meaning of tft display made in china

TFT-based displays have a transistor for each pixel on the screen. This allows the electrical current that illuminates the display to be turned on and off at a faster rate, which makes the display brighter and shows motion smoother. LCDs that use TFT technology are called "active-matrix" displays, which are higher-quality than older "passive-matrix" displays. TFT technology provides the best resolution of all the flat display technologies, but it is also expensive than monochrome lcd. So TFTs are used in high-quality LCD displays, if you see a LCD monitor at your local computer market, it should be an active tft lcd display, Basically, it is a high-quality tft lcd monitor.

Passive-matrix display. A passive-matrix display is anLCD screen display that contains a series of wires that cross each other. See the dual scan display for a full definition on this term.

What is an Active-matrix Display (TFT)? Alternatively referred to as TFT ( thin-film transistor) and AMLCD ( active-matrix LCD ), an active-matrix display is an LCD ( liquid crystal display) introduced with the IBM ThinkPad in 1992.

It uses a matrix of thin film transistors(TFTs) and capacitors to control the image produced by thedisplay. The brightness of each pixel is controlled by modifying the electrical charge of the corresponding capacitors.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

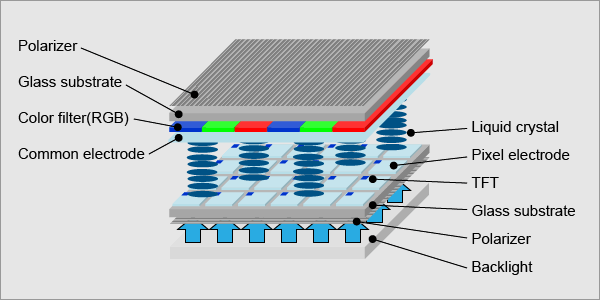

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

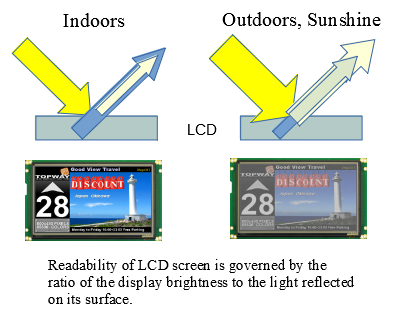

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

There is no doubt that China has taken the mass manufacturing business by storm. There are few products that we can encounter in our lives that don’t have the words ‘Made in China’ scribbled underneath. There is a glut of products that are mass-manufactured by the Chinese and then shipped out internationally to be sold.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

One of the main benefits that you get with Stoneitech.com is that there is a wide range of diverse products that you can purchase. For example, there are three different application types that you can choose from which include the Industrial Type, Advanced Type, and Civil Type. Similarly, there is a range of different sizes that you can choose from. There are 11 different sizes that you can buy, ranging from the smallest 3.5-inch display to the large 15.1-inch one. The same goes for the Android series which where you can choose between 4.5-inch and 31.5-inch displays.

This is probably the biggest advantage that you can get when working with manufacturers from China. It can even be assumed that this is probably the biggest reason why the Asian country is at the forefront of the mass manufacturing business.

When you are going to be ordering in bulk, you need to save up on costs as much as you can. The more you save up, the more profit you can make when reselling. Furthermore, lower costs can allow you to set lower prices when selling. This can attract more customers and your sales can increase.

In the initial period of your business, you want to build trust with your customers and give them more value than they expect. The best way you can achieve this is by making your products available for less than the average price. And this can only be done if you are saving up on costs yourself.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

This is a very useful benefit for small start-up companies. Generally, manufacturers in the USA are not going to be very willing to work with you unless you are a big company or unless you have a large recognition and following. Due to this, smaller companies can have trouble getting their demands heard. However, the refusal of suppliers to do so is not unjustified. Smaller companies are going to start off with smaller orders. Small orders are not very lucrative and beneficial for suppliers. The larger the order, the more convenient it will be for the manufacturer.

However, with Chinese manufacturers, this problem is minimized. The Chinese often don’t care how big a brand you are and what recognition your company has. As long as you meet the minimum order requirements, you can get your products easily. This is highly advantageous for smaller companies. Due to this, smaller firms can get started and kick off their business.

When it comes to LCD modules, the orders are not received by the hundreds or thousands as is the case with other smaller products such as handbags and wallets etcetera. One module can cost around $250, and it is for this reason that the dynamics are a little different with this business. That is why STONE offers single pieces for sale as well as multiple pieces. This encourages smaller businesses to make their purchases since they can easily purchase as many modules as they like. As long as you meet the limit stated by the supplier, you are good to go.

Typically, when you are paying less, you can have the expectation that the quality might not be good or the time taken may be too long. However, when you are buying from the Chinese, you don’t have to face any of these problems. While you are paying less, you can get satisfactory quality and even the production time is cut down.

The factories in China have more machines and workers working simultaneously. This means that you can get bigger orders more quickly. For example, if you are getting 10 units from a domestic supplier in 4 days, you will be able to get 12 units from a Chinese supplier in just 3 days. That means that the production rate is increased, and the time taken is also cut short. This is merely an example to show that both aspects of production are enhanced when you do business with the Chinese.

Another great benefit of getting production done in China is the option for expansion. What that means is that while you can transport your merchandise to your home country, you also have the option of making them available in China. Instead of only bringing the goods back home to resell, you can set up a business that makes your merchandise available for sale in China as well.

In the case of LCD modules, this benefit relates to a reselling business. For example, if you are planning on buying some modules to use in your machines etcetera, then there is not a very suitable opportunity for you to expand. If you want to start a business in another country, you will have to open a manufacturing unit there so that your products can be produced and then get sold. Or, you will have to transport your final products to the other country in order to run your business.

However, if you are buying the LCD modules to resale at a profit, you can use the Chinese markets to grow your business. You can buy the modules at a reduced price and then sell them at a profit in a different area or city where the people will be willing to pay more.

Now that we have seen the benefits of choosing Chinese manufacturers for LCD modules, let us narrow it down a bit and look at why you should choose STONE specifically.

With STONE, you get the option of buying a range of different-sized modules. If your business deals in making different electronics and machines that require panels of different sizes, you don’t have to look at multiple suppliers to fulfill your need. You could be making some products that require 3.5-inch panels, while some of your machines could be needing 15.1-inch modules. Instead of taking the trouble to go to different suppliers, you can enjoy an all-in-one experience from STONE.

STONE offers its customers ease when it comes to making a purchase. Generally, wholesalers and suppliers sell their merchandise in bundles of 10, 50, 100, etc. However, the STONE store gives you the option of buying single pieces so that you can buy as much as you presently need.

One of the main things that you have to look at in any supplier is the level of reliability and trust. This is usually determined by the level of experience and the time that the supplier has spent in the market. STONE was founded in 2010 and has been producing LCD modules for the past 10 years.

If you are looking to buy LCD modules in bulk, look no further than the Middle Kingdom. China has become the hub of mass manufacturing and is the favorite spot for wholesalers and business owners.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

We"ve been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Meaning Of Tft Display, Transparent Lcd, Lcd Touch, Small Touchscreen Monitor,Ips Lcd Module. We are sincerely looking forward to cooperate with buyers all around the world. We imagine we will satisfy you. We also warmly welcome shoppers to visit our organization and purchase our merchandise. The product will supply to all over the world, such as Europe, America, Australia,Lebanon, Bahamas,Paraguay, Hyderabad.In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

One of the main benefits that you get with Stoneitech.com is that there is a wide range of diverse products that you can purchase. For example, there are three different application types that you can choose from which include the Industrial Type, Advanced Type, and Civil Type. Similarly, there is a range of different sizes that you can choose from. There are 11 different sizes that you can buy, ranging from the smallest 3.5-inch display to the large 15.1-inch one. The same goes for the Android series which where you can choose between 4.5-inch and 31.5-inch displays.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

The factories in China have more machines and workers working simultaneously. This means that you can get bigger orders more quickly. For example, if you are getting 10 units from a domestic supplier in 4 days, you will be able to get 12 units from a Chinese supplier in just 3 days. That means that the production rate is increased, and the time taken is also cut short. This is merely an example to show that both aspects of production are enhanced when you do business with the Chinese.

Another great benefit of getting production done in China is the option for expansion. What that means is that while you can transport your merchandise to your home country, you also have the option of making them available in China. Instead of only bringing the goods back home to resell, you can set up a business that makes your merchandise available for sale in China as well.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

With this motto in mind, we"ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Meaning Of Tft Display, Serial Tft Display, Lcd Industrial Monitor, Lcd Screen Tester,Lcd Flat Panel Display. Sincere cooperation with you, altogether will create happy tomorrow! The product will supply to all over the world, such as Europe, America, Australia,Accra, Bhutan,Cairo, Belgium.On today, we"ve got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We"ve been looking forward to doing business with you!

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

TFT-based displays have a transistor for each pixel on the screen. This allows the electrical current that illuminates the display to be turned on and off at a faster rate, which makes the display brighter and shows motion smoother. LCDs that use TFT technology are called "active-matrix" displays, which are higher-quality than older "passive-matrix" displays. TFT technology provides the best resolution of all the flat display technologies, but it is also expensive than monochrome lcd. So TFTs are used in high-quality LCD displays, if you see a LCD monitor at your local computer market, it should be an active tft lcd display, Basically, it is a high-quality tft lcd monitor.

Passive-matrix display. A passive-matrix display is anLCD screen display that contains a series of wires that cross each other. See the dual scan display for a full definition on this term.

What is an Active-matrix Display (TFT)? Alternatively referred to as TFT ( thin-film transistor) and AMLCD ( active-matrix LCD ), an active-matrix display is an LCD ( liquid crystal display) introduced with the IBM ThinkPad in 1992.

It uses a matrix of thin film transistors(TFTs) and capacitors to control the image produced by thedisplay. The brightness of each pixel is controlled by modifying the electrical charge of the corresponding capacitors.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

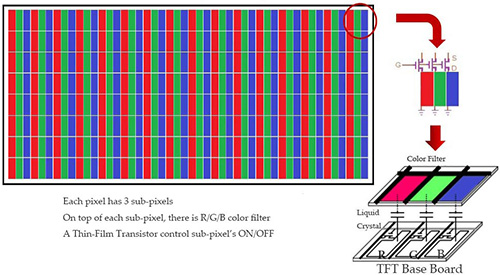

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp text/graphic with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The color TFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

This might come as a surprise to many, but the majority of TFTS (Thin Film Transistor) displays are manufactured in China. So, when China has a holiday or other shut down, your production line suffers.

Many times, the delay is longer than the period of time the factories were closed. This is especially true with the dreaded Chinese New Year. They are shut-down for two weeks, but delays can last more than a month due to the slow return of workers and all the backlog they need to work through.

So, what is the solution? Pull money out of the bank and invest it in LCD inventory. It makes no sense to have your cash in the bank earning .01% interest when you can invest it for future production.

That is why we pulled our money out and purchased inventory on all our TFT"s (including Resistive and Capacitive touch). Now when you need a sample or your production ramps up. We have you covered.

This is in reply to your letter dated August 15, 2002, on behalf of Hitachi Electronic Devices (USA), Inc. (Hitachi) concerning the country of origin of a device that will result from manufacturing operations in China. You seek a ruling that the device, a Thin Film Transistor (TFT) Liquid Crystal Display (LCD) module will be considered a product of China for the purposes of country of origin marking under Section 304 of the Tariff Act of 1930, as amended (19 U.S.C. §1304).

The Hitachi TFT LCD module that is the subject of this ruling is used to display the image on cellular telephones, digital cameras, car navigation systems and other devices.

All parts and materials used in the China manufacturing operations are of Japanese origin. These parts and materials consist of: The TFT LCD No Cutting Cell; the Flexible Printed Circuit; and module parts. The module parts include: liquid crystal agent, epoxy acrylic resin, upper and lower side polarizers, integrated circuit chips, epoxy film, light guide unit, plastic mold, and tapes and resins. There are two main aspects of the Chinese manufacturing operations: 1) production of the TFT LCD Cell from the TFT LCD No Cutting Cell; and 2) assembly of the TFT LCD Module.

Production of the TFT LCD Cell from the No Cutting Cell consists of breaking and cutting the prepared materials into 32 pieces, filling the cells with liquid crystal agent under vacuum conditions, drying and hardening, sealing the filling entrance, and rounding sharp edges, washing and quality inspection.

The TFT LCD Cell is the component that forms the basis of the module. First the cell is covered with a polarizer on both sides. Then the Flexible Printed Circuit is attached at the edge. Then a light guide unit and cover sheet are attached. Finally, the unit is encased in a plastic mold and sealed with adhesive.

The submission is supported by manufacturing flow charts and other technical materials setting forth the operations performed. This office has relied upon them in its evaluation.

You submit that the operations described here concern a product that is identical except for size to a product that was reviewed by this office in Headquarters Ruling Letter (HQ) 562385 (May 14, 2002). In that ruling it was concluded that the production of a TFT LCD module for notebook and desktop computers effected substantial transformation of the individual components, and that the production operations resulted in a product of China. It is urged that the same conclusion is appropriate for the instant operations.

Do the manufacturing operations in China result in substantial transformation of the materials from Japan such that the completed TFT LCD module may be marked as a product of China?

Section 304 of the Tariff Act of 1930, as amended (19 U.S.C. 1304), provides that, unless excepted, every article of foreign origin imported into the United States shall be marked in a conspicuous place as legibly, indelibly, and permanently as the nature of the article (or its container) will permit, in such a manner as to indicate to the ultimate purchaser in the United States the English name of the country of origin of the article. By enacting 19 U.S.C. 1304, Congress intended to ensure that the ultimate purchaser would be able to know by inspecting the marking on the imported goods the country of origin of which the goods were the product. The evident purpose is to mark the goods so that at the time of purchase the ultimate purchaser may, by knowing where the goods were produced, be able to buy or refuse to buy them, if such marking should influence his will. United States v. Friedlander & Co., 27 C.C.P.A. 297, 302 C.A.D. 104 (1940).

The country of manufacture, production, or growth of any article of foreign origin entering the United States. Further work or material added to an article in another country must effect a substantial transformation in order to render such other country the “country of origin” within the meaning of this part; however for a good of a NAFTA country, the NAFTA Marking Rules will determine the country of origin.

Accordingly, the country of origin of an article is the country in which it was wholly grown, or, if processed in several countries, the country in which the last substantial transformation occurred. The well-established test for determining whether a substantial transformation has occurred is derived from language enunciated by the court in Anheuser-Busch Association v. United States, 207 U.S. 556, 562 (1908), which defined the term “manufacture” as follows:

Manufacture implies a change, but every change is not manufacture and yet every change in an article is the result of treatment, labor and manipulation. But something more is necessary, as set forth and illustrated in Hartranft v. Wiegmann, 121 U.S. 609. There must be transformation; a new and different article must emerge, having a distinctive name, character or use.

In determining whether a substantial transformation occurs in manufacture by combining of parts or materials, the inquiry concerns the extent of operations and whether the parts lose their identity and become an integral part of the new article. Belcrest Linens v. United States, 3 CIT 204, 573 F. Supp. 1149 (1983), aff’d 2 Fed. Cir. 105, 741 F. 2d 1368 (1984).

Based on the facts provided, it is our opinion that the assembly of the various components used in producing the TFT/LCD module in China, effects a substantial transformation of the individual components. The numerous individual components, which are made in Japan, lose their identity and become integral part of the new article – TFT/LCD module. The assembly operations are also not minimal or simple. Thus, the TFT/LCD module as imported into the United States qualifies as a product of China and therefore should be marked as such. This office is in agreement with you that the conclusion reached in HQ 562385 is applicable to the production operations described herein.

Also, you have asked whether the TFT-LCD modules may be marked “Made in China” or Assembled in China from foreign (Japanese) components”. Either of these markings would be acceptable. “Assembled in…from components of…” is specifically approved under 19 CFR 134.43(e).HOLDING:

The operations described in the submission result in substantial transformation such that the TFT-LCD module is considered to be a product of China for the purposes of country of origin marking under Section 304 of the Tariff Act of 1930, as amended. The marking indications proposed are acceptable.

A copy of this ruling letter should be attached to the entry documents filed at the time the goods are entered. If the documents have been filed without a copy, this ruling should be brought to the attention of the Customs officer handling the transaction.

KING TECH is a TFT LCD IPS supplier solution specialist since 2003, we are the group company combined byAn Innolux authorized LCD panel&IC distribution company

We Provide Different Kinds of Custom TFT Display ServicesIf needed we can make custom size tft displays for customers, we have a good relationship with original TFT display module factories, and we can negotiate with them to tool up an LCD panel mask. The tooling cost will be very high and paid by the end customer, and MOQ is at least 25K/lot.

We are capable to change every structure of the TFT display module. To increase backlight brightness and make it sunlight readable, the highest brightness we’ve ever reached was 6500cd/m2.To change the display FPC shape and length. To customize a resistive touch panel(RTP) or capacitive touch panel(CTP/PCAP), we have a long-term cooperation supplier to work with us on such tooling, for CTP, we can also make different shapes and thicknesses of cover glass, single touch, and multi-touch, AG/AR/AF is also available.

With our own PCBA hardware& software design company, we can design different kinds of TFT display modules for our customers, from simple convert boards to complete motherboards, from HDMI driver boards to Android controller boards, from non-touch function boards to capacitive touch function boards, they are all part of our working.

We have our own TFT display module panel and driver distribution department, if you want to switch to another structure of display, we can also help, cause we know which TFT display module panel and the driver is more match, and which suit’s supply is more stable, which one we can get the lowest price.

In order to give the customer the best support, Kingtech, as one of the best TFT LCD IPS suppliers in China, also can provide industrial solutions such as developing a mother board, serial port UART board, T-CON board, HDMI board, and monitor according to the customer"s requirements.

Kingtech also has existing industrial solutions for the PV135 motherboard, PV901 Linux board, and PV804 motherboard. They can be connected between Raspberry pi and our TFT display module, which can make them work together.

For serial port UART board, Kingtech has a 2.8inch 240x320 LCD with serial port UART board, 3.5inch 320x480 module with serial port UART board, 4.3inch 480x272 display with a resistive touch with serial port UART board, 7inch 800x480/1024x600 TFT with capacitive touch with serial port UART board.

For the HDMI board, Kingtech has a 1.39inch 454x454 AMOLED round with HDMI board, 3.34inch 320x320 TFT round with HDMI board, 3.4inch 800x800 TFT round with HDMI board, 5inch 1080x1080 TFT with HDMI board, 4.3inch 800x480 TFT with HDMI board, 5inch 800x480 LCD with HDMI board, 7inch 800x480/1024x600 LCD display with HDMI board, 10.1inch 1280x800 LCD module with HDMI board.

Above all TFT display modules with board products can be used for industrial equipment, medical, smart-home, or others. Kingtech can also have industrial custom TFT display solutions according to the customer’s requirements. Ware is welcome to contact us. If you are interested in any tft display module products, we can negotiate with you at a reasonable TFT LCD display price. Thank you.

TFT display module is a Thin Film Transistor, and AMOLED is Active-matrix organic light-emitting Display. The TFT display module is backlight-on the liquid crystal panel; AMOLED is a panel that emits light on its own; TFT display module structure is more thick and strong, AMOLED is very thin and also weak, TFT display module is used widely than AMOLED, AMOLED is used in consumer products the most, like a smartwatch, mobile phone, and TV.

IPS is In-Plane Switching, It is also known as free viewing angle, which means the viewing angle of the display on 4 sides is the same, a normal display has its best viewing angle like 6 o’clock or 12 o’clock. While the TFT display module contains normal viewing angles and IPS display,IPS display is a kind of TFT display module.

TFT display module belongs to LCD, LCD is Liquid Crystal Display, it contains mono(single color) LCD and color LCD, single color LCD is barely used now, and color LCD has STN and TFT two types. Therefore, TFT display module is a kind of LCD display.

OLED is Organic Light Emitting Display, it is a display that emits light on its own, and it does not need an extra backlight, so it requests lower power consumption than TFT display module but its lifetime is shorter than TFT(5000 hours), AMOLED is a kind of OLED but it is more colorful. TFT display module requests a backlight to light on and power consumption are higher than OLED, but its lifetime is much longer(20000 hours).

The LED display is working by lighting up the LED lights, the TFT display module is lighted up by the backlight and the liquid crystal starts to work and shows contents. TFT display module has brighter and more true color, and lower price and LED display has lower power consumption, smaller heat, and longer lifetime.

Compares to other types of display, TFT display module is the more widely used, it can be made in different shapes and sizes, from very small sizes to big sizes. The resolution now is higher and higher, and the price of custom TFT display modules is more and more competitive. Its lifetime is longer than the OLED display, and its color is brighter than OLED.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

TFT LCD modules are thin film field effect transistors. The so-called thin film transistor means that each liquid crystal pixel on the liquid crystal display is driven by a thin film transistor integrated behind it so that it can display screen information with high speed, high brightness, and high contrast. The composition of the liquid crystal display is not complicated. The liquid crystal panel plus the corresponding driving board (also called the main board, whose compositional structure is not intended to be the row and column driving circuit in the liquid crystal panel), power supply board, high voltage board, button control board, etc., constitute a complete liquid crystal display.

Power supply part: The power supply circuit of the liquid crystal display is divided into two parts: switching power supply and DC/DC converter. Among them, the switching power supply is an AC/DC converter, its function is to convert the AC 220V or 110V (European standard) into a 12V DC power supply (some models are 14V, 18V, 24V, or 28V), supply DC/DC Converter and high-voltage board circuit; DC/DC DC converter is used to convert the DC voltage (such as 12V) generated by the switching power supply into 5V, 3.3V, 2.5V and other voltages, which are supplied to the driver board and the liquid crystal panel.

The driver board of the TFT LCD screen is also called the main board, which is the core circuit of the liquid crystal display. It is mainly composed of the following parts: input interface circuit, A/D conversion circuit, clock generator, Sealer circuit, microcontroller circuit, and output interface circuit.

Key board part: The key circuit is installed on the key control board, and the indicator lights are generally also installed on the key control board. The function of the key circuit is to make the circuit on and off. When the switch is pressed, the key electronic switch is turned on, and when the hand is released, the key electronic switch is turned off. The switch signal output by the key switch is sent to the MCU on the driver board. After being recognized by the MCU, the control signal is output to control the relevant circuit to complete the corresponding operation and action.

High-voltage board part: The high-voltage board is commonly known as a high-voltage strip (because the circuit board is generally long and in the form of a strip), and is sometimes called an inverter circuit or an inverter. Its function is to convert the low-voltage DC voltage output by the power supply into a liquid crystal panel ( The high-frequency high-voltage AC above 600V required by the Panel) that lights the backlight on the LCD panel. The high-voltage board of the TFT LCD screen mainly has two installation forms: 1. A dedicated circuit board; 2. It is installed together with the switching power supply circuit (the switching power supply adopts the internal type).

LCD panel part: The LCD panel is the core component of LCD, mainly including the LCD screen, LVDS receiver (optional, LVDS LCD screen has this circuit), driver IC circuit (including source driver IC and gate driver IC), timing sequence Control IC (TC0N) and backlight.

We are more open, more inclusive, providing more competitive 3 5 Inch Tft Lcd Screen Mcu, 7 Inch IPS Display Screen, 7 0 Inch IPS Display for customers, with more preferential prices, more professional services, consulting, after-sales service a whole set of system to do more perfect. We ensure the high quality and consistency of our products and are able to meet the cutting-edge needs of different customers" products. With scientific management means and strong technical force, we will continue to deepen the reform, innovate the mechanism, adapt to the market and develop in an all-round way. We are introduced as a one of the growing manufacture supplier and export of our products. Our products are the best. Our company is constantly recruiting, we are confident to enter the international market.

This company conquered us with their professional industry knowledge, rich industry experience and warm service. We are looking forward to the next cooperation.

2.8 inch tft module screen display HC-280HX3301 is a 2.8 inch tft module LCD display module with an optional resistive touch screen and capacitive touch screen control with a resolution of 240×320...

2.8" 240x320 IPS TFT LCD Display Panel Optional Touch Panel Wide View US$9.00 8051 Microcontroller/MCU Development Board for TFT LCD ER-TFTM028-4 US$28.56 SPI Arduino 2.8"TFT Touch Shield Example...

This 2.8” TFT LCD module is featured with 240(RGB)x320 Dots resolution, it can be operating at temperatures from -20℃ to +70℃. Contact us for wholesale price! ... 2.8 Inch LCD Display....

The TFT display is a kind of LCD that is connected to each pixel using a transistor and it features low current consumption, high-quality, high-resolution and backlight. This 2.8-inch full color LCD...

2.8 inch TFT LCD – This HC-280CI2410 module has built-in ST7789V controller IC, supports MCU interface, power supply voltage (VCC) range is 3.0V to 3.6V, brightness is 380 nits (typ), and...

Sep 25, 2022 · This 2.8″ TFT LCD is a full color display with a resolution of 240 x 320 pixels or 320 x 240 pixels depending on how it is oriented. It uses the ILI9341 controller with SPI interface....

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Industrial Tft Display, 4.3 Inch RGB LCD Display, 4.8 Inch IPS, 4.3 Inch TN. We"re well-known as one of the leading 2.8 Inch TFT LCD Display manufacturers and suppliers in China. Our factory offers high quality 2.8 Inch TFT LCD Display made in China with competitive price. Welcome to place an order.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey