mainstream lcd displays manufacturer

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

With the rapid development of my country’s display industry, the global display industry structure has undergone major changes. At present, the LCD industry is mainly concentrated in China, Japan, and South Korea. With the release of the new production capacity of mainland panel manufacturers, mainland China will become the world’s largest LCD production area shortly. So, what are the top ten LCD manufacturers in the world, and how do they rank?

LG Display (Chinese name is LG Display) is currently the world’s No. 1 LCD panel manufacturer, affiliated to LG Group, headquartered in Seoul, South Korea, with R&D, production, and trading institutions in China, Japan, South Korea, and the United States and Europe.

Innolux is a professional TFT-LCD panel manufacturing company founded by Foxconn Technology Group in 2003. The factory is located in Shenzhen Longhua Foxconn Technology Park, with an initial investment of RMB 10 billion. Innolux has a strong display technology research and development team, coupled with Foxconn’s strong manufacturing capabilities, and effectively exerts the benefits of vertical integration, which will make a significant contribution to improving the level of the world’s flat-panel display industry.

Innolux conducts production and sales operations in a one-stop manner and provides overall solutions for group system customers. Innolux attaches great importance to the research and development of new products. Star products such as mobile phones, portable and car-mounted DVDs, digital cameras, game consoles, and PDA LCD screens have been put into mass production, and they have quickly seized the market to win market opportunities. Several patents have been obtained.

AU Optronics was formerly known as Daqi Technology and was established in August 1996. In 2001, it merged with Lianyou Optoelectronics and changed its name to AU Optronics. In 2006, it acquired Guanghui Electronics again. After the merger, AUO has a complete production line for all generations of large, medium, and small LCD panels. AU Optronics is also the world’s first TFT-LCD design, manufacturing, and R&D company to be publicly listed on the New York Stock Exchange (NYSE). AU Optronics took the lead in introducing an energy management platform and was the first manufacturer in the world to obtain ISO50001 energy management system certification and ISO14045 eco-efficiency assessment product system verification, and was selected as the Dow Jones Sustainability World in 2010/2011 and 2011/2012. Index constituent stocks set an important milestone for the industry.

At present, BOE’s shipments in notebook LCD screens, flat-panel LCD screens, mobile phone LCD screens, and other fields have reached the world’s first place. Its successful entry into Apple’s supply chain will become the world’s top three LCD panel manufacturers soon.

Sharp is known as the “Father of LCD Panels.” Since its establishment in 1912, Sharp Corporation has developed the world’s first calculator and liquid crystal display, represented by the invention of the live pencil, which is the origin of the current company’s name. At the same time, Sharp is actively expanding into new areas to improve the living standards of human beings and society. Contribute to progress.

Toshiba is a well-known multinational enterprise group with a history of 130 years, with a wide range of business, involving social infrastructure construction, household appliances, digital products, electronic components, and other business fields, covering almost all aspects of production and life. Toshiba has the largest R&D institution in Japan. Through unremitting innovation and development, Toshiba has always been at the forefront of world science and technology. From launching Japan’s first washing machines, refrigerators, and other household appliances, to developing the world’s first notebook computer, the first 16MB flash memory, the world’s smallest 0.85-inch HDD; creating advanced HDDVD technology; researching and manufacturing new SED displays, Toshiba has created many “world firsts” and has contributed to changing people’s lives through continuous technological innovation. Recently, Toshiba is gradually withdrawing from the home appliances and electronic product markets and developing into industries with higher technological content.

The company independently masters leading technologies including LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and IN-CELL/ON-CELL integrated touch control. The company has a national engineering laboratory for TFT-LCD key materials and technology, a national-level enterprise technology center, a post-doctoral mobile workstation, and undertakes many major national-level special projects such as the National Development and Reform Commission, the Ministry of Science and Technology, and the Ministry of Industry and Information Technology. The company’s strong technology and scientific research capabilities have become the cornerstone of the company’s sustainable development.

4K Technology (also known in parts of Asia as 4K2K) is the latest development in extra sharp displays, usually TFT LCDs. Its name is derived from the resolution: roughly 4,000 by 2,000 pixels. To put that into perspective, 4K crams the equivalent of four 1080p high resolution panels, or about a quarter of the pixel density of an IMAX movie, into one display.

Long-time display manufacturer Samsung Display will likely stop the production of LCD displays this year. A recent report says several factors have influenced the South Korean firm’s decision.

Samsung has been a reputed LCD display manufacturer since 1991. It manufactures panels for its own devices and also works as a supplier for several other Big Tech firms, such as Apple. Its displays are used in virtually all products, ranging from foldable smartphones to televisions and tablets.

Despite the company’s successful business, a recent report from The Korea Times suggests Apple is exiting the LCD production business for good. One of the biggest reasons cited for the decision is the increased competition from Chinese and Taiwanese display manufacturers in the recent past.

Samsung wanted to shut its LCD production late in 2020 and its move was on the cards for a while now. Samsung probably kept its LCD manufacturing facilities operational during the pandemic due to the sudden and unprecedented spike in demand. However, LCD technology has been eclipsed by OLED and QD-OLED technologies on most mainstream devices in the last few years. This is another reason why Samsung will probably shutter the business later this year.

Moreover, research firm Display Supply Chain Consultants (DSCC) believes the average price index of LCD panels measured as 100 in January 2014 will drop down to just 36.6 in September 2022. The figure is indicative of the demand for LCD panels and it plummeted to a record low of 41.5 in April this year. The April figure is a whopping 58 percent lower than the record-high index value of 87 in June 2021 when the pandemic was raging. This reduction in demand and price could also be detrimental to the company’s plans to soldier on producing LCDs.

The report says that in the future, Samsung will remain focused on manufacturing OLED panels and more advanced quantum dot OLED displays. LCD division staffers will likely be transferred to the QD-OLED division. Meanwhile, Samsung Display did not respond to the Korea Times’ request for comment.

The global TFT-LCD industry has entered its mature stage. In the past 5 years, the overall output value of TFT-LCD is relatively stable and fluctuates around $130 billion. Among which, China has become the world’s largest TFT-LCD producer.

TFT-LCD (thin film transistor liquid crystal display) is an outcome of microelectronics technology and liquid crystal display technology, a kind of LCD, belonging to the active matrix LCD. TFT-LCD has a three-layer structure, among them, the upper glass substrate is a color filter, the lower glass substrate contains a transistor, and the liquid crystal is located between them. TFT-LCD has the following advantages: High resolution, strong interference immunity, low working voltage, low power consumption, long lifetime and wide application range.

TFT-LCD is widely used in TV, PC, laptops, tablets, projectors, car monitors, smart phones, wearable devices, smart homes and many other fields. The large global shipments of smart phones and computers as well as rapid development of wearable devices and smart home market, have brought robust demand for TFT-LCD.

Compared with the overseas market, China"s TFT-LCD production capacity has expanded rapidly in the past five years, and the output value has continued to grow. According to the "China Thin-Film Transistor Liquid Crystal Display Device (TFT-LCD) Industry Market Research Report in 2022-2026" released by the Newsijie Industry Research Center, China"s TFT-LCD production capacity accounted for more than 50% of the total global production capacity for the first time in 2020; China’s TFT-LCD production capacity accounted for 57% of the total global production capacity and its output value reached about 74 billion dollars in 2021. In 2021, Chinese enterprises including BOE, CSOT, Innolux Display Group, AUO and HKC had high shares in the global TFT-LCD market, among which, BOE is the world"s largest TFT-LCD manufacturer with strong competitiveness in the field of large-size TFT-LCDs.

With the continuous improvement in global display panel technologies as well as the incremental iteration and update of products, CRT has been eliminated and LCD has become the mainstream, meanwhile, OLED is squeezing the LCD market due to its lighter, thinner, flexible and transparent display and other advantages. The global TFT-LCD production capacity is concentrated in Chinese mainland, Taiwan and South Korea. In South Korean market, the panel makers such as Samsung and LG are phasing out LCD production lines to expand OLED production capacity. Although TFT-LCD is the current mainstream LCD product, only LG still has some large-size TFT-LCD production lines. TFT-LCD production capacity in overseas market is shrinking, therefore, although China"s TFT-LCD production capacity is expanding rapidly, the output value of global TFT-LCD is still stable.

The experts of Newsijie expressed that the shipment of TFT-LCD still accounted for 65% in the global display panel industry in 2021, far ahead of OLED"s 20%. In comparison, TFT-LCD shipment is relatively stable, and OLED has become the upgrade target of display panel with rapid growth in shipment. In the short term, TFT-LCD will still be the mainstream product in the display panel market, but in the future, its demand will gradually decline under the pressure of OLED; in the long term, the development space of TFT-LCD will shrink. China has become the world"s largest TFT-LCD producer with enterprises developed in scales and products with cost-effective advantages; China will further squeeze the development space of the TFT-LCD manufacturers in South Korea and Taiwan. In the future, Chinese TFT-LCD manufacturers are expected to lead the global TFT-LCD market.

But OLED -- with its larger color range, ability to show true black and high refresh rate compared with LCD; and low power consumption and physical thinness compared with plasma -- is finally ready to go mainstream.

Janice Mahon, vice president of technology commercialization at New Jersey-based Universal Display Corp., which specializes in researching OLED technology, said affordable OLED displays are almost here.

On a smaller scale, Microsoft Corp."s new Zune HD portable media player will ship this fall with a 3.3-inch OLED touch screen, expanding the existing market of mobile devices with OLED displays.

While Apple Inc. opted to use traditional LCD screens on its new iPhone 3G S, it"s possible that OLED could find its way into the company"s iPod Touch media player devices before the end of the year.

On the TV side, the really good news is that, despite what Sony is charging for its 11-incher, prices for OLED TVs are expected to ultimately be lower than what we"re paying for LCD televisions.

"OLEDs will be less expensive than LCDs are today," Mahon said, noting that it takes about 100 steps in a manufacturing plant to build an LCD television, compared with 86 for an OLED.

A few years farther down the road, some really wild stuff is coming in the form of "flexible OLED." Flexible OLED displays are just what they sound like: paper-thin video displays made out of tough plastic that can be bent and rolled.

But flexible OLED will also be able to scale up and be transparent, so imagine everything from OLED wallpaper to OLED window shades, all of which can transform instantaneously from interactive digital decoration to full-scale televisions or computer displays.

While flexible OLED displays only exist in smaller sizes, Mahon said there"s no reason the more dramatic products shouldn"t be feasible and on the market in a few years.

Since 2012, leading TV manufacturers, including LG Electronics, have been trying to expand OLED TV stores. Because of the high price and some factors, high-end TV can not enter the mass market. In addition, high-end TV market is still the stronghold of LCD TV. Compared with OLED,

Nevertheless, large OLED display giant LG Display shows that with more and more enterprises joining the ranks, will OLED TV soon become the mainstream?

Kang In-byoung, LGD Chief Skills Officer, said at a press conference: "With the advent of the 8K TV era, OLED skills with 33 megapixels of controllable display have a more competitive advantage than LCD displays."

The pixels of an 8K display are about four times as large as those of a 4K display with 8.3 million pixels installed on its surface, which means that its clarity and clarity are four times higher. Because each OLED pixel can emit its own light when it receives the current, the OLED LCD panel does not need backlight to display color, which enables OLED TV to provide deeper black. On the other hand, LCD display panels whose pixels can not self-emit need backlight to emit light, which makes it difficult for them to produce deeper black.

Although LGD has now shown its flexible and transparent displays in different activities, it has so far refused to show foldable OLED displays for smartphones, while rivals such as Samsung Display and occasional reads like Beijing Oriental have competing to show their own foldable products.

Under this trend, LGD will also accelerate the development momentum of OLED. Starting from the third quarter of this year, LGD will launch 60,000 OLED LCD panels per month in Guangzhou, China, increasing its total OLED production to 130,000. The LGD Pozhou factory plans to sell 4 million OLED LCD panels this year, compared with 2.9 million in 2018.

Although OLED came in a fierce fashion, could it replace LCD to become the mainstream at that time? All these are unknown, the mainstream of society is not so easy to replace, LCD LCD has its own value of existence, is still the leader of the electronic display industry, many LCD screens in the market will choose LCD, regardless of price or performance still occupies a certain advantage, but new things will impact on things, whether it will become the mainstream is unknown.

They filed a Swiss patent for the idea on Dec. 4, 1970. Though it attracted scant attention at the time, the milestone now stands as the birthdate of the liquid crystal display (LCD) – the technological platform which has transformed consumer electronics and presented a brilliant new way to view the world.

Early LCD developers took a few years to figure out that specialty glass, not plastic, was the best stable substrate for the delicate LCD circuitry and the color backplane component. Once they did, they turned increasingly to Corning to supply them with extraordinarily stable, flat, fusion-formed glass, able to preserve the critical properties of the liquid crystal and withstand high processing temperatures.

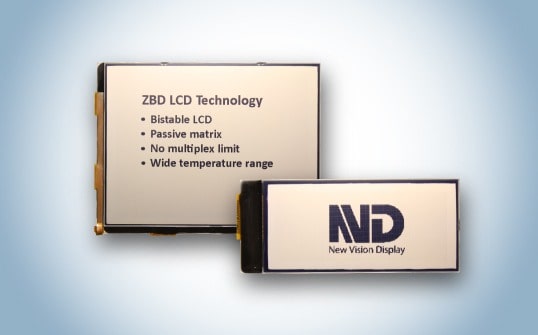

And LCDs rapidly transformed from “passive matrix” models, mostly used in pocket calculators and digital watches, to “active matrix” LCDs in which each sub-pixel was controlled with an isolated thin-film transistor. AMLCDs enabled wide viewing angles; brilliant, fast-moving images; and high-resolution images that had never been possible before.

Corning Incorporated was a critical player in this development, and eventually became the world’s leading supplier of LCD glass substrates. And Corning® EAGLE XG® Glass, the world’s first LCD substrate with no arsenic or other heavy metals, went on to exceed sales of 25 billion square feet, making it one of the most successful products in Corning’s history.

One of the core tactics for making a big visual impact with digital signage is to, well, go big with the displays. The rapid emergence of indoor LED technology in the last seven years or so has made it possible to fill entire physical spaces with seamless digital displays.

There are still super-premium new LED technologies on the market – like the microLED displays made by a small subset of display manufacturers – that are beyond the budgets of most businesses. But in broad terms, LED displays are now within the budgets of many to most businesses. I tend to describe this as LED displays being mainstreamed.

First, when we all did things like business travel (I only kinda sorta miss that!), I would periodically go to Taipei, Hong Kong and China for trade shows and manufacturer tours. In those locales, you see big LED displays all over the place – not just for big advertising boards and on the feature walls of super-premium flagship stores. I was walking down one street in bustling Taipei and saw a football field-length, street-level LED acting as digital hoarding at a building renovation site;

It does not mean LED displays are now so inexpensive they can be used wherever but does mean end-users and solutions providers can stop ruling that option out in the ideation stage because they were always too expensive to seriously consider.

1) No seams: Commercial flat panel displays have, by necessity, thin frames at their edges, and when multiple displays are ganged together to create video walls, there are seams. Those seams have grown increasingly thin, but they’re still there, and noticeable enough that it bothers the people who design physical spaces. With LED, using good equipment and installed properly, there are no visible seams;

2) Design flexibility: With flat panel displays, everything is a flat surface rectangle. A video wall is a collection of stacked and tiled rectangles. With LED, depending on the product, a video wall can match the contours of a physical design. There can be curves. The screens can face down (can’t do that with LCD). They can be transparent. They can even embed in see-through film on windows. It’s a very different technology, though there are sometimes limitations on what’s possible;

3) Physical performance:Premium flat panel displays – both LCDs and OLEDs – still provide superior visual quality and can deliver 8K in a single display, while having enough light pixels to deliver 8K on an LED display might require a display that fills the entire wall of a corporate lobby. But LEDs can be much brighter than conventional flat panels, and they will typically last in the field for 10 years or longer. They also don’t require the same maintenance as LCDs, which regularly need to be calibrated so that the levels match across all the screens in a video wall. If you have ever seen a flat panel video wall that has a patchwork quilt of varied colors and brightness, that’s a wall that badly needs calibration.

For digital signage end-users sourcing flat panel displays, the options were familiar and pretty simple. You could buy from a familiar brand like a Samsung or Sony, and perhaps pay more, or take a risk and go with unfamiliar, less expensive products that came out of China or Taiwan, and hope for the best. Lots of small jobs use TVs instead of commercial displays because upfront costs are lower. LED is mainstream, but

A wholly unfamiliar overseas manufacturer can sell end-users and solutions providers a seemingly good-looking set of displays at a very workable price – likely much better than what the “big guys” can do. But, and this is important, the trade-off tends to be in the quality of components – which directly impacts how long they’ll continue to look good, and how they’ll be supported when or if things deteriorate. The LED video wall that was only 55% the cost of mainstream manufacturers can end up costing more if parts fail and customer support is 12 hours away in Shenzhen or Shanghai, and not very good because of language issues or indifference. LED is mainstream, but

LCD displays use a relatively new technology, but all of the early teething problems have long been worked out and the prices of LCD displays have fallen to the point that they are now mainstream products. A good LCD display, such as the ViewSonic VP191 19" model shown in Figure 11-2, provides top-notch image quality in a compact package. Although traditional CRTs have advantages of their own, most people who experience the bright, contrasty image of a good LCD display will never return to using a CRT monitor.

If you convert from a standard CRT display to a flat-screen CRT display or (particularly) an LCD display, you may notice an odd effect. Your eye and brain become used to seeing the curved surface of the old display as flat. The new display, which truly is flat, looks concave! Straight lines appear to bow inward, particularly if you work close to the display. The effect is so convincing that Robert actually held a straight-edge up to his new LCD display. Sure enough, the "bent" lines were straight. Don"t worry, though. The optical illusion disappears after only a couple hours" use.

CRT monitors were the dominant PC display technology until recently, but that has changed. For displays bundled with new PCs, LCDs exceeded CRTs in popularity by late 2002. By 2005, LCDs had also begun to outsell CRTs in retail channels. Lower cost and other advantages of CRTs ensure that they"ll remain available for years to come, but the emphasis has definitely shifted to LCDs.

Unlike CRT monitors, which have a maximum resolution but can easily be run at lower resolutions, LCDs are designed to operate at one resolution, called the native resolution. You can run an LCD at lower than native resolution, but that results in either the image occupying only part of the screen at full image quality or, via pixel extrapolation, the image occupying the full screen area but with greatly reduced image quality.

LCDs are available in analog-only, digital/analog hybrid, and digital-only interfaces. Using an analog interface requires converting the video signal from digital to analog inside the PC and then from analog to digital inside the monitor, which reduces image quality, particularly at higher resolutions. Synchronization problems occur frequently with analog interfaces, and can cause various undesirable display problems. Finally, analog interfaces are inherently noisier than digital interfaces, which causes subtle variations in display quality that can be quite disconcerting.

Whereas CRT monitors require high vertical refresh rates to ensure stable images, LCDs, because of their differing display technology, can use much lower refresh rates. For example, at 1280x1024 resolution on a CRT monitor, you"ll probably want to use an 85 Hz or higher refresh rate for good image quality. At the same resolution on an LCD, 60 Hz is a perfectly adequate refresh rate. In fact, on LCDs, a lower refresh rate often provides a better image than a higher refresh rate.

Unlike CRT monitors, whose phosphor-based pixels respond essentially instantaneously to the electron beam, LCD panels use transistors, which require time to turn on or turn off. That means there is a measurable lag between when a transistor is switched on or off and when the associated pixel changes to the proper state. That lag, called rise time for when the transistor is switched on and fall time for when it is switched off, results in a corresponding lag in image display.

Fast LCD response time is a Good Thing. Fast response means smoother scrolling and no ghosting or smearing, even when you view fast-motion video. Unfortunately, there"s no standard way to measure or specify response time, so different LCD makers use different methods. That means you can"t necessarily compare the response time specified by one LCD maker directly with that specified by another. (Actually, it"s worse than that; you can"t necessarily compare response times for two different models made by the same company.)

When LCDs first appeared, most makers specified rise-and-fall response in milliseconds (ms), the time required for a pixel to change from black to white (rise time) and then from white to black (fall time), also called the black-white-black (bwb) response. Nowadays, in addition to or instead of bwb, many LCD makers specify white-black-white (wbw) response and/or gray-to-gray (gtg) response, the time required to go from one level of gray to another.

It is not safe to make assumptions about one type of response time based on another type. For example, one LCD may have response times of 20 ms bwb and 8 ms gtg, while another model from the same manufacturer may have response times of 16 ms bwb and 12 ms gtg. So, is the second LCD slower or faster than the first? It depends on which numbers you decide to use. Advertisers use the fastest numbers available. Count on it.

LCDs are brighter than CRTs. A typical CRT has brightness of about 100 candelas/square meter, a unit of measurement called a nit. (Some displays are rated in foot Lamberts (fL); one fL equals about 3.43 nits). A typical LCD is rated at 250 to 350 nits, roughly three times as bright as a typical CRT. CRTs dim as they age, although a brightness control with enough range at the upper end can often be used to set an old CRT to near original brightness. The CCRTs used to backlight LCDs also dim as they age, but generally fail completely before reduced brightness becomes a major issue.

Contrast measures the difference in luminance between the brightest and dimmest portions of an image, and is expressed as a ratio. The ability to display a high-contrast image is an important aspect of image quality, particularly for text. An average CRT may have a contrast ratio of 200:1, and a superb CRT 250:1. An inexpensive LCD may have a contrast ratio of 400:1, and a superb LCD 1,000:1. In other words, even an inexpensive LCD may have higher contrast than an excellent CRT.

Even good flat-screen CRTs are subject to objectionable reflections when used in bright environments, such as having the screen facing a window. Good LCDs are much superior in this respect. Short of direct sunlight impinging on the screen, a good LCD provides excellent images under any lighting conditions.

A typical CRT is about as deep as its nominal screen size. For example, a 19" CRT may be 19" from front to back. Large CRTs may be difficult to fit physically in the available space. Conversely, LCDs are quite shallow. The panel itself typically ranges from 1.5" to 3" deep, and even with the base most LCDs are no more than 7" to 8" deep. Also, where a large CRT may weigh 50 to 100 pounds or more, even large LCDs are quite light. A typical 17" LCD might weigh 10 pounds, and even a 23" unit may weigh less than 20 pounds. That small size and weight means that it"s possible to desk- or wall-mount an LCD with relatively inexpensive mounting hardware, compared to the large, heavy, expensive mounting hardware needed for CRTs.

Stated LCD display sizes are accurate. For example, a 19" LCD has a display area that actually measures 19" diagonally. CRT sizes, on the other hand, are nominal because they specify the diagonal measurement of the entire CRT, part of which is covered by the bezel. For example, a nominal 19" CRT might have a display area that actually measures 18.1" diagonally. A couple of lawsuits several years ago convinced CRT makers to begin stating the usable size of their CRTs. This is stated as VIS (viewable image size or visible image size), and is invariably an inch or so smaller than the nominal size.

This VIS issue has given rise to the belief that a 15" LCD is equivalent to a 17" CRT, a 17" LCD to a 19" CRT, and so on. In fact, that"s not true. The image size of a typical 17" CRT is an inch or so larger than that of a 15" LCD, as is the image size of a 19" CRT relative to a 17" LCD.

Depending on size and other factors, a typical CRT consumes 100 to 160 watts while operating, while an LCD consumes only a quarter to a half as much power. Using an LCD reduces your electricity bill directly by consuming less power and indirectly by reducing the heating load on your air conditioning during hot weather.

Current LCDs are available in analog-only, digital-only, and models with both analog and digital inputs. Analog input is acceptable for 15" (1024x768) models, but for 17" (1280x1024) models analog video noise becomes an issue. At that screen size and resolution, analog noise isn"t immediately obvious to most people, but if you use the display for long periods the difference between using a display with a clean digital signal and one with a noisy analog signal will affect you on almost a subconscious level. For a 19" (1280x1024) LCD, we regard a digital signal as extremely desirable but not absolutely essential. For a larger display or above 1280x1024, we wouldn"t consider using analog signaling.

Insist on true 24-bit color support, which may be described as support for 16.7 million colors. Most current LCDs support 24-bit color, allocating one full byte to each of the three primary colors, which allows 256 shades of each color and a total of 16.7 million colors to be displayed. Many early LCDs and some inexpensive current models support only six bits per color, for a total of 18-bit color. These models use extrapolation to simulate full 24-bit color support, which results in poor color quality. If an LCD is advertised as "24-bit compatible," that"s good reason to look elsewhere. Oddly, many LCDs that do support true 24-bit color don"t bother to mention it in their spec sheets, while many that support only 18-bit color trumpet the fact that they are "24-bit compatible."

Most LCD makers produce three or more series of LCDs. Entry-level models are often analog-only, even in 19" and 21" sizes, and have slow response times. Midrange models usually accept analog or digital inputs, and generally have response times fast enough for anything except 3D gaming and similarly demanding uses. The best models may be analog/digital hybrids or digital-only, and have very fast response times. Choose an entry-level model only if you are certain that you will never use the display for anything more than word processing, web browsing, and similarly undemanding tasks. If you need a true CRT-replacement display, choose a midrange or higher model with a digital interface and the fastest response time you are willing to pay for.

Decide what panel size and resolution is right for you. Keep in mind that when you choose a specific LCD model, you are also effectively choosing the resolution that you will always use on that display.

Buy the LCD locally if possible. Whether or not you buy locally, insist on a no-questions-asked return policy. LCDs are more variable than CRT monitors, both in terms of unit-to-unit variation and in terms of usability with a particular graphics adapter. This is particularly important if you are using an analog interface. Some analog LCDs simply don"t play nice with some analog graphics adapters. Also, LCDs vary from unit to unit in how many defective pixels they have and where those are located. You might prefer a unit with five defective pixels near the edges and corners rather than a unit with only one or two defective pixels located near the center of the screen.

If you buy locally, ask the store to endorse the manufacturer"s warranty that is, to agree that if the LCD fails you can bring it back to the store for a replacement rather than dealing with the hassles of returning the LCD to the maker.

If possible, test the exact LCD you plan to buy (not a floor sample) before you buy it. Ideally, and particularly if you will use the analog interface, you should test the LCD with your own system, or at least with a system that has a graphics adapter identical to the one you plan to use. We"d go to some extremes to do this, including carrying our desktop system down to the local store. But if that isn"t possible for some reason, still insist on seeing the actual LCD you plan to buy running. That way, you can at least determine if there are defective pixels in locations that bother you. Also, use a neutral gray screen with no image to verify that the backlight evenly illuminates the entire screen. Some variation is unavoidable, but one or more corners should not be especially darker than the rest of the display, nor should there be any obvious "hot" spots.

Recommended Brands: Our opinion, confirmed by our readers and colleagues, is that NEC-Mitsubishi, Samsung, Sony, and ViewSonic make the best LCDs available. Their LCDs particularly their midrange and better models provide excellent image quality and are quite reliable. You"re likely to be happy with an LCD from any of these manufacturers.

Stick with good name brands and buy a midrange or higher model from within that name brand. That doesn"t guarantee that you"ll get a good LCD, but it does greatly increase your chances. The LCD market is extremely competitive. If two similar models differ greatly in price, the cheaper one likely has significantly worse specs. If the specs appear similar, the maker of the cheaper model has cut corners somewhere, whether in component quality, construction quality, or warranty policies.

To help with that decision, we’ve summarized all mainstream display types in this article, along with the pros and cons of each. Consider bookmarking this page and returning to it the next time you’re in the market for a new television, monitor, or smartphone.

LCDs, or liquid crystal displays, are the oldest of all display types on this list. They are made up of two primary components: a backlight and a liquid crystal layer.

Since liquid crystals don’t produce any light by themselves, LCDs rely on a white (or sometimes blue) backlight. The liquid crystal layer then simply has to let this light pass through, depending on the image that needs to be displayed.

You may have noticed that the term LCD has started to disappear of late, especially in the television industry. Instead, many manufacturers now prefer branding their televisions as LED models instead of LCD. Don’t be fooled, though — this is just a marketing ploy.

These so-called LED displays still use a liquid crystal layer. The only difference is that the backlights used to illuminate the display now use LEDs instead of cathode fluorescent lamps, or CFLs. LEDs are a better light source than CFLs in almost every way. They are smaller, consume lesser power, and last longer. However, the displays are still fundamentally LCDs.

Twisted nematic, or TN, was the very first LCD technology. Developed in the late 20th century, it paved the way for the display industry to transition away from CRT.

TN displays have liquid crystals laid out in a twisted, helical structure. Their default “off” state allows light to pass through two polarizing filters. However, when a voltage is applied, they untwist themselves to block light from passing through.

However, TN displays have some major downsides, including narrow viewing angles and poor color accuracy. This is because most of them use sub-pixels that can only output 6 bits of brightness. That limits the color output to just 26 (or 64) shades of red, green, and blue. That’s a lot less than 8 and 10-bit displays, which can reproduce 256 and 1,024 shades of each primary color respectively.

IPS displays were originally developed to deliver wider viewing angles than TN. However, they also offer a myriad of other benefits, including higher color accuracy and bit-depth. While most TN panels are limited to the sRGB color space, IPS can support more expansive gamuts. These parameters are important for playing back HDR content and are downright necessary for creative professionals.

Having said that, IPS displays do come with a few minor compromises. The technology isn’t nearly as energy-efficient as TN, nor is it as cheap to manufacture at scale. Still, if you care about color accuracy and viewing angles, IPS is likely your only option.

This default vertical arrangement blocks a lot more of the backlight from coming through to the front of the display. Consequently, VA panels are known for producing deeper blacks and offering better contrast compared to other LCD display types. As for bit-depth and color gamut coverage, VA is capable of doing just as well as IPS.

However, VA displays also have narrower viewing angles than IPS panels. Still, most VAs come out on top when compared to even the best TN implementations.

From this description alone, it’s easy to see how OLED differs from LCD and prior display types. Since the compounds used in OLEDs emit their own light, they are an emissive technology. In other words, you don’t need a backlight for OLEDs. This is why OLEDs are universally thinner and lighter than LCD panels.

Since each organic molecule in an OLED panel is emissive, you can control whether a particular pixel is lit up or not. Take away the current and the pixel turns off. This simple principle allows OLEDs to achieve remarkable black levels, outperforming LCDs that are forced to use an always-on backlight. Besides delivering a high contrast ratio, turning off pixels also reduces power consumption.

Even though Samsung uses the Super AMOLED branding, many of its displays use a plastic substrate too. Smartphones with curved screens would not be possible without the flexibility of plastic. Similarly, almost every POLED display uses an active matrix.

In summary, OLED subtypes aren’t nearly as varied as LCDs. Furthermore, only a handful of companies manufacture OLEDs so there’s even less quality variance than you’d expect. Samsung manufactures the majority of OLEDs in the smartphone industry. Meanwhile, LG Display has a near-monopoly on the large-sized OLED market. It supplies panels to Sony, Vizio, and other giants in the television industry.

In the section on LCDs, we saw how the technology can vary based on differences in the liquid crystal layer. Mini-LED, however, attempts to improve contrast and image quality at the backlight level instead.

The backlights in conventional LCDs have only two modes of operation — on and off. This means that the display has to rely on the liquid crystal layer to adequately block light in darker scenes. Failing to do that results in the display producing grays instead of true black.

Some displays, however, have adopted a better approach recently: they divide the backlight into zones of LEDs. These can then be individually controlled — either dimmed or turned off completely. Consequently, these displays deliver much deeper black levels and higher contrast. The difference is immediately apparent in darker scenes.

This technique, known as local dimming, has become ubiquitous in higher-end LCD televisions. Until recently, though, it wasn’t viable for smaller displays like those found in laptops or smartphones. And even in larger devices like monitors and TVs, you run the risk of not having enough dimming zones.

Still, it’s not hard to see how mini-LEDs can eventually deliver better contrast than conventional local dimming implementations. Furthermore, since mini-LED displays still rely on traditional LCD technologies, they aren’t prone to burn-in like OLEDs.

Quantum dot technology has become increasingly common — usually positioned as a key selling point for many mid-range televisions. You may also know it by Samsung’s marketing shorthand: QLED. Similar to mini-LED, however, it isn’t some radically new panel technology. Instead, quantum dot displays are basically conventional LCDs with an additional layer sandwiched in between.

So how do quantum dots help? Well, they are essentially tiny crystals that emit color when you shine blue or ultraviolet light on them. This is why quantum dot displays use a blue backlight instead of white.

When combined with traditional LCD color filters, quantum dot displays can cover a greater percentage of the visible light spectrum. Put simply, you get richer and ore accurate colors — enough to deliver a satisfactory HDR experience. And since the crystals emit their own light, you also get a tangible bump in brightness compared to traditional LCDs.

However, quantum dot technology does not improve other pain points of LCDs such as contrast and viewing angles. For that, you’d have to combine quantum dots with local dimming or mini-LED technologies. And until those mature, you’re unlikely to find a quantum dot display that can rival OLED in all aspects.

Quantum-dot OLED, or QD-OLED, is an amalgamation of two existing technologies — quantum dots and OLED. More specifically, it aims to eliminate the drawbacks of both traditional OLEDs and LCD-based quantum dot displays.

Modern OLED implementations combat this by leaving the fourth sub-pixel white (without any color filters) to improve the perception of brightness. However, they still usually fall short in terms of brightness, especially against high-end LCDs with larger backlights.

QD-OLED, on the other hand, uses a completely different subpixel arrangement — these displays start with blue emitters instead of white. And instead of color filters, they use quantum dots. In the previous section on QLED, we discussed how quantum dots are capable of producing extremely specific shades of green and red. The same property comes into play here as well. Put simply, quantum dots convert the original blue light into various colors instead of destructively filtering it, preserving the display’s overall brightness.

According to Samsung Display, another advantage QD-OLED brings to the table comes in the form of better color accuracy. Since these displays don’t have a fourth white sub-pixel, color information is rendered correctly even at higher brightness levels. Finally, quantum dots allow displays to achieve higher color gamut coverage and offer wider viewing angles than color filters.

MicroLED is the newest display type on this list and, as you’d expect, also the most exciting. Put simply, microLED displays use LEDs that are even smaller than those used in mini-LED backlights. While most mini-LEDs are around 200 microns in size, microLEDs are as small as 50 microns. For context, human hair is thicker than that at 75 microns.

Brightness is another aspect in which microLED displays manage to surpass existing technologies. Even the highest-end OLED displays on the market today, for instance, top out at 2,000 nits. On the other hand, manufacturers claim that microLED can eventually deliver a peak brightness output of 10,000 nits.

Finally, MicroLED displays can also be modular. Even some of the earliest demonstrations of the technology had manufacturers creating giant video walls using a grid of smaller microLED panels.

It’s almost certain that microLED displays will become more accessible and cheaper in the coming years. After all, OLED is only a decade old at this point and has already become ubiquitous.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey