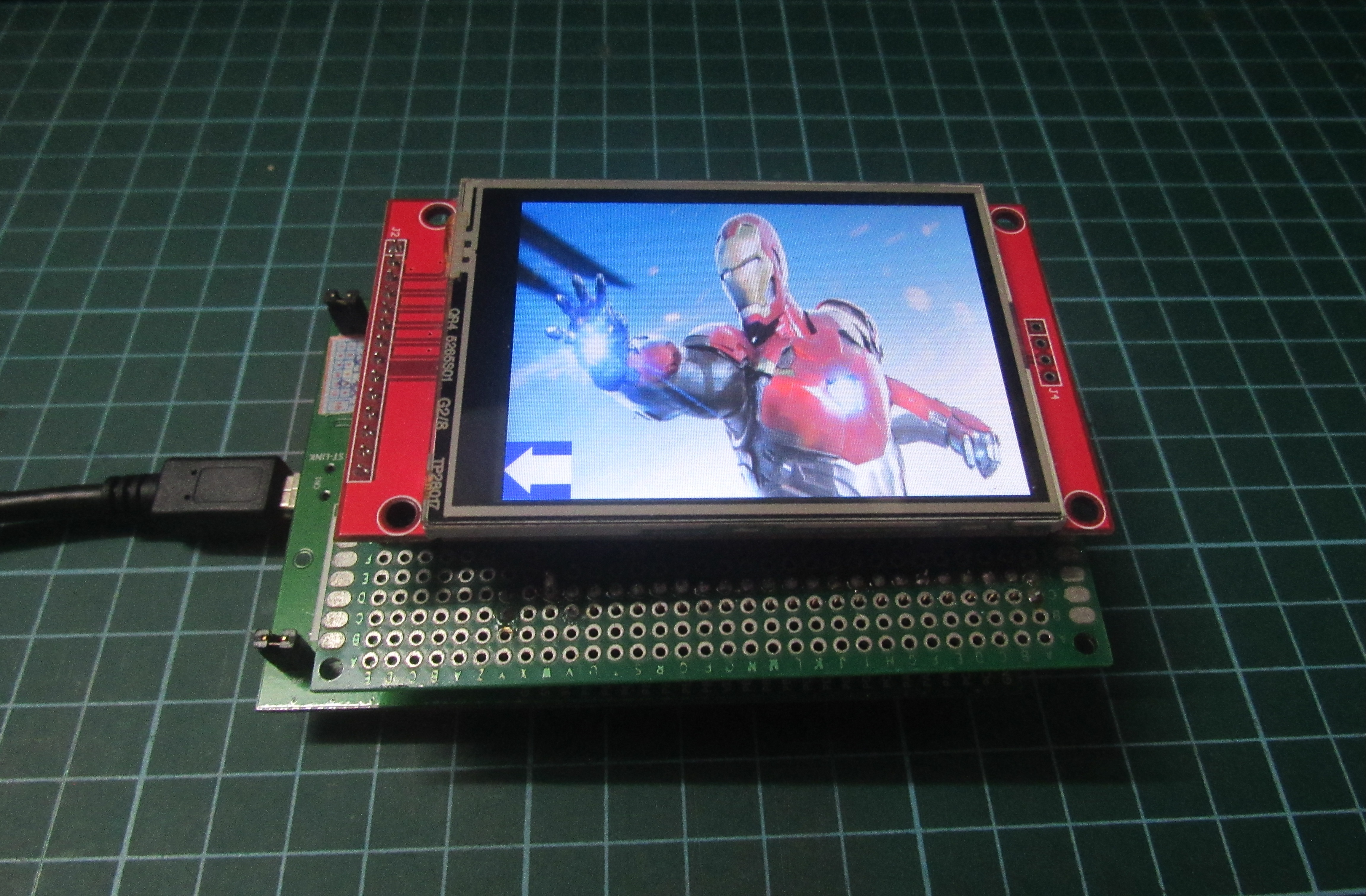

stm32 tft display project in stock

I will start by creating a project in the CubeMx (or in the CUBEIDE). Here, we need to setup the TIMER to create a delay in microseconds. Below is my setup for the same.

Now comes the part for setting up the Pins for the display. As, we are using the parallel connection, there are 8 DATA Pins and 5 CONTROL Pins. It would be really easy, if you connect all the data pins to thesame PORTand in the same order.

After all the Pins work is done, we still need to select the delays according to our clock frequency. As I am using STM32F103C8 at72 MHz, I am going to uncomment the respective code as shown below.

I found the TFT screen and Uno on Banggood.com about a month ago and over the weekend I was messing with the pair and found the tftbmp draw code in the demo.. I extended it with the ability to read any bmp file on the SD card.. so all you do is put your bitmaps on the SD and plug it in.. Having to add/edit/recompile/reload the Uno everytime is BS... Here is my code:

Amateur Radio Single Sideband Transceiver Controller for Arduino and SI5351 Clock generator. Includes Dual VFO, single or double band support for 20 and 40 meter bands, CAT control, optional S-meter, multiple supported displays including options include 20x4 LCD, Color TFT, and 2.8" Nextion Touch Screen

Note: The following picture is the connection diagram of the 2.8-inch TFT screen and Arduino uno, but this product is connected in exactly the same way.

If the Arduino board has an ICSP interface, set the SPI Config switch on the display module to the ICSP direction (by default) (the company"s Arduino UNO motherboard has an ICSP interface, just plug it in directly.).

This product uses the same LCD control chip and touch panel control chip as the 3.5-inch TFT screen of the same series of our company, so the code is completely compatible. The following takes 3.5-inch TFT as an example to introduce.

LCD_Show can display colorful patterns with different shapes and times. LCD_ShowBMP is for displaying the picture in BMP, and LCD_Touch is for using the touching function.

The display controller used in this product is ILI9486, and we need to initialize the controller through the SPI communication protocol, and the initialization functions are written in LCD_Driver.cpp.

The function functions related to the screen display are written in LCD_GUI.cpp. The function of each function and the parameters passed are explained in the source code. You can call it directly when you need to use it.

Before using LCD_ShowBMP to display pictures, first copy the pictures in the PIC folder in the data to the root directory of the SD card (you should understand that in the root directory, that is to save the pictures directly to the SD card, do not put them in any subfolders folder.).

Here is an explanation. This demo shows that the BMP picture first reads the picture data in the BMP format in the SD card through the SPI protocol, and then displays the data as an image.

These functions are all written in LCD_Bmp.cpp. In fact, the image data in BMP format with a specific file name is read from the SD card, and then the display function written by us is called to re-express the data as an image.

In fact, you can also use Image2Lcd image modulo software to convert images of different sizes and formats into array data, and then use the functions we wrote to display them.

The demo has been tested on XNUCLEO-F103RB, just insert XNUCLEO-F103RB as shown below. The model of XNUCLEO-F103RB is STM32F103RBT6. If you need to port the program, please connect it according to the actual pin and the schematic diagram.

Note: The following picture is the connection diagram of the 2.8-inch TFT screen and XNUCLEO-F103RB, but this product is connected in exactly the same way.

The demos are developed based on the HAL library. Download the program, find the STM32 program file directory, and open STM32\XNUCLEO-F103RB\lcd4in-demo\MDK-ARM\ lcd4in-demo.uvprojx.

This product uses the same LCD control chip and touch panel control chip as the 3.5-inch TFT screen of the same series of our company, so the code is completely compatible. The following takes 3.5-inch TFT as an example to introduce.

After running the demo, it displays some characters and patterns at first, then displays four pictures, and finally displays the touch sketchpad function. Actually, three projects in the Arduino platform code are integrated in the main function, we place the three main functions in sequence and place TP_DrawBoard(); in an infinite loop to achieve the above functions.

Before using LCD_ShowBMP to display pictures, copy the pictures in the PIC folder in the data to the root directory of the SD card, and then insert the SD card into the SD card slot on the back of the screen to start the download program verification.

In fact, you can also use Image2Lcd image modulo software to convert images of different sizes and formats into array data, and then use the functions we wrote to display them.

I2C is utterly helpless here; sometimes it appears on panels for configuring settings, or touch controller, stuff like that. It has far too little bandwidth to transfer video. (I"m not sure what displays are even available for video over I2C; probably just small character displays or the like?)

SPI is marginal at best. At a typical 10MHz maximum, it"s just passable for small e.g. 160x128x16bpp displays, capable of a full refresh at maybe 20 FPS. A bigger panel might support up to 50MHz, but even with quad channel (QSPI) it"s going to be a stretch.

Your panel is digital RGB, which requires an external controller (framebuffer, addressing, sync generation, etc.). Some micros have this internal, e.g. STM32F417 I think. Note that sharing video and system RAM (you likely need to add an external SDRAM) will have some performance impact on the CPU; don"t expect the world out of it. (Probably still enough to run Doom, for point of reference.

You can get standalone controllers for these. I"ve played with one before, though the board I made doesn"t quite match your panel"s pinout, so you"d have to make an adapter cable to use it; but I do have spares if you"re interested, and are able to solder SMTs (it"s about 50 components, the most difficult being a 0.4mm pitch TQFP, or a no-lead; hot air or oven reflow is required). It uses an Epson S1D13517F00A100, a... fairly pricey (and, apparently out of stock right now..) controller, which presents a parallel 8/16 bit interface. Would be a good match to an STM32 parallel port, or even FSMC.

As you learn about more of your microcontroller’s peripherals and start to work with more types of sensors and actuators, you will probably want to add small displays to your projects. Previously, I wrote about creating a simple program to draw data to an SSD1331 OLED display, but while they look great, the small size and low resolution can be limiting. Fortunately, the larger (and slightly cheaper) ILI9341 TFT display module uses a nearly-identical SPI communication protocol, so this tutorial will build on that previous post by going over how to draw to a 2.2″ ILI9341 module using the STM32’s hardware SPI peripheral.

We’ll cover the basic steps of setting up the required GPIO pins, initializing the SPI peripheral, starting the display, and then finally drawing pixel colors to it. This tutorial won’t read any data from the display, so we can use the hardware peripheral’s MISO pin for other purposes and leave the TFT’s MISO pin disconnected. And as with my previous STM32 posts, example code will be provided for both the STM32F031K6 and STM32L031K6 ‘Nucleo’ boards.

As with most STM32 projects, the first thing we should do is enable the peripherals that we will use. In this case, that’s just GPIOA, GPIOB, and SPI1. As in previous STM32 posts, I will use the device header files provided by ST for basic peripheral variable definitions, and determine the target chip from definitions passed in from the Makefile:

With the peripherals powered on, we need to set up the GPIO pins used for communicating with the screen. To power the SSD1331 display in my previous tutorial, we configured all of the pins as ordinary push-pull outputs; as a quick refresher, we’ll use the SCK (Clock), MOSI (Data output), CS (Chip Select), D/C (Data or Command?), and RST (Reset) pins. The only difference with using the hardware peripheral is that we should configure the MOSI and SCK pins as ‘alternate function’ with high-speed output.

There are actually multiple sets of pins mapped to the SPI1 peripheral, even on the 32-pin STM32xKx chips. I’ll use pin B3 for SCK and pin B5 for MOSI. Pin B4 is mapped to MISO, but I’ll use it as a general-purpose output to drive the D/C pin on the TFT. As long as the MISO pin is not configured as ‘alternate function’, the peripheral will ignore it and we can use pin B4 as a normal GPIO pin. Finally, pins A12 and A15 are mapped to CS and RST respectively:

With the pins set up, it is also a good idea to set them all to a known starting state, and tell the ILI9341 display to reset by pulling the ‘Reset’ pin low/high with a delay to give the display time to perform its reset sequence:

I don’t want to complicate things by covering timers or precisely-timed assembly code in this tutorial, so I’m using a simple (but inaccurate) ‘delay_cycles’ method to give the display plenty of time to reset itself. If you want to use a better time-based delay, try waiting for about 100-150 milliseconds.

The STM32’s SPI peripheral resets to a convenient state for simple communication, but there are still a few options that we need to configure. First up is the clock ‘polarity’ and ‘phase’ – the SCK clock pin will toggle up and down as data is sent, and these two bits tell the peripheral when the data pins should be written and read. The ‘clock polarity’ defines the clock pin’s resting state when data is not being transferred, and the ‘clock phase’ defines whether the devices should read data on the ‘falling’ or ‘rising’ edge of the clock signal. The ILI9341 seems to like a polarity and phase of either 1 and 1 or 0 and 0; you can inspect the timing diagram in its datasheet, or just try and see what works best.

Next, we need to tell the peripheral that the STM32 will be the one initiating communications by setting its MSTR flag. And to avoid unnecessary complexity, it is also a good idea to tell the STM32’s SPI peripheral not to use its hardware CS pin – just like the ILI9341 has a CS (‘Chip Select’) pin which tells it whether it should listen to the clock/data lines, I think that the STM32 has a similar CS signal which tells it whether to read/write, called NSS in the datasheets. Fortunately, we can ignore all of that by using a software ‘Chip Select’ signal (the SSM flag) and leaving it ‘high’ to permanently enable communication (the SSI flag):

Then all we have to do is set the PE (Peripheral Enable) flag to start communications. The ILI9341 expects its data to be sent with the MSB (Most-Significant Bit) first with 8 bits per data frame, but those are the default reset settings on the STM32’s SPI peripheral so we don’t need to change them:

First, the STM32 has a small queue which it can use to store a few bytes of data while it is busy sending, and we shouldn’t try to send data if that queue is full. The peripheral sets a TXE (‘Transmit Buffer Empty’) flag when it is ready for new data to be written. This means that our ‘write 8 bits’ function should wait for that flag to be set before continuing:

I actually couldn’t get the STM32L0 line to write the full 16 bits this way – I think they have a slightly different peripheral configuration. Anyways, for the ILI9341’s “4-Wire” SPI protocol, we also need to write a ‘send command byte’ method which pulls the D/C pin low during communication. Since we don’t want to change the D/C pin while the peripheral is still sending data in its transmit queue, we should wait for the peripheral’s BSY (Busy) flag to be cleared before changing the state of the D/C GPIO pin:

Initializing the display and drawing to it isn’t too difficult, but if the previous steps aren’t done properly, it can be frustrating to debug the communications. If you run into problems, you can also use the same ‘software SPI’ methods presented in the previous SSD1331 tutorial – just don’t forget to set the SCK and MOSI pins as ‘output’ instead of ‘alternate function’ if you decide to try that.

The pins on your ILI9341 module should be labeled, although if you are using a generic module the labels might be on the back side of the board. The connections are about what you would expect; plug the VCC and LED pins into your board’s +3.3V supply, and connect GND to Ground. The CS, RESET, DC/RS, SDI/MOSI, and SCK pins should connect to the corresponding microcontroller pins, and the SDO/MISO pin can be left unconnected. DC/RS is a different acronym for our D/C ‘Data/Command’ pin, and SDO/SDI are starting to become popular labels on SPI boards – they stand for ‘Serial Data Out/In’, so SDI on the listening device corresponds to the MOSI SPI line and SDO is not needed since we won’t be listening to the display.

When the ILI9341 first powers on it should show a uniform bright white color, but that’s just the backlight LEDs. The display will not try to show anything at all until it is initialized. Be aware that a broken display might still show a bright white screen when power is applied, but these modules are fairly sturdy. I’ve gone so far as to pry them apart and remove the backlights, and the panels worked even after being bluntly removed from the case.

So short of taking a hammer to the screen, you shouldn’t be able to damage them too much by bumping them around or dropping them from a tabletop. Anyways, to start the display and put it into a state where it can draw things, we need to send it a series of startup commands. Like with the SSD1331 display, most commands are followed by one or more ‘option’ bytes, but unlike the SSD1331, those ‘option’ bytes should be sent with the D/C pin held high, not low. You can see all of the commands in the ILI9341 datasheet, but some commands appear to be undocumented, so it is a good idea to look at an existing library for a starting sequence that should work for most purposes.

After the display is reset and those commands are sent, the display should change to a flickering grey color. That tells you that the display is all set up and ready to go, but it has not received any pixel data yet so it is not showing any colors.

To draw to the display, we go through a similar process as we did with the SSD1331; send commands to say which rectangular area we want to draw to, then send one 16-bit color for each pixel in that rectangular area.

To refresh the entire 240 x 320 display, we can set the drawing area to be between (0, 0) and (239, 319) and then draw 320 * 240 = 76,800 pixels of data. That’s a lot of data – even at one bit per pixel, the small chips used in this example would not have enough RAM to store a full framebuffer. You’d need over 600KB of RAM to store a full 16 bits of color per pixel, so we’ll only draw some solid colors in this tutorial.

And that’s all there is to it! As the program runs, your display should cycle between a red and blue color as fast as the chip can send data. This could be made even faster by using hardware interrupts and/or DMA transfers, but that is a topic for a future tutorial.

The ILI9341 is a good display driver to know how to use. Screens using it come in sizes from about 2.2″ – 3.2″ with a resolution of 240 x 320 pixels, and they are very affordable. Their contrast is not as good as the SSD1331 OLED displays, but they get you a lot more pixels on a hobbyist’s budget.

So all in all, they’re nice choices for small applications which need an easy-to-read display. I’ve seen them used in devices ranging from handheld oscilloscopes to CNC machines. Chime in if you wind up making anything with one!

TFT LCDs are the most popular color displays – the displays in smartphones, tablets, and laptops are actually the TFT LCDs only. There are TFT LCD shields available for Arduino in a variety of sizes like 1.44″, 1.8″, 2.0″, 2.4″, and 2.8″. Arduino is quite a humble machine whenever it comes to process or control graphics. After all, it is a microcontroller platform, and graphical applications usually require much greater processing resources. Still, Arduino is capable enough to control small display units. TFT LCDs are colorful display screens that can host beautiful user interfaces.

Most of the smaller TFT LCD shields can be controlled using the Adafruit TFT LCD library. There is also a larger TFT LCD shield of 3.5 inches, with an ILI9486 8-bit driver.

The Adafruit library does not support the ILI9486 driver. Actually, the Adafruit library is written to control only TFT displays smaller than 3.5 inches. To control the 3.5 inch TFT LCD touch screen, we need another library. This is MCUFRIEND_kbv. The MCUFRIEND_kbv library is, in fact, even easier to use in comparison to the Adafruit TFT LCD library. This library only requires instantiating a TFT object and even does not require specifying pin connections.

TFT LCDs for ArduinoUser interfaces are an essential part of any embedded application. The user interface enables any interaction with the end-user and makes possible the ultimate use of the device. The user interfaces are hosted using a number of devices like seven-segments, character LCDs, graphical LCDs, and full-color TFT LCDs. Out of all these devices, only full-color TFT displays are capable of hosting sophisticated interfaces. A sophisticated user interface may have many data fields to display or may need to host menus and sub-menus or host interactive graphics. A TFT LCD is an active matrix LCD capable of hosting high-quality images.

Arduino operates at low frequency. That is why it is not possible to render high-definition images or videos with Arduino. However, Arduino can control a small TFT display screen rendering graphically enriched data and commands. By interfacing a TFT LCD touch screen with Arduino, it is possible to render interactive graphics, menus, charts, graphs, and user panels.

Some of the popular full-color TFT LCDs available for Arduino include 3.5″ 480×320 display, 2.8″ 400×200 display, 2.4″ 320×240 display and 1.8″ 220×176 display. A TFT screen of appropriate size and resolution can be selected as per a given application.

If the user interface has only graphical data and commands, Atmega328 Arduino boards can control the display. If the user interface is a large program hosting several menus and/or submenus, Arduino Mega2560 should be preferred to control the TFT display. If the user interface needs to host high-resolution images and motions, ARM core Arduino boards like the DUE should be used to control the TFT display.

MCUFRIEND_kbv libraryAdafruit TFT LCD library supports only small TFT displays. For large TFT display shields like 3.5-inch, 3.6-inch, 3.95-inch, including 2.4-inch and 2.8-inch TFT LCDs, MCUFRIEND_kbv library is useful. This library has been designed to control 28-pin TFT LCD shields for Arduino UNO. It also works with Arduino Mega2560. Apart from UNO and Mega2560, the library also supports LEONARDO, DUE, ZERO, and M0-PRO. It also runs on NUCLEO-F103 and TEENSY3.2 with Sparkfun Adapter. The Mcufriend-style shields tend to have a resistive TouchScreen on A1, 7, A2, 6 but are not always in the same direction rotation. The MCUFRIEND_kbv library can be included in an Arduino sketch from the library manager.

The 3.5-inch TFT LCD shield needs to be plugged atop the Arduino board. The Mcufriend-style shields are designed to fit into all the above-mentioned Arduino boards. The shields have a TFT touch screen that can display colorful images and interfaces and a micro SD card reader to save images and other data. A 3.5-inch TFT LCD touch screen has the following pin diagram.

How project worksThe code fills a rectangle, then draws a rectangle within which text “EEWORLDONLINE” is displayed. Then, lines, circles, rectangles, and squares are drawn on the screen. The project ends with a greeting and a message.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey