ltps tft lcd factory

According to LCD (Liquid Crystal Display) technology and LCD materials, mobile phone LCD assemblies can be classified into 2 types: TFT (Thin Flim Transistor) and OLED(Organic Light-Emitting Diode). TFT display needs with backlight, but OLED is light-emitting, each pixel is creating its own light.

For Original iPhone LCD, 5-8 plus and Xr, 11 is TFT, X-13 Pro Max is OLED (except XR and 11). But in mobile phone aftermarket, there are too many different types and different qualities, which makes customers confused.

What is in-cell? What is OGS or " with TP"? What is COF? What is COG? What is OEM? What is FOG? What is Original Change Glass? What is IPS? What is LTPS? What is a-Si?

IGZO has 20–50 times the electron mobility than a-Sin. IGZO only has been licensed to Samsung Electronics and Sharp. However, it was Sharp who first implemented IGZO into their smartphones (Aquos Phone Zeta SH-02E), tablets, and 32-inch LCDs. IGZO for mobile phones is only Sharp. Almost all mobile phones on the market didn"t use IGZO.

Because the electrons deflect the liquid crystal molecules through the transistor. Electron mobility fundamentally determines the refresh rates of the TFT device. The smaller mobility, the slower transmission of holes and electrons, and the slower response rate. Can"t physically support high refresh rates.

In order to improve the response performance, can increase transistor size to enhance the migration, but this will lead to the extra TFT device that will occupy the display area pixel area. Therefore, the larger unit transistor area, the single-pixel occupy area is smaller(Pixel Aperture Ratio ), resulting in lower brightness.

As we can see electron mobility of a-Si is very low (0.5-1cm2/Vs). But LTPS can deliver a hundred times the mobility than a-Si, and a much higher aperture ratio and PPI is much higher than a-Si resolution.

Compared with LTPS,a-si TFT have those "weakness":a-Si with so much low resolution and low definition. a-Si is 720*1280 with a very blurred display effect.

a-Si with so much bad display performance, but why are there still so many manufacturers producing phone LCDs with a-Si, or why do the customers willing to use a-Si LCD for their phone?

LCDs business has too much competition and wholesalers want to make more profit, they keep pushing suppliers to make LCDs at lower prices. So some of the suppliers start to produce aftermarket phone displays with a-Si to match customers" lower price requirements.

The customers with asymmetric information. End-Users don"t know how to distinguish LCDs qualities. Some of them just chase the price but not quality. That is another reason wholesalers want a lower price.

Now in the market a-Si LCDs for iPhone is TFT with TP but not in-cell. Our ZY a-Si will be in-cell not just TFT with TP. ZY a-Si incell for Xr and 11 ready now, please to get more details.

For more details or questions about in-cell and TFT with TP or about phone LCD display. Please click here to get more information, or Long press and scran the QR code to add me.

(Low Temperature PolySilicon)An active matrix LCD screen that is faster and more integrated than screens made with amorphous silicon substrates. Rather than the single-crystal silicon used in chips, amorphous silicon advanced the active matrix industry by allowing thin film transistors (TFTs) to be deposited on large substrates. There is a huge investment in existing amorphous technology; however, polysilicon provides an alternate approach for certain applications.Faster, Denser, More IntegratedThe larger and more uniform grains of polysilicon (poly-Si) allow electrons to flow 100 times faster than they do through the random-sized grains of amorphous silicon (a-Si), enabling higher resolutions and higher speed. In addition, instead of surrounding the screen area, the row/column driver electronics are integrated onto the glass substrate, thereby reducing the TFT section and the wiring between the pixels. Thus, LTPS LCD pixels can be closer together and achieve densities of 800 dpi and greater.

The present invention relates to an LCD structure and a method for manufacturing the structure. In particular, the invention relates to an LTPS-TFT LCD structure and a method for manufacturing the structure to reduce photolithography processes with masks and simultaneously enhance pixel capacitance.

Liquid crystal displays (LCDs) are mainstream products on the display market. Not only do LCDs save power and emit low radiation, they are also lightweight and portable. Technologies of thin-film-transistor LCD (TFT-LCD) can be classified into two groups: amorphous silicon (α-Si) and poly-silicon (Poly-Si). The technology and techniques of α-Si are fully developed and frequently used in TFT-LCDs on the display market.

However, low temperature poly silicon (LTPS) is a recent and novel technology for manufacturing Poly-Si LCDs. In comparison with conventional α-Si LCDs, carrier mobility on the LTPS TFT is at least two hundred times higher than that on the α-Si TFT due to its characteristics. The displays which utilize LTPS technology also have higher performance, with shorter response time and greater brightness, resolution, and color saturation. Therefore, LTPS-LCD can present images with higher display quality. Moreover, the physical structure and elements in the LTPS-LCDs can be minimized, so the TFT module area is at least 50% smaller. Thus, LTPS-LCDs can be thinner and lighter to reduce power exhausting. The size advantage of the TFT modules also reduces manufacturing costs of the LTPS-LCDs as well. Because of the many advantages present by LTPS technology, LTPS-LCDs attract lots of attentions on the LCD market.

In the conventional LTPS photolithography manufacturing processes, six masks are usually involved. These processes for manufacturing an LPTS display structure 10 are outlined in FIGS. 1A˜1F. For illustration, a TFT 11 and a capacitance storage device 13 are merely shown in the figures. Firstly, FIG. 1A shows the photolithography process with the first mask. Poly-silicon islands 110, 130 are formed onto a substrate 100 to function as fundamental materials for the TFT 11 and the capacitance storage device 13.

However, the conventional LTPS display structure 10 still has disadvantageous limitations. As shown in FIG. 1B, the poly-silicon island 130 that is sheltered from the first conductive layer 133 cannot be doped during the doping process. Consequently, the final product would not have any effective capacitance between the first conductive layer 133 and the poly-silicon island 130. As a result, the capacitance provided from the display structure 10 is substantially reduced. Furthermore, because of the complicated manufacturing processes of the conventional structure, more photolithography processes with masks are required, raising the cost of manufacturing.

Given the above, an LTPS-LCD structure which can be made from simplified photolithography processes and promote capacitances needs to be developed in this field.

The primary objective of this invention is to provide an LTPS-LCD structure. By previously disposing a transparent electrode on the bottom of the display structure, an effective capacitance can be generated within the un-doped poly-silicon area. Thus, the capacitance of the final product can be promoted to benefit effective operation of the display structure.

Another objective of this invention is to provide a method for manufacturing the LTPS-LCD structure. By disposing the transparent electrode during the previous photolithography process, the processes for manufacturing the entire TFT and capacitance storage device can be simplified to effectively economize costs and shorten manufacturing periods.

To achieve the aforementioned objectives, an LTPS-LCD structure is provided in the present invention. The structure comprises a substrate, a transparent electrode, a lower insulator layer, a control device, a first conductive layer, an upper insulator layer, and a second conductive layer. The substrate is formed with a plurality of pixel areas each including a control area, a capacitance area, and a display area. The transparent electrode is formed on the substrate that corresponds to the display area, the control area, and the capacitance area. The lower insulator layer is formed on the transparent electrode that corresponds to the control area. The control device is formed on the lower insulator layer that corresponds to the control area. The first conductive layer is partially formed on the control device and the transparent electrode that corresponds to the control area and the capacitance area respectively. The upper insulator layer at least partially covers the control device and the first conductive layer. The second conductive layer at least partially covers the upper insulator layer for forming a capacitance storage device with the first conductive layer on the capacitance area, whereby it electrically connects the control device to the transparent electrode disposed on the display area.

A method for manufacturing the aforementioned LTPS-LCD structure is also provided in the present invention. The method comprises the following steps: forming the transparent electrode on the display area, the control area, and the capacitance area of the substrate; forming a silicon-oxide insulator layer that corresponds to the control area; locally forming a first conductive layer on the silicon-oxide insulator layer and the transparent electrode that corresponds to the control area and the capacitance area, and forming the control device on the control area; forming an upper insulator layer which at least partially covering the control device and the first conductive layer; and forming a second conductive layer which at least partially covering the upper insulator layer to form a capacitance storage device with the first conductive layer.

A preferred embodiment of the LTPS-LCD structure of the present invention is shown in FIG. 6, and preferred processes for manufacturing the structure are shown from FIG. 2A through FIG. 6.

The LTPS-LCD structure 20 of the present invention comprises a control device 51, a capacitance storage device 53, and a pixel unit 55. Referring to FIGS. 2A and 2B, the structure 20 comprises a substrate 200 which is formed with a plurality of pixel areas. To specifically disclose the present invention, only a pixel area 30 is representatively shown in the figures. Each pixel area 30 includes a control area 31, a capacitance area 33, and a display area 35.

Finally, as shown in FIG. 6, the photolithography process with the fifth mask of the present invention forms a passivation layer 28 to cover the LTPS-LCD structure 20 on the second conductive layer 271, 272.

In accordance with the aforesaid manufacturing processes, the LTPS-LCD structure 20 of the present invention is obtained. On the control area 31, the structure 20 successively comprises the substrate 200, the transparent electrode 21, the lower insulator layer 22, the control device 51, the mid-insulator layer 24, the first conductive layer 25, the upper insulator layer 26, the second conductive layer 271, and the passivation layer 28. On the capacitance area 33, preferably, the structure 20 successively comprises the substrate 200, the transparent electrode 21, the mid-insulator layer 24, the first conductive layer 25′, the upper insulator layer 26, the second conductive layer 272, and the passivation layer 28. However, on the display area, only the substrate 200 and the transparent electrode 21 remain.

Preferably, the control device 51 is a thin-film-transistor (TFT) and the lower insulator layer 22 can be the silicon-oxide insulator layer 22. The passivation layer 28 completely covers the second conductive layer 271, 272.

According to the above-mentioned LTPS-LCD structure 20 of the present invention, the transparent electrode 21 is previously formed on the substrate 200. This structure can not only enhance the efficiency of the capacitance storage device, but can also diminish the number of steps within the photolithography processes or etching processes with masks from six to five. This can substantially reduce costs and shorten manufacturing processes.

Samsung came up with its unique 18:5:9 AMOLED display for the Galaxy S8. LG picked up its old trusted IPS LCD unit for the G6’s display. These display units have been familiar to the usual Indian smartphone buyer. Honor, on the other hand, has just unveiled the new Honor 8 Pro for the Indian market that ships with an LTPS LCD display. This has led to wonder how exactly is this technology different from the existing ones and what benefits does it give Honor to craft its flagship smartphone with. Well, let’s find out.

The LCD technology brought in the era of thin displays to screens, making the smartphone possible in the current world. LCD displays are power efficient and work on the principle of blocking light. The liquid crystal in the display unit uses some kind of a backlight, generally a LED backlight or a reflector, to make the picture visible to the viewer. There are two kinds of LCD units – passive matrix LCD that requires more power and the superior active matrix LCD unit, known to people as Thin Film Transistor (TFT) that draws less power.

The early LCD technology couldn’t maintain the colour for wide angle viewing, which led to the development of the In-Plane Switching (IPS) LCD panel. IPS panel arranges and switches the orientation of the liquid crystal molecules of standard LCD display between the glass substrates. This helps it to enhance viewing angles and improve colour reproduction as well. IPS LCD technology is responsible for accelerating the growth of the smartphone market and is the go-to display technology for prominent manufacturers.

The standard LCD display uses amorphous Silicon as the liquid for the display unit as it can be assembled into complex high-current driver circuits. This though restricts the display resolution and adds to overall device temperatures. Therefore, development of the technology led to replacing the amorphous Silicon with Polycrystalline Silicon, which boosted the screen resolution and maintains low temperatures. The larger and more uniform grains of polysilicon allow faster electron movement, resulting in higher resolution and higher refresh rates. It also was found to be cheaper to manufacture due to lower cost of certain key substrates. Therefore, the Low-Temperature PolySilicon (LTPS) LCD screen helps provide larger pixel densities, lower power consumption that standard LCD and controlled temperature ranges.

The AMOLED display technology is in a completely different league. It doesn’t bother with any liquid mechanism or complex grid structures. The panel uses an array of tiny LEDs placed on TFT modules. These LEDs have an organic construction that directly emits light and minimises its loss by eradicating certain filters. Since LEDs are physically different units, they can be asked to switch on and off as per the requirement of the display to form a picture. This is known as the Active Matrix system. Hence, an Active Matrix Organic Light Emitting Diode (AMOLED) display can produce deeper blacks by switching off individual LED pixels, resulting in high contrast pictures.

The honest answer is that it depends on the requirement of the user. If you want accurate colours from your display while wanting it to retain its vibrancy for a longer period of time, then any of the two LCD screens are the ideal choice. LTPS LCD display can provide higher picture resolution but deteriorates faster than standard IPS LCD display over time.

An AMOLED display will provide high contrast pictures any time but it too has the tendency to deteriorate faster than LCD panels. Therefore, if you are after greater picture quality, choose LTPS LCD or else settle for AMOLED for a vivid contrast picture experience.

"Apple has long been speculated that it will launch an AMOLED version of its new iPhone in September along with two other LTPS TFT LCD models," industry sources said.

But TRI said that the definition LTPS TFT LCD panels varies proportionally with needed power to drive backlights in handsets, a relationship that is politically-incorrect in this age of eco-awareness and would work against promotions in markets with high proportions of consumers whose buying decisions are actually influenced by the green movement than fad.

Optimization resulting from high transmissivity of LTPS TFT LCD technology achieves a high luminance of 250cd/m2, a high contrast ratio of 400:1 and a wide color gamut of 70%, despite super-high density of 229 ppi.

A combination of high transmissivity of LTPS TFT LCD technology and NEC LCD Technologies" own unique super-reflective natural light TFT (SR-NLT) technology achieves high luminance of 200cd/m2 and a high reflective ratio of 15%, despite a super-high density of 229 ppi.

Optimization based on high transmissivity of LTPS TFT LCD technology achieves high luminance of 200cd/m2, a high contrast ratio of 400:1 and a wide color gamut of 70%, despite ultra-high density of 302ppi.

A combination of high transmissivity of LTPS TFT LCD technology and NEC LCD Technologies" own unique super-reflective natural light TFT (SR-NLT) technology achieves high luminance of 180cd/m2 and a high reflective ratio of 15%, despite ultra-high density of 302ppi.

Leadis supplies display drivers supporting the major small panel display technologies, including a-Si and LTPS TFT LCD"s, color STN LCD"s, and color OLED displays.

Estimated Shipments of Small and Medium-sized Display Panels, by Category Unit: 1 million units Period LTPS TFT LCD a-Si TFT LCD CSTN LCD MSTN LCD AMOLED Q1, 2010 69 234 66 18 6 Q2, 2010 78 252 66 18 6 Q3, 2010 102 264 48 18 12 Q4, 2010 96 252 48 12 18 Q1, 2011 96 228 36 12 18 Q2, 2011 102 300 36 6 24 Q3, 2011 108 300 24 12 36 Q4, 2011 108 280 24 12 42 Q1, 2012 110 300 15 12 42 Q2, 2012 120 310 13 10 42 Q3, 2012 150 320 10 10 54 Q4, 2012 140 320 10 10 54 Source: Topology Research Institute

Shipment Share of Cellphone Main Display by Technology Sum of / Unit Share (%) 2009 Q1 "10 a-Si TFT LCD 52.3% 59.2% CSTN 20.3% 15.3% LTPS TFT LCD 20.4% 17.6% AMOLED 1.4% 1.9% MSTN 5.6% 6% PMOLED 0.1% 0% Source: Display Search Quarterly Mobile Phone Shipment and Forecast Report

Founded in 2001, AFPD is a joint venture between Toshiba Corporation and Matsushita Electric Industrial Co., Ltd., specializing in the manufacture of LTPS TFT LCDs with excellent mass production and related technologies as its intelligence properties.

The present invention relates to a thin film transistor substrate of low temperature poly-silicon (LTPS), and a process for manufacturing the substrate. The instant application relates to the copending application with an unknown serial number, titled “LTPS TFT SUBSTRATE AND MANUFACUTRING PROCESS THEREOF” having the same applicants and the same assignee with the instant application.

The amorphous silicon thin film transistor liquid crystal display (a-Si TFT-LCD) has been a major product in the market as an alternative to the conventional cathode ray tube (CRT) display, because of the a-Si TFT-LCD"s thinness and light weight. However, information technology is continuing to advance rapidly, and the market requirements for resolution and data transmittance have become so high that many a-si TFT-LCDs can no longer meet these requirements. Thus, the industry has developed a superior technology, which is known as low temperature poly-silicon thin film transistor (LTPS TFT) technology. The superiority of an LTPS TFT-LCD is that the driving circuit can be fabricated on the glass substrate, which is known as system on glass—(SOG). This means that the cost of the integrated driving circuit can be reduced, while still meeting stringent requirements for resolution and data transmittance.

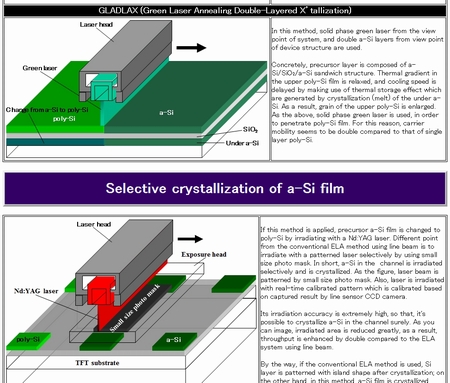

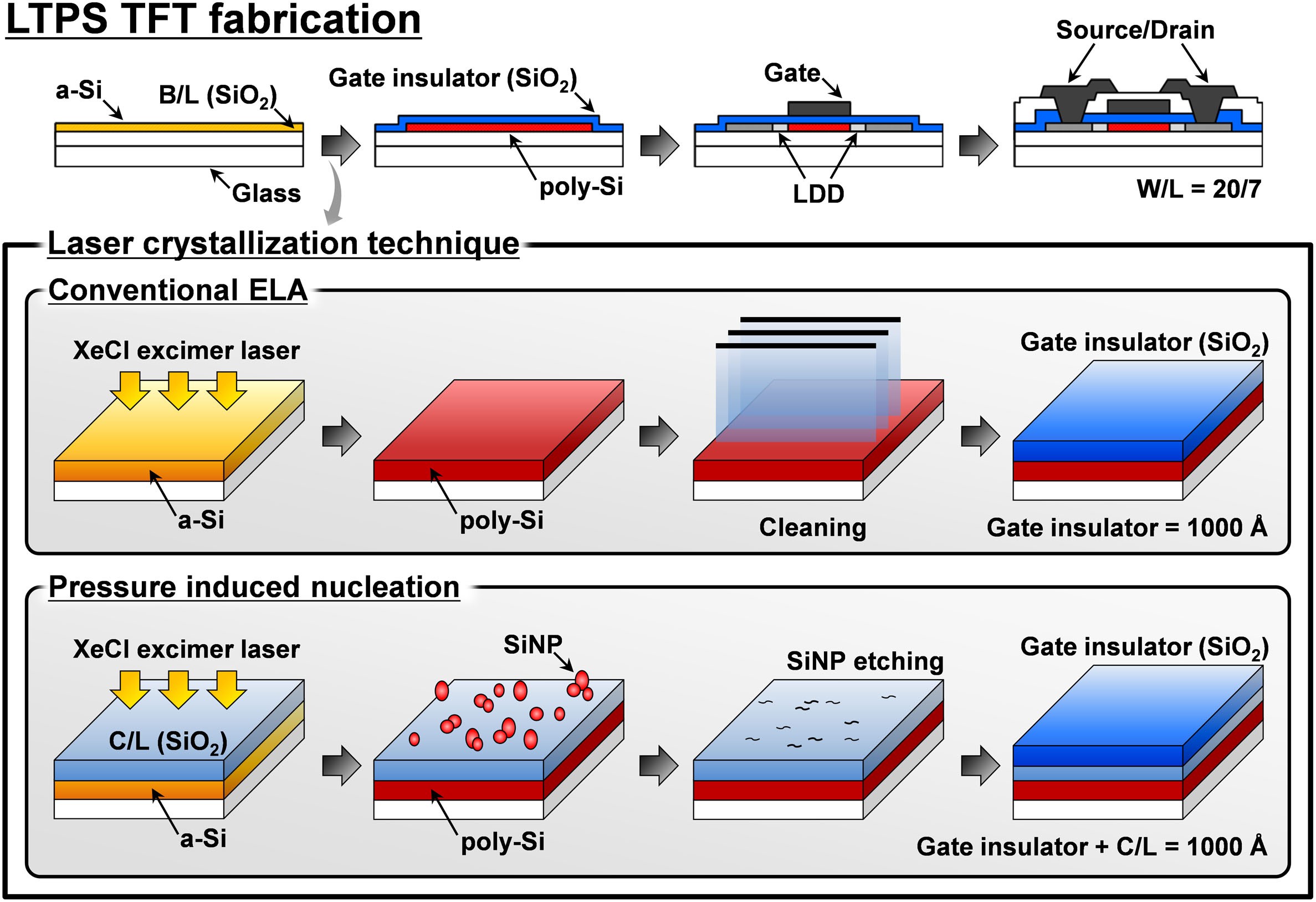

The general technology of LTPS TFTs at least comprises thin film deposition, laser annealing, lithography, and etching processes. These processes can manufacture the thin film transistors and the pixel electrodes on the glass substrate. The laser annealing process is the most important step in these processes. The success or otherwise of the laser annealing process greatly impacts the characteristics of the thin film transistors produced.

A prior art LTPS TFT-LCD is found in U.S. patent application publication number 2004/0018649, which was published on Jan. 29, 2004. Referring to FIG. 5, this is an isometric structural view of an LTPS display panel according to the prior art. The LTPS display panel 100 is manufactured by performing the following steps. First, a glass substrate 110 to be the base of the LTPS display panel 100 is provided. An amorphous silicon film 112 is formed on a surface of the glass substrate 110. The amorphous silicon film 112 comprises a first area 114 and a second area 116. The first area 114 is located in the center of the amorphous silicon film 112. The second area 116 is at the periphery, and has a slanted wall. The thickness distribution of the slanted wall determines the boundary condition of the laser annealing process. The thickness of the amorphous silicon film 112 in the first area 114 is a predetermined value. Then, the substrate 110 is put into a chamber for excimer laser annealing, to make the amorphous silicon film 112 transform into a poly-silicon film. When the thickness of the amorphous silicon film in the boundary condition is larger than a threshold, usually 400Å, an ablation phenomenon occurs in the amorphous silicon film such that any film higher than the threshold thickness is removed. Finally, a driving circuit area and a display panel area are produced in the glass substrate 110.

Referring to FIG. 6, this is a structural plan view of another LTPS display panel according to the prior art. The LTPS display panel 200 comprises an insulating substrate 220, a driving circuit area 210, and a display panel area 230. The driving circuit area 210 and the display panel area 230 are connected together. A plurality of driving circuits 211 is set in the driving circuit area 210. A plurality of pixel units 222 is set in the display panel area 230. Each driving circuit 211 is set corresponding to each pixel unit 222. The excimer laser annealing process is repeated several times to make the thin film transistors on the substrate 220, so the characteristic of each thin film transistor should be different. The requirement (±10˜100 mV) of the characteristic uniformity of the TFTs in the driving circuit area 210 is much higher than the requirement (±1˜2V) of the TFTs in the display panel area 230. Furthermore, the layout of the general LTPS display panel 200 is such that each driving circuit 211 is distributed corresponding to the pixel unit 222 in the substrate 220. Thus, it is hard to achieve the uniformity requirements during the production process. When the uniformity of the process is lower than a threshold requirement, some driving circuits 211 are destroyed, and the display panel area 230 corresponding to the lost driving circuits 211 is also destroyed. This decreases the yield rate and increases costs.

In view of the above, it is desired to provide a new LTPS display panel to solve the problems of the low yield rate and high costs of conventional low-uniformity LTPS display panels.

An object of the present invention is to provide an LTPS display panel to solve or at least mitigate the prior art drawbacks of low yield rate and high costs.

The present invention provides a LTPS display panel that includes a display area and one or more driving circuit areas. The display area is fabricated by cutting from a display substrate. The driving circuit areas are fabricated by cutting from an insulated substrate having a poly-silicon film thereon. The driving circuit areas are electrically connected with the display area.

The present invention further provides a method of manufacturing the LTPS display panel, which comprises the following steps. First, two substrates are provided. One is a display substrate and the other is an insulative substrate. The display substrate includes a plurality of display areas. Second, a poly-silicon film is formed on the insulative substrate, and then a plurality of driving circuits is formed on the poly-silicon film. Third, the display substrate is cut to form a plurality of display areas, and the insulative substrate is cut to form a plurality of driving circuit areas. Finally, one of the cut display areas and at least one of the cut driving circuit areas are electrically connected to form the LTPS display panel.

FIG. 1 is a structural plan view of an LTPS display panel according to an embodiment of the present invention. FIG. 2 is a structural plan view of an insulated substrate according to an embodiment of the present invention. FIG. 3 is a structural plan view of a display substrate according to an embodiment of the present invention. The LTPS display panel 300 comprises a plurality of driving circuits 311, a plurality of pixel units 322, and a soft circuit board. In this embodiment, pins of the driving circuits 311 and pins of TFTs in the pixel units 322 are connected to each other by a pair of soft circuit boards 430. In other embodiments, the soft circuit boards 430 could be replaced by any other suitable conducting material and/or means. The driving circuits 311 and the pixel units 322 are manufactured on separate and differently sized substrates 310, 330. The driving circuits 311 are set in the driving circuit substrate 310, and the pixel units 322 are set in the display substrate 330. A display area comprises a required amount of pixel units 322 cut from the display substrate 330. A pair of driving circuit areas corresponding to the display area is cut from the driving circuit substrate 310. The LTPS display panel is made by interconnecting the display area and the driving circuit areas using the soft circuit boards 430.

Referring to FIG. 4, this is a flow chart of an exemplary method for manufacturing the LTPS display panel 300. The method comprises the following steps. First, an insulative substrate (not labeled) and the display substrate 330 are provided (step 10). The insulative substrate is typically a glass substrate or a quartz substrate. Next, a first Plasma Enhanced Chemical Vapor Deposition (PECVD) is performed on a major surface of the insulative substrate, to form an amorphous silicon film (step 20). Then, an annealing process is performed to re-crystallize the amorphous silicon film to a poly-silicon film (step 30). The poly-silicon film comprises a plurality of source areas, a plurality of drain areas, and a plurality of channel areas of the LTPS TFTs. In the channel areas, a second PECVD is performed to form a silicon oxide layer on the poly-silicon film (step 40). A major constituent of the silicon oxide layer is tetra-ethyl-ortho-silicate (TEOS). The driving circuit substrate 310 is thus manufactured. The driving circuit substrate 310 comprises the plurality of driving circuits 311, and the display substrate 330 comprises the plurality of pixel units 322. According to production conditions and customer requests, the required amount of pixel units is cut from the display substrate 330 to form a display area, and a corresponding amount of driving circuits 311 is cut from the driving circuit substrate 310 to form a pair of driving circuit areas (step 50). Finally, the LTPS display panel 300 is made by connecting the display area and the driving circuit areas using the soft circuit boards 430 (step 60).

The requirement of the characteristic uniformity of the TFTs in the driving circuit area 210 is much higher than the requirement of the TFTs in the display panel area 230. The present invention provides a technology to manufacture the driving circuit areas and the display area separately, and to centralize the driving circuits in the same substrate. This approach reduces the impediment to uniformity that is caused by various different processes, and thus improves the yield rate and reduces production costs.

Low-temperature polycrystalline silicon (LTPS) is polycrystalline silicon that has been synthesized at relatively low temperatures (~650 °C and lower) compared to in traditional methods (above 900 °C). LTPS is important for display industries, since the use of large glass panels prohibits exposure to deformative high temperatures. More specifically, the use of polycrystalline silicon in thin-film transistors (LTPS-TFT) has high potential for large-scale production of electronic devices like flat panel LCD displays or image sensors.

Amorphous silicon TFTs have been widely used in liquid-crystal display (LCD) flat panels because they can be assembled into complex high-current driver circuits. Amorphous Si-TFT electrodes drive the alignment of crystals in LCDs. The evolution to LTPS-TFTs can have many benefits such as higher device resolution, lower synthesis temperature, and reduced price of essential substrates.

XeCl Excimer-Laser Annealing (ELA) is the first key method to produce p-Si by melting a-Si material through laser irradiation. The counterpart of a-Si, polycrystalline silicon, which can be synthesized from amorphous silicon by certain procedures, has several advantages over widely used a-Si TFT:

Apart from the improvement of the TFTs themselves, the successful application of LTPS to graphic display also depends on innovative circuits. One recent technique involves a pixel circuit in which the outgoing current from the transistor is independent of the threshold voltage, thus producing uniform brightness.light-emitting diode (OLED) displays because it has high resolution and accommodation for large panels. However, variations in LTPS structure would result in non-uniform threshold voltage for signals and non-uniform brightness using traditional circuits. The new pixel circuit includes four n-type TFTs, one p-type TFT, a capacitor, and a control element to control the image resolution.

G. A. Bhat, Z. Jin, H. S. Kwok, and M. Wong, “Effect of MIC/MILC Interface On The Performance Of MILC-TFT’s,” in Dig. 56th Annu. Device Research Conf., June 22–24, 1998, pp. 110–111.

Sameshima, T., S. Usui, and M. Sekiya. "XeClExcimer Laser Annealing Used in the Fabrication of Poly-Si TFT"s." IEEE Electron Device Letters 07.05 (1986): 276-78. IEEE Xplore. Web. 2 Mar. 2015.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

A wide variety of ltps tft lcd options are available to you, such as original manufacturer, odm.You can also choose from tft, ips and standard ltps tft lcd,

1.8" 2.0" 2.4" 2.8" 3.0" 3.5" 4.0" 4.3" 5.0" 5.5" 7.0" 8.0" 10.1" IPS TFT LCD Module Touch Screen Panel High Brightness DisplayIPS (in-plane switching) is a screen technology for liquid-crystal displays (LCDs). It was designed to solve the main limitations of the twisted nematic field effect (TN) matrix LCDs which were prevalent in the late 1980s. These limitations included strong viewing angle dependence and low-quality color reproduction.

We are a display manufacturer headquartered in Shenzhen, China. The company employs nearly 200 people worldwide and sells LCD products in more than 68 countries.

We Design and Manufacturing Small Size TFT Displays in sizes from 1.3 "to 10.1" with and without PCAP touch function.The modules are characterized by industrial robustness, wide emperature range, long LED life and high brightness. The displays are therefore suitable for a large number of industrial pplications - from smart homes, mobile to outdoor to automotive.

to industrial applications. Whether your design requires a small LCD, or a fully customized LCD module, our experienced technical support can assist you in designing your custom display.

Samsung Display was considering manufacturing thin-film transistors (TFT) that will be used in Micro LED TVs made by Samsung Electronics, TheElec has learned.

Samsung Display’s is doing so following Samsung Electronics’ request. The South Korean tech giant’s TV business, called Visual Display Business by the firm, had made a request to Samsung Display early in the year to manufacture low-temperature polycrystalline (LTPS) TFT for Micro LED.

TFT acts as a switch that turns the pixel on and off on the display. Samsung had used printed circuit boards (PCB) for its previous Micro LED TVs that exceed 100-inch in size.

This is because smaller TV models mean they will use even smaller LEDs that are more tightly packed together. Use of LTPS TFT will allow for a micro circuit design that can control these smaller LEDs individually. This is difficult to do with circuits on a conventional PCB.

Samsung Display will be manufacturing the LTPS TFT at its A1 line (Gen 4, 730x930mm) at its Cheonan plant. A1 previously manufactured LTPS TFT rigid OLED panels. But Samsung Display currently manufactures rigid OLED panels at its A2 line (Gen 6, 1500x1850mm), which is more productive. As of the first half of 2021, A1’s operation rate was in the single digits, the sources said.

For the Micro LED LTPS TFT production process, a total of 24 masks are expected to be needed, the sources said. This is because it will have a lot of transistors and circuits. Conventionally, for a Gen 6 OLED substrate, 11 to 12 masks are used. More masks means the production process is more sophisticated.

Samsung Electronics’ request to Samsung Display was done at the same time when it was asking its display making subsidiary to extend the production of liquid crystal display (LCD) panels, the sources said.

Initially, Samsung Electronics had requested to Taiwan’s AUO to make the LTPS TFT is needs for Micro LED. However, Samsung Electronics determined that it will be difficult to control a steady supply of the TFT from this deal, and has changed tack to ask Samsung Display instead.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey