tab connectors on the lcd panel manufacturer

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Truly Semiconductors is a wholly owned subsidiary of the Hong Kong-listed company Truly International Holdings. Founded in 1991, and headquartered in Hong Kong, the company’s production base is located in the beautiful coastal city of Shanwei City in Guangdong Province, China.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

In 2002, it signed an IPS patent authorization contract with Hitachi of Japan and started to plan a 5th-generation plant to make the product line more complete and meet the needs of different customers.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

Customers who expect to purchase over $10,000 per year may wish to work with a dedicated CTL Account Manager. An account manager can work with customers to secure discounted pricing, purchase with POs, and request net terms. If plan on purchasing in volume, please let us know and we"ll have an Account Manager get back to you.

CTL products are available from major distributors in the US, and globally. US distributors include: TD SYNNEX and Ingram Micro. Contact us for a full list of distributors around the world.

Customers wishing to purchase in volume may click on the floating "Request a Quote" button to request quantity discounts. After requesting a quote, a CTL Account Representative will respond within 1 business day.

Typical lcd panel display connector have different features, including connector shells, pins and sockets, socket retainers, and seals. They also have different features, and they may be used for various applications. First, there are keyed connectors. They are only supposed to connect when they"re in the right position. This protects the pins from harm and prevents users from putting them in the wrong sockets. The other type of electrical connector is the locked connector. This one has a locking mechanism that prevents connections from shifting when shocked. The other type of lcd panel display connector is the hermetically sealed connector. This connector is designed to work underwater but up to a specific depth. Water-resistant connectors are also another type. These help in protecting electrical connections against water damage.

When it comes to buying lcd panel display connector, there are several factors that you need to consider, including performance and physical parameters. When it comes to performance parameters, choose one depending on the conditions in which it will be used. Such conditions include current, voltage, and operating temperature. Physical parameters are also an important consideration since they determine the design of electrical connections and the type of connections the connectors can be used for. Material is one of the important physical considerations. Most lcd panel display connector are covered with plastic. The wire conductors are made from brass, beryllium copper, phosphor bronze, and high copper alloy.

For wholesale lcd panel display connector, visit Alibaba.com. This online shopping platform has partnered with various Chinese wholesalers to offer you a wide range of connectors. You can visit the website at any time and place your order with a few clicks.

The benefit of this kind of construction is low cost — there is no connector involved at all, just the flex soldered directly down to the PCB. The drawback is that the machine used in the LCD manufacturing process to connect them is expensive, and they are near impossible to re-work.

There are bondmaster machines made by APE that are designed for prototype, rework or repair work. We have had good experience with the APE Bondmaster, and their price is very reasonable ($US4K at last check).

It is possible to hand solder the tail to the PCB. Great care must be taken since the conductors of the tail are completely exposed in the area where they are soldered.

Another approach uses ACF (Anisotropic Conductive Film) combined with heat and pressure to make the electrical connection between the flexible tail and the PCB. This two-step process still uses heat, but the temperature involved is much less than soldering.

For development work, we have found that the SchmartBoards company makes a number of breakout boards in a number of pitches that work with our displays.

For any questions about TAB, COB, COF, COG, hot bar soldering, or what LCD module is best for your product, please contact our knowledgeable and friendly support staff via email, phone, or chat.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You would have to access where that missing pin connects to on the display pcb (at a convenient soldering point on the board) and run a wire from there to where the pin 7 wire in the flex cable connects to on the motherboard (again at a convenient point as connecting it to the connector or the cable would be extremely difficult due to the closeness of the wires) so as to bypass the missing connection

To do this would require the schematics for the tablet to find out where the pin 7 wire connects to at both ends. I couldn"t find them, you may have better luck.

Beautiful work. However, my modern LCD flat screen TV set uses the "No-Fuss Ribbon Cable Connectors" and I think they are fairly common in this application.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A/D or ADC converters must be used to process, store, or transport virtually any analog signal in digital form. TV tuner cards, for example, use fast video analog-to-digital converters. On-chip 8, 10, 12, or 16 bit analog-to-digital converters are common in microcontrollers. Digital storage oscilloscopes need very fast analog-to-digital converters. ADC converters are integral to current music reproduction technology. They are needed to create the pulse-code modulation (PCM) data streams that go onto CDs and digital music files.

The most common type of protective coating on an LCD screen is Anti-Glare (AG). This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge.

The matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it.

Air Gap Bonding is the most common method for touch panel attachment. An adhesive is applied between the display and touch panel using the inactive area around the perimeter of the module. This bonding method results in some inactive space "air gap" between the touch panel substrate and the display. Manufacturing yield for this processing is very high 98% (or higher), so this is the most cost-effective and common solution.

An AMOLED (Active-Matrix OLED) is a TFT display that contains a storage capacitor which maintains the line pixels lit all the time (even though just one line is changed each time). AMOLEDs consume less power than PMOLEDs, have faster refresh rates and allow building larger display with higher resolutions. AMOLEDs are also more complicated and expensive to fabricate.

Samsung and LG already mass produce flexible AMOLED panels, used in mobile phone and wearable devices. Samsung"s Galaxy S6 Edge, for example, uses a 5.1" AMOLED on a plastic substrate that bends around the device edges. LG Display is also producing large flexible AMOLEDs, used in their own mobile phones and also reportedly in the Apple Watch.

An Antireflective or Anti-reflection (AR) coating is a type of optical coating applied to the surface of lenses and other optical elements to reduce reflection. In typical imaging systems, this improves the efficiency since less light is lost.

Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams reflected from the interfaces, and constructive interference in the corresponding transmitted beams. This makes the structure"s performance change with wavelength and incident angle, so that color effects often appear at oblique angles. Good performance can often be achieved for a relatively wide range of frequencies: usually a choice of IR, visible, or UV is offered.

Audiovisual (AV) means possessing both a sound and a visual component, such as PowerPoint presentations, films, television programs, church services and live theater productions.

Business presentations are also often audiovisual. In a typical presentation, the presenter provides the audio by speaking, and supplements it with a series of images projected onto a screen, either from a slide projector, or from a computer connected to a projector using presentation software.

Computer-based audiovisual equipment is often used in education, with many schools and universities installing projection equipment and using interactive whiteboard technology.

A backlight is a form of illumination used in LCDs. As LCDs do not produce light themselves and therefore need illumination (ambient light or a special light source) to produce a visible image. Backlights illuminate the LCD from the side or back of the display panel, unlike frontlights, which are placed in front of the LCD. Backlights are used in small displays to increase readability in low light conditions such as in wristwatches, and are used in computer displays and LCD televisions to produce light in a manner similar to a CRT display.

Backlit LCD screens consist of several layers. The backlight is usually the first layer from the back. But in order to create screen images, a mechanism is needed to regulate the light intensity of the screen"s pixels. The most common element is a filter to polarize the light from the source in one of two transverse directions and then passing it through a switching polarizing filter to block the path of undesirable light. (See “Polarizer” definition above.)

LED backlighting in color screens comes in two varieties: white LED backlights and RGB LED backlights. White LEDs are used most often in notebooks and desktop screens, and make up virtually all mobile LCD screens. A white LED is typically a blue LED with broad spectrum yellow phosphor to result in the emission of white light.

RGB LEDs can deliver an enormous color gamut to screens. When using three separate LEDs (additive color) the backlight can produce a color spectrum that closely matches the color filters in the LCD pixels themselves. In this way, the filter passband can be narrowed so that each color component lets only a very narrow band of spectrum through the LCD. This improves the efficiency of the display since less light is blocked when white is displayed. Also, the actual red, green, and blue points can be moved farther out so that the display is capable of reproducing more vivid colors.

Most LED backlights for LCDs are edge-lit. Several LEDs are placed at the edges of a lightguide, which distributes the light behind the LC panel. Advantages of this technique are the very thin flat-panel construction and low cost. A more expensive version is called full-array or direct LED and consists of many LEDs placed behind the LC panel (an array of LEDs), such that large panels can be evenly illuminated. This arrangement allows for local dimming to obtain darker black pixels depending on the image displayed.

Bezel is a term used to describe the outside frame of a computer, display or any other computing device. This is important for product developers and designers in evaluating the overall perimeter of the device/component and its possible ramifications. Newer device designs such the iPad have extremely narrow bezels, allowing for more screen. This has become an increasingly important design factor for consumers.

Tablet computers and smartphones are increasingly moving toward a bezel-less design. The bezel serves to hold the screen in place, and perhaps also reduce unintentional inputs on a touch screen. However, new designs are increasingly reducing the need for the former, while the latter problem can often be solved with software. For example, when the iPad mini was introduced, its thin bezel led Apple to adapt its software to ignore inputs in which a user is simply resting a finger on the screen.

The measurement of the amount of light the LCD monitor produces is given in nits or one candela per square meter (cd/m2). One nit is equal to one cd/m2. Typical brightness ratings range from 250 to 350 cd/m2 for monitors that perform general-purpose tasks. For displaying movies, a brighter luminance rating such as 500 cd/m2 is desirable.

LCD screens have a backlight within them that provide the luminance that lights the entire screen. The total luminance of a notebook LCD depends largely on the intensity of the backlight within the display. This white luminance is the product of the red, green and blue luminance components. The brightness drastically drops off when viewed from angles other than the main angle that most people view when using their laptop or desktop monitor.

Although the backlight does determine the amount of luminance that is released, other components of the LCD display do as well. Each layer of the display that luminance is passed through, only allows a percentage of that luminance to be transmitted. A typical luminance in a notebook LCD screen starts at roughly 3,000 (cd/m2). By the time the light travels through all the layers of a LCD screen, the luminance is down to about 150-300 cd/m2.

The first polarizer transmits about 42% of the luminance. Each pixel has a black matrix opening, which allows about 60% of the light to transmit. Then the light has to travel through the color filter, which transmits roughly 25% of the luminance. In the end, the light that the notebook user sees is only about 5-10% of its starting luminance.

Continuous Grain (CG) silicon is a next-generation technology developed jointly by Sharp and Semiconductor Energy Laboratory of Japan. CG-silicon is a variant of the LTPS (Low-Temperature PolySilicon) process using laser annealing to get larger domains. In LTPS, the electron mobility is impaired when moving from domain to domain. The advance of CG-silicon was the development of ways to make these domain boundaries less of an impediment through some additional processing steps which triples the carrier mobility (performance) of CG-silicon relative to LTPS and is 600x the performance of amorphous silicon.

The result is that high resolution displays can be made in small formats with far fewer layers so that manufacturability and yield far surpass those of the best LTPS processes. CG-silicon has a cost structure much like the n-channel process. These advances allow more system devices on a panel. This also allows more symmetrical designs when the viewing area is more centered within the outside bezel. Among the many benefits of CG-silicon are far higher transmissance and contrast ratios.

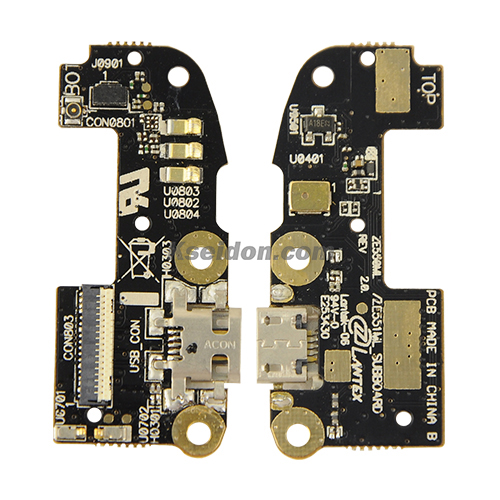

COB is the abbreviation for Chip On Board, which is a most common way of packaging the drive circuit IC of the LCD module or LCM. The IC is attached directly to a specified location on the printed circuit board (PCB) with a sticky piece of plastic. The electrodes of the chip are connected to the corresponding pads of PCB with aluminum wire by a soldering machine. After mounting they are covered by a sticky piece of plastic on the surface.

The COF (Chip On Film) structure is specifically designed for connecting displays, such as TFT and LCD panels, to a PCB. It offers multiple benefits over similar and competing technologies, such as TCP (Tape Carrier Package), which are being phased out (except for PDI (Plasma Display IC)) and replaced by COFs.

The other end of the PCB is bonded to the TFT/LCD display panel"s bonding pad using an ACF (Anisotropic Conductive Film). This is a resin film containing conductive particles.

The final phase involves connection of the TFT/LCD display lines with the COF using one of several techniques, such as use of a reinforcement plate that attaches the film containing the display lines with the COF"s connectors.

Chip-on-Glass (COG) LCD driver ICs are mounted directly on the display glass for the purpose of achieving a significant reduction in system cost. COG is a very reliable and well-established technology, which is often used in automobile and medical displays. Technological advances in areas such as minimally invasive surgery, where imaging provides doctors guidance is creating a bigger demand for COG LCD devices.

In color theory, the gamut of a device or process is that portion of the color space that can be represented, or reproduced. Generally, the color gamut is specified in the hue–saturation plane, as a system can usually produce colors over a wide intensity range within its color gamut.

When certain colors cannot be expressed within a particular color model, those colors are said to be out of gamut. For example, while pure red can be expressed in the RGB color space, it cannot be expressed in the CMYK color space; pure red is out of gamut in the CMYK color space.

While processing a digital image, the most convenient color model used is the RGB model. Printing the image requires transforming the image from the original RGB color space to the printer"s CMYK color space. During this process, the colors from the RGB which are out of gamut must be somehow converted to approximate values within the CMYK space gamut. Simply trimming only the colors which are out of gamut to the closest colors in the destination space would burn the image. There are several algorithms approximating this transformation, but none of them can be truly perfect, since those colors are simply out of the target device"s capabilities.

Liquid crystal display (LCD) screens filter the light emitted by a backlight. The gamut of an LCD screen is therefore limited to the emitted spectrum of the backlight. Typical LCD screens use cold-cathode fluorescent bulbs (CCFLs) for backlights. LCD Screens with certain LED or wide-gamut CCFL backlights yield a more comprehensive gamut than CRTs. However, some LCD technologies vary the color presented by viewing angle. Plane Switching or Patterned Vertical Alignment screens have a wider span of colors than Twisted Nematic.

The functions of contacts in electrical connectors, whether power or signal-related, must be specified in order for connectors to interface properly. When connected, each contact of a connector must mate with the contact on the other connector that has the same function. If contacts of disparate functions are allowed to make contact, the connection may fail and damage may result. Therefore, pinouts are a vital reference when building and testing connectors, cables, and adapters.

Pinouts can typically be shown as a table or diagram. Published pinouts, which are particularly important when different manufacturers want to interconnect their products using open standards, are typically provided by the connector or equipment manufacturer.

Connectors consist of plugs (male-ended) and jacks (female-ended). The connection may be temporary, as for portable equipment, require a tool for assembly and removal, or serve as a permanent electrical joint between two wires or devices. An adapter can be used to effectively bring together dissimilar connectors.

There are hundreds of types of electrical connectors. Connectors may join two lengths of flexible copper wire or cable or join multiple wires to a single connection point.

Terminal blocks: Terminal blocks (also called terminal boards or strips) provide a convenient means of connecting individual electrical wires without a splice or physically joining the ends. They are usually used to connect wiring among various items of equipment within an enclosure or to make connections among individually enclosed items.

Plug and socket connectors: Plug and socket connectors are usually made up of a male plug (typically pin contacts) and a female receptacle (typically socket contacts).

USB connectors: The Universal Serial Bus is a serial bus standard to interface devices introduced in 1996. It is currently widely used among computer peripherals and many other devices. The current standard, USB 3.1, was released in July 2013 with the new transfer mode SuperSpeed+ that can transfer data at up to 10 Gbit/s (1.25 GB/s).

Power connectors: Power connectors must protect people from accidental contact with energized conductors. Power connectors often include a safety ground connection as well as the power conductors. In larger sizes, these connectors must also safely contain any arc produced when an energized circuit is disconnected or may require interlocking to prevent opening a live circuit.

The contrast ratio is a property of a display system, defined as the ratio of the luminance of the brightest color (white) to that of the darkest color (black) that the system is capable of producing. A high contrast ratio is a desired aspect of any display. It has similarities with dynamic range.

There is no official, standardized way to measure contrast ratio for a system or its parts, nor is there a standard for defining "Contrast Ratio" that is accepted by any standards organization so ratings provided by different manufacturers of display devices are not necessarily comparable to each other due to differences in method of measurement, operation, and unstated variables such as those having to do with the room.

A capacitive touchscreen panel consists of an insulator such as glass, coated with a transparent conductor such as indium tin oxide (ITO). As the human body is also an electrical conductor, touching the surface of the screen results in a distortion of the screen"s electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing.

The largest capacitive display manufacturers continue to develop thinner and more accurate touchscreens, with touchscreens for mobile devices now being produced with "in-cell" technology that eliminates a layer, such as Samsung"s Super AMOLED screens, by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance (within millimetres) between the user"s finger and what the user is touching on the screen, creating a more direct contact with the content displayed and enabling taps and gestures to be more responsive.

Another touchscreen technology, resistive touchscreen, works well with almost any stylus-like object, and can also be operated with gloved fingers and bare fingers alike. In some circumstances, this is more desirable than a capacitive touchscreen, which needs a capacitive pointer, such as a bare finger (though some capacitive sensors can detect gloves and some gloves can work with all capacitive screens). A resistive touchscreen operated with a stylus will generally offer greater pointing precision than a capacitive touchscreen operated with a finger. Costs are relatively low when compared with active touchscreen technologies, but are also more prone to damage. Resistive touchscreen technology can be made to support multi-touch input.

A DC-to-DC converter is an electronic circuit which converts a source of direct current (DC) from one voltage level to another. It is a class of power converter.

DC-to-DC converters are important in portable electronic devices such as cellular phones and laptop computers, which are supplied with power from batteries primarily. Such electronic devices often contain several sub-circuits, each with its own voltage level requirement different from that supplied by the battery or an external supply (sometimes higher or lower than the supply voltage). Additionally, the battery voltage declines as its stored energy is drained. Switched DC-to-DC converters offer a method to increase voltage from a partially lowered battery voltage thereby saving space instead of using multiple batteries to accomplish the same thing.

A display is an electronic visual display device for computers and other electronic devices. The user interfaces and interacts with the computer via text and graphics projected onto a screen. Displays are the primary means for the user to both enter and receive information from the computer. Displays are sometimes called, “Windows into the system.” Interaction with the computer through the display is usually accomplished with a keyboard, a hand-activated mouse or by using a touch screen. Touch screens were first used on portable devices such as tablets but are now routinely available on laptops and desktop computers. Displays on smartphones allow voice input as well.

The display device in modern monitors is typically a thin film transistor liquid crystal display (TFT-LCD) thin panel, while older monitors used a cathode ray tube (CRT) about as deep as the screen size.

DP or Data Processing most often refers to electronic data processing controlled by computer programs or software that convert user input data into organized and more useful information or knowledge.

Apple has been granted a patent in 2011 that describes a method for fabricating thin DITO (Double-Sided Indium Tin Oxide) or SITO (Single-Sided Indium Tin Oxide) touch sensor panels with a thickness less than a minimum thickness tolerance of existing manufacturing equipment. In one embodiment, a sandwich of two thin glass sheets is formed such that the combined thickness of the glass sheets does not drop below the minimum thickness tolerance of existing manufacturing equipment when a thin film process is performed on the surfaces of the sandwich during fabrication. The sandwich may eventually be separated to form two thin SITO/DITO panels.

Another fabrication process involves laminating two patterned thick substrates, each having at least the minimum thickness tolerance of existing manufacturing equipment. One or both of the sides of the laminated substrates are then thinned so that when the substrates are separated, each is a thin DITO/SITO panel having a thickness less than the minimum thickness tolerance of existing manufacturing equipment.

Digital Visual Interface (DVI) is a video display interface developed by the Digital Display Working Group (DDWG). The digital interface is used to connect a video source, such as a display controller to a display device, such as a computer monitor. It was developed with the intention of creating an industry standard for the transfer of digital video content.

The interface is designed to transmit uncompressed digital video and can be configured to support multiple modes such as DVI-D (digital only), DVI-A (analog only), or DVI-I (digital and analog). Featuring support for analog connections, the DVI specification is compatible with the VGA interface. This compatibility, along with other advantages, led to its widespread acceptance over competing digital display standards Plug and Display (P&D) and Digital Flat Panel (DFP). Although DVI is predominantly associated with computers, it is sometimes used in other consumer electronics such as television sets, video game consoles, and DVD players.

To promote interoperability between DVI-D and the newer HDMI (High-Definition Multimedia Interface)-compatible devices, HDMI source components and displays support DVI-D signalling. For example, an HDMI display can be driven by a DVI-D source because HDMI and DVI-D both define an overlapping minimum set of supported resolutions and frame buffer formats.

EMI stands for Electro Magnetic Interference. EMI is disturbance that affects an electrical circuit due to either electromagnetic induction or electromagnetic radiation emitted from an external source.The disturbance may interrupt, obstruct, or otherwise degrade or limit the effective performance of the circuit. These effects can range from a simple degradation of data to a total loss of data. The source may be any object, artificial or natural, that carries rapidly changing electrical currents.

Almost all governments have very specific rules and regulations related to the control of electromagnetic interference (EMI). Most spell out the parameters of what is allowed and methods of testing.

In the U.S., EMI guidelines for commercial equipment are handled by the Federal Communications Commission (FCC). The Code of Federal Regulations (CFR) section 47 Parts 15, 18, and 68 contain relevant information that all engineers should be aware of when designing class A and B devices.

The military has its own standards, which are significantly more stringent. These guidelines are detailed in a wide range of military standards, such as MIL-STD-461E, MIL-STD-464.

The International Electrotechnical Commission (IEC), via its International Special Committee on Radio Interference (CISPR), also created globally accepted EMI and electromagnetic compliance (EMC) rules.

Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown.

One of the causes of ESD events is static electricity. Static electricity is often generated through tribocharging, the separation of electric charges that occurs when two materials are brought into contact and then separated. Examples of tribocharging include walking on a rug, rubbing a plastic comb against dry hair, rubbing a balloon against a sweater, ascending from a fabric car seat, or removing some types of plastic packaging. In all these cases, the friction between two materials results in a difference of electrical potential that can lead to an ESD event.

Another cause of ESD damage is through electrostatic induction. This occurs when an electrically charged object is placed near a conductive object isolated from the ground. The presence of the charged object creates an electrostatic field that causes electrical charges on the surface of the other object to redistribute.

The most spectacular form of ESD is the spark, which occurs when a heavy electric field creates an ionized conductive channel in air. This can cause minor discomfort to people, severe damage to electronic equipment, and fires and explosions if the air contains combustible gases or particles.

Many ESD events occur without a visible or audible spark. These invisible forms of ESD can cause outright device failures, or less obvious forms of degradation that may affect the long term reliability and performance of electronic devices. The degradation in some devices may not become evident until well into their service life.

The Electrostatic Discharge Association (ESDA) standards are the most comprehensive and up-to-date industry accepted standards for the control of ESD. The ESD Association became an American National Standards Institute (ANSI) accredited standards development organization.

Today’s standards fall into three main groups. First, there are those that provide ESD program guidance or requirements. These include documents such as ANSI ESD S20.20-2007--Standard for the Development of an ESD Control Program, ANSI/ESD S8.1-Symbols-ESD Awareness , or ESD TR20.20-ESD Handbook.

A second group covers requirements for specific products or procedures such as packaging requirements and grounding. Typical standards in this group are ANSI/ESD S6.1-Grounding and ANSI/ESD S541 –Packaging Materials for ESD Sensitive Items.

A third group of documents covers the standardized test methods used to evaluate products and materials. Historically, the electronics industry relied heavily on test methods established for other industries or even for other materials (e. g., ASTM-257-DC Resistance or Conductance of Insulating Materials). Today, however, specific test method standards focus on ESD in the electronics environment, largely as a result of the ESD Association’s activity. These include standards such as ANSI/ESDA-JEDEC JS-001-2010-Device Testing, Human Body Model and ANSI/ESD STM7.1: Floor Materials -- Resistive Characterization of Materials to cite just a few.

International Electrotechnical Commission, 3, rue de Varembe, Case postale 131, 1211 Geneva 20, Switzerland. Fax: 41-22-919-0300. Web Site: http://www.iec.ch/

Flexible Printed Circuits (FPC) are made with a photolithographic technology. An alternative way of making flexible foil circuits or flexible flat cables (FFCs) is laminating very thin (0.07 mm) copper strips in between two layers of PET (Dacron).

Flex circuits are often used as connectors in various applications where flexibility, space savings, or production constraints limit the serviceability of rigid circuit boards or hand wiring. A common application of flex circuits is in computer keyboards; most keyboards use flex circuits for the switch matrix.

In LCD fabrication, glass is used as a substrate. If thin flexible plastic or metal foil is used as the substrate instead, the entire system can be flexible, as the film deposited on top of the substrate is usually very thin, on the order of a few µM.

A frontlight is a means of illuminating a display device, usually an LCD, which would otherwise be viewed in ambient light. This improves its performance in poor lighting conditions.

An LCD presents an image by absorbing some light passing through it. When an electric field is applied across the crystal, it changes the passing light so it will not pass through a polarization filter. This allows LCDs to operate at low power, as no energy needs to be spent generating light. Many battery-operated electronic devices, including most calculators, use unilluminated LCDs.

An unilluminated LCD must be lit from the front. To use ambient light, the liquid crystal itself is sandwiched between a polarization filter and a reflective surface. The mirror makes the display opaque so it cannot be illuminated from the back. Most often a light source is placed around the perimeter of the LCD.

FSTN stands for Film-compensated STN. This is a passive matrix LCD technology that uses a film compensating layer between the STN display and rear polarizer for added sharpness and contrast. It was used in laptops previous generation cell phones before the DSTN method became popular.

TouchLight can both record and project simultaneously, and due to its 3D capabilities can be used almost as a mirror. This same principle could be applied to link two TouchLights together allowing two people anywhere in the world to communicate with each other as if they were sitting on opposite sides of the same desk. It can capture a high definition image of anything placed up against the screen. This image is then displayed in 2D. The user of the TouchLight can manipulate the size, position and orientation of the image by performing the corresponding action with his or her hands. The screen has a microphone built in that can detect vibration, thus allowing the user to change setting simply by tapping the screen.

TouchLight applications include multi-touch touchscreen-based interaction scenarios, gesture-based interactions, visible light surface scanning, eye-to-eye video conferencing, augmented reality, spatial displays, and displays based on mirror or window metaphors.

In general, capacitive touch can be classified into glass- or film-substrate produced. Glass-substrate capacitive touchscreens are found in Apple’s iPhone and Samsung’s Galaxy S phone. The iPhone uses a glass-glass (GG) structure that forms the X-axis sensing electrode on the upper surface of a glass substrate and Y-axis sensing electrode on the bottom. While Apple’s GG method and other mobile phone makers’ glass/film (GF/GFF) designs are becoming mainstream, attempts to develop products such as G1F, and G2 with better transmittance and thinness will continue. G2 is cover window integrated touch, which does not require separate touch sensor.

The advantages of GFF are low capital cost, suitable for small quantity batch production, and light structure. GG is suitable for mass production and has better appearance properties, but it has high investment costs and is heavier than film-based panels.

HC stands for Hard Coating. HC-2G is the next generation of display coatings based on nano particles that aggressively protects glass. HC-2G is ideal for displays used in areas such as operating rooms where spills, spatters and finger-smudge contamination are likely.

Nano particles form a coating that chemically bonds with surfaces. It completely fills in the microscopic holes in the glass surface. As a result, the surface becomes highly smooth. This slippery quality repels most cutting tools. Minerals from hard water or sea water are prevented from embedding into the glass. The anti-static quality helps prevent grime from collecting on the glass.

In computer systems an interface is a way two separate components of the system exchange information. The exchange can be between software, computer hardware, peripheral devices, humans or any combinations of these. Some computer hardware devices such as LCD touchscreens can both send and receive data to and from the user through the display interface, while others such as a mouse, microphone, joystick or trackball are one way only. UI refers to the User Interface to a computer. Modern display software has a GUI or Graphical User Interface

A network interface bridge works by learning the MAC addresses of the devices on each of its network interfaces. It forwards traffic between networks only when the source and destination MAC addresses are on different networks. In many respects, a bridge is like an Ethernet switch with very few ports.

A Media Access Control address (MAC address) is a unique identifier assigned to network interfaces for communications on the physical network segment. MAC addresses are used as a network address for most IEEE 802 network technologies, including Ethernet and WiFi.

In hardware interface bridges USB ICs eliminate software complexity and driver compatibility issues, providing a cost-effective, small-footprint turnkey solution for adding USB and human interface device connectivity to applications such as personal medical devices, smartphones, smart card and flash card readers, bar code readers, wireless modems and industrial control systems.

In-Plane Switching is a screen technology used in LCDs. It was designed in the 1980s to solve the main limitations of the Twisted Nematic (TN) field effect matrix. These limitations included a restricted viewing angle and low-quality color reproduction. In-plane switching involves arranging and switching the orientation of the molecules of the liquid crystal (LC) layer between the glass substrates. This is done essentially parallel to these glass plates.

Today, IPS technology is widely used in panels for TVs, tablet computers, and smartphones. In particular, all Apple Inc. products marketed with the label “Retina Display” feature IPS LCDs with LED backlighting.

A liquid-crystal display (LCD) is a flat panel display, electronic visual display, or video display that uses the light modulating properties of liquid crystals. Liquid crystals do not emit light directly but are arrayed in front of a light source (backlight) or reflector to produce images in color or monochrome.

Each pixel of an LCD typically consists of a layer of liquid crystals aligned between two transparent electrodes and two perpendicular polarizing filters. An electric current passed through the liquid causes the crystals to align so that light cannot pass through them. Each crystal, therefore, is like a shutter, either allowing light to pass through or blocking the light.

The low electrical power consumption of LCD’s allows them to be used in battery-powered portable electronic equipment.such as digital watches and portable computers.

Monochrome LCD images usually appear as blue or dark gray images on top of a grayish-white background. Color LCD displays use two basic techniques for producing color: Passive matrix is the less expensive of the two technologies. The other technology, called thin film transistor (TFT) or active-matrix, produces color images that are sharper, but the technology is expensive. Recent passive-matrix displays using new CSTN (Color Super Twisted Nematic) and DSTN (Dual-Scan Super Twisted Nematic) technologies produce sharp colors rivaling active-matrix displays.

A Light-Emitting Diode (LED) is a two-lead semiconductor light source which emits light when activated. When a suitable voltage is applied to the leads, electrons are able to recombine with electron holes within the device, releasing energy in the form of photons. This effect is called electroluminescence, and the color of the light (corresponding to the energy of the photon) is determined by the energy band gap of the semiconductor.

In an OLED the electroluminescent material comprising the emissive layer of the diode is an organic compound. The organic material is electrically conductive and functions as an organic semiconductor. The organic materials can be small organic molecules in a crystalline phase or polymers.

The advantages of OLEDs include thin, low-cost displays with a low driving voltage, wide viewing angle, and high contrast and color gamut. Polymer LEDs have the added benefit of being printable and are used in flexible displays.

Many of today’s portable electronics require backlight LED-drivers with the following features: direct control of current, high efficiency, Pulse-Width-Modulation (PWM) dimming, over-voltage protection, load disconnect, small size, and ease of use.

By driving LED light sources with a regulated constant-current power supply the light output variation and lifetime issues resulting from voltage variation and voltage changes can be eliminated. Therefore, constant current drivers are generally recommended for powering LED light sources.

The average light source in an LCD backlight will last around 60,000 hours. Some makers of LCD displays make claim that their backlights can last upward of 80,000 hours if the display is kept at room temperature and is used on a regular basis.

Based on the 60,000-hour average, if the screen is used 30 hours/week (which works out to 1,440 hours a year), the backlight should last around 41 years.

Certain factors can have an effect on the life span of an LCD backlight and reduce the number of hours of use before the light source burns out. One factor is heat. If an LCD display is kept under bright lights or in a room that is often above room temperature (77° F), it can shorten the life of the LCD.

Another factor is the actual settings on the display. The contrast setting is important for maintaining the backlight quality. If the contrast setting is too high, it forces the light source to work harder, which shortens its life span.

The biggest technical problem for OLEDs was the limited lifetime of the organic materials. In particular, blue OLEDs historically have had a lifetime of around 14,000 hours to half original brightness (five years at 8 hours a day) when used for flat-panel displays. This is lower than the typical lifetime of LCD, LED or PDP technology. Each currently is rated for about 25,000–40,000 hours to half brightness, depending on manufacturer and model. Degradation occurs because of the accumulation of nonradiative recombination centers and luminescence quenchers in the emissive zone.

At the circuit board level, a Priinted Circuit Board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs can be single sided (one copper layer), double sided (two copper layers) or multi-layer (outer and inner layers). Multi-layer PCBs allow for much higher component density. Conductors on different layers are connected with plated-through holes called vias. Advanced PCBs may contain components such as capacitors, resistors or active devices embedded in the substrate.

Originally PCBs were designed manually by creating a photomask on a clear mylar sheet, usually at two or four times the true size. Starting from the schematic diagram the component pin pads were laid out on the mylar and then traces were routed to connect the pads. Rub-on dry transfers of common component footprints increased efficiency. Traces were made with self-adhesive tape. Pre-printed non-reproducing grids on the mylar assisted in layout. To fabricate the board, the finished photomask was photolithographically reproduced onto a photoresist coating on the blank copper-clad boards. PCBs are now laid out on dedicated CAD machines using specialized software.

At the IC level photolithography is a process used in microfabrication to pattern parts of a thin film or the bulk of a substrate. It uses light to transfer a geometric pattern from a photomask to a light-sensitive chemical "photoresist", or simply "resist," on the substrate. A series of chemical treatments then either engraves the exposure pattern into, or enables deposition of a new material in the desired pattern upon, the material underneath the photoresist.

Projected capacitive touchscreens recognize multiple points of contact. The structuring of the projection-type is more complex than that of the surface-type, but it has high-precision position detecting. It has also been adopted into mobile devices such as smartphones and tablet PCs as it allows advanced multi-touching operations where the user can enlarge, reduce, or rotate photos in the screen with two fingers.

Projected Capacitive Touch (PCT; also PCAP) technology is a variant of capacitive touch technology. All PCT touch screens are made up of a matrix of rows and columns of conductive material, layered on sheets of glass. This can be done either by etching a single conductive layer to form a grid pattern of electrodes, or by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid. Voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. Unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved fingers.

New capacitive sensors have the ability to tell exactly what is a hand or other interference and ignore these elements to produce exactly the affect desired by the user. For example, the software will ignore your hand, even if it is touching the screen accidentally, in favor of a touch with greater capacitance. This recognition is done automatically with no changes in the settings being necessary.

Highly reactive nanoscale multilayer systems used as an intermediate layer between bonding substrates results in a process known as reactive bonding. The multilayer system consists of two alternating different thin metallic films. The self-propagating exothermic reaction within the multilayer system contributes the local heat to bond the solder films. Based on the limited temperature the substrate material is exposed, temperature-sensitive components and materials with different CTEs (Coefficients of Thermal Expansion) including metals, polymers and ceramics, can be used without thermal damage.

OCA stands for Optically Clear Adhesive. Optical bonding, including LOCA (Liquid Optically Clear Adhesive) and non-liquid OCA tape, are used in a wide range of electronic equipment – especially those with touch panels. The adhesive is used to bond the touch panel to the main liquid crystal display, and also to bond any protective cover, such as the lens, to the touch panel. The adhesive is then cured onto the device through UV, heat, moisture, or a combination of these three methods, depending on the manufacturer and specifications. Major applications include capacitive touch panels, 3D televisions (3D TV), and glass retarders.

Optical bonding improves the optical performance of the display. It eliminates the air gap between the cover glass and the LCD, and usually includes an anti-reflective (A/R) coating (as well as anti-smudge and anti-glare treatments on the cover glass). Optical bonding improves the contrast ratio by reducing the amount of reflected light, thus improving the viewability of the LCD screen. This is especially important in outdoor.

Besides the optical advantages, bonding a sheet of glass to the LCD also improves the durability of the display. It can resist scratches, condensation, and has an improved range of operating temperatures. As touchscreen devices become ubiquitous in consumer markets, this increased ruggedness becomes even more important. Also, by reducing the light loss due to reflection, the battery life of the device can be extended as the device does not need as much backlight to power the display.

Optical character recognition (OCR) is the mechanical or electronic conversion of images of typed, handwritten or printed text into machine-encoded text. It is widely used as a form of data entry from printed paper data records. It is a common method of digitizing printed texts so that it can be electronically edited, searched, stored more compactly, displayed on-line, and used in machine processes such as machine translation, text-to-speech, key data and text mining. OCR is a field of research in pattern recognition, artificial intelligence and computer vision.

Matrix matching involves comparing an image to a stored glyph on a pixel-by-pixel basis; it is also known as "pattern matching", "pattern recognition", or "image correlation".

Feature extraction decomposes glyphs into "features" like lines, closed loops, line direction, and line intersections. These are compared with an abstract vector-like representation of a character, which might reduce to one or more glyph prototypes. General techniques of feature detection in computer vision are applicable to this type of OCR.

OLED stands for Organic Light-Emitting Diode, a display device that sandwiches carbon-based films between two charged electrodes, one a metallic cathode and one a transparent anode, usually being glass. The organic films consist of a hole-injection layer, a hole-transport layer, an emissive layer and an electron-transport layer. When voltage is applied to the OLED cell, the injected positive and negative charges recombine in the emissive layer and create electro luminescent light. Unlike LCDs, which require backlighting, OLED displays are emissive devices — they emit light rather than modulate transmitted or reflected light.

OLED technology was invented by Eastman Kodak in the early 1980s. It is replacing LCD technology in hand-held devices such as smart phones and tablets because the technology is brighter, thinner, faster and lighter than LCDs, use less power, offer higher contrast and are cheaper to manufacture.

A new flexible OLED display patent was filed in 2014 by Apple. The patent revealed techniques of reducing the display border by bending the sides of a display surface. Such a technique is used on wearable devices such as the iWatch and could be applied to future generations of iPhones and iPads.

There are two main types of OLED, those based on small molecules and those based on polymers. The two basic addressing schemes used are passive-matrix (PMOLED) and active-matrix (AMOLED).

Some small and simple flexible (conformable) PMOLED displays are already on the market. PMOLED displays can be curved and are being used in fitness wrist bands.

On-Cell Touch (OCT) technology permits the Projected Capacitive (PCAP) touch sensor layer to be built into the LCD structure. With this integrated structure, the touch functionality is embedded within the display itself rather than a separate touch screen component on top of the display.The reduction in the number of layers also reduces parallax errors providing a superior touch interface. Fewer layers also means backlight intensity can be reduced while providing the same brightness level. The usual multitouch display has an 88% transparency while an OCT display is 93%. This helps reduce lighting power requirements and extends battery life.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey