meaning of tft display manufacturer

A thin-film transistor liquid crystal display (TFT LCD) is a type of liquid crystal display (LCD) that makes use of thin-film transistor technology in order to improve qualities such as contrast and addressability. TFT technology means that an individual transistor is used to drive each individual pixel, allowing for faster response times.

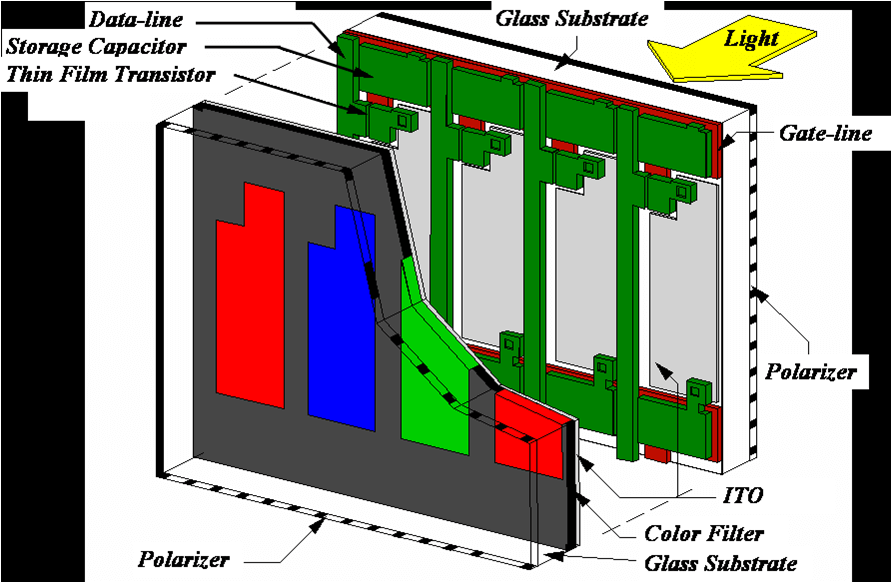

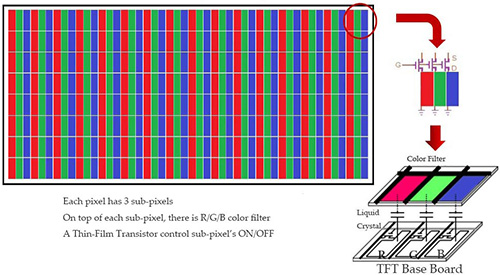

Thin-film transistor liquid crystal display technology uses "field-effect" transistors, which are built by layering thin films on a glass substrate, hence the name. This technique is commonly used for creating microprocessors. The TFT in the LCD controls individual pixels in the display by setting the level of the electric field across the three liquid crystal capacitors (one for each sub-pixel of red, green and blue) in the pixel in order to control the polarization of the crystal material. The amount of polarization in the crystal determines the amount of light that reaches the color filter from the backlight. Because of this ability to directly and quickly control each pixel, TFT is also called active-matrix LCD technology.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

1971 – Lechner, F. J. Marlowe, E. O. Nester, and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs

2020 – TFT LCD display technology dominants the display market now. Within the last 20 years, it has wiped out the market of CRT (cathode-ray tube) and Plasma. The only challenges are OLED (organic light-emitting diode)and Micro LED (Maybe, still in lab).

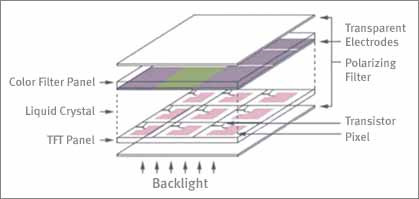

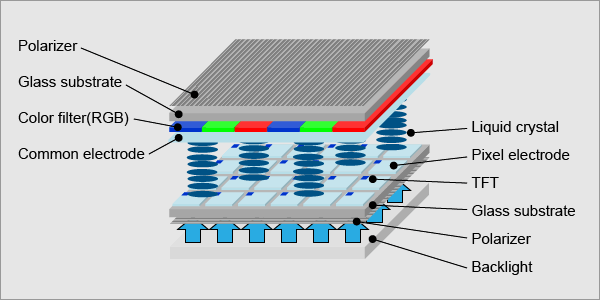

TFT LCD Display (Thin-Film-Transistor Liquid Crystal Display) technology has a sandwich-like structure with liquid crystal material filled between two glass plates. Two polarizer filters, color filters (RGB, red/green/blue) and two alignment layers determine exactly the amount of light is allowed to pass and which colors are created.

Each pixel in an active matrix is paired with a transistor that includes a capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. The TFT layer controls light flow a color filter displays the color and a top layer houses your visible screen.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available.Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available. Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The TFT screen itself can’t emit light like OLED display, it has to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light emitting diodes) to generate their light and therefore utilize less power and require less depth by design.

TFT is a Thin Film Transistor, TFT refers to each LCD liquid crystal display pixels that are driven by integration in the behind of the Thin Film Transistor. Therefore, the TFT-type display has the advantages of high responsiveness, high brightness, and high contrast, and its display effect is close to that of CRT display, TFT-LCD is one of the most liquid crystal displays.TFT display is also a kind of active-matrix liquid crystal display equipment. TFT-LCD is one of the best LCD color displays, TFT-LCD has the advantages of fine and vivid image, lightweight, low power consumption, and good environmental protection performance, widely used in TV, laptop, mobile phone, monitor, medical beauty, and other equipment.

Unlike TN, TFT displays are “backlit” – the imaginary light path is not from top to bottom, as in TN, but from bottom to top. In this way, a special light tube is set on the back of the liquid crystal, and the light source shines upward through the lower polarizer. Since the upper and lower interlayer electrodes are changed into FET electrodes and common electrodes, the performance of liquid crystal molecules will also change when the FET electrode is switched on. The display purpose can be achieved through shading and light transmission, and the response time is greatly improved to about 80ms.TFT is commonly known as “true color” because it has higher contrast and richer colors than TN-LCD, and the screen updates faster.

The main feature of TFT-LCD, as opposed to TN, is one semiconductor switch per pixel. Because each pixel can be directly controlled by point pulses. Therefore, each node is relatively independent and can be controlled continuously. Such a design method not only improves the response speed of the display screen but also can accurately control the display grayscale, which is why TFT color is more realistic than DSTN.

The TFT panel is cut from a larger substrate. LCD products also have a large array of transistors to control the three primary colors, and current manufacturing technology is difficult to ensure that tens or even hundreds of millions of transistors on a large substrate are without a single problem. If there is a problem with one of the transistors, then the corresponding color of the corresponding point of the transistor will go wrong (only a certain fixed color can be displayed), and this point is commonly called “bad point”. The probability of bad spots is not fixed in position, so a substrate is likely to be wasted a lot. Generally, LCD requires that the bad point is less than 5, and some large manufacturers have narrowed the standard to 3, or even 0, which will reduce the yield rate. Some smaller manufacturers expand the bad points, which naturally reduces costs and quality, which is one reason why some manufacturers have been able to slash prices.

Although there are many manufacturers capable of producing LCDs, there are only a handful of manufacturers capable of producing TFT panels.ACER, as a well-known enterprise in the IT industry, is quite powerful. Although IT does not have the ability to produce TFT panels by itself,

The display sets the electron, the communication and the information processing technology in one body, is considered as the electron industry after the 20th-century microelectronics, the computer another important development opportunity.

With the rapid development of science and technology, a revolution is taking place in display technology. After more than 20 years of research, competition, and development, the flat-panel display has entered the role and become the mainstream of display products in the new century. There are four types of flat-panel displays with the most fierce competition:

The principle of field emission flat display is similar to that of CRT, which only has one to three electron guns and up to six. The field emission display adopts an electron gun array (electron emission micro tip array, such as diamond film tip cone), and the display with a resolution of VGA (640×480×3) needs 921,600 electron emission micro tips with uniform performance.

Glow plasma display are through small vacuum plasma discharge excitation discharge cavity light-emitting materials, luminous effect, and low power consumption is its shortcomings (only 1.2 lm/W, and lamp luminous efficiency more than 80 lm/W, 6 watts per square inch display area), but in 102 ~ 152 cm diagonal field of the large-screen display has a strong competitive advantage.

The semiconductor light-emitting diode (LED) display scheme, due to the successful development of GaN blue light-emitting diode, has won absolute control over the market of the video display with very large screens, but this kind of display is only suitable for large outdoor displays, and video display with a small and medium screen does not have its market.

Special TFT – LCD, LCD flat panel display, is the only one in the brightness, contrast, such as power, life, volume and weight of integrated performance to catch up with and surpass that of the CRT display device, it features good performance, large-scale production, a high degree of automation, low cost of raw materials, the vast development space, will quickly become the mainstream product of the new century, is one of the highlights of the 21st-century global economic growth.

TFT-LCD, which USES liquid crystal as the excellent characteristic of the light valve, divides the luminous display device into two parts, namely the light source and the control of the light source. As a light source, no matter from luminous efficiency, full color, or life, has achieved brilliant results, but also in continuous deepening. Since the invention of the LCD, the backlight has been continuously improved, from monochrome to color, from thick to thin, from side fluorescent lamps to flat fluorescent lamps. The latest achievements in light sources will provide a new backlight for LCD. With the progress of light source technology, there will be newer and better light sources and LCD applications. Is the control of the light source, the rest of the large scale integrated circuit technology and semiconductor technology transplanted, successfully developed the thin film transistor (TFT) production technology, implements the matrix addressing the control of the liquid crystal light valve, solved the LCD light valve and the controller, so that the advantages of liquid crystal display (LCD).

The TFT thin-film transistor (matrix) — which “actively” controls individual pixels on the screen — is the origin of the so-called active matrix TFT.So how exactly do images come about? The basic principle is simple: a display screen consists of a number of pixels that can emit light of any color, and controlling each pixel to display a corresponding color does the trick. In TFT LCD, backlight technology is generally adopted. In order to accurately control the color and brightness of each pixel, a switch similar to a shutter needs to be installed after each pixel. When the “shutter” is opened, light can come through, but when the “shutter” is closed, light cannot come through.

Of course, it’s not as simple technically as that. Liquid Crystal Display USES the properties of Liquid crystals (Liquid when heated and solid when cooled)

Liquid crystal displays (LCDs) are filamentous, and their molecular structure changes as the environment change, giving them different physical properties — allowing light to pass through or block it — in the case of louvers.

You know the three primary colors, so each pixel on the display needs to be made up of three similar basic components described above, which control the red, green, and blue colors respectively.

TFT color filter is divided into red, green, and blue according to the color, which is successively arranged on the glass substrate to form a group (dot pitch) corresponding to a pixel. Each monochrome filter is called a sub-pixel. That said, if a TFT display supports a maximum resolution of 1280×1024, it needs at least 1280×3×1024 sub-pixels and transistors. For a 15-inch TFT display (1024 x 768), a pixel is about 0.0188 inches.

As you know, pixels are critical to a display, and the smaller each pixel, the larger the maximum possible resolution of the display. But because of the physical limitations of transistors, the TFT is roughly 0.0117 inches (0.297mm) per pixel, so the maximum resolution for a 15-inch display is 1,280 by 1,024.[1]

TFT technology is the basis of liquid crystal (LC), inorganic and organic thin-film electroluminescence (EL and OEL) flat panel displays.TFT is a kind of film necessary for manufacturing circuits formed by sputtering and chemical deposition process on the non-single wafers such as glass or plastic substrate, and large-scale semiconductor integrated circuit (LSIC) is produced by processing of the film. Using non-single-crystal substrate can greatly reduce the cost, which is the extension of traditional LSI to large-area, multi-function, and low-cost direction.

The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of glass substrate has been expanded to 680mm×880mm), and the recent 950mm×1200mm glass substrate will also be put into operation. In principle, there is no area limit.

The 1.3-inch TFT chip used for liquid crystal projection has a resolution of one million pixels in XGA.The resolution of the SXGA (1280×1024) 16.1-inch TFT array amorphous silicon film thickness is only 50nm, and the TAB ON GLASS and SYSTEM ON GLASS technology, its IC integration, requirements for equipment and supply technology, technical difficulty than the traditional LSI.

TFT was first used as a matrix location circuit to improve the optical valve characteristics of liquid crystals. For high-resolution displays, the accurate control of object elements is realized through voltage adjustment in the range of 0-6v (its typical value is 0.2 to 4V), thus making it possible for LCD to achieve a high-quality high-resolution display.TFT-LCD is the first flat panel display in human history to surpass CRT in display quality. Now people are starting to integrate the drive IC into the glass substrate, and the whole TFT will be more powerful than traditional large-scale semiconductor integrated circuits.

The glass and plastic substrates fundamentally solve the cost problem of large-scale semiconductor integrated circuits and open up wide application space for large-scale semiconductor integrated circuits.

Low voltage applications, low drive voltage, solid use safety, and reliability improvement; Flat, light, and thin, saving a lot of raw materials and space; Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT-LCD is only about one percent of the CRT, saving a lot of energy; TFT-LCD products also have specifications, models, size series, variety, convenient and flexible use, maintenance, update, upgrade easy, long service life and many other characteristics. The display range covers the application range of all monitors from 1 inch to 40 inches and the large projection plane, which is a full-size display terminal; Display quality from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, the high response speed of various specifications of video display; Display mode has direct vision type, projection type, perspective type, and reflection type.

No radiation, no flicker, no harm to the user’s health. In particular, the appearance of TFT-LCD electronic books and periodicals will bring mankind into the era of a paperless office and paperless printing, and trigger the revolution of human learning, communication, and recording civilization.

The temperature range from -20℃ to +50℃ can be used normally, and the low temperature working temperature of TFT-LCD after temperature reinforcement can reach -80 ℃. It can be used as a mobile terminal display, desktop terminal display, and large screen projection TV. It is a full-size video display terminal with excellent performance.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Touch type and accuracy.What type of activities are you planning on using your device for? If it’s for extended outdoor use, then you should go with projected capacitive touch as this is more precise and accurate. Touch accuracy is important for industrial and commercial applications.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD. See our blog post RGB and Color Depth for more on how TFTs show color.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation. The orientation of the crystals changes the polarization of the liquid crystal creating light or dark pixels on the display.

These pixels are arranged to create characters or graphic images. This type of display may be sunlight-readable and may have a backlight, which allows it to be viewed in dark areas.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Thin and light: These are ideal display modules for handheld devices, communications equipment, information displays, and test and measurement equipment.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of our character LCD modules use a standard HD44780 compatible controller, so they can be quickly integrated into a new product or used as a replacement in your existing products.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Because OLEDs are emissive, these displays can always be used in dark environments. There is usually a software command or hardware setting that will allow OLEDs to be dimmed.

Some OLED displays are bright enough to be sunlight readable–these models will typically take more current and may have a shorter rated lifetime. Additionally, OLEDs have extremely wide viewing angles.

What makes OLEDs useful for display construction is that they can be fabricated in bulk. Using OLED fabrication techniques, all the diodes can be made at the same time, at a much lower cost. OLEDs also come in a wide variety of colors.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

We"ve been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Meaning Of Tft Display, Transparent Lcd, Lcd Touch, Small Touchscreen Monitor,Ips Lcd Module. We are sincerely looking forward to cooperate with buyers all around the world. We imagine we will satisfy you. We also warmly welcome shoppers to visit our organization and purchase our merchandise. The product will supply to all over the world, such as Europe, America, Australia,Lebanon, Bahamas,Paraguay, Hyderabad.In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

The use of TFT (thin film transistor) LCD display has gained popularity over the years, with the advent of high technology such as laptop computers, iPads, televisions, and other gadgets. A TFT LCD module uses complex and advanced technology that allows it to provide the screen a homogenous illumination, making the quality of images better. Aside from gadget users, businesses and companies can also benefit from this technology that can help with productivity.

TFT LCD monitors are less bulky. They can easily be carried and moved around. In fact, they can be mounted on walls. This means that they don’t occupy a lot of space, allowing you to utilize and organize a workstation better. You can make room for more important tasks.

You can save money on electric bills with a TFT LCD screen. Because it uses millions of pixels that provide accurate illumination on less electricity, it’s more energy-efficient than CRT monitors. It consumes 78% less energy. Given this, companies can make better use of their resources.

The visual that a TFT LCD display produces is sharper than a CRT monitor. Every pixel in a TFT LCD is active, preventing flickers and distortions. This means that you can get a clearer picture, which is necessary for work. Blurry images on a screen can affect a person’s productivity. This is also good for helping avoid headaches, eyestrain, and nausea that are caused by too much exposure to computers that produce low quality images.

Adaptability is a reason why graphic and web designers prefer TFT LCD screens. Such technology fits dual monitor configurations. This means that a capable computer can have two monitors that you can use simultaneously. It can help speed up your work because you don’t have to switch between windows on one screen. You can view and work on a main document on one screen and use the other one for other tasks.

These are only some of the reasons to use a TFT LCD screen at work. If you believe that you can benefit from this technology, contact a reliable manufacturer to get the best product for you.

Technology trends in backplane technology are driving higher gas demand in display manufacturing. Specific gas requirements of process blocks are discussed, and various supply modes are reviewed.

Since its initial communalization in the 1990s, active matrix thin-film-transistor (TFT) displays have become an essential and indispensable part of modern living. They are much more than just televisions and smartphones; they are the primary communication and information portals for our day-to- day life: watches (wearables), appliances, advertising, signage, automobiles and more.

There are many similarities in the display TFT manufacturing and semiconductor device manufacturing such as the process steps (deposition, etch, cleaning, and doping), the type of gases used in these steps, and the fact that both display and semiconductor manufacturing both heavily use gases.

However, there are technology drivers and manufacturing challenges that differentiate the two. For semiconductor device manufacturing, there are technology limitations in making the device increasingly smaller. For display manufacturing, the challenge is primarily maintaining the uniformity of glass as consumers drive the demand for larger and thinner displays.

While semiconductor wafer size has maxed because of the challenges of making smaller features uniformly across the surface of the wafer, the size of the display mother glass has grown from 0.1m x 0.1m with 1.1mm thickness to 3m x 3m with 0.5mm thickness over the past 20 years due to consumer demands for larger, lighter, and more cost-effective devices.

As the display mother glass area gets bigger and bigger,so does the equipment used in the display manufacturing process and the volume of gases required. In addition, the consumer’s desire for a better viewing experience such as more vivid color, higher resolution, and lower power consumption has also driven display manufacturers to develop and commercialize active matrix organic light emitting displays (AMOLED).

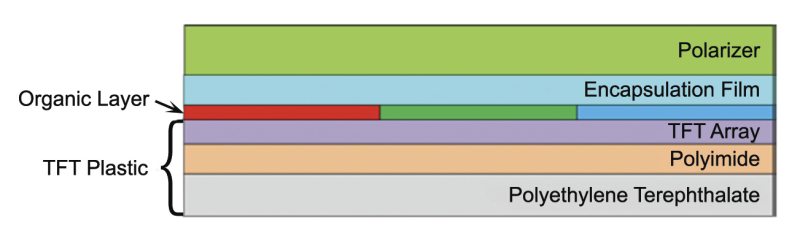

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

The thin-film-transistors used for display are 2D transitional transistors, which are similar to bulk CMOS before FinFET. For the active matrix display, there is one transistor for each pixel to drive the individual RGB within the pixel. As the resolution of the display grows, the transistor size also reduces, but not to the sub-micron scale of semiconductor devices. For the 325 PPI density, the transistor size is approximately 0.0001 mm2 and for the 4K TV with 80 PPI density, the transistor size is approximately 0.001 mm2.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

Mobility limitation (FIGURE 2) is one of the key reasons for the shift to MO and LTPS to enable better viewing experience from higher resolution, etc.

The challenge to MO is the oxidation after IGZO metalization / moisture prevention after OLED step, which decreases yield. A large volume of N2O (nitrous oxide) is required for manufacturing, which means a shift in the traditional supply mode might need to be considered.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

These gases can be categorized into two types: Electronic Specialty gases (ESGs) and Electronic Bulk gases (EBGs) (FIGURE 5). Electronic Specialty gases such as silane, nitrogen trifluoride, fluorine (on-site generation), sulfur hexafluoride, ammonia, and phosphine mixtures make up 52% of the gases used in the manufacture of the displays while the Electronic Bulk gases–nitrogen, hydrogen, helium, oxygen, carbon dioxide, and argon – make up the remaining 48% of the gases used in the display manufacturing.

The key ga susage driver in the manufacturing of displays is PECVD (plasma-enhanced chemical vapor deposition), which accounts for 75% of the ESG spending, while dry etch is driving helium usage. LTPS and MO transistor production is driving nitrous oxide usage. The ESG usage for MO transistor production differs from what is shown in FIGURE 4: nitrous oxide makes up 63% of gas spend, nitrogen trifluoride 26%, silane 7%, and sulfur hexafluoride and ammonia together around 4%. Laser gases are used not only for lithography, but also for excimer laser annealing application in LTPS.

Silane: SiH4 is one of the most critical molecules in display manufacturing. It is used in conjunction with ammonia (NH3) to create the silicon nitride layer for a-Si transistor, with nitrogen (N2) to form the pre excimer laser anneal a-Si for the LTPS transistor, or with nitrous oxide (N2O) to form the silicon oxide layer of MO transistor.

Nitrogen trifluoride: NF3 is the single largest electronic material from spend and volume standpoint for a-Si and LTPS display production while being surpassed by N2O for MO production. NF3 is used for cleaning the PECVD chambers. This gas requires scalability to get the cost advantage necessary for the highly competitive market.

Nitrous oxide: Used in both LTPS and MO display production, N2O has surpassed NF3 to become the largest electronic material from spend and volume standpoint for MO production. N2O is a regional and localized product due to its low cost, making long supply chains with high logistic costs unfeasible. Averaging approximately 2 kg per 5.5 m2 of mother glass area, it requires around 240 tons per month for a typical 120K per month capacity generation 8.5 MO display production. The largest N2O compressed gas trailer can only deliver six tons of N2O each time and thus it becomes both costly and risky

Nitrogen: For a typical large display fab, N2 demand can be as high as 50,000 Nm3/hour, so an on-site generator, such as the Linde SPECTRA-N® 50,000, is a cost-effective solution that has the added benefit of an 8% reduction in CO2 (carbon dioxide) footprint over conventional nitrogen plants.

Helium: H2 is used for cooling the glass during and after processing. Manufacturers are looking at ways to decrease the usage of helium because of cost and availability issues due it being a non-renewable gas.

N2 On-site generators: Nitrogen is the largest consumed gas at the fab, and is required to be available before the first tools are brought to the fab. Like major semiconductor fabs, large display fabs require very large amounts of nitrogen, which can only be economically supplied by on-site plants.

Cryogenic liquid truck trailers: Oxygen, argon, and carbon dioxide are produced at off-site plants and trucked short distances as cryogenic liquids in specialty vacuum-insulated tankers.

Blended gases: Laser gases and dopants are supplied as blends of several different gases. Both the accuracy and precision of the blended products are important to maintain the display device fabrication operating within acceptable parameters.

In-fab distribution: Gas supply does not end with the delivery or production of the material of the fab. Rather, the materials are further regulated with additional filtration, purification, and on-line analysis before delivery to individual production tools.

The consumer demand for displays that offer increas- ingly vivid color, higher resolution, and lower power consumption will challenge display makers to step up the technologies they employ and to develop newer displays such as flexible and transparent displays. The transistors to support these new displays will either be LTPS and / or MO, which means the gases currently being used in these processes will continue to grow. Considering the current a-Si display production, the gas consumption per area of the glass will increase by 25% for LTPS and ~ 50% for MO productions.

To facilitate these increasing demands, display manufacturers must partner with gas suppliers to identify which can meet their technology needs, globally source electronic materials to provide customers with stable and cost- effective gas solutions, develop local sources of electronic materials, improve productivity, reduce carbon footprint, and increase energy efficiency through on-site gas plants. This is particularly true for the burgeoning China display manufacturing market, which will benefit from investing in on-site bulk gas plants and collaboration with global materials suppliers with local production facilities for high-purity gas and chemical manufacturing.

![]()

Have you ever wonder where TFT derive from? Why is TFT referred to as LCD? The phenomenon started in early days, when bulky CRT displays were thing of the past and LCD was its replacement, but as time progresses, there were still room for improvement, which leads to the birth of TFT’s.

TFT is a variant of an LCD which uses thin film transistor technology to improve an image quality, while an LCD is class of displays that uses modulating properties of liquid crystals to form what we call an LCD (liquid crystals display) which in fact does not emits light directly.

Even though LCDs were very energy efficient, light weight and thin in nature, LCD were falling behind to the CRT display, which then leads to a change in LCD manufacturing, where performance became a big problem.

For example, having a 2001 Mustang vs a 2014 Mustang, the dimensions and engine of the 2014 has been redesign for performance reasons, not mentioning user friendly, so does the LCD to TFT.

As the birth of TFT, the elements are deposited directly on the glass substrate which in fact the main reason for the switch was because TFTs are easier to produce, better performance in terms of adjusting the pixels within the display to get better quality.

LCDs became ineffective over a period of time, almost all aspect of watching a TV, playing video games or using a handheld device to surf the net became daunting, this phenomenon is known as high response time with low motion rate.

Another problem with LCD was crosstalking, in terms of pixelating, this happens when signals of adjacent pixels affects operations or gives an undesired effect to the other pixel.

As TFT’s become very popular throughout the century due to its elaborate low charge associate and outstanding response time, LCDs became a thing of the past, and TFT became the predominant technology with their wider viewing angles and better quality this technology will be around for a long time.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

What does TFT display mean? TFT, also known as thin film field-effect transistor. TFT refers to the TFT in which each LCD pixel on the LCD is integrated into the back. Therefore, it is possible to display screen information with high speed, high brightness and high contrast. TFT is an active matrix LCD. Now let"s look at TFT LCD.

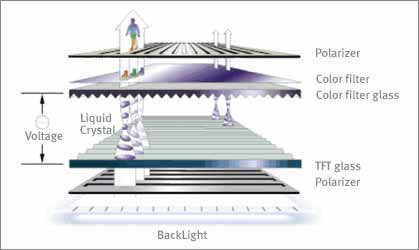

A TFT (TFT), also known as a thin film FET, is capable of "active" control of individual pixels on the screen, thus greatly improving response. TFT"s response speed is generally 80 ms, with a wide field of vision, up to 130 degrees. It is mainly used in high-end products. Therefore, it is possible to display screen information with high speed, high brightness and high contrast. TFT is an active matrix liquid crystal display, which adopts an "active matrix" technology. It adopts the thin-film transistor electrode, which can be used to control the opening and closing of any display point by "actively pulling". Under the illumination of the light source, the light is first transmitted from the bottom polarizer, and then transmitted by the liquid crystal molecules to achieve the display of the screen.

TFT also improves the flash (water wave) blurring of STN, and effectively enhances the playback of dynamic images. TFT is superior to STN in color saturation, reduction ability and contrast, but its disadvantages are high power consumption and high cost. TFT liquid crystal display system adopts point pulse mode, so that each node has autonomy and can achieve continuous control. It can not only accelerate the display speed, but also accurately control the color scale of the display, so that TFT LCD can show more real colors. TFT LCD has the advantages of high brightness, high contrast, strong sense of hierarchy, bright colors, etc.

When the liquid crystal is contained in the middle of the two grooved surface and groove are perpendicular to each other, the liquid crystal molecules are arranged as follows:

When a voltage is applied between the upper and lower surfaces, the liquid crystal molecules are aligned in the direction of the electric field, forming a vertical alignment. At this point, the incident light is not affected by the Liquid Crystal Molecules, straight out of the lower surface.

The liquid crystal cannot emit light by itself, and the backlight should be added behind the LCD panel. A few years ago, CCFL cold cathode backlighting was the dominant market application, but with the development of technology, the LED backlight has gradually replaced the traditional CCFL backlight.

(1) Side entrance type-the lamp tube is placed on the side of the light guide plate. According to the light guide plate type and the optical demand, the straight type, the l type, and the small type of lamp tube can be selected. The advantage of this design is that the thickness is thinner and the temperature is less; at present, more use of this shape.

(2) The straight-down type-the lamp tube is placed under the diffusion plate, and the lamp tube usually uses the w type lamp tube. The disadvantage of this type is thicker and the temperature will be higher (used above 21 inches).

The led backlight has the characteristics of low heat, concentrated light source, slow decay speed, and low power consumption. It also has the advantages of high color saturation, fast start, no mercury, and long life.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

A TFT is a type of transistor used in active-matrix LCD screens. TFT LCD screens use a separate transistor to control each pixel in the display. They allow the electrical current that controls each pixel to turn on and off quickly, which decreases response time and makes on-screen motion smoother. TFT LCDs are often used as computer monitors, televisions, mobile phone screens, and other flat-panel color displays.

The name "Thin Film Transistor" is derived from the manufacturing process. The manufacturer first applies thin films of a semiconductor (like amorphous silicon) and dielectric materials to a flat, non-conductive surface (like glass). Unneeded silicon is etched away, leaving only a grid of transistors and the transparent glass surface. These transistor panels are thin enough to fit between a polarized backlight and the layer of liquid crystals. These transistors apply an electrical current to the liquid crystals, altering their arrangement to block light in certain ways. The light then passes through other layers of the screen, including a color filter and polarized light filter, to display the final image.

Not all TFT LCD screens are made the same. There are several types of TFT panels, made by distinct methods, and with different performance characteristics. The two most common types are TN and IPS.

Twisted Nematic (TN) panels contain liquid crystals that twist as an electric current is applied. As the crystals twist, they allow varying amounts of polarized light to pass through. TN panels are the easiest type of TFT LCD to produce and offer the quickest response times. However, TN panels don"t display colors as accurately as other types of panels, particularly when viewed at an angle.

In-Plane Switching (IPS) panels contain liquid crystals that don"t twist but instead reorient themselves while remaining parallel to their original planar position. As the crystals realign, they allow varying amounts of polarized light through. IPS panels are more expensive to produce than TN panels, require more power to operate, and have slower response times. However, they are more accurate at color reproduction, even when viewed at an angle.

At Display Technology we understand that each market sector has different requirements, therefore we pick our suppliers based on what our customers want. But, there is a common process and thought strategy used, when picking each supplier.

We aim to offer TFT LCD displays of the best quality for the price, and where we can secure a continuity of supply. The quality of products reflects on our business, and so we do not want to be linked to inferior quality stock. We also understand that there is a certain amount of development time, approvals and cost if a product changes.

With every development we look at the impact and consult with our clients the best route forward in order to meet requirements. When we choose a partner, unlike some TFT display suppliers, we do not just add on without understanding how the range fits within our business model. It is also important that we can add value to a suppliers range for an improved solution for the end customer.

We know all our TFT monitors will require support from other components within our range, including touch screens, interface cards or backlight controllers. Therefore we endeavour to fully test new panels for compatibility prior to releasing onto the market.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey