tft lcd temperature range price

The T-57152GD042H-LW-AAN and the T-55923GD050J-LW-ABN, small-format TFT LCD modules designed for use in harsh environments, have been introduced by Kyocera.

The T-57152GD042H-LW-AAN, which measures 4.2”, features a resolution of 480x272px, a brightness of 700cd/m², a digital 18-bit RGB interface, a contrast ratio of 1200:1, and horizontal and vertical viewing angles of 160° each. The design is based on automotive requirements and boasts an expanded operating temperature range of -30 to +85°C and a storage temperature range of -40 to +95°C. In addition, the anti-glare surface treatment improves readability in bright surroundings.

Measuring 5.0”, the T-55923GD050J-LW-ABN is a portrait-mode display that features a resolution of 480x640px. Optical characteristics include 800cd/m² brightness and a 500:1 contrast ratio. The viewing angle amounts to 140º horizontally and 110° vertically. This module comes with a 24-bit digital RGB interface and has a wide operating temperature range of -30 to +80°C.

“Portable outdoor devices are liable to fall down and are exposed to low temperatures, heat and humidity. Even in these conditions, they should always work reliably, and our components are designed for that purpose,” says Eberhard Schill, Manager Distribution and Marketing, Kyocera Display Europe.

GDT250T2080 is a 2.5 inch color TFT-LCD display panel, 320x240 resolution, wide operating temp. -30℃~85℃, suitable for outdoor or cold environment, 4:3 contrast, 6 o"clock viewing angle, surface anti-glare treatment, 18-bit RGB (with T-CON) + 4-wire SPI interface, superior display quality, wide range of applications.

GDT250T2080 is a 2.5 inch color TFT-LCD display panel, 320x240 resolution, wide operating temp. -30℃~85℃, suitable for outdoor or cold environment, 4:3 contrast, 6 o"clock viewing angle, surface anti-glare treatment, 18-bit RGB (with T-CON) + 4-wire SPI interface, superior display quality, wide range of applications, it can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.

{"specs":[],"skus":[{"id":4697,"useViewType":false,"productId":373,"templateId":1,"code":"","name":"2.5 inch TFT LCD Display Panel, Wide Operating Temperature, GDT250T2080","stock":0,"price":0.00,"retailPrice":0.00,"weight":0.00,"status":"1","isDefault":"1","createDate":"2022-03-08 11:33:57","updateDate":"2022-03-08 11:33:57","productSkuSpecs":[],"moq":1,"skuId":0,"chargedWeight":0.00}],"specConfs":[]}

ASI-T-17711A1SPN/D is a 1.77 inch transflective TFT with a resolution of 160 x 128, SPI interface and with a brightness of 110 Nits; viewable in direct sunlight.

ASI-T-240DA10SMN/AQ is a 2.4 inch high brightness TFT with a resolution of 240 x 320, SPI & MCU interface, IPS all-angle view and with a brightness of 1000 Nits; viewable in direct sunlight. It also features an extra wide operating temperatures of -30 to +80C; perfect for extreme environmental applications.

ASI-T-350EA8RCY6/A is a 3.5 inch high brightness TFT with a resolution of 320 x 240, 24-bit Parallel RGB/Serial RGB/CCIR/YUV interface and with a brightness of 850 Nits; viewable in direct sunlight with Capacitive Touch Panel

ASI-T-350EA10SRN/A is a 3.5 inch TFT with a resolution of 320 x 240, SPI & RGB interface and with a high brightness of 1,000 Nits and wide temperature range of -30 - +85 C.

ASI-T-430FA2F6/AY is a 4.3 inch IPS TFT with a resolution of 480 x 272, RGB interface, a brightness of 220 nits, wide operating temperature and a capacitive touch panel.

ASI-T-430MA10FN/A is a 4.3 inch TFT with a resolution of 800 x 480, IPS all view, RGB interface, a brightness of 1000 Nits with an ultra wide temperature operating and storage range.

ASI-T-430MA8F6/A is a 4.3 inch TFT with a resolution of 800 x 480, IPS all view, RGB interface, a brightness of 850 Nits, capacitive touch panel with an ultra wide temperature operating and storage range.

ASI-T-700MAKFN/A is an industrial grade, high reliability, 7 inch TFT with a resolution of 800 x 480, 24-bit RGB interface, wide temperature range, IPS all view and with a high brightness of 1000 Nits; viewable in direct sunlight.

ASI-T-10251248AKLN/D is a 10.25 inch wide TFT, with a resolution of 1280 x 480, LVDS interface, IPS all view, with wide temperature operation and storage and a high brightness of 1,000 Nits.

ASI-T-1040GA6TN/D is a 10.4 inch wide TFT, with a wide operating temperature and a resolution of 640 x 480, All View display, RGB interface and a brightness of 500 Nits.

ASI-T-1040HB4LN/D is a 10.4 inch wide TFT, with a wide operating temperature and a resolution of 800 x 600, LVDS interface and a brightness of 400 Nits.

ASI-T-1210HB4LN/D is a 12.1 inch wide TFT, with a wide operating temperature, a resolution of 800 x 600, all view display, LVDS interface and a brightness of 450 Nits.

Focus Displays offers a wide range of standard full color TFT displays. 64 million unique colors, high brightness, sharp contrast, -30C operating temperature, and fast response time are all good descriptions of a TFT display. This is why TFT technology is one of the most popular choices for a new product.

Thin Film Transistor (TFT) display technology can be seen in products such as laptop computers, cell phones, tablets, digital cameras, and many other products that require color. TFT’s are active matrix displays which offers exceptional viewing experiences especially when compared to other passive matrix technologies. The clarity on TFT displays is outstanding; and they possess a longer half-life than some types of OLEDs and range in sizes from less than an inch to over 15 inches.

CCFL’s are still available, but are becoming a legacy (obsolete) component. TFT displays equipped with a CCFL require higher MOQs (Minimum Order Quantities) than displays with LED backlights.

The majority of TFT displays contain a touch panel, or touch screen. The touch panel is a touch-sensitive transparent overlay mounted on the front of the display glass. Allowing for interaction between the user and the LCD display.

Some touch panels require an independent driver IC; which can be included in the TFT display module or placed on the customer’s Printed Circuit Board (PCB). Touch screens make use of coordinate systems to locate where the user touched the screen.

Resistive touch panels are the lowest cost option and are standard equipment on many TFT modules. They are more common on smaller TFT displays, but can still be incorporated on larger modules.

Resistive touch panels allow a single touch, although advances in new resistive technology will allow multi-touch operation in the near future. One main advantage of a resistive touch screen is the ability to be activated by the touch of any material. This includes a range of items from a bare finger, to a pencil, to even the edge of a credit card; regardless of its composition.

They also have the added advantage of operating in a wide temperature range and environments, including anything from the arctic cold of Alaska to the extreme heat of Death Valley.

Contrast ratio, or static contrast ratio, is one way to measure the sharpness of the TFT LCD display. This ratio is the difference between the darkest black and the brightest white the display is able to produce. The higher the number on the left, the sharper the image. A typical contrast ratio for TFT may be 300:1. This number ratio means that the white is 300 times brighter than the black.

TFT LCD displays are measured in inches; this is the measurement of the diagonal distance across the glass. Common TFT sizes include: 1.77”, 2.4”, 2.8”, 3”, 4.3”, 5”, 5.7”, 5.8”, 7”, 10.2”, 12.1 and 15”.

TFT resolution is the number of dots or pixels the display contains. It is measured by the number of dots along the horizontal (X axis) and the dots along the vertical (Y axis).

Certain combinations of width and height are standardized and typically given a name and a letter representation that is descriptive of its dimensions. Popular names given to the TFT LCD displays resolution include:

Transmissive displays must have the backlight on at all times to read the display, but are not the best option in direct sunlight unless the backlight is 750 Nits or higher. A majority of TFT displays are Transmissive, but they will require more power to operate with a brighter backlight.

A primary job of the driver is to refresh each pixel. In passive TFT displays, the pixel is refreshed and then allowed to slowly fade (aka decay) until refreshed again. The higher the refresh frequency, the sharper the displays contrast.

The TFT display (minus touch screen/backlight) alone will contain one controller/driver combination. These are built into the display so the design engineer does not need to locate the correct hardware.

If you do not see a Thin Film Transistor (TFT) Display module that meets your specifications, or you need a replacement TFT, we can build a custom TFT displays to meet your requirements. Custom TFTs require a one-time tooling fee and may require higher MOQs.

Ready to order samples for your TFT design? Contact one of our US-based technical support people today concerning your design requirements. Note: We can provide smaller quantities for samples and prototyping.

US Micro Products manufactures a wide selection of TFT LCD (Active Matrix LCDs) displays to accommodate the needs of OEMs across many different industries, including medical, industrial, gaming, military and many more.

An array of available interfaces, brightness levels, and temperature ranges ensure that our TFT LCDs work well with your design and in the environment of your choice

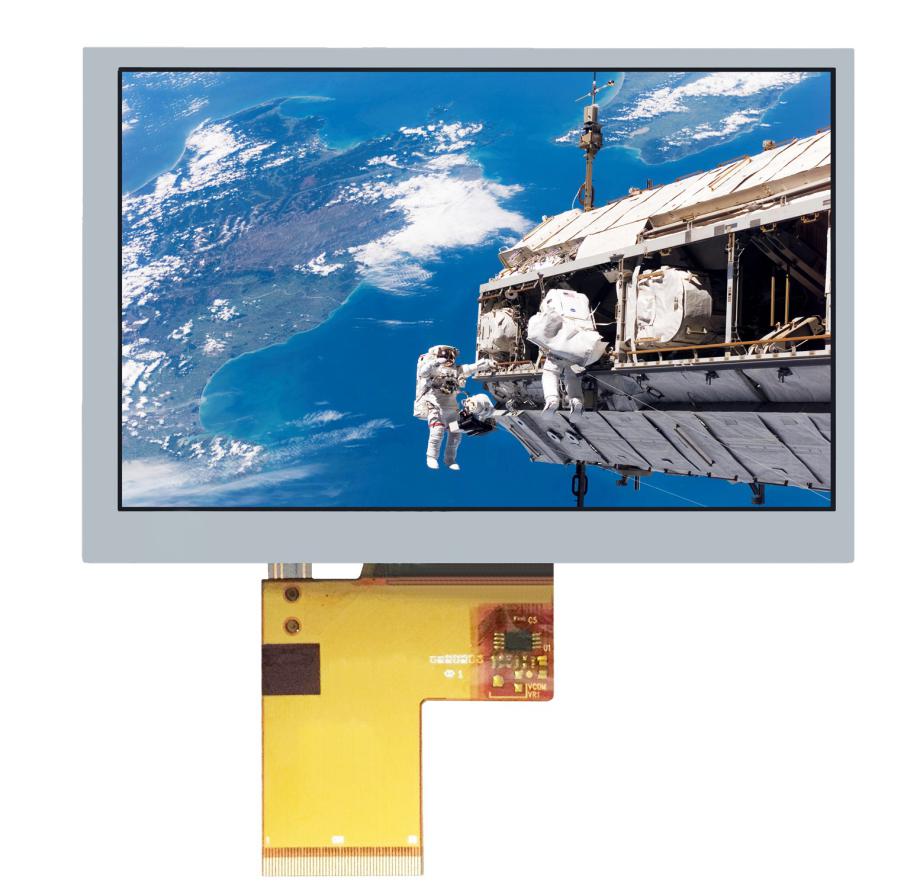

Full-color (262K) 800x480 RGB display module consists of a TFT panel, a driver IC, an FFC/FPC flexible cable, and an LED backlight. This TFT LCD display module does not include an on-board LCD controller.

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

Some devices that are used in extremely high ambient temperatures may even require air conditioning. With air vents to carry the heat out, the device can expel it into the surroundings.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

If the device is not adapted for the cold, it would be good to keep it bundled up, trapping the heat within layers. However, this is only a temporary solution. Adapted, rugged devices have advantages such as screen enclosure insulation for heat level preservation and, in more extreme cases, heaters to generate extra heat to raise the internal temperature to a level above the minimum.

When selecting the appropriate module, it is necessary to understand the device’s expected primary application. The application will decide factors such as display type, environmental conditions, whether or not power consumption is a factor, and the balance between performance and cost. These factors can have an effect on the operation and storage temperature ranges for the device.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

These benefits, in addition to its ability to achieve a wide temperature range, provide more options for consumers in search of high quality displays for extreme climates.

Levia Technologies a leading supplier of touch systems. With over more than 300 products to choose form, it offers varied range of touchscreens component, touchmonitors, touchcomputers, interactive digital signages for various applications. Levia Technologies team works on pricipal of offering best solution at economic costs.

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

In the idle state, the liquid twists the plane of polarization of the incoming light by 90° so that it can pass the analyzer unhindered. The LCD is thus transparent. If a specific voltage is applied to the metallic film coating, the crystals rotate in the liquid. This twists the plane of polarization of the light by another 90°, for example: The analyzer prevents the light getting through, and the LCD thus becomes opaque.TN, STN, FSTN, blue mode, yellow-green mode

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

Pacer offers an extensive range of colour TFT LCD panels from 1.8″ through the popular 3.5″ and 5.7″ sizes to 82″. Our range includes sunlight readable panels from 5.6″ to 70″, bar cut panels, and SMART TFT displays with built-in control. We offer TFT displays with high brightness, high contrast ratio, wide viewing angle, wide temperature operation, longer lamp life, and lower power consumption.

TFT displays are used extensively in many industrial, commercial and scientific applications, including ATMs, POS terminals, kiosks, security systems, lottery and gambling gaming machines, medical equipment, factory automation, digital advertisement signage, transportation information, and marine equipment.

TFT technology is being used to replace Mono LCD in many applications, and Raystar Optronics now offers a 5.2″ TFT module designed specifically to fit the footprint of the industry standard RG24064-series 240×64 mono graphic STN LCD. The RFS520A can replace traditional STN displays of 8×2 or 16×2 format as it shares the same 16 pin footprint.

Our TFT modules are fully supported with a variety of options including wide operating temperatures, high brightness and contrast, built-in DC-DC and temperature compensation circuitry and most with white LED backlights. Resistive Touchscreens and Projected Capacitive Touchscreens are available for most models. Many panels can be configured as a kit – see our Interface Kits page for more details.

IMPORTANT ANNOUNCEMENT – Mitsubishi has decided to end production of TFT-LCD modules, as the company is no longer able to maintain the products’ competitiveness after significant price falls in the global market. Production of TFT-LCD modules is scheduled to end in June 2022 with a Last Time Buy date of June 2021. Please contact us as soon as possible to discuss last time buy or identification of suitable alternative displays.

Raystar is a professional TFT (Thin Film Transistor) module manufacturer. Whether you need a TFT display with control board, high brightness, wide viewing angle, monochrome or bar type, we have TFT active matrix display models for you to choose from.

LITEMAX® Industrial Display solution provide a wide range of reliable displays from 5.7″ to 85″ including LCD panel modules, open frame LCD displays, outdoor displays, and panel mount monitors. LITEMAX have developed and focused on LCD display technologies such as high brightness technology, optical bonding solutions, and color enhancement technology that bring more add-on value to enhance their products.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey