nodemcu lcd display in stock

I think the Wire.begin() syntax is Wire.begin(SDA, SCL);. So, for the code to match the diagram it would be Wire.begin(4,3);. I also connected my display"s LCD Vcc to Vin on the NodeMCU which differs from the diagram. It works for me with these changes.

Wire.begin(2.0) is same with Wire.begin(D4,D3), the different is (2.0) is GPIO pin, only name is different but is referring to the same pin, u can google the pin out of nodeMCU.

i know it"s late but..i"ve found some solution for this problem..at least it was for me..try change "lcd.backlight();" to "lcd.setBacklight((uint8_t)1);0

he copiado el programa en un nodemcu v3 de lolin en el IDE y cuando lo clequeo me aparece el siguiente error: Tampoco me funciona lo de dar corriente a traves del pin Vin a la lcd, le proporciono corriente a traves de un pin 3,3V

Want to display sensor readings in your ESP8266 projects without resorting to serial output? Then an I2C LCD display might be a better choice for you! It consumes only two GPIO pins which can also be shared with other I2C devices.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an ESP8266 into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting I2C LCD to ESP8266 is very easy as you only need to connect 4 pins. Start by connecting the VCC pin to the VIN on the ESP8266 and GND to ground.

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the ESP8266’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this. Below is a simple I2C scanner sketch that scans your I2C bus and returns the address of each I2C device it finds.

After uploading the code, open the serial monitor at a baud rate of 115200 and press the EN button on the ESP8266. You will see the I2C address of your I2C LCD display.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

Want to add little graphic pizzazz to your ESP8266 IoT projects? Or maybe you want to display IP address of your ESP8266 without resorting to serial output. These super-cool OLED (Organic Light-Emitting Diode) displays might be the perfect fit! They’re super-light, almost paper-thin, theoretically flexible, and produce a brighter and crisper picture.

The OLED display module breaks out a small monochrome OLED display. It’s 128 pixels wide and 64 pixels tall, measuring 0.96″ across. It’s micro, but it still packs a punch – the OLED display is very readable due to the high contrast, and you can fit a deceivingly large amount of graphics on there.

As the display makes its own light, no backlight is required. This significantly reduces the power required to run the OLED and is why the display has such high contrast, extremely wide viewing angle and can display deep black levels.

Regardless of the size of the OLED module, the SSD1306 driver has a built-in 1KBGraphic Display Data RAM (GDDRAM) for the screen which holds the bit pattern to be displayed. This 1K memory area is organized in 8 pages (from 0 to 7). Each page contains 128 columns/segments (block 0 to 127). And each column can store 8 bits of data (from 0 to 7). That surely tells us we have

Next, Connect the SCL pin to the I2C clock D1 pin on your NodeMCU and connect the SDA pin to the I2C data D2pin on your NodeMCU. Refer to ESP8266 NodeMCU Pinout.

The SSD1306 controller of the OLED display has flexible yet complex drivers. Vast knowledge on memory addressing is required in order to use the SSD1306 controller. Fortunately, Adafruit’s SSD1306 library was written to hide away the complexities of the SSD1306 controller so that we can issue simple commands to control the display.

This Adafruit SSD1306 library is a hardware-specific library which handles lower-level functions. It needs to be paired with Adafruit GFX Library to display graphics primitives like points, lines, circles, rectangles etc. Install this library as well.

Adafruit’s SSD1306 Library isn’t set up for the 128×64 OLED displays (the one we are using right now). The display size must be changed in the Adafruit_SSD1306.h header file to make it work for us. If it is not changed, an error message saying #error (“Height incorrect, please fix Adafruit_SSD1306.h!”);may appear when attempting to verify the example sketch in the Arduino IDE:

Open Adafruit_SSD1306.h file in a text editor. Scroll down the file to find the section with the SSD1306 Displays or directly go to line no. 73. Comment out #define SSD1306_128_32 and uncomment #define SSD1306_128_64 so that the code in this section looks like this:

The sketch starts by including four libraries viz. SPI.h, Wire.h, Adafruit_GFX.h and Adafruit_SSD1306.h. Although SPI.h library is not required for I2C OLED displays, we need to add it for the sake of compiling our program.

Next, we need to create an object of Adafruit_SSD1306.h. The Adafruit_SSD1306 constructor accepts ESP8266 pin number to which reset pin of the display is connected. As the OLED display we are using doesn’t have a RESET pin, we will send –1 to the constructor so that none of the ESP8266 pins is used as a reset for the display.

In setup function: we need to initialize the OLED object using begin() function. The function takes two parameters. First parameter SSD1306_SWITCHCAPVCC turns the internal charge pump circuitry ON while second parameter provides I2C address of the OLED display. I2C address of such OLED display module is generally 0x3C. It’s fixed and cannot be changed.

For displaying text on the screen, we need to set the font size. This can be done by calling setTextSize(font-size) and passing font size (starting from 1) as a parameter.

In order for the library to perform extremely fast mathematical operations on the screen buffer (more than 100 frames per second), calls to the print functions do not immediately transfer the contents of screen buffer to the SSD1306 controller. A display() command is required to instruct the library to perform the bulk transfer from the screen buffer in the ESP8266 to the internal memory of the SSD1306 controller. As soon as the memory is being transferred, the pixels corresponding to the screen buffer will show up on the OLED display.

For displaying inverted text, we will call setTextColor(FontColor,BackgroundColor) function again. If you are paying attention, you know we passed only one parameter to this function earlier, but now we are passing two parameters. This is possible because of something called function overloading. Function overloading is the ability to create multiple functions of the same name but with different set of parameters. Calls to an overloaded function will run a specific implementation of that function depending upon the parameters passed.

Numbers can be displayed on the OLED display by just calling print() or println() function. An overloaded implementation of these functions accepts 32-bit unsigned int, so you can only display numbers from 0 to 4,294,967,295.

The print() & println() functions send data to the display as human-readable ASCII text while write() function sends binary data to the display. So, you can use this function to display ASCII symbols. In our example sending number 3 will display heart symbol.

You can scroll the display horizontally by calling startscrollright(start page, stop page) & startscrollleft(start page, stop page) functions and diagonally by calling startscrolldiagright(start page, stop page) & startscrolldiagleft(start page, stop page). All these functions accept two parameters viz. start page and stop page. Refer to OLED Memory Map section for explanation of the pages. As there are eight pages in the display from 0 to 7, you can scroll entire screen by scrolling all the pages i.e. passing parameters 0x00 and 0x07.

Sometimes we don’t want to scroll entire display. You can do that by passing proper start page and stop page information to scrolling functions. Refer to OLED Memory Map section for explanation of the pages. As there are eight pages in the display from 0 to 7, you can scroll some part of the screen by passing specific page numbers as parameters.

You can draw rectangle on the display by using drawRect(X-coordinate, Y-coordinate, Width, Height, color) function. Actually this function draws hollow rectangle with 1 pixel border. You can draw filled rectangle using fillRect() function.

You can draw round rectangle on the display by using drawRoundRect(X-coordinate, Y-coordinate, Width, Height, color) function. This function takes same parameters as drawRect() function except one additional parameter – Radius of corner rounding. Actually this function draws hollow round rectangle with 1 pixel border. You can draw filled round rectangle using fillRoundRect() function.

You can draw circle on the display by using drawCircle(X-coordinate of center, Y-coordinate of center, radius, color) function. This function draws hollow circle with 1 pixel border. You can draw filled circle using fillCircle() function.

You can draw triangle on the display by using drawTriangle(x0, y0, x1, y1, x2, y2, color) function. The function takes seven parameters viz. 3 X & Y coordinates of vertices of triangle and color. (X0,y0) represents top vertex, (x1,y1) represents left vertex and (x2,y2) represents right vertex.

This last example shows how to draw bitmap images to the OLED Display. This is useful for creating splash screens of company logos, making sprites or just creating fun graphics for displaying information. Copy the following code, paste it into the Arduino IDE and click upload.

To show bitmap image on the OLED display we need to call drawBitmap(X-coordinate, Y-coordinate, bitmap array, width, height, color) function. It takes six parameters viz. Top left corner X coordinate, top left corner Y coordinate, byte array of monochrome bitmap, width of bitmap in pixels, height of bitmap in pixels and Color.

But, before we can call the drawBitmap() function, we first need an image to draw. Remember, the screen resolution of the OLED display is 128×64 pixels, so images larger than that will not display correctly. To get a correctly sized image, you can use your favorite drawing programs like Inkscape, Photoshop, Paint, etc., setting the canvas size to 128×64 pixels.

Once you have a bitmap, it’s time to convert it into an array that the SSD1306 OLED controller can understand. This can be done using two ways: Online method using image2cpp and Offline method using LCD Assistant.

There’s an online application called image2cpp – http://javl.github.io/image2cpp/ which can convert your image into an array. Image2cpp is newer and much more powerful than LCD Assistant (later solution). It will allow you to:

Just for your information, there’s an option called Draw mode. It actually creates image according to the scanning patter of the display. If your image looks all messed up on your display, try changing the mode.

There’s another application called LCD assistant – http://en.radzio.dxp.pl/bitmap_converter/ which can convert your bitmap image into data array. It’s not as powerful as image2cpp but still popular among hobbyists.

Just for your information, there’s an option called Byte Orientation. It actually creates image according to the scanning patter of the display. If your image looks all messed up on your display, try changing the mode.

Than displays are the way to go. There are different kinds of displays like 7 Segment LED display, 4 Digit 7 Segment display, 8×8 Dot Matrix display, OLED display or the easiest and cheapest version the liquid crystal display (LCD).

Most LCD displays have either 2 rows with 16 characters per row or 4 rows with 20 characters per row. There are LCD screen with and without I2C module. I highly suggest the modules with I2C because the connection to the board is very easy and there are only 2 instead of 6 pins used. But we will cover the LCD screen with and without I2C module in this article.

The LCD display has an operating voltage between 4.7V and 5.3V with a current consumption of 1mA without backlight and 120mA with full backlight. There are version with a green and also with a blue backlight color. Each character of the display is build by a 5×8 pixel box and is therefore able to display custom generated characters. Because each character is build by (5×8=40) 40 pixels a 16×2 LCD display will have 16x2x40= 1280 pixels in total. The LCD module is able to operate in 8-bit and 4-bit mode. The difference between the 4-bit and 8-bit mode are the following:

If we use the LCD display version without I2C connection we have to add the potentiometer manually to control the contrast of the screen. The following picture shows the pinout of the LCD screen.

Also I added a table how to connect the LCD display with the Arduino Uno and the NodeMCU with a description of the LCD pin. To make it as easy as possible for you to connect your microcontroller to the display, you find the corresponding fritzing connection picture for the Arduino Uno and the NodeMCU in this chapter.

3VEEPotentiometerPotentiometerAdjusts the contrast of the display If this pin is grounded, you get the maximum contrast. We will connect the VEE pin to the potentiometer output to adjust the contrast by changing the resistance of the potentiometer.

4RSD12D2Select command register to low when we are sending commands to the LCD like set the cursor to a specific location, clear the display or turn off the display.

8Data Pin 1 (d1)Data pins 0 to 7 forms an 8-bit data line. The Data Pins are connection to the Digital I/O pins of the microcontroller to send 8-bit data. These LCD’s can also operate on 4-bit mode in such case Data pin 4,5,6 and 7 will be left free.

Of cause we want to try the connection between the microcontroller and the LCD display. Therefore you find an example sketch in the Arduino IDE. The following section shows the code for the sketch and a picture of the running example, more or less because it is hard to make a picture of the screen ;-). The example prints “hello, world!” in the first line of the display and counts every second in the second row. We use the connection we described before for this example.

Looks very complicated to print data onto the LCD screen. But don’t worry like in most cases if it starts to get complicated, there is a library to make the word for us. This is also the case for the LCD display without I2C connection.

Like I told you, I would suggest the LCD modules with I2C because you only need 2 instead of 6 pins for the connection between display and microcontroller board. In the case you use the I2C communication between LCD and microcontroller, you need to know the I2C HEX address of the LCD. In this article I give you a step by step instruction how to find out the I2C HEX address of a device. There is also an article about the I2C communication protocol in detail.

The following picture shows how to connect an I2C LCD display with an Arduino Uno. We will use exact this connection for all of the examples in this article.

To use the I2C LCD display we have to install the required library “LiquidCrystal_I2C” by Frank de Brabander. You find here an article how to install an external library via the Arduino IDE. After you installed the library successful you can include the library via: #include < LiquidCrystal_I2C.h>.

The LiquidCrystal library has 20 build in functions which are very handy when you want to work with the LCD display. In the following part of this article we go over all functions with a description as well as an example sketch and a short video that you can see what the function is doing.

LiquidCrystal_I2C()This function creates a variable of the type LiquidCrystal. The parameters of the function define the connection between the LCD display and the Arduino. You can use any of the Arduino digital pins to control the display. The order of the parameters is the following: LiquidCrystal(RS, R/W, Enable, d0, d1, d2, d3, d4, d5, d6, d7)

If you are using an LCD display with the I2C connection you do not define the connected pins because you do not connected to single pins but you define the HEX address and the display size: LiquidCrystal_I2C lcd(0x27, 20, 4);

xlcd.begin()The lcd.begin(cols, rows) function has to be called to define the kind of LCD display with the number of columns and rows. The function has to be called in the void setup() part of your sketch. For the 16x2 display you write lcd.begin(16,2) and for the 20x4 lcd.begin(20,4).

xxlcd.clear()The clear function clears any data on the LCD screen and positions the cursor in the upper-left corner. You can place this function in the setup function of your sketch to make sure that nothing is displayed on the display when you start your program.

xxlcd.setCursor()If you want to write text to your LCD display, you have to define the starting position of the character you want to print onto the LCD with function lcd.setCursor(col, row). Although you have to define the row the character should be displayed.

xxlcd.print()This function displays different data types: char, byte, int, long, or string. A string has to be in between quotation marks („“). Numbers can be printed without the quotation marks. Numbers can also be printed in different number systems lcd.print(data, BASE) with BIN for binary (base 2), DEC for decimal (base 10), OCT for octal (base 8), HEX for hexadecimal (base 16).

xlcd.println()This function displays also different data types: char, byte, int, long, or string like the function lcd.print() but lcd.println() prints always a newline to output stream.

xxlcd.display() / lcd.noDisplay()This function turn on and off any text or cursor on the display but does not delete the information from the memory. Therefore it is possible to turn the display on and off with this function.

xxlcd.scrollDisplayLeft() / lcd.scrollDisplayRight()This function scrolls the contents of the display (text and cursor) a one position to the left or to the right. After 40 spaces the function will loops back to the first character. With this function in the loop part of your sketch you can build a scrolling text function.

Scrolling text if you want to print more than 16 or 20 characters in one line, than the scrolling text function is very handy. First the substring with the maximum of characters per line is printed, moving the start column from the right to the left on the LCD screen. Than the first character is dropped and the next character is printed to the substring. This process repeats until the full string is displayed onto the screen.

xxlcd.autoscroll() / lcd.noAutoscroll()The autoscroll function turn on or off the functionality that each character is shifted by one position. The function can be used like the scrollDisplayLeft / scrollDisplayRight function.

xxlcd. leftToRight() / lcd.rightToLeft()The leftToRight and rightToLeft functions changes the direction for text written to the LCD. The default mode is from left to right which you do not have to define at the start of the sketch.

xxlcd.createChar()There is the possibility to create custom characters with the createChar function. How to create the custom characters is described in the following chapter of this article as well as an example.

xlcd.backlight()The backlight function is useful if you do not want to turn off the whole display (see lcd.display()) and therefore only switch on and off the backlight. But before you can use this function you have to define the backlight pin with the function setBacklightPin(pin, polarity).

xlcd.moveCursorLeft() / lcd.moveCursorRight()This function let you move the curser to the left and to the right. To use this function useful you have to combine it with lcd.setCursor() because otherwise there is not cursor to move left or right. For our example we also use the function lcd.cursor() to make the cursor visible.

xlcd.on() / lcd.off()This function switches the LCD display on and off. It will switch on/off the LCD controller and the backlight. This method has the same effect of calling display/noDisplay and backlight/noBacklight.

Show or hide a cursor (“_”) that is useful when you create a menu as navigation bar from the left to the right or from the top to the bottom, depending on a horizontal of vertical menu bar. If you are interested how to create a basic menu with the ESP or Arduino microcontroller in combination with the display, you find here a tutorial.

The following code shows you the Arduino program to use all three LCD display functions of the library divided into three separate functions. Also the video after the program shows the functions in action.

The creation of custom characters is very easy if you use the previous mentioned libraries. The LiquidCrystal and also the LiquidCrystal_I2C library have the function “lcd.createChar()” to create a custom character out of the 5×8 pixels of one character. To design your own characters, you need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a wiggling man.

In the section of the LCD display pinout without I2C we saw that if we set the RS pin to how, that we are able to send commands to the LCD. These commands are send by the data pins and represented by the following table as HEX code.

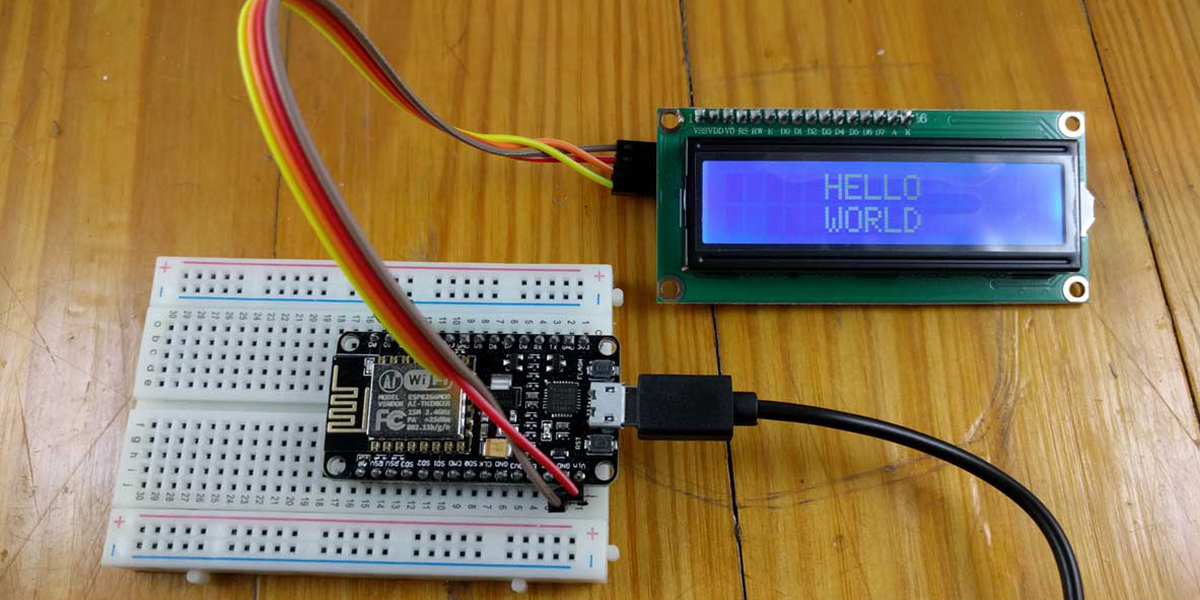

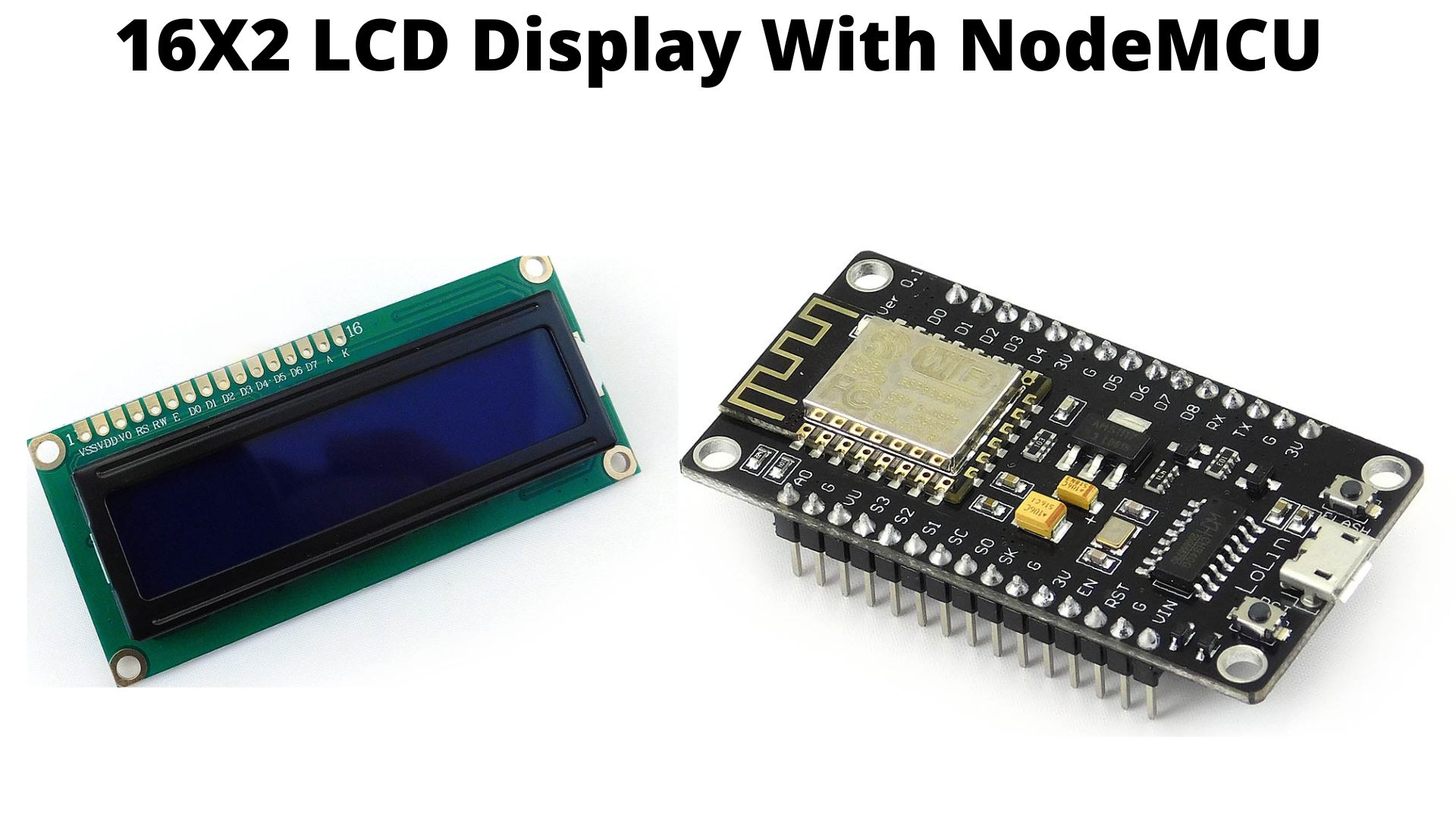

Hey guys, hope you are doing fine. Are you searching for the working of a 16×2 LCD display with NodeMCU? If yes then this article is for you in which we are going to display some text on the 16×2 LCD using a NodeMCU esp8266 board.

We are using an I2C module here which helps us to reduce the number of GPIO pins. Check how you can set up your NodeMCU with the Arduino IDE application and start to program it.

NodeMCU is a microcontroller board used to develop IoT projects with a built-in wifi module. A 16×2 LCD can display 16 alphanumeric characters in a single line and it has a total of two lines only.

You can use it directly with the board but it is easy if you connect an I2C module with it. If you like this project, you can also check out more amazing projects on NodeMCU.

We are able to display the text on the LCD by using the print function and passing the content which is going to be displayed as the parameter value of the function.

You can change the content as per your need by modifying the given code. You can also check out our project on lcd with potentiometer and lcd with I2C modulle.

NOTE: Please upload the code given below to the NodeMCU. Before compiling the code you have to install

The LCD2004 back lighted 20 character by 4 line display is quite easy to use. It utilizes the I2C protocol so it is easy to connect to the ESP8266 with a minimum number of connections.

Connect the VCC pin on the LCD display to the VIN pin on the ESP8266. The VIN pin on the ESP8266 is tied directly to the 5V pin on the incoming USB port. You can also use one of the 3V3 (3.3V) pins on the ESP8266, but it may be difficult to read the LCD display.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

Similar to the cursor() function, this will create a block-style cursor. Displayed at the position of the next character to be printed and displays as a blinking rectangle.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

A custom character allows you to display any pattern of dots on a 5×8 matrix which makes up each character. You have full control of the design to be displayed.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

In this tutorial we will see how to interface NodeMCU with 16x2 LCD without using I2C communication. Here we will interface 16x2 LCD using shift register SN74HC595. We can also interface it even without using any shift register. We will see both kinds of interfacings in this tutorial. Main difference between both interfacings is the number of pins used in NodeMCU.

If you have used 16x2 LCD with the Arduino board then it will going be very easy. You have to just hookup pins in NodeMCU just same as you have done with Arduino board.

Now, upload the code using Arduino IDE as explained earlier. Code is same as for Arduino board which can be found in Liquidcrystal example. Program is simple and easily understandable if you want to learn more about the program check our LCD interfacing with Arduino Program.

As we saw, we already used 6 pins of NodeMCU. There are already less pins available for this little board and we are left with few pins to interface other sensors.

The code is simple as we have to just give data pin, latch pin and clock pin as argument in LiquidCrystal595 lcd(); and rest of the code is same as we have done previously.

NodeMCU has ESP-12 based serial WiFi integrated on board to provide GPIO, PWM, ADC, I2C and 1-WIRE resources at your finger tips, built-in USB-TTL serial with super reliable industrial strength CH340 for superior stability on all supported platforms.

The breakout has the TFT display soldered on (it uses a delicate flex-circuit connector) as well as a ultra-low-dropout 3.3V regulator and a 3/5V level shifter so that you can use it with 3.3V or 5V power and TTL control logic.

In this lesson, we will show how to use the NodeMCU to subscribe to messages that published by MQTT client,then display these messages on a 1602 I2C LCD display.

*0x27 means the address of this 1602 I2C LCD display,different LCD may have different address,if the LCD do not work,please connect your 1602 I2C LCD dispaly to your NodeMCU,then upload below code to your NodeMCU, you will get the I2C address from the Serial Monitor.You can check following link to get more usages about 1602 I2C LCD dispaly : https://osoyoo.com/2014/12/07/16×2-i2c-liquidcrystal-displaylcd/.

The NodeMCU serial monitor will show the IP address and the connection satatus,then print the “publish data”.As you can see from the sketch,the initial data is 1.

If you want to build the project on LCD panel with multiple sensors and other IO devices, you’ll probably need several IO pins from your IO device using an I2C module that helps us reduce the number of IO PIN’s.

In the module left side, we have 4 pins, and two are for power (Vcc and GND ), and the other two are the interface I2C ( SDA and SCL ) . The plate pot is for display contrast adjustment, and the jumper on the opposite side allows the back light is controlled by the program or remain off for power saving.

Hitachi’s HD44780 based 16×2-character LCD are very cheap and widely available. Using the LCD backpack module, desired data can be displayed on the LCD through the I2C bus. this is a general purpose bidirectional 8 bit I/O port expander that uses the I2C protocol.

To communicate LCD display with ESP32 board we need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Once you know the lcd’s i2c address, uploads the code below with updating your i2c address before uploading the code to the NodeMCU, then prints “hello” in the LCD line. As we have printed something else on the following image.

This tutorial we have seen, how to interface an 16X2 LCD display using I2C protocol with I2C module which made circuit interfacing easy and helps to reduce number of IO,s for connecting LCD display with Arduino board.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey