nanotechnology display screens pricelist

Nanotechnology—the study of one-billionth-sized things—has been lauded as a solution to every problem from cancer to climate change. And now nanotechnology is here to save your computer monitor and iPhone.

In late 2019, Apple introduced an upgrade to the Pro Display XDR that includes nano-textured glass. Manufacturers make this specialty product by creating minute scratches on the glass that prevent light from making the screen hard to see. Whereas the display with standard glass costs $5,000, the version with nano-textured glass, which promises a “screen with beautiful image quality that maintains contrast while scattering light to reduce glare to the barest minimum,” will set you back $6,000. I did not test this awfully expensive display for Wirecutter, but other reviewers have tried the technology and given it mixed feedback. It’s not only that the price is high; reportedly the nano-textured glass is relatively hard to clean, and it has less image sharpness.

In my interviews with three scientists about nanotechnology, all were skeptical about its value for most people, though they said it might be useful for high-end professionals such as graphic designers or videographers, or if the price goes down in the future. “I personally would not invest on this for a small screen device,” said Ricardo Castro, professor of materials science and engineering at the University of California Davis, via email, “but I’d love to have nanotextures in my TV screen, so it doesn’t reflect my kitchen light on it, distracting me from watching Thanos’ speech in Avengers.”

The next frontier of nanotechnology is multifunctionality, according to the experts I interviewed—especially when it comes to electronic screens. People want strength and fingerprint resistance and durability and touch sensitivity, and they want their phone to be ice- and waterproof. But can nanotechnology actually do all that? Well …

Quantum dots have applications beyond TVs, including deployments in computer monitors. After all, the most significant difference between a computer display and a TV is the absence of a TV tuner. And for anyone who uses a computer to edit photographs or to publish color documents, such as print magazines, color gamut and accuracy are key. Because of the narrow spectrums of red, green, and blue that quantum dots produce, the colors mixed from them are far more accurate, and hence more discernable.

Philips just announced a quantum dot 27-inch display that it says delivers 99 percent of the Adobe RGB color space. The average flat-panel computer display doesn’t come anywhere near that.

Imagine an electronic screen that looks and feels like paper that could connect to your smartphone. You can shift your longer readings and video viewing to this bendable screen, then roll it up and throw it in your bag when you arrive at your subway stop. This may sound like sci-fi, but Israeli researchers have actually found a way to develop such thin, flexible screens you can use on the go.

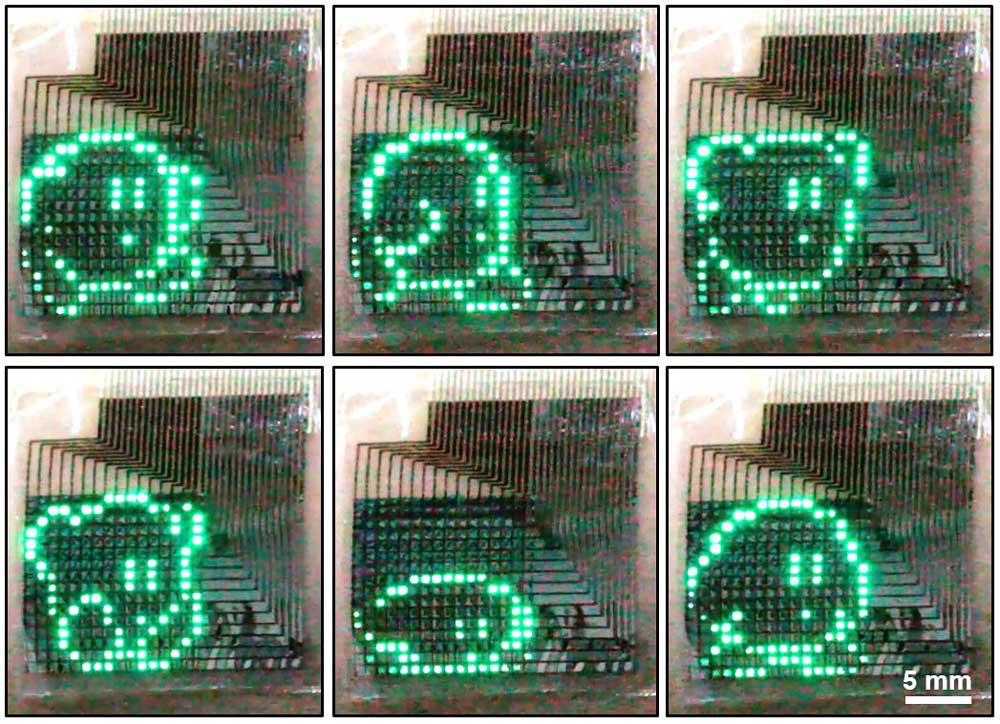

A new Tel Aviv University study suggests that a novel DNA nanotechnology could produce a structure that can be used to produce ultra-thin, flexible screens. The research team’s building blocks are three molecules they’ve synthesized, which later self-assembled into ordered structures. Essentially, the team has built themolecular backbone of a super-slim, bendable digital display.In the field of bio-nanotechnology, scientists utilize these molecular building blocks to develop cutting-edge technologies with properties not available for inorganic materials such as plastic and metal.

This could provide a solution to roughly 2 billion smartphone users who may not want the content they view to be confined to a pocket-sized screen. That’s because currently the size of smartphone screens makes it particularly hard to read more than a few hundred words at a time or watch videos without feeling like you’re on the tilt-a-whirl at Six Flags.

The structures formed by the researchers were found to emit light in every color, as opposed to other fluorescent materials that shine only in one specific color. Moreover, light emission was observed in response to electric voltage — which makes this technology a perfect candidate for display screens.

The TAU researchers, who recently published their findings in the scientific journal Nature Nanotechnology, are currently building a prototype of the screen and are in talks with major consumer electronics companies regarding the technology, which they’ve patented. “Our material is light, organic and environmentally friendly,” TAU’s Prof. Ehud Gazit said in a statement. “It is flexible, and its single layer emits the same range of light that requires several layers today.” Moreover, fewer layers are better for consumers, he says: “By using only one layer, you can minimize production costs dramatically, which will lead to lower prices.”

It’s important to mention that this technology is still in its early stages and a price tag for these screens remains unknown. What is clear, however, is that the desire to consume content on portable, large screens isn’t going away and consumer preferences are trending more and more toward bigger screens.

Ironically, people seem to be drawn back to the old newspaper display – thin, flexible, and capable of being rolled up; now, all of these features are turning digital.

Regardless of flexibility, the tendency to enlarge mobile screens was already evident last year. It is widely believed that sales of Apple and Samsung (500 million smartphone in 2014) were buoyed by their newest smartphone iterations which boast larger screens than past versions. Apple especially took note of this trend, releasing the iPhone 6 (4.7 inch screen) and iPhone 6 Plus (5.5 inches) simultaneously.

A new breakthrough in electrode design could be the answer for brighter OLED TVs and displays and better battery life for laptops and phones. Thanks to a nanotech refinement of the light-emitting portion of OLED (organic light-emitting diode) displays, the new electrode design can deliver up 20% more light using the same power input.

Current diode designs used in OLED TVs and display panels can trap as much as 80% of the light generated by a light-emitting diode, with only the light that exits the device at a near perpendicular angle being projected toward the viewer, and the rest reflecting back into the device.

The new design does just that, as detailed in a paper published in Science Advances(opens in new tab). Using a nanoscale layer of transparent silver in the anode instead of the conventional indium tin oxide, as much as 20% of that trapped light is now liberated, driving more of the light directly out of the light emitting diode toward the viewer. This provides a brighter, and more vibrant display without requiring higher power consumption.

Even better, this new process doesn"t require completely changing how OLED displays are manufactured, since the energy-efficient design can be fit into existing OLED manufacturing processes. “With our approach, you can do it all in the same vacuum chamber,” said Guo.

Brighter light-emission from OLED displays would solve one of the long-standing problems faced by OLED TVs and panels, namely a general dimness when compared to backlit technologies like LED TVs.

Apple"s biggest change for the new 27-inch iMac is the option to add the company"s highest-quality anti-reflective technology, previously only seen on the $5,999 Pro Display XDR. Here"s what it provides to the user, and why you may want to pony up the extra cash for it.

While the new 27-inch iMac does not feature the much-awaited redesign, and it does feature chiefly minor specification improvements, it"s also got one big extra. Previously, to get Apple"s high-quality nano-texture glass on a Mac display you had to pay $5,999 for the top-range Pro Display XDR.

Now you just have to pay from $2,299 — and you get a 27-inch iMac thrown in for the price. The base 27-inch iMac costs $1,799, so this nano-texture technology adds $500 to the purchase price. However, it used to cost $1,000 on top of the base $4,999 Pro Display XDR, so the technology has come down in price considerably.

What you get for your money, whether in the new 27-inch iMac"s screen or the Pro Display XDR"s 6K one, is reportedly far better anti-reflective glass.

"The cover glass has our industry leading anti reflective coating," said Colleen Novielli, Apple"s Worldwide Senior Product & Marketing Manager, when introducing the $4,999 version of the Pro Display XDR. "But for challenging lighting conditions. We have created an innovative matte option."

She was speaking at the launch of both the Pro Display XDR and the Mac Pro in 2019, and she had just been praising the new display"s color accuracy and viewing angle. Then she showed how Apple tackled the issue of reflective glare on the screen, compared to other manufacturers.

"Most map displays, they add a coating to the glass, and this coating it scatters the light," she explained, "but it also adds unwanted haze and sparkle and it lowers the contrast."

Rather than diffusing reflections on the glass or perhaps trying to compensate for them with greater brightness, Apple cuts fine lines into the display. This means the monitor does not present a single plane for ambient light to bounce back from.

Even after the Pro Display XDR has been officially available since December 10, 2019, it also hasn"t really been confirmed yet just how much of a difference the nano-texture technology makes. That"s partly because at this price, far fewer Pro Display XDRs will ever be sold than most monitors.

However, it"s also because people whose work requires Pro Display XDR monitors won"t typically have regular screens to compare it with. That"s the real difference here, that Apple is bringing this technology to more people.

But now, alternative energy researchers think that something really small—nanotechnology, the engineering of structures a fraction of the width of a human hair—could give a gigantic boost to solar energy. (See related quiz: "What You Don"t Know About Solar Power.")

"Advances in nanotechnology will lead to higher efficiencies and lower costs, and these can and likely will be significant," explains Matt Beard, a senior scientist for the U.S. Department of Energy"sNational Renewable Energy Laboratory(NREL). "In fact, nanotechnology is already having dramatic effects on the science of solar cells."

Nanotechnology may provide an answer to the efficiency problem, by tinkering with solar power cells at a fundamental level to boost their ability to convert sunlight into power, and by freeing the industry to use less expensive materials. If so, it would fulfill the predictions of some of nanotechnology"s pioneers, like the late Nobel physicist Richard Smalley, who saw potential in nanoscale engineering to address the world"s energy problems. (See related: "Nano"s Big Future.") Scientists caution that there’s still a lot of work ahead to overcome technical challenges and make these inventions ready for prime time. For example, more research is needed on the environmental, health, and safety aspects of nano-materials, said the National Academy of Sciences in a 2012 report that looked broadly at nanotechnology, not at solar applications in particular. (See related pictures: "Seven Ingredients for Better Car Batteries.")

But Luke Henley, a University of Illinois at Chicago chemistry professor who received a 2012 National Science Foundation grant to develop a solar-related nanotechnology project, predicts there will be major advances over the next five to ten years. "It’s potentially a game changer," he says. Here are five intriguing recent nanotechnology innovations that could help to boost solar power.

To reduce the amount of sunlight that is reflected away from silicon solar cells and wasted, manufacturers usually add one or more layers of antireflective material, which significantly boosts the cost. But late last year, NREL scientists announced a breakthrough in the use of nanotechnology to reduce the amount of light that silicon cells reflect. It involves using a liquid process to put billions of nano-sized holes in each square inch of a solar cell’s surface. Since the holes are smaller than the light wavelengths hitting them, the light is absorbed rather than reflected. The new material, which is called "black silicon," is nearly 20 percent more efficient than existing silicon cell designs. (See related photos: "Spanish Solar Energy.")

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey