touch digitizer vs lcd screen manufacturer

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

Your iPod, iPhone and tabletare commonly known to have three key components: a glass panel, digitizer (aka touch screen) and LCD. What are the differences? Let’s clearly define these layers:

Digitizer –The digitizer is located just under the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer. The digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa. UEGoffers a Front Glass (Digitizer Touch Screen) Repair Service on tablets.

Touch Screen – The term touch screen is interchangeable with the term digitizer. You’ll often see the combined terms Digitizer Touch Screen offered as a repair service.

LCD – LCD is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. UEGoffers LCD repairs on tablets, iPhonesand iPods.

The easiest repair for mobile phones to complete is the LCD assembly replacement. This repair takes less than an hour and requires the least amount of technical ability. For some devices the LCD assembly can be replaced simply by removing a few screws and cables. Also, as the assembly includes the glass, touch screen and the LCD, you can be confident it will fix all common screen issues.

For iPad and other tablets, if the screen parts aren"t fused, then you can do a glass touch digitizer only replacement. Otherwise, the full assembly is the easiest repair. Either way, it usually takes 1-2 hours.

While it can be significantly cheaper repair, If the screen parts are fused, the screens must be heated to loosen the adhesive between the screen and LCD and you need special equipment. This includes all iPhone and most other mobile phones and some iPads or tablets. A heat gun or hair dryer can be used for this. The screen is then gently and very slowly pried apart from LCD. DIYers need to use care to insure the LCD is not damaged in the process.

Tip: Transferring the home button on an iPhone or an iPad can be the most tricky part. It takes a little patience and heat. You can purchase screens that have the home button pre-installed (along with other small parts) and this is the easiest of all repair. This can take 15-30 minutes. However, Touch ID function only works with the original home button so you have to transfer if you want to retain it. Note: some of the iPads don"t have a screen replacement option that includes the home button like the iPad Pro and newer iPad Mini. iPad 1st Gen to 9th Gen screens, have a home button pre-installed option.

A touch screen display is usually made with three main parts. The protective glass sheet, the digitizer sheet, and the LCD. The digitizer is a thin transparent sheet that is adhered to the protective glass sheet with a transparent conductive adhesive. The digitizer is the only part of the display assembly that is responsible for sensing touch. Since the human touch is conductive it allows the screen to sense the location you touch. The LCD is only responsible for displaying the image on the screen. If the screen is not responding to touch then usually the digitizer is damaged or faulty. Usually a damaged or cracked LCD will display a distorted image or no image at all. So if the phone displays a good image but does not respond to touch then you may have the option of only replacing the digitizer. It"s not as easy of a repair as replacing the whole display but is cheaper. A new digitizer part already has the digitizer sheet adhered to a protective sheet of glass. If a person can remove the faulty digitizer from the phone without damaging the LCD then it is surely more cost effective repair. Some displays have the digitizer fused to the LCD which makes it hard not to damage the LCD if trying to remove the digitizer. If that is the case with your phone"s display it is a lot easier to just replace the whole display. Hope this information is helpful.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

Touchscreen devices consist of numerous different components that must work cohesively together in order to make it functional. The touch sensor, controller, and the software all play important roles. But there’s one component that’s often overlooked in the equation and that’s the touchscreen digitizer. This is the component that allows users to directly interact with what’s on the screen and issue commands.

As you know, touchscreen devices consist of multiple layers each of which serve a different purpose and carry out various functions. The purpose of the touchscreen digitizer glass layer is essentially to translate or convert physical touch commands into digital signals that the device can understand and then carry out.

Commercial and industrial displays such as capacitive and resistive screens all feature touchscreen digitizers that are placed on top of and connected to the LCD layer using a flex cable. While the LCD layer is responsible for displaying sharp and crystal-clear images on the screen, the LCD touchscreen digitizer reads, understands, and translates the commands given so that the device can perform the appropriate functions.

Touchscreen digitizers are fairly common components of modern LCD displays, but not all of them are equipped with one. The sole purpose of an LCD display touchscreen digitizer is to convert touch commands on the top layer into digital data that the device can understand and perform. Once the touch commands are converted into digital data, the device can then perform the required function and change the images displayed on the screen accordingly.

Touchscreen digitizers are made of a single glass layer, which means they can be susceptible to damage if the device is dropped or comes into contact with a brute force. Although the device can still marginally function depending on the extent of the damage to the touchscreen digitizer glass, its functionality and ability to comprehend touch commands may be limited. If the glass is completely shattered, then the device won’t be able to interpret touch commands at all.

The LCD and touchscreen digitizer layers of a device display serve completely different functions, but they work in tandem to maximize user experience and device performance. Since both of these components are made of thin glass layers, they’re not impervious to damages such as cracks or scratches as a result of being dropped or coming into contact with external physical stressors.

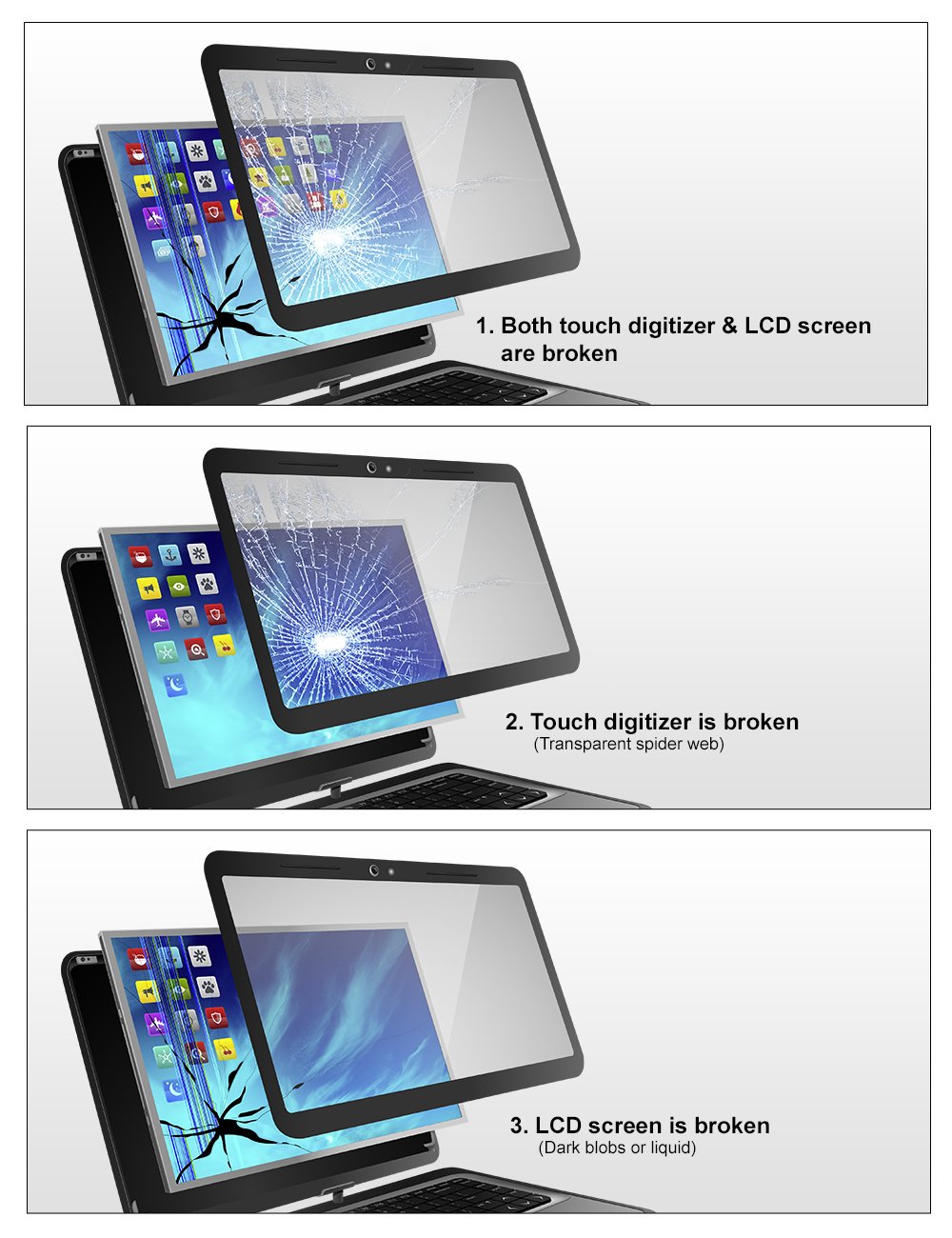

If it’s only the touchscreen digitizer that’s broken, you’ll still be able to make out what’s being displayed on the screen by the LCD component for the most part. The only difference is that parts of the screen or the entire screen might be unresponsive to your touch commands as a result of the damages. Moreover, blobs or splotchy images may appear in certain parts of the screen.

This indicates that there’s a disconnection between the touchscreen digitizer and the LCD display, which is preventing the device from performing the desired functions issued by touch commands.

The LCD screen is responsible for the visual component of your device. Pixelation in the form of multicoloured splotches or dots throughout the screen indicates that the LCD component has sustained a certain level of damage. It can be caused by wear and tear over time or if your device sustains physical damage.

A black screen indicates that the LCD layer of the device is damaged. The device itself will most likely still turn on and function like normal, but you won’t be able to see what it’s doing on the screen itself. Typically, this just means that the LCD layer needs to be repaired or replaced. Depending on the extent of the damage, it might be more practical and cost-effective to simply purchase a new device altogether unless you’re still within the warranty period.

When you drop your device, you may immediately pick it up and try to turn it on to see what happened. Sometimes, the screen will be completely cracked, but there’s still a display. Other times, the screen is cracked and there is no display. A few different things happen when an iPad or iPhone drops. Understanding what happens to the screen can help you know what type of repair you need.

When you drop your iPad or iPhone and the screen doesn’t come on (there is no display) or the display is distorted, it’s likely the LCD screen is broken. This screen has everything to do with seeing what you love about your device. Videos, games, email, and everything else depends on your LCD screen.

Sometimes, you may be able to see the screen, but when you touch it to do something, it won’t react to your touch. This is usually because the digitizer is damaged. Many times, this happens even when you can’t see a crack on your device. This is why many people don’t think they need a screen replacement, and actually, in some cases they still don’t need it. Other components may be damaged that cause the touch not to work, but when those are all working okay, it’s the screen.

There are some cases in which both the LCD and digitizer need to be replaced. If there’s no display or a distorted one AND there’s no touch response, the LCD and digitizer need to be replaced. This is usually what people need when they turn to us with a shattered iPad or iPhone.

If you still don’t know if you should have a LCD or digitizer repair, contact our certified technicians. They can look at your device for free to provide you a repair quote. You can trust our technicians to give you the truth, so you can save money when you may not need both screens replaced. If you do, you can be sure that you’ll receive a quality repair with quality parts.

However, if the digitizer or LCD is also damaged during a fall, that screen no longer carries value because it cannot be refurbished. Repair shops cannot sell broken LCDs to refurbishing companies; therefore, they cannot offset the cost of an LCD repair. That is why repair stores often charge a little extra if there is damage to the LCD or digitizer, to make up for that loss. Repair stores that don’t have an additional charge for an LCD repair typically inflate their glass repair price to make up for the loss from damaged LCDs. If they have one price, that means everyone is paying more to cover the cost of customers who have damaged LCDs and customers who only have cracked glass. This is why TCR separates the price of glass and LCD repairs for you! If you only have cracked glass, you only have to worry about paying to replace the cracked glass.

If your phone or tablet’s glass is shattered there will be cracks or chips on the screen itself. If it is just the glass that is damaged, the device may still function and you may be able to use it normally. If this is the case, it is likely that only the glass needs to be replaced. To prevent further damage to your device it is best to get it repaired quickly. For example, if liquids seep through the cracks it could cause permanent damage to the LCD.

Many people may continue to use their touchscreen with shattered glass and delay fixing the glass on their devices; however, if the touchscreen isn’t responsive, it could be a sign of more significant damage to the device’s digitizer which is integrated with the LCD screen.

A pixelated screen can indicate LCD damage. This would look like a patch of multicolored dots, a line or lines of discoloration, or a screen with rainbow colors. For many people, these colors are an easy way to know that their LCD is broken and that they should get it repaired.

Dropping your phone isn’t the only reason you’ll end up with a pixelated screen. Over time, your screen’s LCD may break down through regular use. This happens to other devices aside from your smartphone or tablet. Pixelation can happen to TVs and computers, too. People typically decide to buy a new device when this happens. Fortunately, with an LCD repair, you can fix the device without needing to replace it.

A black screen or black spots on your smartphone or tablet is an indication of a damaged LCD. Often with a bad LCD, a phone may still turn on and make noises, but there is no clear picture. This does not necessarily mean any other part of the phone is damaged and a simple screen replacement will get it functioning again. Sometimes it can mean a battery or other internal component is damaged. It is best to have a highly qualified phone repair technician diagnose what is wrong so the appropriate repair can be made.

Fortunately, your mobile device is fixable whether you cracked the glass or damaged the LCD. Stop by or call TCR: Triangle Cellular Repair at (919) 263-2699 for a free diagnostic and quick, affordable cell phone repair in Chapel Hill and surrounding areas. We’re always happy to help!

As an official phone repair provider who has been in the business for almost a decade, one unique question people ask when they visit our service centres to replace their phone screen is: "what"s the difference between original and copy phone screen?"

Well, the answer is, there are many differences between these two screens, which is mostly in their quality. And while “copy” phone screens are somewhat cheaper than the originals, it doesn’t justify the difference in quality. So, before you regret replacing your phone screen with a forbidden part, the tips below will tell you the critical differences between original and copy phone screens.

Generally, phone screens manufactured from your brand"s factory are the original ones while ‘Copy’screens are the ones designed and produced by third-party manufacturers and factories that are not related to your brand.

Many people usually like to go for copy screens because of their cheaper price. However, the "real" differences between original and copy screens lie in their quality, and here’s what you need to know about them.

One of the principal issues with "copied" phone screens and why it differs from the originals is touch and digitizer problems. And that"s a big problem since you"re going to control the device with the touchscreen anyway.

As far as we could remember, phone manufacturers build the touch panel/digitizer with the LCD itself, while the copied screen manufacturer build it separately on the surface glass. Hence, there"s a difference in touch sensitivity. Additionally, copied phone screens usually drop the high touch sampling rate, meaning your screen may not respond to your touches faster.

Here"s also another major issue with the digitizer on copied phone screens. When you crack a copied screen accidentally, the touchscreen stops working, stopping you from accessing the device until you fix it again. Meanwhile, the touch on the original phone screen works perfectly, even after undergoing severe cracking.

Besides having touch problems, most copy phone screens usually have poor display properties. That means you get lower brightness, colour accuracy, sharpness, contrast, etc. And when the display isn"t great, watching movies and viewing other content becomes boring.

For instance, if the original screen is supposed to have 480 nits of brightness, but the copy screen has just 200 nits, the screen becomes unusable under bright lights. Moreso, copied phone screen seems to have more blue light, which, in return, affect your sight and disrupts your sleep at night.

Among others, copied phone screens drop higher refresh rates, and that"s a bummer since most phones come with at least 90Hz refresh rate screens. What that means is the copied screen won’t feel smooth as it’s supposed to be.

It"s not all about the display quality. A copy phone screen may also affect other parts of the phone system if its specifications don"t tally with the original one. In such a case, it could drain your battery at an alarming rate, or at worse, damage your backlight.

If you happen to have a phone with an in-display fingerprint sensor, then replacing its screen with a copied one is not an option – it’s going to mess with your fingerprint accuracy.

We know copied phone screens for their poor quality, and it also extends to the fingerprint sensor. Hence, it takes a longer time to unlock your device. And in other cases, the security of the sensor is not accurate. We"ve seen situations where phones get unlocked with many unregistered fingers after replacing the screen with a copied one.

If you care about your phone"s security and you don"t want a sluggish fingerprint sensor, then we recommend you only go for the original phone screen replacement.

That brings us to the last difference we’re going to mention between copied and original phone screens. They manufacture copied phone screens with poor glass materials. Hence, they break quicker than the originals. And when they do, you’ll be left with only one option: to replace the screen again.

The major reason for choosing the official service centre over third-party/local repair shops summarizes what we"ve said earlier. The official service centre is the reliable place to get original phone screen replacement parts.

Besides offering you the original screen spare parts, the official service centres also have other advantages. These include certified and well-experienced technicians to fix the screen, the use of modern tools that won"t damage your phone further, and most importantly, a reliable warranty. Local repair shops usually don"t offer these features; most especially a reliable warranty, which means you"re on your own if the replaced screen gets faulty afterwards.

As far as choosing the official service centre is concerned for genuine screen replacement, then you shouldn"t shy away from Carlcare Service if you own a TECNO, Infinix, or itel phone with a cracked screen.

We"re the official service center for these three brands to cater for your mobile repair needs. And for screen replacement, Carlcare delivers excellently. Our brand-trained technicians replace your cracked screen with genuine OEM parts at affordable rates.

We understand you have a busy schedule; and yes, we"ll replace your screen in the shortest possible time. Start by checking how much it cost to fix your cracked phone screen, then you can book an online reservation service with us to reduce your waiting time and also become a VIP customer.

Remanufacturer and distributor of liquid crystal, panel and touch screen displays. Available with 100 VAC to 240 VAC power supply. Features include front bezels, USB support, windows, auto-adjust buttons, built-in power supply and USB cable brackets. AutoCAD files accepted. Most items available in stock. 24/7 services provided. RoHS compliant. UL and cUL listed. CE certified. Two year warranty.

Manufacturer of custom rugged displays for military, marine, industrial, avionic, medical, transportation, commercial and other applications. Diverse engineering team able to design to fit any enclousure. Many types of touch screen technologies available, including surface capacitive, projected capacitive, resistive, SAW, infrared, optical, DST. Other features include sunlight readable, NVIS, waterproof, flip-up, flip-down, rack mount drawer, panel or rack mount, and much more. All sizes are available, from small to large. Suitable for workstations, cockpits, medical devices and other safety- or mission-critical applications. Manufactured, serviced, and supported in the USA.

Manufacturer of standard and custom liquid crystal display (LCD) displays. Thin film transistor (TFT) and graphical displays are available. Offered with LED backlight and integrated capacitive or resistive touchscreen. Suitable for medical devices, embedded systems, airplanes, amusement parks, golf carts and vehicles. Serves automotive, automation, gaming, security and OEM industries.

Distributor of touch screen panel liquid crystal displays (LCDs). Available in 10.1 in. sizes. Inventory management services are also offered. Serves the electronics, computer, telecommunications, aerospace, aviation, medical, automotive and transportation industries. ITAR registered. Stock items available.

Manufacturer of optically bonded, non-touch and touchscreen displays. Features vary depending upon model, including vision 2 display controllers with quad-core multimedia processors, liquid crystal displays, auto-dimmable display backlights, housings with powder-coated die-cast front, horizontal and vertical viewing angles, membrane keyboards, internal temperature sensors, programmable software and resistive touch screens. Meets ASME and OHSAS 18001 standards. CSA and NFPA approved. API registered. CE certified.

Manufacturer of flat-panel industrial monitors and displays rated for Division 1 and Division 2 environments. Custom engineered, designed, and manufactured to handle the dust, dirt, debris and chemical exposure common to rugged and hazardous applications in the oil and gas, pharmaceutical and food processing, manufacturing and chemical industries. Types of monitors include military grade, LCD, rugged, washdown, high definition, wide screen, panel mount, rack mount, flush mount, gas purged, and more.

Manufacturer of resistive touchscreen HMI displays with anodized aluminum housings, USB and Ethernet. Available in four screen sizes, 6.102 to 11.535 in. width, 2.283 in. depth and 5.315 to 8.78 in. height. Surrounding air operating temperature ranges up to +55 degrees C. Serves the automotive, railway system, power engineering, building, lighting, marine, offshore and process industries. Most items available in stock. RoHS compliant. UL listed. CE certified. JIT delivery.

Distributor of integrated touch screen displays. LCD, sunlight readable TFT, monochrome, chip on glass, TFT LCD, LED, automotive rear seat and OLED displays are also available. Vendor managed inventory (VMI) programs and stock items available. Meets AS9100 Rev C standards. Kanban and JIT delivery.

Manufacturer of Industrial touchscreen displays suitable for railway sign, airport control tower, digital signage, agriculture, factory automation, kiosk and retail applications. Available in 10.4 to 21.5 in. display size, -10 to 60 degrees C operating temperature and 9 to 50 volts DC voltage. Some monitors are offered with fanless and rugged design, LCD display, front panel IP65 waterproof, dual speakers, resistive and capacitive (PCAP) touch options available. EPA registered.

Manufacturer of standard and custom thin film transistor liquid crystal displays (LCD) including human machine interface diagonal touchscreens. Available in 5 VDC power at 200 mA current, 4.3 in. screen sizes, 0.92 in. depth, 4.75 in. width and 3.70 in. height. Features include programmable, graphical operating systems, front panel mountable enclosures, protective overlays, built-in copy protection options and power management controllers. Serves the pharmaceutical packaging identification, instrumentation, emergency response service, recording and bioprocessing industries. Made in the USA.

Manufacturer of touchscreen panel displays for medical and industrial applications. Available in 10.1 to 27 in. display sizes. Features vary depending upon model, including LED backlights, plastic design, USB, flat, power connectors, optional side brackets, input video signal interfaces and terminals. Accessories such as power adaptors, cords, cables and stands offered. Meets EN 60601-1-2 standards. Custom options depending upon applications are also provided.

Manufacturer and distributor of touchscreen, sound, video and theatrical displays. Types include counter top, back-up, extension, dual USB charger, heads up and four sided color changing displays. Available in a variety of configurations. Features vary depending upon model and include LED light strips, wireless remote control, LCD widescreen rear view mirrors and license plate cameras.

Manufacturer of touchscreen displays for home automation, video intercom and door entry system. Features include up to 16 control functions, intuitive operation and capacitive touch display. Lifecycle management, engineering, consulting, installation, maintenance, replacement and training services are provided. Serves the automotive, chemical, marine, metal, food, beverage, mining, power generation or distribution, solar power, printing, aluminum, cement, automation, water, wind power, pulp and paper industries.

Manufacturer of alphanumeric, touchscreen and LCD displays. Features vary depending upon model, including built-in Ethernet ports, hand-held versions, single port multi access (SPMA), integrated simulation functions, analog resistive touch, multiple communications, compact flash memory cards and FTP web interfaces. Serves the automotive, food/packaging, electronics, life sciences, material handling, machine tool, oil and gas, water, wastewater, security, detection, entertainment and other industries. 24/7 predictive maintenance services also provided.

ISO 9001 certified worldwide manufacturer of touchscreen terminals, monitors & displays. Graphics touchscreen terminals enable operating, monitoring & control of large scale projects with different PLC"s simultaneously. Features include plain text messages & graphical overview screens for user-friendly diagnostics. Touchscreen terminals are available in sizes of 5.7 in., 6.5 in., 10.4 in. 12.1 in. & 15 in. Terminal features also include Microsoft Windows ® CE.net operating system, USB interfaces, serial interfaces, Ethernet interface, IP65 front, IP20 back & PCMCIA slots.

Six Sigma capable, ISO 9001:2008 & ISO 14000 certified manufacturer of touchscreen displays including flat panel monitors. Types of flat panel monitors include DVI/RGB and hazardous location compatible. Flat panel monitors feature front USB interface, 256K or 16 million color display, analog resistive touch panel, serial/USB touch interfaces, on-screen-display menu for brightness & contrast control, & VESA standard wall mounts. Available with a 2-year warranty. Markets served include industrial, automotive, oil & gas, water/wastewater, semiconductors & agriculture. Modbus-IDA, OMAC & ODVA affiliated. Products are UL® listed, CSA® approved, and ATEX & CE certified. Products are RoHS compliant.

Custom manufacturer of touchscreen displays for stationary storage, equipment, electric and hybrid vehicles. Battery management systems and vehicle control systems are offered. Fleet management software is also provided. Consulting is available as value added service. Serves the e-mobility, automotive and mobile robotics industries.

Precision CNC machining, sheet metal fabrication and assembly services. Repair services are also provided. Fiber optic junction boxes, converters, latches and switches are offered. Uninterruptible power supplies (UPS), liquid crystal displays (LCD), racks, consoles, multiplexers, control panels and quad-core processors and servers are also available. Serves aerospace and defense industries.

Distributor of electronic components for retail and business applications. Mixer or audio amplifiers, menu boards, cameras, columns, converters, and enclosures are available. Interfaces, zoom lenses, loudspeakers, mixers, LED wall mounts, and laser projectors are offered. Touchscreens, LED, video and flat panel displays are provided.

ISO 9001:2008 certified distributor of industrial automation and motion control products including touchscreen displays. Touch screens feature built-in Ethernet communications and live video input capabilities. Message displays feature password-protected screens and programmable function keys. Also available touch screens with integrated PLCs and built-in operating panels into a single compact device.

Custom manufacturer of touchscreen displays. TFT high resolution and high brightness displays are available in resistive, capacitive and infrared touch types. Offered in display sizes ranging from 6.5 in. to 19 in. Capabilities include designing, prototyping, small volume production, lean manufacturing, automated optical inspection and testing. Markets served include industrial, commercial, automation, transportation, telecommunications, aerospace, OEM, power generation, military and medical. ITAR compliant.

Manufacturer of standard & custom LCD touch screen displays for industrial, medical & surgical applications. 5-wire resistive touch, capacitive, SAW & IR touch screen technologies. Sizes include 4.3 in. to 42 in. LCD panels, 4:3 & 16:9 aspect ratio, 12 vdc, 24 vdc, and 90-240 vac. Touchscreen displays are available with various video inputs including VGA, BNC, S-Video, component, composite, HDMI, DVI, & DisplayPort. Available in standard, rack mount, panel mount, sunlight readable, optically bonded & waterproof enclosures. UL, cUL, FCC, CE & RoHS approved. Three year warranty.

icd and touch screen digitizer provide the touch interface in smartphones, which are vital for them to function. Alibaba.com stocks a stunning range of high-tech icd and touch screen digitizer with vibrant color depictions. Truly crystal-clear displays of icd and touch screen digitizer are available covering various brands and models such as the Samsung Galaxy Edge 2, OnePlus 7T, Samsung Galaxy C5, and many more.

icd and touch screen digitizer are the most commonly used displays, as they produce great image quality while consuming low power. Rather than emitting light directly, they use back lights or reflectors to produce images, which allows for easy readability even under direct sunlight. icd and touch screen digitizer are energy-efficient, and are comparatively safer to dispose of, than CRTs. icd and touch screen digitizer are much more efficient when it comes to usage in battery-powered electronic equipment, due to their minimal power consumption.

Some other advantages of icd and touch screen digitizer over the CRT counterparts are - sharper images, little to no heat emission, unaffected by magnetic fields, narrow frame borders, and extreme compactness, which make them very thin and light. Some types of icd and touch screen digitizer are transmissive, reflective, and transflective displays. Transmissive displays provide better image quality in the presence of low or medium-light, while reflective displays work best in the presence of bright light. The third type of icd and touch screen digitizer, transflective, combine the best features of both the other types and provide a well-balanced display.

Whether as an individual purchaser, supplier or wholesaler, browse for an extensive spectrum of icd and touch screen digitizer at Alibaba.com if you don"t want to stretch a dollar yet find the best fit.

If your car or truck factory radio LCD with touchscreen monitor needs replaced then we provide some of the best replacement car touch LCD screen replacement parts available on the market today. As is Factory Radio Parts standard: all of our car touchscreen repair kits are developed for both ease of use and functionality – so you can get your tunes blasting again in no time!

Car touchscreen damaged? Car radio or car DVD player not working? Let us provide you with 8.4” touchscreen parts, VP3 and VP4 radio replacement touch screens, MyFord touch sync 2 radio screens, RB5 RE2 radio replacement screens from Uconnect, 439 RBZ, 430N and 730N touch screen repairs and 7 inch screens. We supply big names like Ford Lincoln Clarion Navigation replacement parts, Toyota Tundra Panasonic touch screen fixes, RAM Truck, Chevrolet, Cadillac and more!

When customers visit a shop for a screen repair, some shops will give them an option to choose between an original screen and a ‘copy’ screen. Most of the time, the first question that a customer asks is “What’s the difference between the two?” Originals are manufactured for Apple while copy screens are only compatible replacements that are manufactured by third party companies. Most of the time, customers choose the relatively affordable copy rather than the original because of the price distinction, but original iPhone screens are still recommended because of its far higher quality.

One of the most noticeable differences between an original and a copy is how the touch sensor also called the digitizer is designed. Original Apple screens manufacture digitizers as part of the LCD while copy screens manufacture it on the glass.

There are some companies that manufacture bare LCDs themselves, but these LCDs are also bought by other companies, who in turn add the other parts to create a complete working screen. Because of this, it is possible that you get a great LCD screen, but the digitizer is poor quality.

, iPhones transferred the chips necessary for the digitizer to work directly on the LCD, that means that when you buy a ‘copy screen’ for these models, you are not only getting a copy of the screen but a copy of the chip.

When you buy a copy screen you are also buying a low image quality for your phone. This is because the LCD is of poor quality. The problems experienced are weak brightness, contrast and vibrancy, grainy appearance because of low image resolution and lower refresh rate.

In most cases, the performance specification of copy screens is not identical to the original ones. As a result, the battery of the phone drains faster and the OS or operating system is misled. This mismatch is also a possible cause of damage to your backlight.

Copy screens can also create damage to your phone’s touch ID fingerprint reader. The home button flexes on the copy screens design which makes it stop working, and we all know the struggle of not having a working ID fingerprint reader.

Some shops offer copy screens to remain competitive in the market since the difference in price ranges to £20-30. Still, you can get the most of your money with the original for having a better performing iPhone screen. Even though there are different qualities of copy screens, from good copies that actually work to cheaply made ones, there are several factors at play to have your iPhone be used seamlessly. Aside from the points above, one of the factors that might affect the use of your phone with a copy is the Apple updates that conflict with the low grade copy screens.

Eventually, it is your decision whether to choose an original one or not. But additional pounds for an original screen is a good investment. You can avoid all the possible damage caused by copy screens which in turn will help you save money in the long run since you won’t need to return to a shop for further repairs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey