temp glass tft lcd display free sample

Focus Displays offers a wide range of standard full color TFT displays. 64 million unique colors, high brightness, sharp contrast, -30C operating temperature, and fast response time are all good descriptions of a TFT display. This is why TFT technology is one of the most popular choices for a new product.

Thin Film Transistor (TFT) display technology can be seen in products such as laptop computers, cell phones, tablets, digital cameras, and many other products that require color. TFT’s are active matrix displays which offers exceptional viewing experiences especially when compared to other passive matrix technologies. The clarity on TFT displays is outstanding; and they possess a longer half-life than some types of OLEDs and range in sizes from less than an inch to over 15 inches.

CCFL’s are still available, but are becoming a legacy (obsolete) component. TFT displays equipped with a CCFL require higher MOQs (Minimum Order Quantities) than displays with LED backlights.

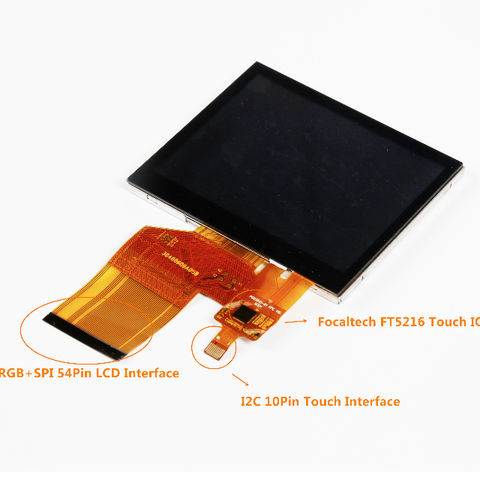

The majority of TFT displays contain a touch panel, or touch screen. The touch panel is a touch-sensitive transparent overlay mounted on the front of the display glass. Allowing for interaction between the user and the LCD display.

Some touch panels require an independent driver IC; which can be included in the TFT display module or placed on the customer’s Printed Circuit Board (PCB). Touch screens make use of coordinate systems to locate where the user touched the screen.

Resistive touch panels are the lowest cost option and are standard equipment on many TFT modules. They are more common on smaller TFT displays, but can still be incorporated on larger modules.

Custom resistive touch screens are an option if the customer requires a seal or gasket to be in contact with the glass and not in contact with the touch panel.

They also have the added advantage of operating in a wide temperature range and environments, including anything from the arctic cold of Alaska to the extreme heat of Death Valley.

Contrast ratio, or static contrast ratio, is one way to measure the sharpness of the TFT LCD display. This ratio is the difference between the darkest black and the brightest white the display is able to produce. The higher the number on the left, the sharper the image. A typical contrast ratio for TFT may be 300:1. This number ratio means that the white is 300 times brighter than the black.

TFT LCD displays are measured in inches; this is the measurement of the diagonal distance across the glass. Common TFT sizes include: 1.77”, 2.4”, 2.8”, 3”, 4.3”, 5”, 5.7”, 5.8”, 7”, 10.2”, 12.1 and 15”.

As a general rule, the larger the size of the glass the higher the cost of the display, but there are exceptions to this rule. A larger display may be less expensive than a smaller display if the manufacture produces higher quantities of the larger displays. When selecting your color display, be sure to ask what the cost is for one size smaller and one size larger. It may be worth modifying your design requirements.

TFT resolution is the number of dots or pixels the display contains. It is measured by the number of dots along the horizontal (X axis) and the dots along the vertical (Y axis).

The higher the resolution, the more dots per square inch (DPI), the sharper the display will look. A higher resolution results in a higher cost. One reason for the increase in cost is that more driver chips are necessary to drive each segment.

Certain combinations of width and height are standardized and typically given a name and a letter representation that is descriptive of its dimensions. Popular names given to the TFT LCD displays resolution include:

Transmissive displays must have the backlight on at all times to read the display, but are not the best option in direct sunlight unless the backlight is 750 Nits or higher. A majority of TFT displays are Transmissive, but they will require more power to operate with a brighter backlight.

Transflective displays are readable with the backlight off provided there is enough ambient light. Transflective displays are more expensive than Transmissive also there may be a larger MOQ for Transflective. However, Transflective displays are the best option for direct sunlight.

Drivers update and refresh the pixels (Picture Elements) of a display. Each driver is assigned a set number of pixels. If there are more pixels than a single driver can handle, then an additional drivers are added.

A primary job of the driver is to refresh each pixel. In passive TFT displays, the pixel is refreshed and then allowed to slowly fade (aka decay) until refreshed again. The higher the refresh frequency, the sharper the displays contrast.

The controller does just what its name suggest. It controls the drivers. There is only one controller per display no matter how many drivers. A complex graphic display with several thousand pixels will contain one controller and several drivers.

The TFT display (minus touch screen/backlight) alone will contain one controller/driver combination. These are built into the display so the design engineer does not need to locate the correct hardware.

If you do not see a Thin Film Transistor (TFT) Display module that meets your specifications, or you need a replacement TFT, we can build a custom TFT displays to meet your requirements. Custom TFTs require a one-time tooling fee and may require higher MOQs.

Ready to order samples for your TFT design? Contact one of our US-based technical support people today concerning your design requirements. Note: We can provide smaller quantities for samples and prototyping.

As an option, you can order this TFT pre-assembled onto a breakout/carrier board. The board allows easy prototyping through its 0.1" headers. You can also include the carrier board in your end product to simplify construction and assembly.

This development kit includes everything needed to get started with the 3.5" EVE module: a 320x240 display mounted on an EVE2 graphically accelerated PCBA, a Seeeduino, an EVE breakout board, jumper wires, USB cable and a ribbon cable. We even assemble this kit and pre-load some demonstration software so that you can have a functioning module in your hands within seconds.

Because the display module includes an EVE (embedded video engine) chip, it"s a perfect choice for an HMI. EVE is a graphics controller solution that can control both display and audio operations. Additionally, Bridgetek/FTDI supports the EVE chip with graphical design toolchains to aid in development.

This kit consists of a CFAF320240F-035T a 320x240 3.5" Full Color TFT LCD module mounted on a carrier board (CFA-10074). The carrier board supports a current driver for the LED backlight of the display.

This TFT LCD display module is perfect for the designer who"s looking to have a graphic and audio processor already embedded in the display unit. Powered by an FTDI/BridgeTek FT810 Embedded Video Engine (EVE) graphics accelerator chip, simply send over a few commands via SPI or I2C and the EVE will put your stored image up on the display. Need to draw a line, create dials/knobs/buttons, or rotate an image? Send a handful of bytes and the EVE will take care of it.

Panox Display provides free connectors for clients who purchase more than five products from us. Our product range includes connectors from Molex, Kyocera, AXE, AXG, JAE, Hiros, and more.

Panox Display provides a customized cover glass/touch panel service. We supply cover glass from Gorilla, AGC, and Panda, which all have excellent optical performance. We also supply driver ICs from Goodix and Focaltech.

If your applications are directly connected to a PC, a cellphone, or Raspberry Pi, and you have enough space to insert a board to input video, Panox Display can provide customized Controller/Driver boards with input connections for VGA, HDMI, DVI, DP, Type-C video input, MIPI, RGB, LVDS, and eDP.

Established in 2010, Topfoison has devoted itself to the manufacturing and development of high-quality products for the Wearable device, Smart Watch, VR, Medical device, Industrial LCD display including Color LCD modules/OLED/LCD display/Round lcd screen/Round AMOLED/ Square transflective lcd screen/ IPS full wide display/ 1080p fhd AMOLED and 2K 1440p lcd. Topfoison focus on1.22-7.0 inch small size displays, all the products produced in our company enjoys the most advanced production craft and technology as well as the strictly ISO quality management system.

Established in 2010, Topfoison has devoted itself to the manufacturing and development of high-quality products for the Wearable device, Smart Watch, VR, Medical device, Industrial LCD display including Color LCD modules/OLED/LCD display/Round lcd screen/Round AMOLED/ Square transflective lcd screen/ IPS full wide display/ 1080p fhd AMOLED and 2K 1440p lcd. Topfoison focus on1.22-7.0 inch small size displays, all the products produced in our company enjoys the most advanced production craft and technology as well as the strictly ISO quality management system.

Orient Display is a company that specializes in manufacturing LCD glass panels, glass display screen, glass panel display, glass LED display,cover lens glass and other panels with glass. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years,Orient Display factory is now the world’s lead display glass panel manufacturer in flat panel industry and is listed as a public company in China stock market. Orient Display factory has 4 plants that can produce lcd glass panels. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. LCD display glass panel is a traditional product, Orient Display is always working on the ways to reduce glass panel price and cost to meet the simple display market requirement.

Orient Display LCD display panels include different options of polarizer in reflective (saving power), transmissive (better contrast) or transflective (sunlight readable and battery powered) types. Orient LCD glass panels include 1; 2; 2.1/2; 3; 3.1/2; 3.3/4; 4; 4.1/2; 5; 6; 8; and 24 digits. Orient LCD glass panels also include 7 , 14 or 16 segments to display digits and alphanumeric letters. The temperature ranges are from room temperature to wide temperature applications. Orient LCD glass panels can have metal pin or zebra connections. Some of them have different color backlight (blue, white, Yellow-green, pure green and amber) available.

We understand that the standard LCD display screens can’t meet the customer’s various requirements, Orient Display offers custom made LCD glass panel with low NRE (tooling cost), low MOQ, fast sample, and production lead time. Orient Display is proud to have all the display technologies related with LCD glass panel displays.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

There a lot of considerations for how to choose a most suitable TFT LCD display module for your application. Please find the check list below to see if you can find a right fit.

It is the start point for every project. There aretwo dimensions to consider: outside dimension (width, height, thickness) and AA (active area or pixel area). Orient Display’s standard product line ranges from 1.0” to 32”. Our OLED size can go down to 0.66” which fit for wearable devices.

Resolution will decide the clearance. Nobody likes to see a display showing pixel clearly. That is the reason for better resolution, going from QVGA, VGA to HD, FHD, 4K, 8K. But higher resolution means higher cost, power consumption, memory size, data transfer speed etc. Orient Display offers low resolution of 128×128 to HD, FHD, we are working on providing 4K for our customers. For full list of resolution available, please see Introduction: LCD Resolution

TFT screen brightness selection is very important. You don’t want to be frustrated by LCD image washout under bright light or you drain the battery too fast by selecting a super brightness LCD but will be used indoor only. There are general guidance listed in the table below.

Orient Display offers standard brightness, medium brightness , high brightness, and high end sunlight readable IPS TFT LCD display products for our customers to choose from.

If the budget is tight, TN type TFT LCD can be chosen but there is viewing angle selection of either 6 o’clock or 12 o’clock. Gray scale inversion needs to be taken of carefully. If a high-end product is designed, you can pay premium to select IPS TFT LCD which doesn’t have the viewing angle issue.

It is similar to viewing angle selection, TN type TFT LCD has lower contrast but lower cost, while IPS TFT LCD has much high contrast but normally with higher cost. Orient Display provides both selections.

Normal TFT LCD displays provide wide enoughtemperature range for most of the applications. -20 to 70oC. But there are some (always) outdoor applications like -30 to 80oC or even wider, special liquid crystal fluid has to be used. Heater is needed for operating temperature requirement of -40oC. Normally, storage temperature is not an issue, many of Orient Display standard TFT display can handle -40 to 85oC, if you have any questions, feel free to contact our engineers for details.

Power consideration can be critical in some hand-held devices. For a TFT LCD display module, backlight normally consumes more power than other part of the display. Dimming or totally shutdown backlight technology has to be used when not in use. For some extreme power sensitive application, sleep mode or even using memory on controller consideration has to be in design. Feel free to contact our engineers for details.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

If you can’t find a very suitable TFT LCD Display in our product line, don’t be discouraged. The products listed on our website is only small part of standard products. We have thousands of standard products in our database, feel free to contact our engineers for details.

If you like to have a special display, Orient Display is always flexible to do partial custom solution. For example, to modify the FPC to different length or shape, or use as fewer pinouts as possible, or design an ultra-bright LCD display, or a cover lens with your company logo on it, or design an extreme low power or low cost TFT display etc. our engineers will help you to achieve the goals. The NER cost can start from hundreds of dollars to Thousands. In rare case, it can be tens of thousands of dollars.

A fully custom TFT LCD panel can have very high NRE cost. Depending on the size of the display, quantity and which generation production line to be used. The tooling cost can start from $100,000 to over $1M.

NHD-320240WG-ATMI-TZ# | Monochrome Graphic Module | 320x240 Pixels | Transmissive LCD | White Backlight | STN (-) Negative Blue Display | Built-in Negative Voltage | Built-in Temperature Compensation

Newhaven 320x240 graphic Liquid Crystal Display module shows white pixels on a blue background. This transmissive LCD Display requires a backlight for visibility and offers a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-320240WG-ATMI-TZ# display includes temperature compensation as well as built-in negative voltage. It has an optimal view of 6:00, operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

As you can see in the table above, with chemical strengthening we can make glass even 6 or 8 times mechanically stronger than the regular one. This is a very long process; it can take several hours, and we need hot temperature, 400 or more degrees. Thermally tempered glass is a separate way of strengthening glass. We use hot temperature and very fast cooling to make the glass stronger. We need a higher temperature, 700 degrees in this process, but it is much faster, it takes just several minutes, and we achieve strong glass, 4 to 5 times stronger than regular float glass. Thermally tempered glass is not as strong as chemically strengthened glass. It is cheaper, but we cannot use it for thin glass. The thinnest glass that we can thermally temper is 3-4 millimeter. If the glass is thinner, with hot temperature it starts floating and the surface will not be flat again. So, if we have a thick glass, it would be cheaper to use the thermally tempered solution. That is why it is more popular. For thinner glass we use chemical strengthening, because we cannot use the thermally tempered solution.

Now we will talk about the other difference between these two methods of strengthening glass. On the left side of the picture above, you can see chemically strengthened glass broken, and on the right side there is thermally tempered glass broken. Chemically strengthened glass breaks like regular glass because we do not change the internal part of the glass. We only make the surface stronger, but inside the glass is the same as regular float glass, and it breaks just like it. Thermally tempered glass changes the internal structure of the glass and it breaks into very small pieces. In many cases it is better because it is safer for humans, that is why we normally use thermally tempered glass in cars or in places where broken glass may injure people.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now we know how glass is made, how it is being strengthened, how it breaks and what types of glass, Float and Optiwhite, we have. To continue, we will talk about surface treatments other than strengthening. The other treatments that we use are anti-glare, anti-fingerprint, anti-reflective and anti-bacterial. About anti-reflective treatment we have talked in another video about

On the picture above there are examples of glass. One of them is a little bit blurry, it is anti-glare and the other one is clear – it is anti-reflective. In the past, anti-glare glass was more popular and used in some commercial devices, but later manufacturers have found that devices with anti-glare are being sold less frequently than the glare ones. It is because as humans we think that there is something wrong with a little bit blurry image even if the reflections are lower. When we are in a shop and looking at phones, we do not see the image clearly and we think that there is something wrong and we do not want this device. That is why we do not see any more anti-glare glass in consumer products. Everything is glare in consumer products, it could be anti-reflective or could be only regular without any surface treatment. But in the professional market that we are working on, like medical devices, military devices, we have many projects where we use anti-glare and anti-reflective treatments, both solutions to reduce reflections and increase contrast.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

This scale is about surface hardness – how hard is it to scratch the surface. As you know, even glass with hardness 9 can be scratched, everybody has some scratches on their phone because this hard layer is very thin – 10 micrometers only. If we put enough force and break this barrier, then we have soft glass with hardness 6 or even lower, that is why we have the scratches.

A couple more words about Gorilla glass. Now there is the sixth generation of Gorilla Glass on the market. The goal for Corning company and Gorilla Glass is to make the glass as strong and as light as possible, because most of the cases are handheld devices, where we want the glass to be light, that is why we want to make it very thin. We have also other companies that are making equivalents of Gorilla Glass, like Dragontrail from AGC or Xensation from Shott. They are not so popular but in many mobile phones or tablets on the market you can find these types of glass.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

When we do the Screen Printing, we need a screen for each color, so to minimize cost, we try to reduce the number of colors to 2–4, like the background and the colored logo. Each color is a different process, we need to wait until the previous painting dries and then we need to put another screen and print another color. More colors mean a longer process and of course a higher cost. Of course, we can change the shape of the glass, we can make rounded corners or custom design of the glass, but it is expensive because first it is just the rectangular piece, then you need to go to the CNC machine to make the proper shape of the glass.

Now we will talk about mechanical impact protection. It is different than the surface hardness we talked about before. On the picture above, we have the test and scale to measure the mechanical strength of glass, that means how much energy we can put on the glass before it breaks. It is measured in IK rate. IK rate is a scale where we have different levels and different energy that will boost. For example, if we want to test IK 9, we need to take 5-kilogram mass from 200-millimeter height. The mass is kept above the tested glass using an electromagnet, then we just drop it, and we see if it breaks or not. If not, of course the test is passed.

If the glass has not passed the test, we can try to change the glass type from thermally tempered to chemically strengthened or go to a thicker glass.

The last point in this article is laminated glass. We laminate glass because of a few reasons. First, what is laminated glass. Laminated glass is like putting the film inside two glass sheets. This process is expensive, we need pressure, we need temperature, we need time, and we need an exceptionally clean environment, because when we laminate together two sheets of glass, we need to be sure that no particles get inside. This kind of process needs to be done in a Clean Room, so it is expensive, but as you see on the picture above, even if the glass is broken, it still holds up because of the laminated film inside.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

An import function allows additionally to use Windows fonts. With the FontEditor it is easy to generate for example Cyrillic, Greek and Arabic fonts. The preview function shows immediately the size and style in simulation window. When the testboard EA 9780-2USB is connected to the USB port, you can see the character (or any predefined text) live on the display which is plugged-in!

A thermal image (thermographic) is a digital representation of thermal radiation emitted by pictured objects. Thermal image is captured by thermographic camera, which is a device capable of sensing radiation in the form of infrared light. With that, we are able to remotely measure the temperature of an object.

Temperature measurement in public places, is a good assessment to determine whether a person has elevated body temperature, potentially caused by COVID-19 infection. Thus, we could limit the spread of COVID-19.

Non-contact thermal imaging devices can quickly measure and display temperature reading on TFT LCD screen. So, a large number of people can be checked individually and quickly.

Suitable for different environments – high brightness, wide viewing angle, weather proof and anti-UV measurement enable TFT display working in both indoor and outdoor settings.

3.5 inch colour LCD from Topway is such TFT LCD that fits for handheld thermal imaging device. The screen features 480×320 resolution and 262K colors, can nicely present thermal image in fine details. Very low power consumption and compact in size make it perfect for hand-held thermal imaging application.

As we are transitioning out of the epidemic phase, businesses are re-opening. We see more and more information robots deployed across shopping malls, office buildings, transportation hubs, etc. These robots usually have infrared camera and TFT LCD touch screen installed. And they become the first line defence to weed out potential COVID-19 virus carrier. Moreover, the high-definition colour TFT LCD touch screen turns the robot into shopping guide, information desk, and advertising carrier, etc.

A Smart TFT LCD Display from Topway is perfect for thermal imaging device’s screen. Smart TFT LCD display embeds LCD driver, controller and MCU, sets engineer free from tedious UI & touch screen programming. HMT121ATA-D is a 12-inch Smart LCD display module with 1024 x 768 high-definition resolution, multi-touches capacitive touch screen.

Using touch screen LCD has become a normal practice in modern society. We are very much used to such Human Machine Interface. From cell phone display to thermal imaging system’s screen, TFT LCD display is a necessity in our day-to-day lives.

Boron Flat Panel Display Glass is an important mineral used in LCD and plasma television panels. It is commonly used in high-tech glass for LCD and plasma TV screens. Its use in these products significantly increased around 2000 as consumer preference shifted away from CRT TVs to flat-panel screens. Substitutes for boron are, however, beginning to appear given its presence in glass, which some consider an environmental hazard.

The term flat panel display (FPD) may be used to refer to any number of “flat” display technologies, such as liquid crystal displays (LCD), plasma displays, and field emission displays (FED).

FPDs use borosilicate glass primarily for TFT displays. Since flat panel displays (FPDs) have replaced cathode ray tubes (CRTs) in markets such as televisions (TVs) and computer monitors, thin-film transistor (TFT) glass has historically been an important market for borates. The most common type of FPD is the LCD, which utilizes TFTs glass in manufacturing the devices.

Using boron in flat panel display glass continues to be widespread. Boron exhibits advantages in heat resistance, processing range, and devitrification stability in Flat Panel Display Glass. Other benefits of boron in flat panel displays include improved brightness and colour rendering, and boron-infused glass can even improve the display’s contrast

Displays with TFTs are constructed using two sheets of alkaline-free borosilicate or boroaluminosilicate glass between which is a filling including TFTs (which control the electronic current to the pixels), transparent conductors, and colour filters.

The glass used in these substrates mustn’t contain alkaline elements, such as sodium, since these may interact with the TFT and degrade it. As a result of its purity, boric acid is commonly used to produce borosilicate TFT glass, which contains between 10-15% B₂O₃.

Boron’s low refractive index allows it to withstand high temperatures as well as thermal shock. Having the ability to be sealed to metal can make it an excellent choice for displays. Despite its lower density than soda-lime glass, it is still capable of breaking into large chunks. Creating flat panels requires a combination of low refractive index and low thermal shock resistance. Televisions rely on it for the technology behind flat panel displays.

Apart from TFT glass, borosilicate glass can also be used as a cover glass for touch screens on mobile devices such as smartphones and tablets. Asahi, for example, produces alkaline-free aluminosilicate glass for use in this market, so not all cover glass contains boron.

A form of borosilicate glass is also used to backlight LCD televisions and PC monitors with cold cathode fluorescent lamps (CCFLs). CCFLs began to be replaced by light-emitting diodes (LEDs) in the late 2000s, which do not use borosilicate glass.

However, there is a trend to lower usage of boron to reduce the volatile amount of boron during TFT-LCD base plate glass manufacturing. The presence of boron in flat panel display glass can cause an increase in the risk of radiation damage. It is a contaminant in flat panel display glass and will corrode it.

The use of boron in flat panel display glass is the subject of discussion in the industry, and the absence of this metalloid in the mirror makes the technology unreliable. Recently, substitute materials for TFT-LCD glassinclude rare earth elements such as lanthanum, yttrium, cerium, or Erbium. The rare earth elements are added to reduce the boron content in flat panel display glass.

The presence of boron in flat panel display glass is also a concern among consumers. While boron is harmless in small quantities, it is present in glass at levels that may be hazardous to the environment. The presence of boron in glass in flat-panel displays can also cause colour casts. Although the levels of uranium are low, this element is a significant pollutant that affects the performance of LCD and plasma panels.

Manufacturers of portable battery-operated devices, such as laptop computers, are particularly attracted by these properties. The switch away from borosilicate glass has probably been the greatest in this market.

TFT glass is primarily produced in Japan, South Korea, Taiwan, Singapore, and China. In addition, the logistical requirements of TFT glass panels require their production to take place mainly in these countries. Currently, only a few suppliers provide glass substrates for TFTs, mainly due to the high-quality requirements and the difficulty of manufacturing.

The largest manufacturer is Corning (including its joint venture with Samsung), but other companies include Asahi Glass, Nippon Electric Glass, and AvanStrate (formerly NH Techno Glass).

TFT-LCD sealing-in of the present invention is made up of the parent glass of (85~95) % (weight) and the low bulk mineral filler of (5~15) % (weight) with unleaded low-coefficient glass powder.Wherein, parent glass comprises the following component of forming by mass percentage: the Bi of (40~60) %

---the step of preparation parent glass; The method of this step is: earlier that each raw materials mix is even, process compound, and then said compound is smelted into glass metal in High Temperature Furnaces Heating Apparatus; After the glass metal cast molding, grind to form parent glass after being ground into parent glass or shrend again; The composition of each raw material and quality percentage composition thereof see table 1 for details.

---with said parent glass and beta-eucryptite microcrystalline glass powder thorough mixing and pulverize and process glass powder (being that unleaded low-coefficient glass is used in TFT-LCD sealing-in of the present invention); Wherein, the quality percentage composition of parent glass and beta-eucryptite microcrystalline glass powder is specifically seen table 2.

The prepared quality percentage composition that obtains parent glass of table 1 embodiment 1-11 is formed and relevant preparation technology ginseng

The prepared TFT-LCD sealing-in that obtains of table 2 embodiment 1-11 is formed and performance with the quality percentage composition of unleaded low-coefficient glass powder

The glass powder (being that unleaded low-coefficient glass is used in TFT-LCD sealing-in of the present invention) that embodiment 1-11 is finally processed carries out following performance analysis (referring to table 2):

Thermal expansivity, glass transformation temperature and softening temperature: 10g glass powder is put into mould; Press down the right cylinder that is made as Ф 12mm at 7MPa pressure; Place it in the glass block center then; Put into resistance furnace together and be heated to 450 ℃ with the temperature rise rate of 5~10 ℃/min, the sample mill that sinters is processed the right cylinder sample of Ф 5 * 25mm.This sample records out the thermal expansion curve through thermal dilatometer, analyzes the thermal expansion curve and can draw thermal expansivity, second-order transition temperature and softening temperature (referring to table 2).

Mobile: that 10g glass powder is put into mould; Press down the right cylinder that is made as Ф 12mm at 7MPa pressure; Make it on matrix, sprawl shape the right cylinder heat fused then into button; Through measuring the mean diameter of this " button ", diameter all surpasses 27.4mm, shows that prepared sample 1~11 all has good flowability (referring to table 2).

Chemicalstability: glass powder is pressed into the bulk sample of 1cm * 2cm * 2cm, cleans several times, clean twice with raw spirit then, put into baking oven takes by weighing glass after oven dry about 100 ℃ quality with zero(ppm) water.The sample of oven dry is put into beaker, injects 500ml zero(ppm) water, or good acidity or the basic soln of configured in advance, places water bath to heat, and experimental temperature is respectively 40 ℃, 60 ℃, 80 ℃, 100 ℃, and the pH value is respectively 3,6,7,11.With the sample oven dry after corroding, the weightlessness of testing its unit surface is all less than 0.005g/cm

-7)/℃ between the beta-eucryptite microcrystalline glass powder as filler, glass sealing place smooth surface, mobile better, overall sealing-in effect is better.Can find out that from Fig. 1 and Fig. 2 parent glass adds after certain filler, the coefficient of expansion of glass powder has certain amplitude to reduce; Through regulating the filler adding proportion; Can be lower than under 600 ℃ the sealing temperature, realize that thermal expansivity is adjustable, setting range is in (40~60) * 10

-7/ ℃, but the two phase tolerace ± 9%, therefore low bulk sealing glass powder of the present invention can satisfy the sealing-in requirement of TFT-LCD Thin Film Transistor-LCD.

Noritake’s electronics division has been around since the creation of the Vacuum Fluorescent Display(VFD). We have grown to provide a wide array of products and services to ensure a smooth and efficient development cycle for your application. Our customer support staff will gladly provide you with technical support to assist with your needs.

Dr Pan: Hello, Greg. TFT LCD module is one of the best LCD technology. We can simply consider it as TFT+LCD+LED backlight, and monochrome LCD module consists of LCD+LED backlight. An image on an LCD we can see is composed of pixels. TFT is the abbreviation for thin film transistor and it controls the R, G, B colors of each pixel respectively on the surface of LCD.

TFT LCD is a high standard product and it is not well customized as monochrome LCD. But still, it has a variety of options to meet the customers’ requirements.The sizes range from 1.44 inch to 130.0 inch;

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey