tft display vs led display supplier

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) we are talking here is TN (Twisted Nematic) type TFT displays which is align with the term in the TV and computer market. Now, TFT displays have taken over the majority of low-end color display market. They have wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, consumer electronic products etc. For more information about TFT displays, please visit our knowledge base.

Talking about Pros and Cons of TFT displays, we need to clarify which display they are compared to. To some displays, TFT displays might have advantages, but compared with another display, the same character might become the disadvantages of TFT displays. We will try our best to make clear as below.

Less Energy Consumption: Compared with CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) and LED (Light Emitting Diode) display, which made laptop possible.

Excellent physical design. TFT displays are very easy to design and integrated with other components, such as resistive and capacitive touch panels (RTP, CTP, PCAP) etc.

Minimum Eye Strain: Because TFT panel itself doesn’t emit light itself like CRT, LED, VFD. The light source is LED backlight which is filtered well with the TFT glass in front for the blue light.

More Energy Consumption: Compared with monochrome displays and OLED (PMOLED and AMOLED) display, which makes TFT displays less attractive in wearable device.

Poor response time and viewing angle: Compared with IPS LCD displays, AMOLED displays and recent micro-LED display. TFT displays still need to note viewing angle of 6 o’clock or 12 o’clock in the datasheet and still have the gray scale inversion issue.

High tooling cost: Depending on which generation production line to produce and also depending on its size. Building a TFT display fab normally need billions of dollars. For a big size display which needs high generation production line to produce. The NRE cost can be millions dollars.

Sunlight Readability: Because it is very expensive to produce transflective TFT LCD displays, in order to be readable under the sunlight, very bright LED backlight (> 1,000 nits) has to be used. The power needed is high and also need to deal with heat management. If used together with touch panel, expensive optical bonding (OCA or OCR) and surface treatment (AR, AF) technologies have to be used.

Confused about LED vs. LCD vs. TFT? Here"s everything you need to know. Creating or upgrading a device display or screen can involve a lot of different things, but it often comes down to one major question - what kind of display should you get?

So, there are 3 common displays LED, LCD and TFT available in the market. All terms refer to the flat-panel display, or screen, of a computer monitor or television set. In this article, we are going to differentiate between them. It will help you to choose a better one.

LCD stands for liquid crystal display. Works by adjusting the amount of light blocked. Usually has a backlight but might not (clocks, calculators, Nintendo Gameboy). The green-black ones can be very cheap and are a mature technology. Response time can be slow. An LCD display uses the light balancing qualities of crystals. Today LCDs are used in a great number of products and applications. Your TV, computer screen, calculator, cell phone and the dreaded alarm clock are all made of an LCD flat panel. Color LCDs produce the color based on two techniques: Passive matrix and active matrix. Passive matrix is the cheapest technology of the two. The other technology is called an active matrix or TFT. Active matrix displays produce really sharp and clear images.

This is a type of LCD with a thin film transistor attached to each pixel. All computer LCD screens are TFT since the early 2000s; older ones had slower response times and poorer color. Cost is now very good; power consumption is fairly good but dominated by the backlight. Has to be manufactured out of glass. The TFT layer is embedded in the screen itself, it reduces crosstalk between pixels. Crosstalk happens when a signal sends to a pixel also affects the pixel next to it. This makes the TFT technology the technology offering the best resolution and image quality. It also makes it a bit more expensive. Today TFTs have become the standard when producing LCD screens.

LED stands for a light emitting diode. As the name suggests, emits light rather than blocking it like LCD. Used for red/green/blue/white indicator lights everywhere. Some manufacturers advertise "LED" displays that are TFT screens with a white LED backlight, which is just confusing. Ones that are real LED screens are usually OLED.

Some devices actually have backlights made from Red, Green and Blue LEDs, normally referred to as RGB LED, which tend to have better color reproduction than any other display.

LED screen is just like saying that it is a plastic screen. You still have the WHOLE screen illuminated all the time and LED is "good" only for being more eco-friendly and probably more bright at max setting if you ever need this.

An LCD panel is, in fact, 2 layers of glass with some volume of Liquid Crystal in between. These two form the panel itself. The 2 layers are usually called Color Filter Glass (above) and TFT glass (below).

A standard TFT has a whole "lamp" behind it, illuminating the whole screen all the time. This way, you cannot have a true black, as it is still illuminated and stay grayish.

TFTs are a type of active matrix display that controls individual pixel updates several times per second on the screen to update the image relative to the content source.

TFT displays use more electricity than regular LCD screens, so they not only cost more in the first place, but they are also more expensive to operate.

LCDs use fluorescent lights while LEDs use those light emitting diodes. The fluorescent lights in an LCD are always behind the screen. On an LED, the light emitting diodes can be placed either behind the screen or around its edges.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

.jpg)

As you might already be aware, there’s a large variety of versatile digital display types on the market, all of which are specifically designed to perform certain functions and are suitable for numerous commercial, industrial, and personal uses. The type of digital display you choose for your company or organization depends largely on the requirements of your industry, customer-base, employees, and business practices. Unfortunately, if you happen to be technologically challenged and don’t know much about digital displays and monitors, it can be difficult to determine which features and functions would work best within your professional environment. If you have trouble deciphering the pros and cons of using TFT vs. IPS displays, here’s a little guide to help make your decision easier.

TFT stands for thin-film-transistor, which is a variant of liquid crystal display (LCD). TFTs are categorized as active matrix LCDs, which means that they can simultaneously retain certain pixels on a screen while also addressing other pixels using minimal amounts of energy. This is because TFTs consist of transistors and capacitors that respectively work to conserve as much energy as possible while still remaining in operation and rendering optimal results. TFT display technologies offer the following features, some of which are engineered to enhance overall user experience.

The bright LED backlights that are featured in TFT displays are most often used for mobile screens. These backlights offer a great deal of adaptability and can be adjusted according to the visual preferences of the user. In some cases, certain mobile devices can be set up to automatically adjust the brightness level of the screen depending on the natural or artificial lighting in any given location. This is a very handy feature for people who have difficulty learning how to adjust the settings on a device or monitor and makes for easier sunlight readability.

One of the major drawbacks of using a TFT LCD instead of an IPS is that the former doesn’t offer the same level of visibility as the latter. To get the full effect of the graphics on a TFT screen, you have to be seated right in front of the screen at all times. If you’re just using the monitor for regular web browsing, for office work, to read and answer emails, or for other everyday uses, then a TFT display will suit your needs just fine. But, if you’re using it to conduct business that requires the highest level of colour and graphic accuracy, such as completing military or naval tasks, then your best bet is to opt for an IPS screen instead.

Nonetheless, most TFT displays are still fully capable of delivering reasonably sharp images that are ideal for everyday purposes and they also have relatively short response times from your keyboard or mouse to your screen. This is because the pixel aspect ration is much narrower than its IPS counterpart and therefore, the colours aren’t as widely spread out and are formatted to fit onto the screen. Primary colours—red, yellow, and blue—are used as the basis for creating brightness and different shades, which is why there’s such a strong contrast between different aspects of every image. Computer monitors, modern-day HD TV screens, laptop monitors, mobile devices, and even tablets all utilize this technology.

IPS (in-plane-switching) technology is almost like an improvement on the traditional TFT display module in the sense that it has the same basic structure, but with slightly more enhanced features and more widespread usability. IPS LCD monitors consist of the following high-end features.

IPS screens have the capability to recognize movements and commands much faster than the traditional TFT LCD displays and as a result, their response times are infinitely faster. Of course, the human eye doesn’t notice the difference on separate occasions, but when witnessing side-by-side demonstrations, the difference is clear.

Wide-set screen configurations allow for much wider and versatile viewing angles as well. This is probably one of the most notable and bankable differences between TFT and IPS displays. With IPS displays, you can view the same image from a large variety of different angles without causing grayscale, blurriness, halo effects, or obstructing your user experience in any way. This makes IPS the perfect display option for people who rely on true-to-form and sharp colour and image contrasts in their work or daily lives.

IPS displays are designed to have higher transmittance frequencies than their TFT counterparts within a shorter period of time (precisely 1 millisecond vs. 25 milliseconds). This speed increase might seem minute or indecipherable to the naked eye, but it actually makes a huge difference in side-by-side demonstrations and observations, especially if your work depends largely on high-speed information sharing with minimal or no lagging.

Just like TFT displays, IPS displays also use primary colours to produce different shades through their pixels. The main difference in this regard is the placement of the pixels and how they interact with electrodes. In TFT displays, the pixels run perpendicular to one another when they’re activated by electrodes, which creates a pretty sharp image, but not quite as pristine or crisp as what IPS displays can achieve. IPS display technologies employ a different configuration in the sense that pixels are placed parallel to one another to reflect more light and result in a sharper, clearer, brighter, and more vibrant image. The wide-set screen also establishes a wider aspect ratio, which strengthens visibility and creates a more realistic and lasting effect.

When it comes to deciphering the differences between TFT vs. IPS display technologies and deciding which option is best for you and your business, the experts at Nauticomp Inc. can help. Not only do we offer a wide variety of computer displays, monitors, and screen types, but we also have the many years of experience in the technology industry to back up our recommendations and our knowledge. Our top-of-the-line displays and monitors are customized to suit the professional and personal needs of our clients who work across a vast array of industries. For more information on our high-end displays and monitors, please contact us.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

Have you ever wonder where TFT derive from? Why is TFT referred to as LCD? The phenomenon started in early days, when bulky CRT displays were thing of the past and LCD was its replacement, but as time progresses, there were still room for improvement, which leads to the birth of TFT’s.

TFT is a variant of an LCD which uses thin film transistor technology to improve an image quality, while an LCD is class of displays that uses modulating properties of liquid crystals to form what we call an LCD (liquid crystals display) which in fact does not emits light directly.

Even though LCDs were very energy efficient, light weight and thin in nature, LCD were falling behind to the CRT display, which then leads to a change in LCD manufacturing, where performance became a big problem.

For example, having a 2001 Mustang vs a 2014 Mustang, the dimensions and engine of the 2014 has been redesign for performance reasons, not mentioning user friendly, so does the LCD to TFT.

As the birth of TFT, the elements are deposited directly on the glass substrate which in fact the main reason for the switch was because TFTs are easier to produce, better performance in terms of adjusting the pixels within the display to get better quality.

As TFT’s become very popular throughout the century due to its elaborate low charge associate and outstanding response time, LCDs became a thing of the past, and TFT became the predominant technology with their wider viewing angles and better quality this technology will be around for a long time.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

At Display Technology we understand that each market sector has different requirements, therefore we pick our suppliers based on what our customers want. But, there is a common process and thought strategy used, when picking each supplier.

We aim to offer TFT LCD displays of the best quality for the price, and where we can secure a continuity of supply. The quality of products reflects on our business, and so we do not want to be linked to inferior quality stock. We also understand that there is a certain amount of development time, approvals and cost if a product changes.

With every development we look at the impact and consult with our clients the best route forward in order to meet requirements. When we choose a partner, unlike some TFT display suppliers, we do not just add on without understanding how the range fits within our business model. It is also important that we can add value to a suppliers range for an improved solution for the end customer.

We know all our TFT monitors will require support from other components within our range, including touch screens, interface cards or backlight controllers. Therefore we endeavour to fully test new panels for compatibility prior to releasing onto the market.

KING TECH is a TFT LCD IPS supplier solution specialist since 2003, we are the group company combined byAn Innolux authorized LCD panel&IC distribution company

We Provide Different Kinds of Custom TFT Display ServicesIf needed we can make custom size tft displays for customers, we have a good relationship with original TFT display module factories, and we can negotiate with them to tool up an LCD panel mask. The tooling cost will be very high and paid by the end customer, and MOQ is at least 25K/lot.

We are capable to change every structure of the TFT display module. To increase backlight brightness and make it sunlight readable, the highest brightness we’ve ever reached was 6500cd/m2.To change the display FPC shape and length. To customize a resistive touch panel(RTP) or capacitive touch panel(CTP/PCAP), we have a long-term cooperation supplier to work with us on such tooling, for CTP, we can also make different shapes and thicknesses of cover glass, single touch, and multi-touch, AG/AR/AF is also available.

With our own PCBA hardware& software design company, we can design different kinds of TFT display modules for our customers, from simple convert boards to complete motherboards, from HDMI driver boards to Android controller boards, from non-touch function boards to capacitive touch function boards, they are all part of our working.

We have our own TFT display module panel and driver distribution department, if you want to switch to another structure of display, we can also help, cause we know which TFT display module panel and the driver is more match, and which suit’s supply is more stable, which one we can get the lowest price.

In order to give the customer the best support, Kingtech, as one of the best TFT LCD IPS suppliers in China, also can provide industrial solutions such as developing a mother board, serial port UART board, T-CON board, HDMI board, and monitor according to the customer"s requirements.

Kingtech also has existing industrial solutions for the PV135 motherboard, PV901 Linux board, and PV804 motherboard. They can be connected between Raspberry pi and our TFT display module, which can make them work together.

For serial port UART board, Kingtech has a 2.8inch 240x320 LCD with serial port UART board, 3.5inch 320x480 module with serial port UART board, 4.3inch 480x272 display with a resistive touch with serial port UART board, 7inch 800x480/1024x600 TFT with capacitive touch with serial port UART board.

For the HDMI board, Kingtech has a 1.39inch 454x454 AMOLED round with HDMI board, 3.34inch 320x320 TFT round with HDMI board, 3.4inch 800x800 TFT round with HDMI board, 5inch 1080x1080 TFT with HDMI board, 4.3inch 800x480 TFT with HDMI board, 5inch 800x480 LCD with HDMI board, 7inch 800x480/1024x600 LCD display with HDMI board, 10.1inch 1280x800 LCD module with HDMI board.

Above all TFT display modules with board products can be used for industrial equipment, medical, smart-home, or others. Kingtech can also have industrial custom TFT display solutions according to the customer’s requirements. Ware is welcome to contact us. If you are interested in any tft display module products, we can negotiate with you at a reasonable TFT LCD display price. Thank you.

TFT display module is a Thin Film Transistor, and AMOLED is Active-matrix organic light-emitting Display. The TFT display module is backlight-on the liquid crystal panel; AMOLED is a panel that emits light on its own; TFT display module structure is more thick and strong, AMOLED is very thin and also weak, TFT display module is used widely than AMOLED, AMOLED is used in consumer products the most, like a smartwatch, mobile phone, and TV.

IPS is In-Plane Switching, It is also known as free viewing angle, which means the viewing angle of the display on 4 sides is the same, a normal display has its best viewing angle like 6 o’clock or 12 o’clock. While the TFT display module contains normal viewing angles and IPS display,IPS display is a kind of TFT display module.

TFT display module belongs to LCD, LCD is Liquid Crystal Display, it contains mono(single color) LCD and color LCD, single color LCD is barely used now, and color LCD has STN and TFT two types. Therefore, TFT display module is a kind of LCD display.

OLED is Organic Light Emitting Display, it is a display that emits light on its own, and it does not need an extra backlight, so it requests lower power consumption than TFT display module but its lifetime is shorter than TFT(5000 hours), AMOLED is a kind of OLED but it is more colorful. TFT display module requests a backlight to light on and power consumption are higher than OLED, but its lifetime is much longer(20000 hours).

The LED display is working by lighting up the LED lights, the TFT display module is lighted up by the backlight and the liquid crystal starts to work and shows contents. TFT display module has brighter and more true color, and lower price and LED display has lower power consumption, smaller heat, and longer lifetime.

Compares to other types of display, TFT display module is the more widely used, it can be made in different shapes and sizes, from very small sizes to big sizes. The resolution now is higher and higher, and the price of custom TFT display modules is more and more competitive. Its lifetime is longer than the OLED display, and its color is brighter than OLED.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

MicroLED shows promise as a display technology, potentially offering power savings and a reduced screen thickness when put beside current-generation display panels. Apple has recognized the potential, and has invested heavily into developing the technology over the last few years, with a view to using it in the company"s future products.

To understand fully how MicroLED can benefit Apple, it is worth understanding how the commonly-used display technologies work in the first place, before examining how different MicroLED really is in a comparison.

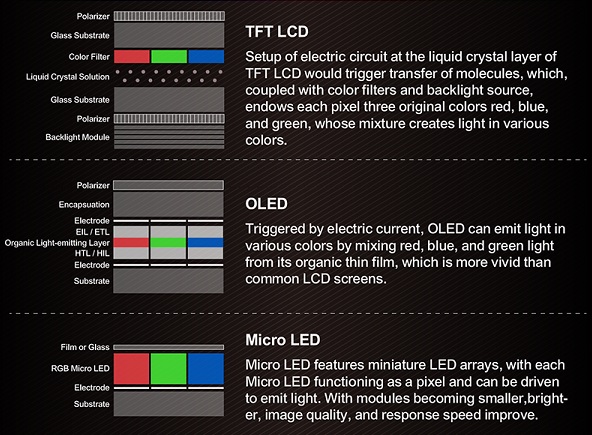

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

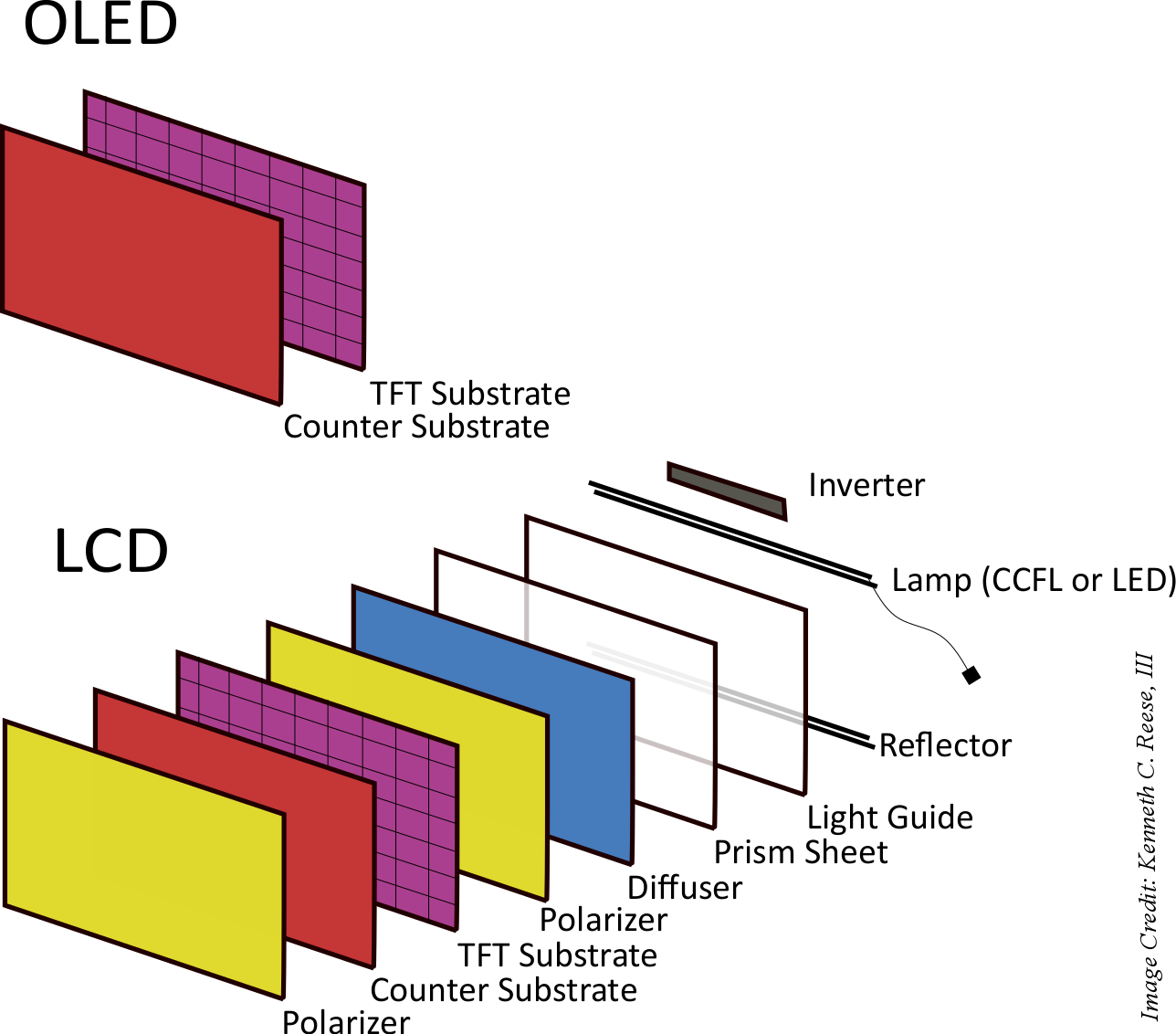

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

Displays that use collections of LEDs as individual pixels do exist, but it isn"t usually found in consumer products. LED screens are commonly used for billboards, in attractions, and as a large-scale display for events.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

As the name implies, OLED uses an organic compound film that is put between two electrodes, which are used to provide charge. Instead of the charge changing how light passes through, the current instead causes the emissive electroluminescent layer to emit light, without the need for a rear light source.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

OLED also can be produced on plastic substrates instead of glass, allowing it to be used to create flexible displays. While this is currently embodied in curved and other non-flat screens in some devices, it has the potential to be employed in foldable smartphones or rolled up for storage, an area Apple is also allegedly examining.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

OLED panels are also affected by the presence of water, both in production and in use. Small amounts of water contacting the organic substrate can cause immediate damage to the display, rendering parts of the screen useless.

So far, Apple"s usage of OLED consists of the premium iPhone X and the Apple Watch. As the cost of production drops down, it is plausible for Apple to use OLED in more future products, providing a better screen for customers to use.

Thought to be the next big thing in display technology, MicroLED basically takes the idea of using LEDs for pixels in a large stadium-style screen and miniaturizes it all.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED doesn"t use an organic compound to produce light, making it less susceptible to failure compared to OLED. Just like OLED, it can be applied onto a flexible material, allowing it to be used for curved displays or non-stationary components, like a watch strap, and can result in an extremely thin display panel.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

While MicroLED is an attractive proposition for Apple, it is not the only technology under development by the company"s engineers. Apple has previously filed patent applications for a technology described as "Quantum Dot LED and OLED Integration for High Efficiency Displays."

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

Image: Lee, Changhee & BAE, Wanki & KWAK, Jeonghun. (2014). "Quantum Dot LED (QLED) Emerging as a Next-generation Display Technology" in Physics and High Technology

The technology in theory can create an even thinner display than OLED, along with a more streamlined manufacturing process. True QD displays are also capable of high pixel densities of up to 1,000ppi, multiple times the density required to be called a Retina-quality display, and based on Apple"s hybrid invention, will also boast the response times of OLED technology.

As is usually the case, Apple does produce a considerable number of patent applications every week that are filed with the US Patent and Trademark Office, and not everything it files will be fully commercialized.

The QD patent application certainly shows Apple is thinking about display technology in multiple ways, and how it can be applied to future devices, but short of getting firm supply chain information or an official announcement from Apple directly, it is difficult to confirm which direction it will be heading.

Apple has been interested in using the technology for some time now, with the first notable sign being its acquisition of LuxVue in May 2014, alongside assorted related patents. A MicroLED specialist, LuxVue was rumored to have been the display producer for the ill-fated Google Glass headset, but was also the holder of assorted patents in the LED display field, including MicroLED.

At the time, the acquisition was thought to be an attempt by Apple to bring part of its display technology development in-house, with suggestions the MicroLED technology would be used in another rumored-at-the-time device, the Apple Watch. A more recent report suggests Apple is working with TSMC to make small panels for a future premium Apple Watch, potentially starting mass production by the end of the year.

Apple has also reportedly set up a secret facility just 15 minutes away from Apple Park, believed to be used for developing MicroLED. The 62,000 square-foot facility is thought to house around 300 engineers on a project named "T159," relating directly to the technology"s development.

The facility is also claimed to be sufficient in size to perform small scale manufacturing of display panels, allowing the company to keep development and testing in-house without involving third-parties. Considering Apple"s previous history in developing technologies before issuing information to manufacturing partners, it is possible that Apple is trying to work out the kinks in production before suppliers even attempt to make MicroLED panels.

The rumored small screen production may be for the Apple Watch now, but it may also benefit another often-rumored device, namely the VR or AR headset. This type of hardware relies on light components to keep the weight off the user"s head and neck, as well as displays with a high refresh rate and as close to perfect color reproduction as possible.

Apple is also apparently planning to use the technology in larger displays, said to be bigger in size than those in the MacBook Pro lines. This could be an iMac or iMac Pro, or even an external display, but ultimately there"s no real indication of Apple"s plans at this point, regardless of the scale of the screen.

Reports from last year also suggest Apple"s investment in MicroLED was a cause for concern for Samsung, LG, and other South Korean suppliers who provide display panels for the company"s products. Owning the process for MicroLED manufacturing could allow Apple to migrate away from its existing display suppliers in the coming years, reducing revenues and profits.

Aside from Apple"s development, there has been little in the way of announcements from other firms for products using the technology that could be bought by consumers in the coming months. The exception is Samsung, Apple"s main rival in the mobile marketplace and a major supplier of display panels, but its usage of MicroLED is not aimed at producing smaller screens.

At CES 2018, Samsung introduced The Wall, a 148-inch TV claimed to be the "world"s first consumer modular MicroLED" television. According to the South Korean electronics giant, The Wall"s modularity meant consumers would be able to customize their television"s size and shape to suit their needs.

The impending use of the technology in a high-priced consumer product could be considered proof that MicroLED display technology is maturing enough for use in devices. If the reports claiming Apple is getting close to mass producing panels is true, the inclusion of MicroLED in the Apple Watch could end up being the first mainstream usage of the technology.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. The quantum dors may be in a separate layer as a quantum dot enhacement film, or replace pigment-based green and red resists normally used in LCD color filters. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is too low or the user is sensitive to flicker, this may cause discomfort and eyestrain similar to the flicker of CRT displays at lower refresh rates.

Competing display technologies for the best image performance; A.J.S.M. de Vaan; Journal of the society of information displays, Volume 15, Issue 9 September 2007 Pages 657–666; http://onlinelibrary.wiley.com/doi/10.1889/1.2785199/abstract?

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

LED TVs: 10 things you need to know; David Carnoy, David Katzmaier; CNET.com/news; 3 June 2010; https://www.cnet.com/news/led-tvs-10-things-you-need-to-know/

Chen, Haiwei; Zhu, Ruidong; Li, Ming-Chun; Lee, Seok-Lyul; Wu, Shin-Tson (24 January 2017). "Pixel-by-pixel local dimming for high-dynamic-range liquid crystal displays". Optics Express. 25 (3): 1973. doi:ISSN 1094-4087.

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; https://ieeexplore.ieee.org/document/6520956

Broadband reflective polarizers based on form birefringence for ultra-thin liquid crystal displays; S.U. Pan; L. Tan and H.S. Kwok; Vol. 25, No. 15; 24 July 2017; Optics Express 17499; https://www.osapublishing.org/oe/viewmedia.cfm?uri=oe-25-15-17499&seq=0

Apollo specializes in TFT-LCD flat panel technologies and supply chain solutions. We offer a huge selection of TFT-LCD monitors and touchscreens, as well as corresponding components. We also offer hardware and software solutions for all of our products and digital signage applications.

As a worldwide supplier of state-of-the-art TFT technologies and system solutions, Apollo Displays supports you in all project phases – 1 from construction of the metal housing and procurement of specific parts to in-house development of controller boards and touchscreen integration.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey