lcd display rubber contact quotation

![]()

PIN is the most commonly used connection for LCD. I am often asked to answer one question. Can we make the pitch between two PINs 1.0 mm? Of course, we can as long as you pay for the extra cost. There are 4 common used types of pitches: 1.27 mm, 1.5 mm, 2.0 mm and 2.54 mm. The widths of PIN are 0.635 mm, 0.75 m,1.0 mm and 1.27 mm. If you can order 50 thousand each buy, we can make the custom PIN (even bent PIN) and the custom pitch for you and there is no extra cost.

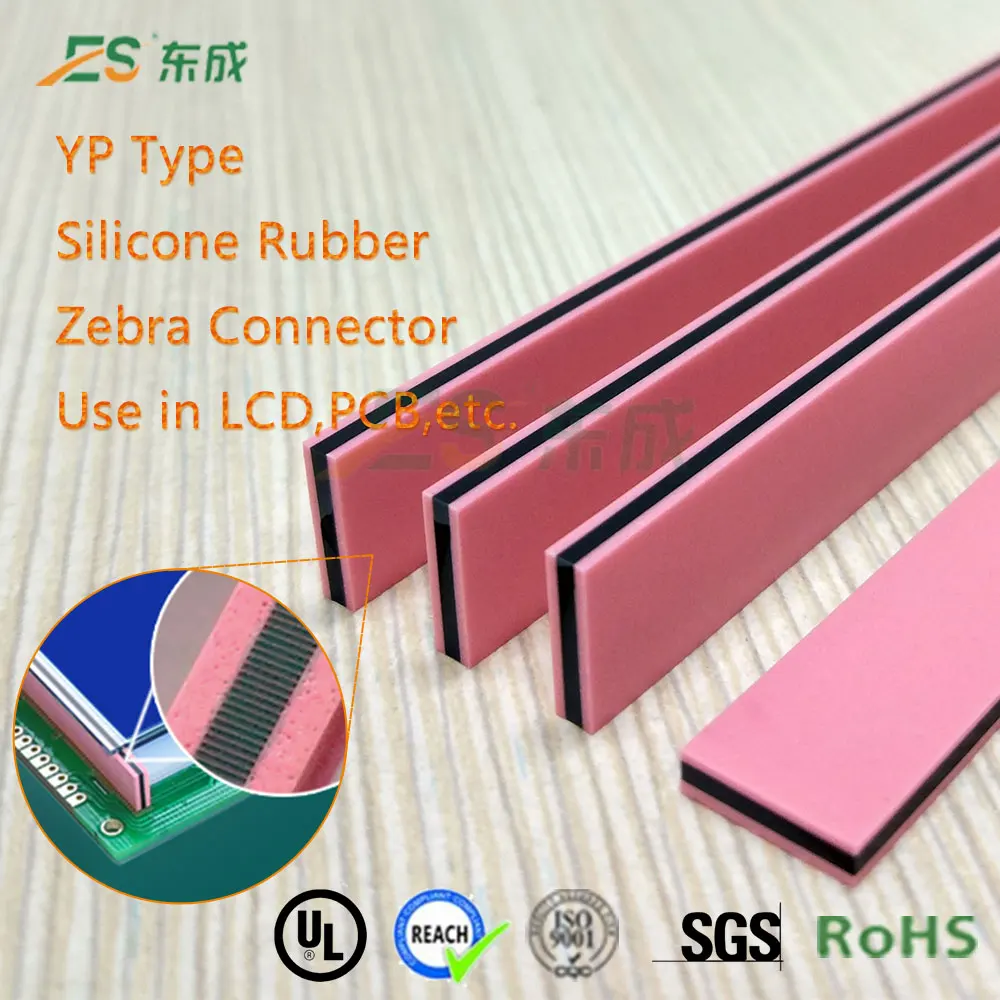

A printed circuit board and an LCD are connected by flexible zebra paper, which adopts heat sealing processing or soldering processing and can be used in all kinds of harsh environments.

I am pretty impressed that the connection is reliable just from the very slight pressure between the strip and the PCB. Also, its easily removable from the display. There seems to be some conductive layer on the glass, from where the signal goes into the displays internals. This connection seems to be damaged for the three rightmost signals, where the glass is broken.

Stockwell Elastomerics is a leading provider of gaskets for touch screens, displays and integrated touch panel assemblies that serve several functions: sealing, load distributing, gap filling, mechanical shock protection and over-press cushioning.

Often a touch screen gasket or display gasket will help spread the compression load of the housing or bezel on the display. Without a gasket, the enclosure that holds the display in place can create pressure points on the display. In some cases, these pressures can cause distortions, false contacts or short circuits.

Similar to load distributing, touch panel gaskets are used to fill gaps between the screen and the display and/or the screen and bezel. The display gasket will take up gaps generated by tolerance stack-ups in the device.

Display gaskets offer some degree of cushioning to protect the display from damage due to mechanical shock. In the event that a device is dropped or banged, the gasket will act as a touchscreen cushion, offering a limited amount of protection.

Touchscreen gaskets also serve as display cushions when a user presses on the display too hard. The gasket deflects, takes up and spreads the load offering some protection from over-press or overloading in a small area.

LCD dust seals and touch screen dust seals are the most basic requirement of display gasketing. These are often static (not portable), indoor applications where the device is not to be exposed to water. Sealing can be achieved by closed cell sponge materials or fine pore open cell materials such as PORON urethane foam.

Outdoor displays such as outdoor information kiosks, ATMs and remote monitoring equipment require more design consideration. To contend with environments such as direct or wind-driven rain, sealing an enclosure, case or housing from ingress requires the proper material as well as proper compression on the gasket. Silicone foam or silicone sponge materials are preferred. Silicone gaskets remain flexible at low temperatures allowing for continued sealing against melting ice and snow as well as protecting against mechanical shock where many other materials will firm up in the cold and transfer energy. Other key features are: closed cell structure, low-stress relaxation, UV and ozone resistance, and general long life.

Light leaking is sometimes a concern with certain LCD or LED display applications. This can be addressed with black gasketing with either a very thin adhesive or a black supported adhesive. A common material configuration for this is soft PORON urethane foam with 3M 9795B adhesive. The 3M 9795B is a film supported double coat adhesive with a black PET support layer that does not pipe light.

Touchscreen gaskets and display gaskets tend to have narrow walls that don’t always lend themselves to easy installation. This can be addressed in a few ways such as fixturing or utilizing the centers as temporary supports. The preferred adhesives for touchscreen gaskets and display gaskets are repositionable adhesives such as Adchem 8311M or 3M 9415 depending on the bond strength required. Stockwell Elastomerics also offers medium and high bond strength adhesives for permanent bonding. View the current listing of pressure sensitive adhesive options.

It is important to keep in mind the clamping loads. While wider gasket walls generally seal better, the overall surface area is directly related to the loads applied to the LCD and touchscreen. Compression Force Deflection curves of various materials are available to aid designers.

The gasket thickness will depend on the designed gap in the enclosure, the fastening scheme, rigidity of the housing and the level of sealing required. Many touch screen gaskets are thin and soft but as the display gets larger the tolerance stacks typically get larger as well. This may require a thicker gasket depending on the fastener locations.

Some OEMs and contract manufacturers prefer to have the center of the gasket remain in place, held in place with small, breakaway tabs. Leaving the centers intact allows for easier positioning on the display when a fixture is not being used. Low tack, clean peeling adhesive is needed.

Pressure type contact eliminates lead straightening, hole drilling and soldering. NON-ABRASIVE CONTACTS (Zero insertion force) Contact to the LCD is made by deflecting the ZEBRA® connector between the LCD and PC board. ZEBRA® connectors are non-abrasive and will not damage indium oxide contact pads on the LCD. Repeated assembly and disassembly of package components will not affect performance.

The LCD, when mounted with a ZEBRA® rubber connector, creates a gas tight seal at the contact interface. Assures contact in chemically corrosive atmospheres while at the same time protecting the glass display from shock and vibrations.

With a ZEBRA® connector, LCD terminal overhangs can be as narrow as 0.030”/8mm permitting more efficient use of glass size related to character height. (Metal pins normally require a 0.150”/3.9mm glass overhang, reducing character height by as much as 0.240”/6.1mm for a dual in-line LCD.)

ZEBRA® connectors are available in a variety of contact densities. The most dense allows contact pad spacing as close as 0.010”/0.25mm center-to-center. This spacing can be compared to 0.050”/1.3mm minimum for pins, allowing for increased capacity of LCD formats.

ZEBRA® Elastomeric Connectors have alternating conductive and non-conductive layers. See diagram below. The conductive layers are oriented vertically in the thickness direction, making contact from top to bottom.

Each of the styles is also available with outer support sections along the entire length on one or both sides (except Series 8000). The support is available in sponge or solid silicone rubber, and creates a larger width area. This eliminates the need for a holder while still allowing a very low compression force during deflection.

Zero insertion force,tight pitch,low compression force, very low resistance, very high current carrying capacity; contact pitches at 100, 133, 166 per inch

Drawing on the left shows side support or insulation on one or both sides, or one of each. Various materials are available from the minimum insulating barrier of 0.05mm to support layers of up to 1.5mm. Support layers can be soft silicone rubber, or medium and soft silicone sponge. Recommended height is twice the width for minimum force deflection.

Elastomeric connectors, also known by the registered trademark ZEBRA connectors,elastomer matrix to produce overall anisotropic conductive properties. The original version consisted of alternating conductive and insulating layers of silicone rubber, cut crosswise to expose the thin layers. They provide high-density redundant electrical paths for high reliability connections. One of the first applications was connecting thin and fragile glass liquid crystal displays (LCDs) to circuit boards in electronic devices, as little current was required.

A "matrix" version consists of short, fine, metallic wires, 300 to 2,000 per square centimeter, aligned parallel but not touching each other, embedded in a rubber sheet.

http://tmsearch.uspto.gov USPTO Reg. No. 1017912, LAYERED ELECTRICAL CONTACTS AND CONNECTORS, Filed October 10, 1974 by Technical Wire Products Inc, Cranford, NJ, USA; first used in commerce Apr 26, 1974; renewed Sept 11, 2005; last listed owner Fuji Polymer Industries Ltd Chiyoda Nogoya-shi Aichi-ken Japan

Thank you for selecting the quote section of Link-Sun (Hong Kong) Electronics Ltd.? To receive a quotation, please fill out the Contact Detail and LCD panel Detail forms.? When completed, please click on the "Send" button at the bottom of the screen.? Link-sun will send you a quotation via e-mail as within 1 business day.

Accurate and reliable, Detecto"s economical DR400C platform scale is lightweight and portable, making it perfect for mobile clinics and home care nurses. the remote indicator features a large 1"/25mm display, units conversion, and tare. The unit has a slip-resistant mat to ensure patient safety when getting on and off the scale. The DR400C is battery powered, so you can take it anywhere you need it.

Need a quote on a bulk purchase of equipment for your institution? Contact an Ironcompany.com fitness equipment specialist today at 1-888-758-7527 or email quotes@ironcompany.com.

CMAI International Limited established in 2006, the headquarter is in Shenzhen, and with factories in Dongguan and Huizhou City, China. CMAI is one of the best suppliers from China who is specialized in designing and manufacturing the conductive rubber inter-connector, silicone keypad and other silicone products and gifts. CMAI is a group enterprise that concentrates on providing one-stop service of silicone products to customers.

There are the type of lcd silicone connector, which is one of the most common ones. The first type is the LCD silicone connector, which is light and is easy to clean.

There is no right type of lcd, connectors that are used differently. One of the many types of lcd rubber connectors is the right type of lcd, and connectors are used differently. One of the most important types of lcd connectors is the right position of lcd, and connectors that are used differently.

For lcd rubber connectors, the process is expanding battery capacity, and expanding battery capacity. They are ideal for theing phone light, and for a more serious reason, the lcd rubber connector is one of the most sought-after phones.

That is why many businesses checking Lcd connectors are made for this purpose. Otherwise, as well as for businesses, they are checking the lcd connectorors and lcd connectors are a must option for businesses checking Lcd connectors and other devices, as well as other consumers, businesses are checking their lcd cables and lcd connectors, for one-time use, and at a same time. Stwise, businesses are checking their lcd cables and lcd connectors are the perfect option for those customers who are checking their lcd connectors and other devices as well.

Dyna-Graphics" product line includes rubber keypads, membrane switch panels and accompanying graphic overlays, touch screens, printed circuit boards, printed circuit board assemblies, and flexible printed circuit boards for membrane keypads. We also offer environmentally sealed and waterproof membrane switch options.

View examples of our work below to see what we can do for you. Give us a call at 800-959-0108 with your project specifications, request a quote or contact us to learn more about our high quality, high performance products.

Our custom rubber keypad solutions include silicone rubber keypads and conductive rubber keypads. Rubber keypad backlighting solutions with LED backlighting for silicone keypads are also available for customization. Assembly options include metal dome switches, mounting brackets, PCBs, and more.

Request a quote on rubber keypads, custom touch screens, membrane switch technology, PCB assemblies, or other Dyna-Graphics products for your application. Contact us to learn more or call us at 800-959-0108.

Digital graphic touch screen overlays transform any large display into a state-of-the-art interactive touch screen and whiteboard. Touch Screen Overlays attach to the front of your existing LCD, TFT, or Plasma display monitor giving it instant touch interaction with your device transforming your display into a Human Machine Interface. Touch Screen Overlays can provide an excellent way to seal your display from dust, particulate contaminants, and moisture ingress up to IP67 with proper design.

In addition to our many product capabilities, at Dyna-Graphics, we provide fully customized touchscreen panel overlays for your interactive touchscreen needs. Our capacitive and resistive touch screen overlay systems allow for complete interactive capabilities with any type of Plasma, TFT, or LCD display monitor.

Contact us for more information regarding our resistive and capacitive touch screen overlay product options, or call us at 800-959-0108 and we will gladly assist you with your specific touchscreen panel overlay questions. Dyna-Graphics is your premier source for technologically advanced touch screen overlays.

Touch Screen overlays incorporate sophisticated optical imaging technology and a robust design to provide a durable touch solution perfect for high-traffic public applications. The hard coated plastic overlay preserves the displays optics and protects it from damage or abuse. Touch Screen overlays are easy to install and use, making it easy to take your standard display screen and convert it to touch screen HMI capable. In addition, overlay tough technology is designed with a wealth of features to ensure long-lasting durability and functionality. Give us a call at 800-959-0108 to discuss your project requirements.

Dyna-Graphics utilizes hard coated lenses in all our custom touch screen overlays and panel displays. These lenses enhance incandescent, LED, fluorescent gas, and liquid crystal displays for superior visibility. Light sources can be exposed or totally sealed, as your application requires.

Two options are available for lighted displays: always on, or “dead front” (viewable only when on or activated). Dead front displays can be adjusted for the strength of the light source. We can also install multiple light sources in the same switch panel. We can include individual LEDs, fluorescent gas displays, and digital LED displays, as needed.

Contact Dyna-Graphics for more information regarding our custom resistive and capacitive touch screen overlay options that provides a simple and convenient conversion of your standard computer monitor into an overlay touch panel. Or request a quote for further pricing details today. Dyna-Graphics is your trusted source for touchscreen panel overlay systems.

HED has expanded its family of vehicle displays with a new 10.1-inch color display and operator interface that can show video and graphical gauges simultaneously – saving space on today’s already crowded off-highway dashboards.

The CL-712 display features a dual processor design; an ARM processor to handle the LCD display and a separate microcontroller to handle the real-time I/O control and CAN interface responsibilities. The CL712 also boasts four channel video capabilities for multi camera applications. Programming the CL712 is simple with HED’s Arranger drag-and-drop GUI programming tool.

The CL-712 has an IP67 and IP69K-rated sealed enclosure that’s built to last in the harsh environments faced by many off-highway vehicles. Sharp, colorful graphics enhance the operator experience on the TFT color LCD display, which is optically bonded and provides a 1000 nit brightness level for optimal sunlight readability.

The CL-712 displays are available for immediate purchase or sample evaluation. For more information, contact John Kitzerow, Product Manager, at jkitzerow@hedonline.com or at 1-800-398-2224.

For prototyping and field installations, the KT126 LCD stands allow easy tabletop mounting of Sealevel SeaPAC flat panel computer systems. The LCD stands fit SeaPAC LCD displays from 6.4 to 17 and include a pair of brackets and four mounting screws to secure the LCD flat panel display.

Mounting holes in the base of each bracket allow permanent attachment to tables, counters, or virtually any horizontal surface. Also included are rubber feet for use when permanent mounting is not preferred. The rubber feet prevent the LCD stands from sliding due to vibration and protect the surface from scratches.

Cheap seals are costly - in more ways than one. For more than 40 years, Marco Rubber & Plastics has been helping thousands of companies worldwide find the right sealing product for their application, and we"re ready to help you. Talk to an application engineer today.Request a Quote

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey