flsun i3 lcd panel install brands

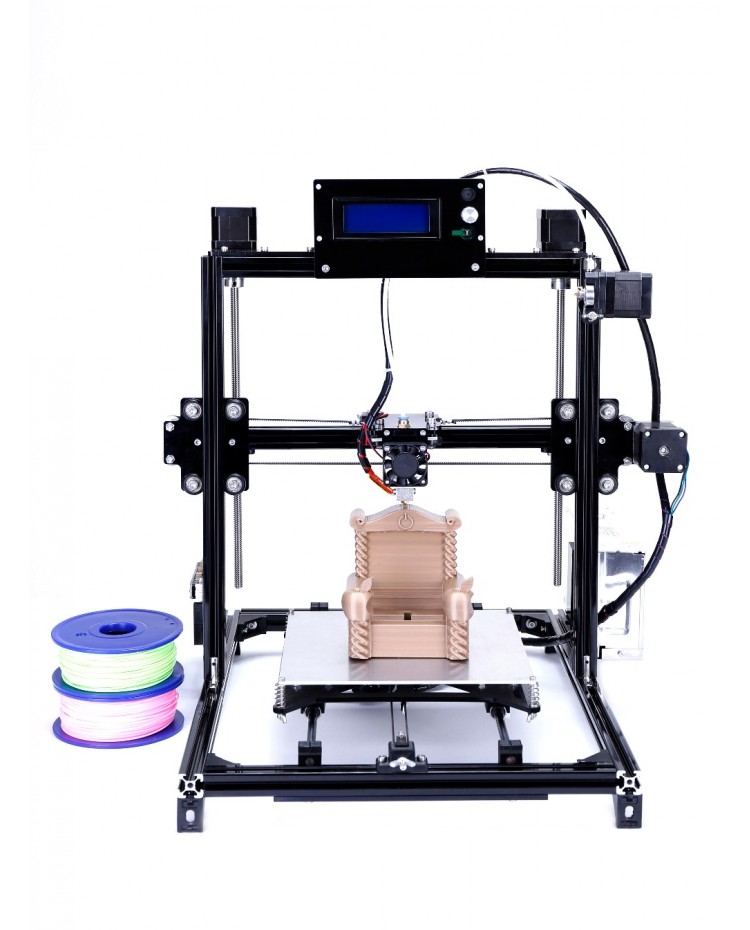

I bought the same exact printer back in September. I’m getting great prints with it and i’ve made only a few minor improvements to it. Not knowing anything about 3D printers or 3D printing in general, after about a month of researching the subject, I pulled the trigger on the Flsun. I knew i wanted a kit, normallly cheaper and i wanted to assemble it to become familiar with the machine and to insure that everything was straight, square, true, and tight. I read about using M4 PZRT 2020 nuts to assemble the frame instead of the included square nuts, so an extra $10 for a pack of 50. They arrived before the printer.

And as far as Flsun’s upside-down Z motors causing Z wobble because of this or that is just incorrect. If there is any bend in the lead screws and the lower ends of the lead screws are constrained, the X axis is forced to follow along with any bow. They are better left to hang and follow the X. If you have a printer with the Z motors at the bottom, the lead screw is constrained by the stepper, right at the same relative level of the bed and x beam. If the flex coupler doesn’t provide a concentric connection between the z motor and lead screw, it can induce z wobble in to the X. I feel Flsun did it the better way and it’s better left just the way it is.

I haven’t tried the dual nozzle setups yet. I’ve got it dialed in great with the V5. Prints great. Way nicer than my friends Ender3. Hate to mess with it just to be disappointed with the dual. I think you’d be disappointed no matter what printer you installed the dual on. If and when the X carriage breaks, i’ve got a 3 wheel x carriage with plenty of accessories printed and ready to go. I think you’ve made a great choice.

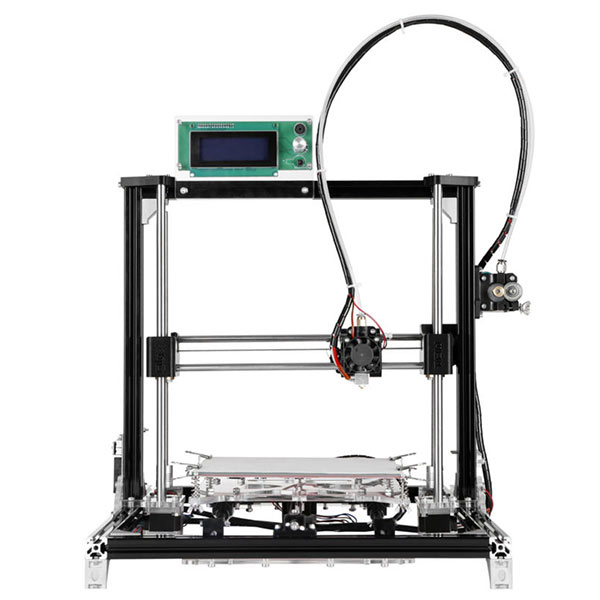

The LCD screen is vital for operating the printer. Should you encounter any kind of trouble, such as a dead screen, corrupted text, or other issues, please refer to the guide below.

First of all, unscrew the LCD screen from the printer frame, remove both M3x10 screw holding it the LCD board in the plastic casing, and remove it from the casing. See if the problem still appears when the LCD is not pressed by the casing.

Firmware updates are necessary to keep your printer up to date. However, the installation of incorrect firmware can lead to letter corruption on the LCD screen. There"s an easy fix, though:

There is a small chance the printer"s LCD screen can glitch out by electrostatic discharge when inserting the SD card. Try to turn the printer off and on again.

This problem usually appears only on user-assembled printers. If your printer"s LCD screen remains blank or displays corrupted symbols after you turn on the printer, there is a chance it is caused by incorrect wiring. Follow these steps to fix the issue.

If you suspect that the LCD ribbon cables connectors are not firmly seated in the slots, disconnect the LCD ribbon cables and check the slots for any bent pins. If there are bent pins, you can use tweezers to fix them. However, be very careful not to break the pin(s) completely.

I found a cheap Prusa i3 clone from FLSUN and ordered the DIY kit for November"s project. Assembling the printer was a great fun as I love hardware projects and working with my hands.

Some of the connecting cables are very short (for example LCD connection to main board), so placing everything neatly on the frame was a bit of a challenge.

I wished I had purchased an FLsun printer first...I have 2 other traditional 3d printers...I always have to tinker with them. I first got the QQ S Pro...flawless printing ( any fails were due to operator error ) Now I"ve got the Speed Racer, this unit has all of the reliability of it"s cousin but is much faster. I have been slicing HOURS off of prints, yet quality is high! Example:. 34 hours estimated by slicer...act [...]

Dave Gershgorn is a senior staff writer at Wirecutter and an avid 3D-printing enthusiast. He has printed through dozens of rolls of filament, has owned multiple printers, and has designed custom 3D-printable models for home improvement, product testing, and cosplay. His current personal printers are the Prusa i3 MK3S+ and the Elegoo Mars 3.

We time how long we take to get each printer from the box to set up on our desk, and we jot down notes on the initial software installation and navigation process. Then we get to printing. We allow each printer eight attempts to produce as many acceptable models as possible. We rate each print as either a success, a mediocre effort, or a failure. Successful prints look smooth, with no obvious imperfections. Mediocre prints have readily visible layers or imperfections but still look like a completed model. Failure takes many forms—everything from broken filament string that causes the print to stop to wild spaghetti-like misprints due to software or hardware errors.

We used a USB stick to transfer files from our computer to the printer, but Prusa has published a guide to a DIY upgrade that allows you to send files over Wi-Fi. Once you plug in the USB stick, you can use a knob to scroll through the menu and file list on the Mini+’s color screen, which we found to be much easier to parse than the blue and white, text-only screen of the Prusa i3 MK3S+.

The Mini+ has a totally open design, which means that it releases the VOCs and particulates that it produces while using certain types of filament like ABS. You might notice a maple-syrup or plastic smell from the melting filament. If you’ll be using the machine in a home environment, it’s a good idea to use a “healthier” plastic such as PLA. It’s also a good idea to print at the lowest temperature possible for your chosen material; the lower the temperature, the less bad stuff the printer releases into the air. If you plan to spend time in the same room as a running 3D printer and don’t have a ventilated hood or HEPA air filter, turn on a fan or crack a window to improve ventilation (PDF). It’s also a good idea to wear gloves to prevent skin transfer.Upgrade pick: Prusa i3 MK3S+

The Prusa i3 MK3S+ offers the reliability and print quality of the Mini+ along with a larger print bed, a more stable design for greater printing detail, and a better extruder that can handle a wide array of materials. It also comes preassembled or in a DIY kit, though we found the preassembled kit much simpler to set up than the Mini+.

You can print on the MK3S+ over Wi-Fi directly from PrusaSlicer if you install a Raspberry Pi Zero W into your machine, or you can save your file to an SD card and insert it into the machine. Using a knob, you can scroll through the black-and-white menu on the MK3S+’s small screen to select which model you want to print. It isn’t the flashiest or most intuitive system, but it is similar to what you’ll find on most other $1,000 printers.

If you aren’t sure you want to commit to using a 3D printer regularly, or if you just want to spend a bit less, the Monoprice MP Cadet is a good budget option. In our testing, this $200 printer made prints that looked just as good as the results from printers that cost several times more, and its small size makes it especially desk friendly. Its removable, unheated bed is also more suitable for little fingers and releases finished prints with ease (though it puts your prints at risk of warping). However, this machine lacks the relatively advanced features you get from more expensive printers such as the Prusa Mini+ and i3 MK3S+.

The MP Cadet is noticeably smaller than most printers, with an overall footprint of just 8.3 by 8.3 inches. However, because its print bed is not enclosed and it doesn’t have a heated bed, you need to keep it away from open windows and in an area with a relatively constant temperature so that the air doesn’t warp prints. The work area should also have good airflow, such as a small fan nearby. The melting filament gives off a maple-syrup or plastic smell, so in addition to having airflow in the room, you should avoid sitting right next to the printer as it operates to avoid inhaling the fumes. The MP Cadet is noisier than the Prusa i3 MK3S+, too, though it isn’t unbearably loud.Also great: Artillery Sidewinder X2

In some ways, the Dremel DigiLab 3D40 impressed us: For about 50% more than you typically pay for the Prusa i3 MK3S+, you get an enclosed print area, a huge print bed (though not quite as large as that of the MK3S+), a touchscreen, and cloud-based printing. However, its prints in our tests didn’t look quite as nice as those of the MK3S+. We also found removing prints to be difficult, and we managed to ruin two flexible beds when the top layer ripped off during print removal. Finally, we dislike that the 3D40 prints only with proprietary spools of PLA—if you want to use other types of Dremel filament, you have to spend several hundred dollars more on the Dremel DigiLab 3D45.

Once the firmware has been compiled from C++ source code it is installed and runs on a mainboard with onboard components and general-purpose I/O pins to control and communicate with other components. For control the firmware receives input from a USB port or attached media in the form of G-code commands instructing the machine what to do. For example, the command G1 X10 tells the machine to perform a smooth linear move of the X axis to position 10. The main loop manages all of the machine"s real-time activities like commanding the stepper motors through stepper drivers, controlling heaters, sensors, and lights, managing the display and user interface, etc.

Marlin was first created in 2011 for the RepRap and Ultimaker printers by combining elements from the open source Grbl and Sprinter projects. Development continued at a slow pace while gaining in popularity and acceptance as a superior alternative to the other available firmware. By 2015, companies were beginning to introduce commercial 3D printers with Marlin pre-installed and contributing their improvements to the project. Early machines included the Ultimaker 1, the TAZ series by Aleph Objects and the Prusa i3 by Prusa Research.

Marlin is distributed under the GPL license which requires that organizations and individuals share their source code if they distribute the firmware in binary form, including firmware that comes pre-installed on the mainboard. Vendors have occasionally failed to comply with the license, leading to some distributors dropping their products.

FLSUN was developed in 2015, an independently developed the first DELTA 3D Printer. The Delta 3D Printer was very popular, shipped and sold all around the world. Unlike I3 3D printer model, Delta 3D printer is a space-saver 3D printer as all axis only move up and down, left, right, front, back movement is not necessary. Also, thanks to 3-axis linkage printing technology, speed can be improved.

The Flsun V400 come with 30mm(Diameter) X 410mm(Height) print bed size which is a popular size for most user and suitable for different printing purpose.

Full-colour 7" wide-angle IPS touch screen, In-build Full klipper firmware with 1G DDR4 Memory, on-board 16G EMM. Fast responsive touch panel, easy to Control, multiple management and full printing details and analysis. User-friendly, more convenient, and more comfortable.

The speed of the printer is 4-5 time faster than the most printer in the market (model of I3). Reducing the time by half without any lose of accuracy and quality. Fast and high quality printing is what Flsun V400 design for.This function is the main key for this printer to be a high standard 3D printer.

3 ways cooling fans with direct extruder was installed on V400 printer. High printing temperature reach to 300°C with effective cooling system make the printer run smoothly with special filament like wood, PC, Nylon and soft filament like TPU.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey