flsun i3 lcd panel install quotation

FLSUN QQ-S is designed for speed, the printing speed is 1.5 times that of the I3 structure printer, and the printing accuracy is the same. Relying on the high-speed products and high-quality services, it has been unanimously recognized by customers at home and abroad. It has a flexible three-axis linkage system, a powerful 32-bit motherboard, a 24V power supply, a lattice hot bed, and an all-metal side shell to ensure better printing quality and a more stable structure.

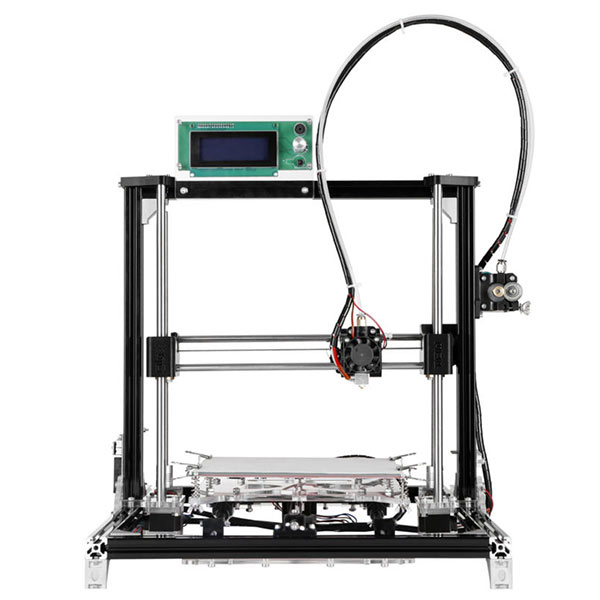

I have prusa i3 acrylic and i have problem. i dont have instructions to building or wiring so i watched youtube video to build it right, but in wiring i had a different mainboard and im now confused what should i do. If someone can help me and tell me where do what wires go in MKS gen 2z v1.2 board

I just started using the i3 v2 and compared to my previous printer (Q3d Three-Up) this is a Cadillac. Pretty well printed right out of the box, with only minor assembly issues. A little picky getting the bed level so I use a simple raft. Great rig for the beginner.

Hello. I am looking for help with my Anet a8. I have set to 110v and everything is connected correctly bit no LCD displaying. Sound coming from microchip, LED box is lighting up. Unfortunately I don"t know where to start looking for help on this knock off...

I3 Rework original and I would never ever wish this printer on anyone. Nothing I do can level the bed and it only got worse over time and is upside down taco shaped now. MK2B and everything I have purchased for this printer arrives to me bent so I end up having to return them and out of over 2k hours of tweaking I have nothing to show for it.

I"m just browsing and shopping for parts for my build. I"m designing a Prusa i3 RAMPs based printer with 0.4mm hotend for 1.75mm filament. My main design idea is to make it a "briefcase" printer so it can be easily folded and transported.

I have a Prusa I3 from 3D Printing shop here in South Africa. It has a Full Metal Hot End and I have printed ABS, PLA, and Flexible Filament through it.

Prusa i3 XXL from DIY Tech shop, I replaced most of the printed pieces it came with along with most of the steppers and the hot end and extruder. So I guess it"s mostly a custom machine at this point.

I built a kit from ebay from a seller in las vegas called "roaddog labs" I got the baja i3 rework kit, melamine frame, e3d v6 hot end and added a reprap discount lcd. ive had it about a month and have used it every day!

I"ve got one of these http://www.aliexpress.com/item/Free-shipping-High-Quality-Precision-Reprap-Prusa-i3-DIY-3d-Printer-kit-with-2-Roll-Filament/32424257787.html added a filament guide I designed in sketchup, really good printer once it"s all calibrated and you know what settings are best. I blew the original PSU so I wired in an 850w corsair PSU because it was the only spare PSU I had sitting around.

Please, I have challenges how to install the software. I bought my printer from the same seller on aliexpress.I will be glad if you can give step by step guide.I have setup my 3d printer.but have not use it to print.thanks

I"m seriously thinking of selling my Sunhokey Prusa I3. I"m afraid it"s beyond my abilities. I have it all put together OK but the software side of things simply leaves me cold. Basically it"s all ready to go though, now it"s come to the switch on I"m up the creek without a paddle. I"m in a small country town in NSW and there is no one to consult. What would be a fair price. Obviously if freight is involved I"d have to dismantle and repack it. Strange thing is I have a Laser engraver I"ve had no trouble with. .. Weird.

no body builds in a weekend, at least not your first .. i have seen some videos of people doing it in a few days time lapse .. but it was not their first kit build .. the folgertech prusa i3 i got in jan took about a month.. the plans were ok for download , the video was outdated (they said that guy doesnt work here anymore() - there was no instructional sound on the videos on the google drive and there was no phone support only email - the engineer came in once a week or so .. i had to rely on mostly other sources to get help -- i was not working on it full time , (ie all day long) , mostly morning, evening

I build my prusa i3 acryllic also within a few hours. It was also the first time and I build it with my children. There were 15 and 10. It"s absolutely not a problem.

The frame was already laser cutted, we assembled it then installed the motors and axes and finished with the board and screen. Started friday evening finished sunday afternoon.

Thanks Spandexgoblin, an easy answer :-) Another question if you don"t mind. What are the most popular upgrades to the Prusa I3 which give a marked improvement. I"m ordering the printer in the morning and I thought I may as well order a good upgrade whilst I"m doing it to save time.

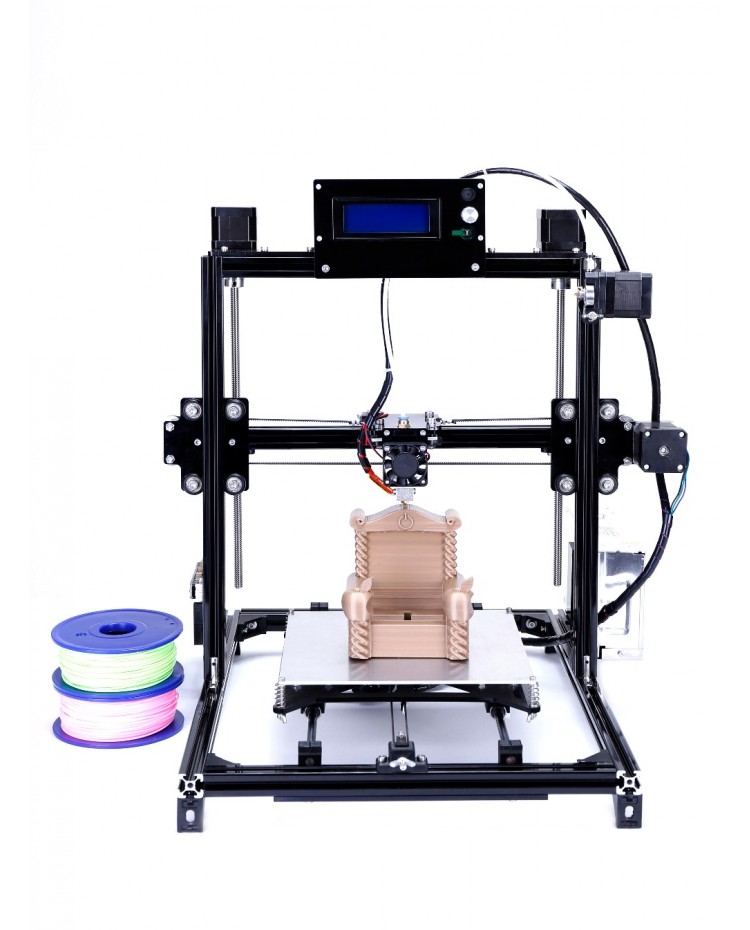

Honestly, the biggest upgrade you can do is rigidity in the frame (by switching to aluminum) and stability in your print bed (since the prusa i3 uses the moving heat bed as the y-axis instead of an xyz head) to get to printing speeds at double what you have. A well built prusa i3 can get to 120-150 mm/s print speed with the right adjustments and print at .1 maybe .06 resolutions.

I almost bought ready made kit however I wanted it to be made of sturdier materials then wood or acrylic plus the limited amount of kits that is larger than the 200mm build area. Since I prefer not to spend money twice to upgrade a part I designed and built my own version of the prusa i3 steel

There"s a guy on YouTube who gives a review of his Prusa I3. He has his head in the clouds I think. He reckons he can buy a kit, build it and sell it for double the price he originally paid. If that was true I think everyone would be building them.

I just received a quote for my first 3D printer a 2015 Prusa I3. $275 with a free 8Gb SD card and 2kg filament. Delivered via DHL. I"m in hospital at the moment and I"ve spent 2 days following the build routine but now find the one I"m getting has a lot more Acrylic than the one being built. I see many sleepless nights in front of me, :-(.

I finally managed to order my printer. What is it with Chinese sellers. They like to keep you talking for days if you let them. Then when it comes to buying they go into hiding :-) Anyway, it"s a SunHokey 2015 version Prusa I3 and it comes with 2Kg ABS and PLA, 8Gb SD card, Roll of crepe paper to cover the heat bed and a free extra "Thermal head" (I assume it"s a hot end) Plus the usual video DVD and software.

I also built mine from scratch. It"s a Prusa i3 box frame. I got the printed parts off ebay and spent about 11 months picking up parts when I could to build it. I started with a wildseyed hotend, but could only print for a week before I needed to rewire, so I bought a e3d. I have a RAMPS board, LCD and a Mk2b heatbead.

if it was me I would go with the one that has more print area if I only had those two to chose from, however I prefer the i3 steel versions they are more straight forward and less adjustments needed for assembly as the ones you are looking at uses all thread rods to setup the Y axis and I would go with a V slot setup as they are quieter and smoother then round rod versions

I have the Reprap Aurora Prusa i3 with a single 1.75mm extruder. Tends to jam a lot and I"m not a fan of the software, but it does ok. It"s about as cheap as they come so it"s to be expected.

Migbot Prusa I3 kit working like a top. First 3d printer owner here and it took a bit to get working properly but its going great now! 1.75 Filament, 3.5mm hot end, inductive sensor, 270 x 210 x 180 mm build area with heated bed and PLA only so far.

I"ve a home made Prusa i3 Box Frame (see here : http://www.thingiverse.com/thing:688383) with Arduino Mega 2560 and RAMPS 1.4. I"m using a 1.75 J-Head with 0.4mm noozle and have a MK2B heatbed.

I"ve got a Prusa Mendel i3 Steel running Arduino Mega with RAMPS 1.4, stepper drive DRV 8825, hot end 0,5 mm and 3mm filament. I"ve use only PLA. Hotbed 40°

I"ve just finished building a Prusa i3 with 3d printed parts completely redesign by me acording to my experience on other prusas that i"ve built and worked with. Is has a 12V30A superslim power supply, ramps and the e3d v6 for 1.75mm. I"ll be using it with PLA mostly, it"s the material i prefer to work with.

Sunhokey Prusa i3 w/ full 6mm acrylic frame, full metal hotend (0.4mm) and bowden-fed 1.75mm filament. Its controller board is something similar to this one: http://reprap.org/wiki/MKS_GEN_V1.1

I built my i3 around the SeeMeCNC laser cut 7mm melamine frame ($45) – which seemed so small and light when it arrived, but has proved to be very sturdy, especially with the added triangular fins, which also provide mounting space for electronics and the PSU.

The stepper motors ($10-15 each) and replicated parts ($40) are all from eBay. The 1Nm torque PG extruder motor ($15) is from 2engineers. The rods and most vitamins are from McMaster-Carr. The original power supply was an ATX power supply that had just enough amps, and while it never had any problems I replaced it with a 30A LCD Strip PSU ($25). I cut the bed glass from a cheap full-length wall mirror, so that"s one of few truly FREE parts on the bot.

The original cost was higher than hoped-for, but definitely within my budget. I bought the wrong parts in a couple of cases, but some of that cost was recouped from re-selling the parts, and from selling a few Prusa i3 parts sets on eBay. I"ve had to replace stepper drivers, so I got a few extras, and of course I now have tools and extra parts. With a working RepRap in my workshop, and with the know-how and experience I have gained, I feel confident I could self-source for a lower cost than getting (for example) a Replikeo kit – although that kit makes an okay starting point, from what I hear.

Same as Jedimaster711 , plus installing a flexdrive in a couple of days , received all the hardware for it. Also planning on using astroprint on the pi , already have a couple of raspberry pi working for other task with raspi cam ,astroprint doesn"t support it (yet), but there"s a loop around it .

It"s a bit to advance for me , a lot of tweaking an understanding is needed to operated those , I had a couple of good print with it , then switch for a Prusa I3 to make it a bit more easier on me. Learning curve ^^^ .

I"v got a Prusa i3 Rework, J-head 0.4mm w/ 1.75mm filament, hotbed and an LCD screen. I"v bought a raspberry pi witch runs OctoPi to monitor my printer.

OctoPi (special distrubution of Octoprint for Raspberry Pi) is pretty easy to install (burn image to sd card, power you pie and you are done). Configuring network might be a bit tricky depending of your network and knowledge of command line line.

Prusa i3 improved with 3mm e3d v6 hotend attached to a modified Infill3d extruder. New 1.75mm extruder is just waiting for some vitamins to arrive. Printer also has an aluminum heat bed and is controlled by an Azteeg X3 controller and a VIKI LCD control panel. Running with the latest Repetier firmware and host.

FLSun QQ-S is a budget-friendly 3D printer suitable for hobbyists and professionals not requiring fine feature detail and precision with a print speed of 60 mm/s. The QQ-S also features auto-feeding filament, dual z-axis motors, and a larger build volume measuring 250 x 250 x 350 mm.

The Original Prusa i3 MK3S+ is the flagship of Prusa Research’s 3D printer line. It features a fully enclosed frame to protect prints from drafts and dust, as well as a graphical LCD display with easy menu navigation. The Original Prusa i3 MK3S+ costs about $1,099.

The print area of the i3 MK3S+ now measures 9.8 x 8.3 x 8.3 inches – a difference from its predecessors: 9.8 x 8.3 x 7.9 inches. The i3 MK3S+ utilizes PrusaSlicer, the proprietary software suite developed by the company.

With so many 3D printers on the market and various speeds available, choosing the best printer for your project can be challenging. If you’re a hobbyist starting some personal projects, the FLSun QQ-S or Photon M3 Plus could be a good option.

The LCD screen is vital for operating the printer. Should you encounter any kind of trouble, such as a dead screen, corrupted text, or other issues, please refer to the guide below.

First of all, unscrew the LCD screen from the printer frame, remove both M3x10 screw holding it the LCD board in the plastic casing, and remove it from the casing. See if the problem still appears when the LCD is not pressed by the casing.

Firmware updates are necessary to keep your printer up to date. However, the installation of incorrect firmware can lead to letter corruption on the LCD screen. There"s an easy fix, though:

There is a small chance the printer"s LCD screen can glitch out by electrostatic discharge when inserting the SD card. Try to turn the printer off and on again.

This problem usually appears only on user-assembled printers. If your printer"s LCD screen remains blank or displays corrupted symbols after you turn on the printer, there is a chance it is caused by incorrect wiring. Follow these steps to fix the issue.

If you suspect that the LCD ribbon cables connectors are not firmly seated in the slots, disconnect the LCD ribbon cables and check the slots for any bent pins. If there are bent pins, you can use tweezers to fix them. However, be very careful not to break the pin(s) completely.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey