lcd screen on iphone made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Mandy, ETS is obviously a company that you are connected to and this could easily be taken for spam. I think we can make an exception at this time since you are asking a good market research question that may be useful to many.

Having checked out your video, I personally will not use the aftermarket screen as a replacement for my X. It just doesn"t have what I expect for a $1000 USD phone. I recognize that $300 USD for a replacement is hefty but the aftermarket screen does not appear to have the quality that I would expect for my phone.

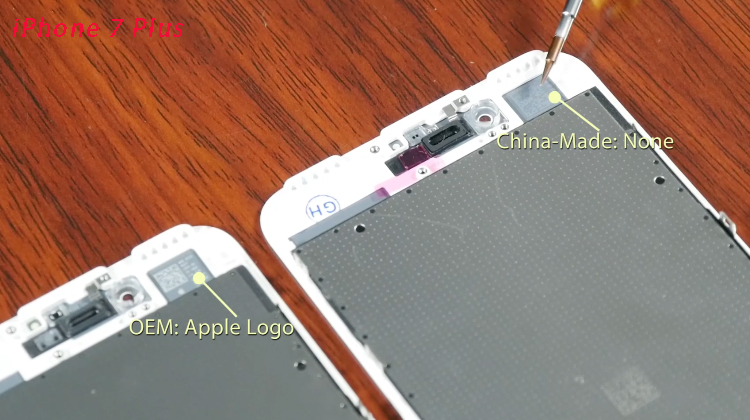

Since the iPhone 7/7 Plus has been released for quite a long time, finally the China made iPhone 7/7 Plus screen replacementscame out in the market. we’ve got some iPhone 7 series LCD screen replacements samples and done some tests on them, now let’s take a closer look at these new iPhone 7 series LCD screen replacements!(TianmaandLGsources for testing)

After installing all the sample screens to the iPhone 7/7 Plus rear housing assembly, we found that all the China made iPhone 7 series screen replacements are fitting well just like the original ones - the home button fits well, the screen assembly and the rear housing also fits well.

From the picture below, we can see that there is no difference between the China made iPhone 7 series display and the original ones, however, back to the rear side, we can easily figure out which one is which, cause the original one has Apple logo on it while the China made screen has none.

By comparing these two iPhone 7 screens, we can find that the screen flex cables are much different, there are extra IC on the China-Made iPhone 7 screen while the original one has none. And the original iPhone 7 series screen flex cable is integrated together while on the China-Made iPhone 7 series screen the touch function flex cable is soldered to the display and 3D touch flex cable.

Another difference between the original and China made iPhone 7 screen replacements is the exposed IC on the after-market iPhone screen, just like other China-Made iPhone 5 or 6 series screen replacement, which has more potential risk of electrostatic damage and more likely to get damaged and this problem needs to be improved.

During our test, we found that the display color between our after-market iPhone 7 screen and original screen seems a little different although they are not effecting the touch function. And to be honest, there may have some black dots on the screen because of impurities within the screen module when laminating the LCD and backlight together, without any doubt, this can be solved with technical improvement.

The screen touch sensitivity is another big concern for all of us, luckily, during our test, almost all home button and touch functionality on both iPhone 7 and 7 Plus works well, except one piece of iPhone 7, the 3D touch function is not acting so well on the central part of the screen.

The China-Made iPhone 7 series LCD screen assembly replacement still remains to be improved in quality and performance compared to the original ones, the exposed IC, heavier screen flex cable ribbon, and the screen color difference, the touch function stability, although the price is attractive. However, the China made iPhone 7 series screen replacement is under the improvement, and sooner or later their quality and performance can be quite close to original ones and acceptable, if you"re going to stock up some non-original iPhone 7 series LCD screen replacement, pay more attention and we’ll keep you updated with further information about after-market iPhone 7 series screen replacement!

1. Every single digitizer assembly we shipped was strictly checked in good condition before shipping, so please be sure to check carefully after receiving it. If there is any damage, please contact us within 3 days.

3. For those digitizer assemblies HAVE BEEN INSTALLED AND CAUSED DAMAGE on appearance or labels, they are outside the scope of warranty, returning is not supported, please be kindly understood.

If your phone has image display issues, an unresponsive touch screen or physical cracks or scratches on the glass, this LCD and touch screen assembly is what you need

This is not an easy job for someone who has no technical skills with Disassembling or Assembling Cellphones/mobile phones, so only purchase this item if you know how to install it

Highly recommend professional installation. We will not be held responsible for any damages to your cellphone/mobile phone that you may cause during the changing of replacement parts

All the test procedures were analyzed in detail with opinions proposed. Now, let’s take a close look to the first China madeiPhone 7 Plus LCD Screen sample with professional testing report below.

To analyze inside layers of the iPhone screen, we tear it down layer by layer .The sample China made screen applies G + G layer structure, there is a glass base touch layer,

The quality and performance is quite close to OEM and acceptable, and sure it will come with impressive lower price offer. The display panel is China made with G + G layer structure, and the screen is assembled with a third-party driver IC solution.

Not too long ago, we’ve just got some samples of the new China Made iPhone 6 LCD Display. No doubt that this will be another option for all who are suffering from the high price of the iPhone screens. Let’s take a deep look of these screens.

At the moment, there are two companies producing theiPhone 6 LCD screens, one is LT, the other one is JDF (no iPhone 6 screens made by TM are available now). Below are some detailed comparisons after our tests.

When taking a closer look at both of the LT and JDF iPhone 6 screens under direct light, you’ll see the digitizer textures. While for the original screen, the textures had been hidden by a special painted layer.

The glass lens of LT made iPhone 6 screen is far too thin compared with the original one, which can’t secure the display well. At the same time, thinner glass lens will make the home button stick up above the screen. While for the JDF made screen, a plastic layer has been added to make it thicker.

It’s hard to be realized through eyes, but it’s easily to be touched. When you grab the iPhone 6 with LT made screen, it’s hard to ignore that annoying uncomfortable feeling. At this point, the JDF made screen is much better.

High and low temperature tests have been applied to both the LT and JDF iPhone 6 screens. Both of them have survived and worked well after been putted in a 55 centi degrees room for 2 hours and -5 centi degrees room for 2 hours.

Through our tests, the first version of both the LT and JDF displays are not good choices for the repair industry. The obvious color differences, thickness differences still need to be improved. If you have any questions regarding the LT/JDF iPhone 6 screens, please leave your comment below, we’ll try our best to answer it.

With the lack stock of the original iPhone 5 & 6 series LCD screen, the China made LCD screens becomes more and more popular among the repair shops. As the originaliPhone 6 Plus LCD screenprices are still high and not likely to fall down, plus more and more repair shops are tending to accept the China made LCD screens replacement instead, therefore, China made iPhone 6 Plus LCD screen appeared on the market naturally.

Recently we have got some samples of the China Made 6 Plus LCD screen, which have been called ‘LG 1:1 version’ on the market. We did some tests with these samples and found some differences compared to other China made LCD screens.

After tests, we found some differences in LCD frame height, glass screen thickness and the home button location among these 5 samples. You may wonder why these differences exist while they are sourcing from the same manufacturer?

Thus we need to learn the production process of the China made LCD screens, which was assembled by the 3rd party manufacturers, who purchased the China made LCD,LCD frame,glass lens,metal shields, screen foam and digitizer from different manufacturers, which could be original or high copied ones. Since there are some differences among theseglass lenses, LCD frames and so on, even though they shared the same LCD, there will still be some difference.

There is no doubt that significant differences existed between these 2 kinds of LCDs whether in display effect or working stability. In pursuit of greater profits, there is no strict requirements and standards for China made LCDs production process as long as the LCDs can achieve the basic using requirements. Therefore there is quite a gap in color difference, viewing angle and working stability compared to original ones, as the LCDs which are designed for the other brand cellphones, after replacing the IC and flex cable, have been inspected strictly before flowing to the market. (Such as the Samsung GalaxyS3 LCD screen assemblywhich are transformed from the GiONEE phones. Due to the few original stock in availability, most of the S3 LCD screen assemblies are produced by Samsung through transforming GiONEE LCDs.

It is said that these China made iPhone 6 Plus LCD screens are transformed from the MeiZu Meilan Note LCDs (Also features 5.5 inches) which are produced by Sharp and AUO, the overall performances of these LCD screens are better than LT/TM/JDF’s. And what’s big different from the other LCD screens is that there is one more LCD drive IC on the screen flex cable.

Because of the big production MOQ and long R & D cycle, the customized China made LCD screens had some difficulties intechnologyimprovementwith the changes of the marketing demands, while the original LCD features higher quality and reliability.

For these China made iPhone 6 Plus LCD screens, theLCD frametending to pop off and LCD screens are thicker. But in display effects, China made iPhone 6 plus LCD screens are better than5 series. Those customers who cared more about the prices will have one more choice once the improvements of the China made iPhone 6 Plus have been implemented. And we also will continue to focus on the China made iPhone 6 Plus LCD screen assembly.

Anyone who has bought an iPhone or another Apple product has seen the note on the company’s packaging that its products are designed in California, but that doesn"t mean they"re manufactured there. Answering the question of where the iPhone is made isn"t simple.

When trying to understand where Apple manufactures its devices, there are two key concepts that sound similar but are different: assembling and manufacturing.

Manufacturing is the process of making the components that go into the iPhone. While Apple designs and sells the iPhone, it doesn"t manufacture its components. Instead, Apple uses manufacturers from around the world to deliver individual parts. The manufacturers specialize in particular items—camera specialists manufacture the lens and camera assembly, screen specialists build the display, and so on.

Assembling, on the other hand, is the process of taking all the individual components built by specialist manufacturers and combining them into a finished, working iPhone.

Because there are hundreds of individual components in every iPhone, it"s not possible to list every manufacturer whose products are found on the phone. It"s also difficult to discern exactly where those components are made because sometimes one company builds the same component at multiple factories.

Camera: Qualcomm, based in the U.S. with locations in Australia, Brazil, China, India, Indonesia, Japan, South Korea, and more than a dozen locations through Europe and Latin America

Glass screen:Corning, based in the U.S., with locations in Australia, Belgium, Brazil, China, Denmark, France, Germany, Hong Kong, India, Israel, Italy, Japan, South Korea, Malaysia, Mexico, Philippines, Poland, Russia, Singapore, South Africa, Spain, Taiwan, The Netherlands, Turkey, the U.K., and the United Arab Emirates

Touch-screen controller: Broadcom, based in the U.S. with locations in Israel, Greece, the U.K., the Netherlands, Belgium, France, India, China, Taiwan, Singapore, and South Korea

Wi-Fi chip: Murata,based in the U.S. with locations in Japan, Mexico, Brazil, Canada, China, Taiwan, South Korea, Thailand, Malaysia, Philippines, India, Vietnam, The Netherlands, Spain, the U.K., Germany, Hungary, France, Italy, and Finland

The components manufactured by those companies all around the world are ultimately sent to just two companies to assemble into iPods, iPhones, and iPads. Those companies are Foxconn and Pegatron, both of which are based in Taiwan.

Technically, Foxconn is the company’s trade name; the firm’s official name is Hon Hai Precision Industry Co. Ltd. Foxconn is Apple"s longest-running partner in building these devices. It currently assembles the majority of Apple"s iPhones in its Shenzen, China, location, although Foxconn maintains factories in countries across the world, including Thailand, Malaysia, the Czech Republic, South Korea, Singapore, and the Philippines.

By continuing to use AliExpress you accept our use of cookies (view more on our Privacy Policy). You can adjust your Cookie Preferences at the bottom of this page.

If your phone has image display issues, an unresponsive touch screen or physical cracks or scratches on the glass, this assembly part is what you need

The assembly part also contains flex cable, button fixation metal sheet, LCD metal sheet, smart wake up/sleep sensor flex cable, receiver, front camera, earpiece mesh, sensor IC holder, camera frame and receiver fixation frame.

This is not an easy job for someone who has no technical skills with Disassembling or Assembling cellphones/mobile phones, so only purchase this item if you know how to install it

Highly recommend professional installation. We will not be held responsible for any damages to your cellphone/mobile phone that you may cause during the changing of replacement parts

1. Every single digitizer assembly we shipped was strictly checked in good condition before shipping, so please be sure to check carefully after receiving it. If there is any damage, please contact us within 3 days.

3. For those digitizer assemblies HAVE BEEN INSTALLED AND CAUSED DAMAGE on appearance or labels, they are outside the scope of warranty, returning is not supported, please be kindly understood.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey