lcd screen heat damage made in china

Chemicals leaking from millions of computer screens in homes, offices and schools could damage human health, according to research by Chinese scientists.

Chemistry professor Su Guanyong and colleagues at Nanjing University of Science and Technology in eastern Jiangsu province studied more than 360 types of chemicals used in computer and mobile phone screens and found that 87 of them could be a danger if they got into the environment.

Some chemicals in liquid crystal displays (LCDs) could alter genes, they said. Animal cells mutated unexpectedly if exposed, and preliminary results of their ongoing study published in Proceedings of the National Academy of Sciences on Monday showed that one of the most polluted places was the home.

Researchers said about a quarter of the chemicals from screens they tested might be pollutants. Photo: Getty alt=Researchers said about a quarter of the chemicals from screens they tested might be pollutants. Photo: Getty

Studies found that excessive radiation from screens could speed up the ageing of skin and blue light from diodes could harm the retina of the eye. "But nobody has looked beyond the brightness to unveil the dark secrets behind," Su said.

Over the years, screen panel manufacturers have pushed LCD technology to higher resolutions and faster refreshing rates, but the chemical composition of the liquid crystal that fills their screens has hardly changed.

Smartphones mean booming demand for components such as screens. Photo: Ben Sin alt=Smartphones mean booming demand for components such as screens. Photo: Ben Sin

They exposed embryonic chicken cells to liquid crystal taken from the screens and compared them to cells grown in normal conditions. They found genetic changes that suggested the exposed cells had mutated.

The Nanjing team was baffled by the amount of liquid crystal in the air. They knew screens were made in dust-free factories and sealed, but their surveys of hotels, school buildings, canteens, dormitories, electronic product repair centres, homes and laboratories revealed surprising results.

Scientists say cracked screens and leaking chemicals are a worldwide problem. Photo: Shutterstock alt=Scientists say cracked screens and leaking chemicals are a worldwide problem. Photo: Shutterstock

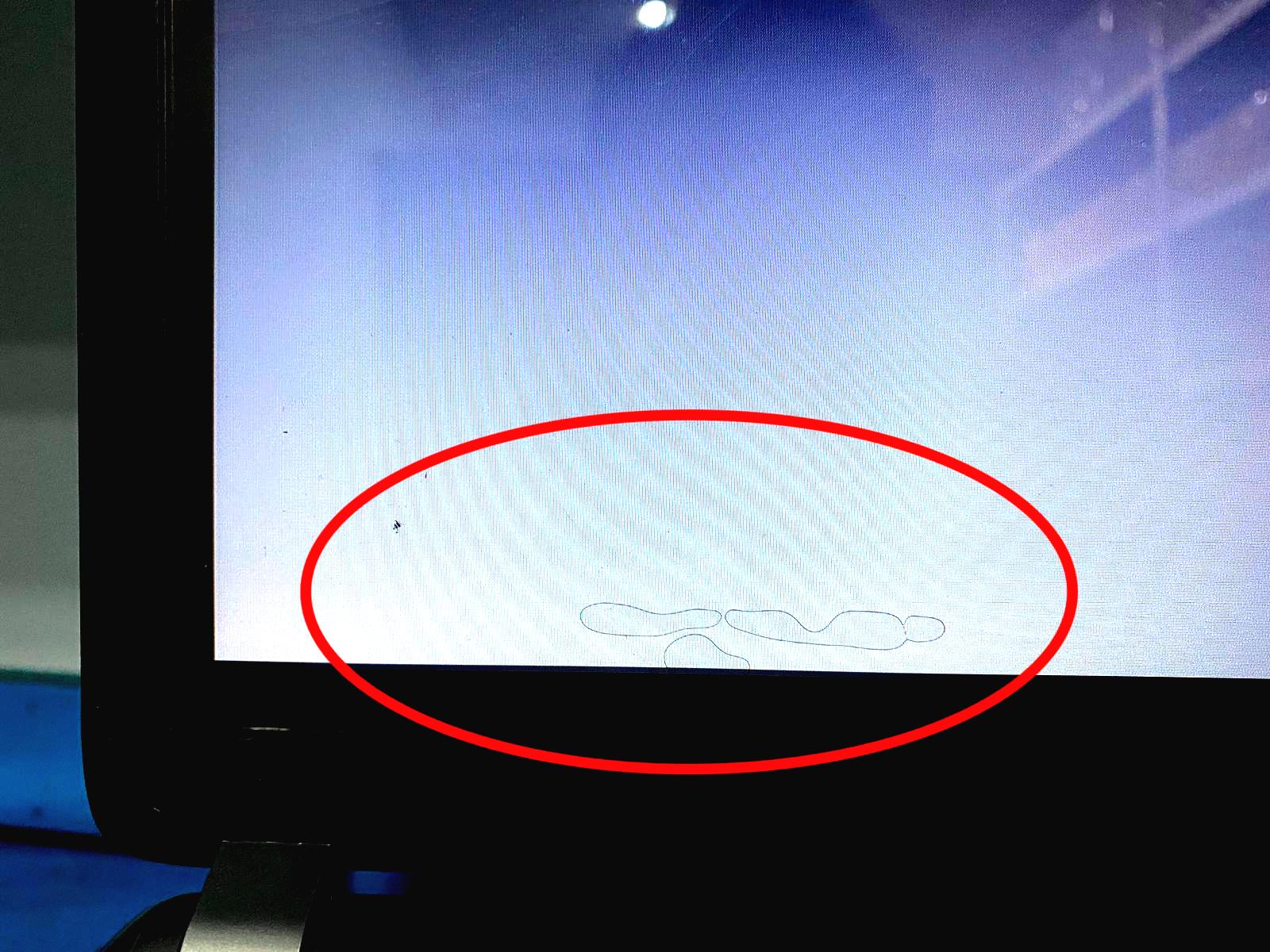

The lowest levels were found in a canteen, a dormitory and classrooms. Su said they were not sure where the drifting liquid crystals came from. Some screens might have been cracked or broken, he said. If a screen was left on for a long time, heat and radiation might cause liquid crystal to evaporate.

"Electric device recycling plants could be a major source of emissions, with broken screens dumped everywhere and little protection. This practice must stop," he said.

JIANGSU (China) — Chemicals leaking from millions of computer screens in homes, offices and schools could damage human health, according to research by Chinese scientists.

Chemistry professor Su Guanyong and colleagues at Nanjing University of Science and Technology in eastern Jiangsu province studied more than 360 types of chemicals used in computer and mobile phone screens and found that 87 of them could be a danger if they got into the environment.

Some chemicals in liquid crystal displays (LCDs) could alter genes, they said. Animal cells mutated unexpectedly if exposed, and preliminary results of their ongoing study published in Proceedings of the National Academy of Sciences on Monday (Dec 9) showed that one of the most polluted places was the home.

Dr Su, professor at the school of environmental and biological engineering, said he had been worried about the effect of exposure to computer screens on human health for a long time.

Studies found that excessive radiation from screens could speed up the ageing of skin and blue light from diodes could harm the retina of the eye. “But nobody has looked beyond the brightness to unveil the dark secrets behind,” Dr Su said.

Over the years, screen panel manufacturers have pushed LCD technology to higher resolutions and faster refreshing rates, but the chemical composition of the liquid crystal that fills their screens has hardly changed.

Dr Su’s team went to a phone repair shop and bought used screens found in six mobile phone brands in China and abroad. “We don’t want to name them because this is not a problem of specific manufacturers. It is the whole industry,” he said.

They exposed embryonic chicken cells to liquid crystal taken from the screens and compared them to cells grown in normal conditions. They found genetic changes that suggested the exposed cells had mutated.

The Nanjing team was baffled by the amount of liquid crystal in the air. They knew screens were made in dust-free factories and sealed, but their surveys of hotels, school buildings, canteens, dormitories, electronic product repair centres, homes and laboratories revealed surprising results.

Liquid crystal was not only present in the air in all of these places, but the second-highest concentration was found in flats, while a laboratory that housed a large number screens topped the list.

The lowest levels were found in a canteen, a dormitory and classrooms. Dr Su said they were not sure where the drifting liquid crystals came from. Some screens might have been cracked or broken, he said. If a screen was left on for a long time, heat and radiation might cause liquid crystal to evaporate.

“Electric device recycling plants could be a major source of emissions, with broken screens dumped everywhere and little protection. This practice must stop,” he said. SOUTH CHINA MORNING POST

A fire at an LCD monitor assembly plant in China ultimately damaged 14 production lines and caused an estimated NT$2.27 billion (US$71.27 million) in damage, according to Lite-On IT, the Taiwanese owner of the factory.

A short circuit caused the fire at Lite-On"s Dongguan, China factory on Feb. 3, but the company reported the cause and damages on Tuesday in a public release. The damaged lines are used to make LCD (liquid crystal display) computer monitors and LCD TVs and the fire damage will affect shipments.

Over the next two months, Lite-On, a major contract LCD monitor assembler, will only be able to partially fill orders to major customers. The company has been able to shift some production to other production lines, it said in the statement.

Analysts do not expect the supply disruption to affect global LCD monitor or LCD TV markets, but said it could cause headaches for some of Lite-On"s customers.

There are two ways to properly perform this task on any OEM adhered lcd assembly. One way is very costly to setup and the other is not but it is slightly more time consuming.

Following these steps you will have a reconditioned lcd assembly in under 30 minutes using common household items and a few you will need to hit the harware store to obtain.

Do not listen to what was said earlier about using no heat. In order to properly loosen the adhesiv you NEED 100 degrees F (77 C) or you run the risk of destroying the polarizer layer.

While wearing leather gloves, wrap the ends of the wire around your index fingers on each hand enough times to give you a very sturdy grip. Keeping the assembly face down on the griddle apply slight pressure on the lcd with your thumbs while you gently work the wire between the glass and the digitizer/polarizer layers. You only want to get the wire in a few millimeters, just enough to get your playing card in behind it.

Take off the gloves, leave the wire in the glass and slide a playing card in right behind the wire. Make sure the card spans the ENTIRE width of the lcd and protrudes from both edges, left and right.

Have someone hold the hair dryer for you and point it at the glass, to the very bottom edge of the card. Moving together, slowly but steadily work the card down between the layers, separating the glue. Do not bend the card towards the lcd at this point or you may shatter it. Continue moving the card through as your friend follows the edge of the card down with the hair dryer. You will more than likely need to throw away the card and use another 3-4 times to get all the way through as the card will get mangled and lose its edge, becoming ineffective.

You will notice that your lcd is free of all the glass but is also covered in gooey gum. Much of this can be removed by simply grabbing some tightly and peeling it back with your fingers. If you run into any stubborn gum use the safe scrap plastic razors to remove it. Do not use any solvents to remove the gum unless you are proficient with a soldering iron and do not mind re applying the back light layer on the rear of the lcd.

Place your lcd face up in the LOCA mold. Apply a line of LOCA straight down the middle of the lcd from top to bottom. Excess will not hurt but it is messy, however you are better off using too much adhesive than not enough. Once the LOCA is applied, place ONLY the bottom edge of the glass into the mold but hold the top edge up and do not allow the glass to contact the glue yet. VERY SLOWLY begin to lower the top edge down to the lcd. ONLY move as fast as it takes for the glue to make it all the way to the left and right edges, it will like watching a horizon of glue rise to the top and outward to the sides.

Congratulation, you have rebuilt your lcd assembly. In our shop we often do have to perform this task in a similar fashion as the machines we use do not work when the glass is completely shattered, so this advice is based on my personal experience from owning one of only 3 facilities in the United States that is capable of this on a large scale.

Keep in mind that iPhone screens are so inexpensive comparatively speaking that there are probably many things you could be doing with your time other than attempting this. But if you are like me, and it always bothers you when someone tells you something cant be done, then enjoy. Remember, patience is the key. Frustration, shaky hands, being irritated or distracted often leads to a shattered lcd. If you are having trouble put it down and take a break for 5 minutes.

quick edit: I forgot about the Alcohol! using a q-tip NOT dripping in isopropyl alcohol gently clean excess glue form underneath your new glass. Unlike solvents, this only removes uncured LOCA and will not effect the bond you created. Be careful to use as little as possible or you may need to solder a new back light layer on the lcd, as even alcohol is not pure and contains some water which will stain the otherwise immaculate back light layer, giving you that bad whiteout splotchy look.

Not too long ago, we’ve just got some samples of the new China Made iPhone 6 LCD Display. No doubt that this will be another option for all who are suffering from the high price of the iPhone screens. Let’s take a deep look of these screens.

At the moment, there are two companies producing the iPhone 6 LCD screens, one is LT, the other one is JDF (no iPhone 6 screens made by TM are available now). Below are some detailed comparisons after our tests.

When taking a closer look at both of the LT and JDF iPhone 6 screens under direct light, you’ll see the digitizer textures. While for the original screen, the textures had been hidden by a special painted layer.

The glass lens of LT made iPhone 6 screen is far too thin compared with the original one, which can’t secure the display well. At the same time, thinner glass lens will make the home button stick up above the screen. While for the JDF made the screen, a plastic layer has been added to make it thicker.

It’s hard to be realized through eyes, but it’s easily to be touched. When you grab the iPhone 6 with LT made screen, it’s hard to ignore that annoying uncomfortable feeling. At this point, the JDF made screen is much better.

High and low temperature tests have been applied to both the LT and JDF iPhone 6 screens. Both of them have survived and worked well after been putted in a 55 centi degrees room for 2 hours and -5 centi degrees room for 2 hours.

Through our tests, the first version of both the LT and JDF displays are not good choices for the repair industry. The obvious color differences, thickness differences still need to be improved. If you have any questions regarding the LT/JDF iPhone 6 screens, please leave your comment below, we’ll try our best to answer it.

“Original” screens are those containing LCDs manufactured for Apple. “Copy” screens are compatible replacements entirely designed and manufactured by third-party companies not associated with Apple.

LCD display panel can have poorer resolution (i.e. looks “coarser”), worse brightness, contrast and vibrancy and reduced refresh rate amongst other problems.

Changes in specification from original can result in battery and performance issues. Certain badly-engineered screens could even damage the backlight circuitry.

Customers who bring their iPhones to us for a screen repair are offered two choices of replacement- an original or a “copy” screen. The most common response is “Is there a difference- and which one would you recommend?”

Originals are those screens containing LCDs that were manufactured for Apple. So-called “copy” screens are compatible replacements, but designed and manufactured entirely independently by third-party companies, typically in China.

Our answer is simple- the original screen is the one we’d go for ourselves, every time. Some people think we make more money on them, but this isn’t the case. We recommend originals because they’re far higher quality and the price difference is fairly small.

We’d rather only fit original screens. The only reason we don’t is that many people will shop around and choose purely on price. As such, we need to offer the cheaper copy screens to remain competitive and avoid losing these customers. In some cases, they didn’t even know there was a difference in the first place- especially since it’s not in some shops’ interest to draw people’s attention to the issue!

This may well be the worst copy screen we’ve ever come across. As a result, the unfortunate customer has ended up paying twice to have their screen replaced- we’re sure that had they been properly informed, they would have chosen an original in the first place.

While the difference in price between copies and originals can vary across devices, it’s generally around £10 – £14 extra to have an original screen fitted. This really isn’t a lot considering the improved quality and reliability.

We compare our prices to our competitors- and we know that we come out of it favourably. While we have to offer copy screens to remain competitive, we always advise customers to go for the original.

When you’ve spent- directly or indirectly- several hundred pounds for an iPhone with a Retina display, it doesn’t make sense to replace it with a lower-quality screen that can make a £400 phone look like a £40 one! Not only that, but you’re likely to have fewer issues, and a longer-lasting screen.

Many- if not most- don’t even acknowledge the existence of copy screens, let alone explain the difference to the customer. Hardly in their interest to do so if they only fit cheap, low-quality copies. Some of them can hardly be blamed- they know so little, they’re not even clear on the differences between OEM, non-OEM and copy displays themselves! Others can be more deliberately misleading… and some outright lie.

Generally, these shops are looking for the cheapest price on replacement screens.. When offered a copy at a half or a third of a price of the original, they’re going to go for that. That might be fine if they offered the customer a cheaper price- what we disagree with is selling “supermarket beans” (i.e. the copy screens) at “Heinz beans” prices!

Heading towards the “blatantly fraudulent”, we’re aware of companies that shamelessly fit copy screens while claiming them to be original. Worse, they’ll take your broken original screen and sell that to a recycler for more than they paid for your copy!

Apple tightened up their supply chain around 2015, which reduced the number of screens available for repairs and increased their price dramatically. A lot of companies went bankrupt, and Chinese manufacturers responded by making their own “copy” screens from scratch. At first, these weren’t much cheaper than the Apple ones, but the price soon fell.

We should be clear that- despite the name- “copy” screens aren’t direct copies of the Apple originals. Rather, they’re compatible replacements that have been designed from scratch and- as a result- vary in some respects that have an effect on usability and quality.

One of the most important differences between an original and a “copy” screen is how the digitizer (touch sensor) is designed. Apple has it manufactured as part of the LCD itself, whereas the copies have it on the glass.

Although there are only a small number of manufacturers of the bare LCDs themselves, these are then bought by countless other companies who add the remaining components needed to turn these into a complete working screen. As a result, you could easily end up with an LCD from the best “copy” manufacturer, but the digitizer/touch (as part of the separately-manufactured glass) from the worst.

There are countless digitizers out there, and you can only take the supplier’s word that the quality is good. Many ship good ones at first, then switch to cheaper parts to make more profit. This is particularly bad with the iPhone 6S and 6S+, since Apple moved the chips responsible for touch processing onto the LCD itself. As a result, you’re not just getting a copy screen- you’re getting copy chips too.

The performance specification (power drain, etc.) of most copy screens isn’t identical to the originals. As a result, they can drain the battery more quickly and mislead the operating system which was optimised for the original screen design.

It’s even possible that this mismatch could damage your backlight. We do a lot of subcontracted repairs for less-experienced shops, and get backlight repairs in almost every day. We’ve had cases where we fixed the circuit, fitted the new copy screen to test it, and had it break the circuit again!

Copy screens can disrupt the touch ID fingerprint reader. With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. Frequently the home button flexes on aftermarket designs don’t work properly and stop the touch ID working- annoying if you use it to unlock the phone or log in to your bank.

We’ve seen many lift away from the frame that holds them in place. This usually results in the flex cable getting torn, and the screen needing replacing. You don’t even need to have dropped the phone- this often happens through general everyday wear and tear.

That brings us to another major issue with the copies. When you drop an Apple original, the glass often breaks, but if the LCD itself is intact, you can continue to use it until it’s fixed. With the copies, the touch/digitizer is on the glass and stops working when that’s broken. Even worse, the LCD itself is more likely to break due to the thinner and more fragile glass.

We’re not convinced this will happen, since Apple recently changed their repair policy to accept iPhones with third-party screens. However, it is possible that copy screens could be stopped from working via an iOS update, since those make a number of security checks.

Since the iPhone 7/7 Plus has been released for quite a long time, finally the China made iPhone 7/7 Plus screen replacementscame out in the market. we’ve got some iPhone 7 series LCD screen replacements samples and done some tests on them, now let’s take a closer look at these new iPhone 7 series LCD screen replacements!(TianmaandLGsources for testing)

After installing all the sample screens to the iPhone 7/7 Plus rear housing assembly, we found that all the China made iPhone 7 series screen replacements are fitting well just like the original ones - the home button fits well, the screen assembly and the rear housing also fits well.

From the picture below, we can see that there is no difference between the China made iPhone 7 series display and the original ones, however, back to the rear side, we can easily figure out which one is which, cause the original one has Apple logo on it while the China made screen has none.

By comparing these two iPhone 7 screens, we can find that the screen flex cables are much different, there are extra IC on the China-Made iPhone 7 screen while the original one has none. And the original iPhone 7 series screen flex cable is integrated together while on the China-Made iPhone 7 series screen the touch function flex cable is soldered to the display and 3D touch flex cable.

Another difference between the original and China made iPhone 7 screen replacements is the exposed IC on the after-market iPhone screen, just like other China-Made iPhone 5 or 6 series screen replacement, which has more potential risk of electrostatic damage and more likely to get damaged and this problem needs to be improved.

During our test, we found that the display color between our after-market iPhone 7 screen and original screen seems a little different although they are not effecting the touch function. And to be honest, there may have some black dots on the screen because of impurities within the screen module when laminating the LCD and backlight together, without any doubt, this can be solved with technical improvement.

The screen touch sensitivity is another big concern for all of us, luckily, during our test, almost all home button and touch functionality on both iPhone 7 and 7 Plus works well, except one piece of iPhone 7, the 3D touch function is not acting so well on the central part of the screen.

The China-Made iPhone 7 series LCD screen assembly replacement still remains to be improved in quality and performance compared to the original ones, the exposed IC, heavier screen flex cable ribbon, and the screen color difference, the touch function stability, although the price is attractive. However, the China made iPhone 7 series screen replacement is under the improvement, and sooner or later their quality and performance can be quite close to original ones and acceptable, if you"re going to stock up some non-original iPhone 7 series LCD screen replacement, pay more attention and we’ll keep you updated with further information about after-market iPhone 7 series screen replacement!

AMOLED burn-in on screens and displays is permanent. Fortunately, you can slow it down and reduce its visibility by using a few simple tricks, which can also increase battery life.

Everyone with an OLED display has some burn-in. But often, it"s not fully visible unless you display a solid color at maximum brightness. The Android operating system has access to many apps that detect burn-in damage. The best of these is Screen Test.

Screen Test is ultra-simple: install and run the app. Touching the screen shifts between colors and patterns. If you see a persistent image impression or blotchy coloration, you have burn-in.

For my AMOLED phone, I"ve taken every precaution against screen burn-in. Even so, the display is still a little blotchy after over a year of use. Fortunately, there are no indications of burn-in where the navigation buttons are.

Android made it possible to get rid of the navigation bar in Android 10. Once enabled, gestures allow navigation by swiping your finger on the screen. You can enable Gesture mode by doing the following:

Some might notice that the stock wallpapers in Android aren"t usually suited for OLED screens. OLED screens consume very little energy when displaying the color black, and they do not burn-in when displaying black. Unfortunately, older Android versions don"t include a solid black wallpaper option.

If you don"t have Android 10 or newer, the default Android Launcher isn"t OLED friendly. In Android 5.0, it forces the App Drawer wallpaper to white (the worst color for OLED screens). One of the best launchers for darker colors is Nova Launcher. Not only is it more responsive, it offers better customization options.

Minma Icon Pack changes your bright, screen-damaging icons into a darker, OLED-friendly palette. Over 300 icons are available, which cover the default icons as well as many others.

There are a few other burn-in repair tools, but I don"t recommend them since they either require root access and/or can increase screen damage. However, for reference, you can read about them below and why using them is a bad idea. They fall into two categories:

I do not recommend using this option unless your screen is already trashed. It will cause additional damage but may reduce the appearance of already existing on-screen burn. Inverting colors simply reverses the colors displayed on your screen. Whites become blacks and vice-versa.

Several tools claim to reduce the appearance of burn-in by attempting to age the entirety of your OLED panel. These screen burn-in tools flash red, green, and blue (or other) colors on your screen.

The reason is pretty simple: AMOLED burn-in occurs as a natural part of an organic LED"s life cycle. Therefore, tools that claim to fix AMOLED burn-in will cause uniform damage across all AMOLED pixels thus potentially worsening its image quality.

None of these methods will stop the inevitable and slow destruction of your device"s screen. However, using all the recommended options in this article will dramatically decrease the rate at which it decays. That said, some of the oldest AMOLED phones have very little burn-in. The decay of organic LEDs is almost entirely aesthetic, particularly on newer phones.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey