese government has significantly expanded financial support for R&D in corporate enterprises, promoted links between research institutes and

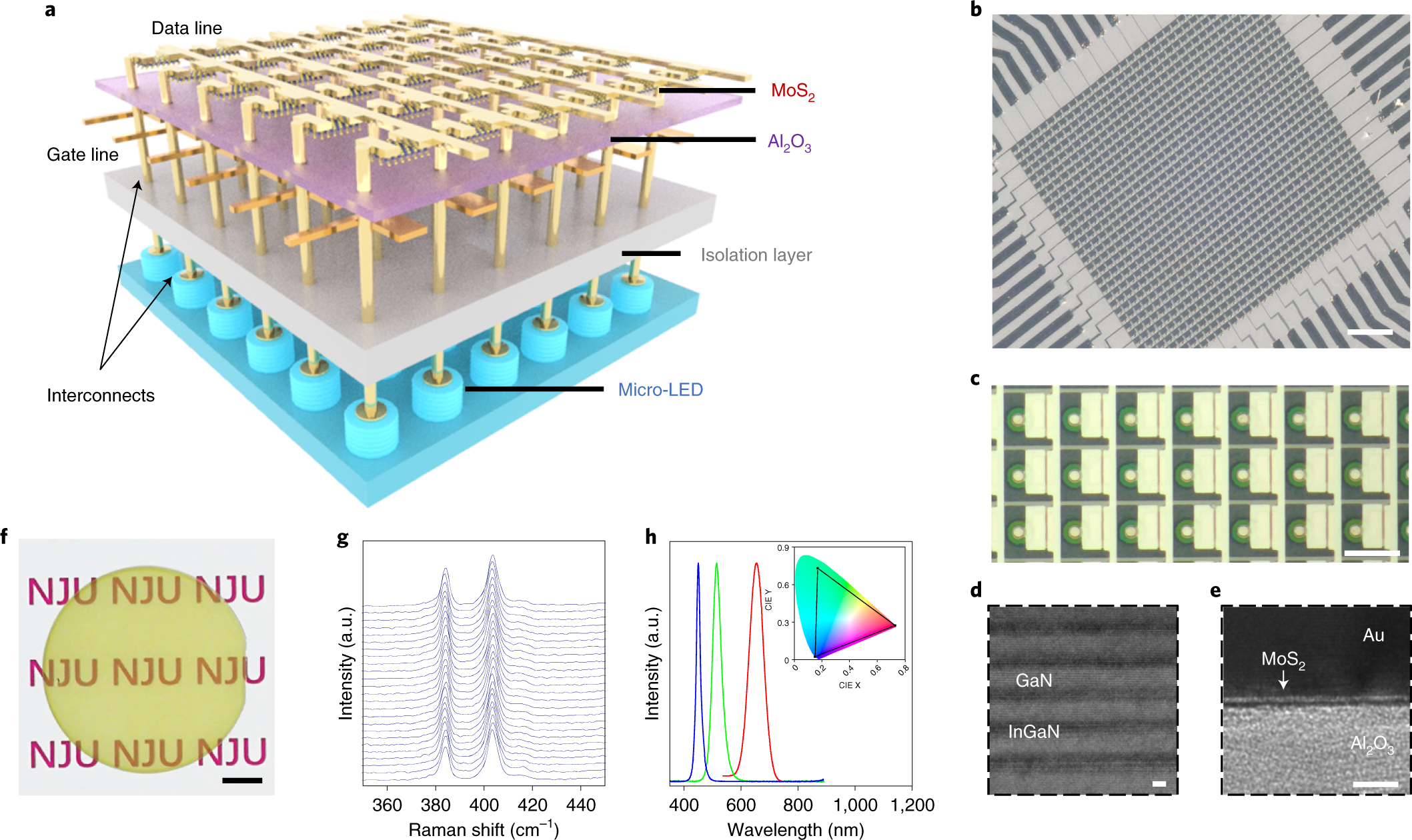

The concept of microLEDs was developed in the early 2000s, with a handful of companies and research organisations showing an interest. But it was LuxVue"s acquisition by Apple in 2014 that really put the microLED on the map. From that moment, the technology started getting the attention of established display makers as well as other OEMs, with patents then starting to get filed. You typically have a six to 18 months delay between patent filing and publication, and so we have seen this huge acceleration in patent activity from around 2017.

We are seeing disruptive changes in the die architecture. The fact that microLEDs are so small creates many challenges, especially in terms of efficiency. But we"re starting to see unique die structures that are specific to microLEDs and very different from what has been used in traditional LEDs. These patents are coming from everywhere - from start-ups such as PlayNitride, Mikro Mesa, XDC, Aledia and others, but also the traditional LED makers that were latecomers here. I have been surprised that companies such as Samsung, LG, some of the Chinese display makers, and of course Apple whose core expertise hasn"t been in LEDs, are developing very valid and credible microLED chip IP. They"ve really ventured out of their comfort zone to develop LED design expertise.

Facebook hasn"t been an early starter in microLEDs, showing interest in augmented and virtual reality from 2014, when it acquired Oculus. However, Facebook"s Oculus then acquired infiniLED and the IP of mLED. Last year, Facebook also did what I call a "pseudo acquisition" of Plessey, buying exclusivity to the company"s capacities, capabilities and technology for an estimated $150 million. While Facebook made this acquisition to supercharge and speed up its microLEDs efforts, it"s difficult to quantify what"s going on here as the company is very quiet. The social media giant has also set up two microLED labs and purchased equipment for full pilot lines from MOCVD to the finished microdisplays but I"m not expecting a commercial product from Facebook within the next couple of years.

Yes, besides mass transfer, this is probably the single largest challenge. Because of the massive numbers of microLEDs needed in a TV, even if you have a 99.99% yield - you still have about 10,000 defective pixels. Repairing these is more expensive than manufacturing the entire display, so any company needs a robust yield management and repair strategy to be a success. This is actually an area where I"m not seeing a lot of intellectual property right now, but the problem has to be tackled or micro-LEDs will not happen.

For me, one of the most intriguing and potentially disruptive technologies is Samsung"s "QLED" or quantum nanorod LEDs. [During display manufacture], a self-assembly process is used and patent analysis shows that the technology is maturing. The technology promises to bring the best of OLEDs and microLEDs together and solve some of the most vexing issues for each, delivering rugged nanorod LEDs with a better lifetime and brightness than OLEDs while potentially solving microLED transfer and yield issues with a self-assembly process and built-in redundancy.

Clearly, Apple is very well positioned as are the big names in displays, including Samsung, LG, BOE and CSOT, all of which have vast numbers of pending patent applications. But it"s interesting to see that at least in terms of patent activities, some of the startups can play in the same court as these larger companies. For example, PlayNitride has been filing a lot of patents recently, Aledia is also accelerating its IP effort and XDC remains strong. Chinese company Konka has many patents pending and Visionox, also from China, looks equally ambitious - the company has announced plans to start mass production by 2023. We are also seeing many gaps in the supply chain getting filled, and while issues such as mass transfer still exist, I am more confident that challenges will be overcome and microLEDs are going to happen.

The escalating coronavirus crisis is impacting production at display panel factories located in the semi-quarantined city of Wuhan, China, spurring a significant near-term reduction in the global supply of panels used in liquid crystal display televisions (LCDs) and other products.

The five factories in the city producing liquid crystal displays (LCDs) and organic light-emitting diode (OLED) panels will experience near-term slowdowns in production compared to expected levels, according to IHS Markit technology research, now a part of Informa Tech.

With the situation evolving quickly, IHS Markit technology research is still assessing the magnitude of the supply shortfall on multiple display types and markets. However, leading Chinese panel makers stated they believe that total capacity utilization for all LCD fabs in the country could fall by at least 10 percent and perhaps by more than 20 percent during the month of February.

With China expected to own 55 percent of global display manufacturing capacity in 2020, the immediate impact of the production reduction has been a worldwide decrease in availability and an increase in pricing for LCD-TV panels. This has resulted in turmoil throughout the display supply chain as suppliers and purchasers alike scramble to adjust to swiftly changing market conditions.

“Display facilities in Wuhan currently are dealing with the very real impacts of the coronavirus outbreak,” said David Hsieh, senior director, displays, at IHS Markit technology research. “These factories are facing shortages of both labor and key components as a result of mandates designed to limit the contagion’s spread. In the face of these challenges, top display suppliers in China have informed our experts that a near-term production decline is unavoidable.”

Beyond the immediate production impact at these facilities, the coronavirus is also likely to trigger delays in the ramp-up of manufacturing at new display fabs during the first half of 2020. This will reduce overall panel availability during the next few months. It also could result in further panel supply tightness as TV display buyers hasten the pace of their panel purchases to build stockpiles for future shortfalls.

The module shortage potentially could expand the impact of the contagion beyond China—with a knock-on effect on production at display manufacturers worldwide.

A Chinese company"s patent technology can change transparent media into screens, which is expected to provide display solutions across a wide range of industries.

(Reuters) - Nanoco Group Plc said commercial production of quantum dots, used to make vibrant screen displays, is expected to begin in the first half of next year at a plant in South Korea being built by its partner, Dow Chemical Co.

The launch of quantum dot production, which analysts said was probably linked to a supply agreement with a big display manufacturer, signals a major breakthrough for Nanoco and the quantum dot industry.

Quantum dots are semiconductor nanocrystals, 10,000 times finer than a human hair, that can convert electrical energy into light and be manipulated to produce precise colors for display.

They are cheaper and consume less power than organic light-emitting diodes (OLED), their rival technology at the sharp end of the display business, but cannot yet be produced in the same quantities.

With demand expected to soar, the handful of companies able to make quantum dots are partnering with big display makers to set up industrial-scale manufacturing.

Dow Chemical, which holds exclusive worldwide rights to sell Nanoco’s quantum dots for use in electronic displays, said on Wednesday it would begin construction of the manufacturing plant in Cheonan, South Korea.

Touch Display Research, a market research and consulting firm, forecasts that the global market for quantum dot displays and lighting components will rise to $9.6 billion (5.85 billion pounds) by 2023 from $508 million in 2014.

Dow Chemical said the new plant would “enable the manufacture of millions of quantum dot televisions and other display applications to meet growing consumer demand.”

Among the largest South Korean display makers, Samsung Electronics Co Ltd declined immediate comment and a spokeswoman for LG Electronics Inc said the company had not decided whether or not to release quantum dot TVs.

LED lights, which stands for light-emitting-diodes, have become ubiquitous lighting solutions for homes and businesses, but when it comes to large, high-resolution displays, traditional LEDs have documented disadvantages. LED displays use a high voltage and a factor called the internal power conversion efficiency is low, which means the energy costs to run the displays are high, the displays do not last as long, and they can run too hot.

In a paper published in Nano Research on August 26, researchers outline how a technological advance called quantum dots could be the solution to some of these challenges. Quantum dots are tiny, man-made crystals that act as semiconductors. Because of their size, they have unique properties that can make them useful in display technology.

�Traditional LEDs have been successful in fields like display, lighting, and optical communications. However, the technique used to acquire high-quality semiconductor material and devices is highly energy- and cost-consumptive,� said assistant professor Xing Lin of the College of Information Science & Electronic Engineering at Zhejiang University. �Colloidal quantum dot provides a cost-effective way to construct high-performance LEDs using inexpensive solution processing techniques and chemical grade materials. Furthermore, as inorganic material, colloidal quantum dot surpasses emissive organic semiconductors in long-term operation stability.�

All LED displays are made up of multiple layers. One of the most important layers is the emissive layer, where the electric energy becomes colorful light. Researchers used a single layer of quantum dots for the emissive layer. Typically, the colloidal quantum dot emissive layer is a source of voltage loss since the conductivity of colloidal quantum dot solid is poor. By using mono-layer quantum dots as emissive layer, researchers theorize that they can reduce the voltage to the largest extend to power these displays.

Another feature of quantum dots that make them ideal for use in LEDs is that they can be made without any defects that would affect their efficiency. Quantum dots can be engineered without impurities and surface defects. �Quantum dot LEDs (QLEDs) can achieve near unity internal power conversion efficiency at current densities suitable for display and lighting applications. Traditional LEDs, based on epitaxially-grown semiconductors, exhibit serious efficiency roll-off in the same current density range. This difference originates from the defect-free nature of high-quality quantum dots,� said Lin.

The comparably low cost of producing emissive layers with quantum dots and the ability to improve the light extraction efficiency of QLEDs using optical engineering techniques, researchers suspect that QLEDs can be an efficient improvement over traditional LEDs for lighting, displays, and beyond. But there is still more research to be done and QLEDs, as they are now, have disadvantages that need to be overcome before they can be adopted widely.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey