using a tft lcd to move a servo arduino uno brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

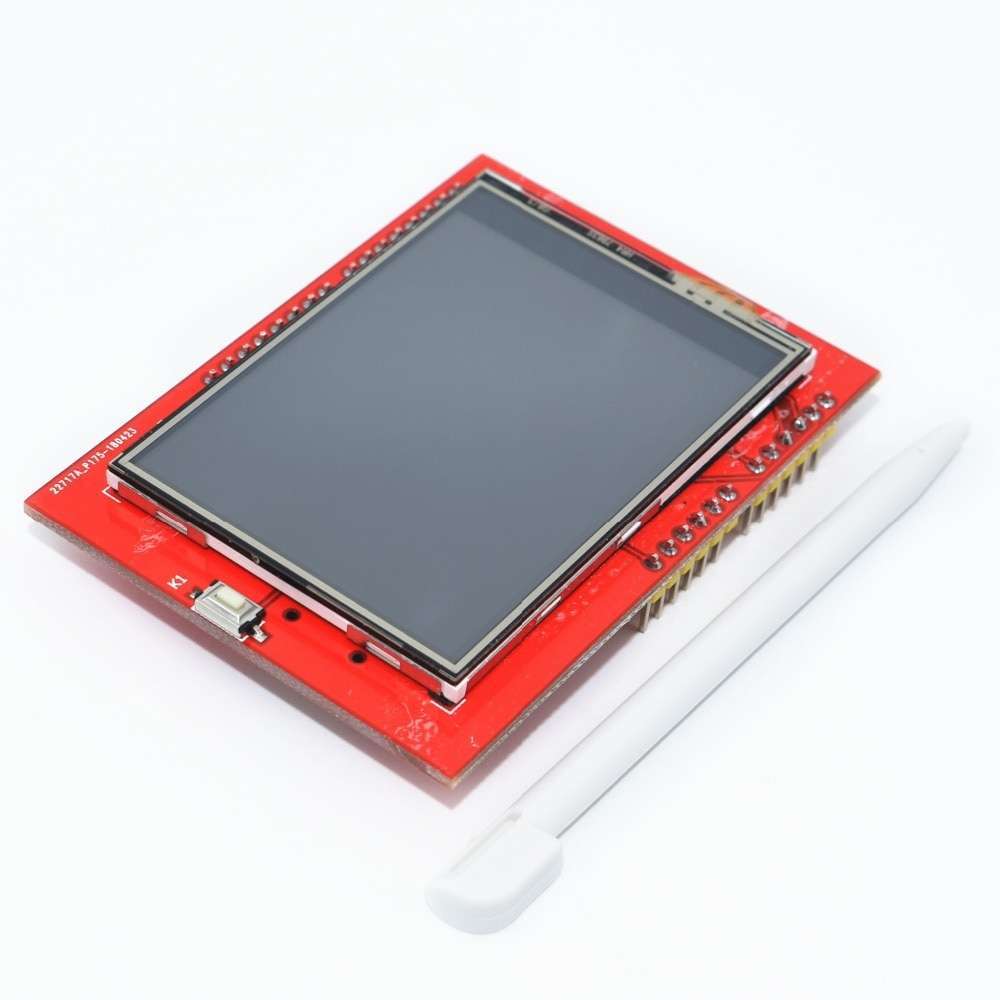

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

One of the first uses of servo motors was to control the steering mechanisms of RC airplanes, cars, and boats. Today, you can find them in robots, industrial equipment, and many different Arduino projects.

Servo motors are capable of precise control of the rotation of a motor shaft. They allow you to set an exact angle of rotation with code, or with inputs like joysticks, push buttons, or potentiometers.

In this tutorial, we’ll take a look at how servo motors work and how to use an Arduino to control them. We’ll also look at two example programs you can run on the Arduino. The firstprogram will show you how to control the direction and position of a servo using two push buttons. Thesecondprogram will show you how to use a potentiometerto controlthe position of the servo.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

Servos are DC motors that have been geared down to reduce the speed and increase the torque of the motor. They also have built in circuits that control the angle of rotation one degree at a time, and hold that position until another input is received. Servos will rotate a certain number of degrees depending on the width of the electrical pulses delivered by the Arduino:

The servo expects one pulse every 20 ms. For most servos, a 1 ms pulse results in a zerodegree rotation, a 1.5 ms pulse results in a 90 degree rotation, and a 2 ms pulse results in a 180 degree rotation.

Depending on the servo you use (larger ones especially), you should use a separate DC power supply to power it. Otherwise, the current drawn by the servo could damage your Arduino.

If you want to learn more about the Arduino, check out our Ultimate Guide to the Arduino video course. You’ll learn basic to advanced Arduino programming and circuit building techniques that will prepare you to build any project.

We’re going to use the Arduino’s built-in Servo library to program the servo. This library is included with the Arduino IDE, so there’s no need to install it.

The servo motorshould move to 0degrees, pause for one second, then move to 90degrees, pause for one second, then move to 180degrees, pause for one second, then start over.

On the first line we include the Servo library with #include

In the setup section, we initialize the servo with the attach() function. The attach() function takes one parameter – the pin that the servo is connected to. So we have servo1.attach(servoPin).

To move the servo, use the write() function with the angle of rotation as the argument. The angle is in degrees, from 0 degrees to 180 degrees. The angle changes the pulse width sent to the servo motor, which then determines the amount of rotation. We’re calling the function through the servo1 object, so we use servo1.write(angle), with 0 degrees, 90 degrees, and 180 degrees.

The write() function will work for most servos, but not all. Some servo motors have a range of 180 degrees, some have a range of 90 degrees, and some have anywhere in between. Using the write() function only allows for a maximum of 180 steps. However, there is a function that allows up to 1000steps, called writeMicroseconds(). If you want more precise control of your servo, you may want to use the writeMicroseconds() function instead of write().

In this sketch, we’ve replaced each write() function with a writeMicroseconds() function. Change the angular values from (0, 90, 180) degrees to (1000, 1500, 2000) microseconds. Upload and run the program using the same hardware setup. For a servo motor capable of a range up to 180, the values will be 1000 microseconds = 0 degrees, 1500 microseconds = 90 degrees, and 2000 microseconds = 180 degrees.

Depending on the servo motor you are using, you may notice a difference. Interestingly on my setup, while monitoring the pulses on an oscilloscope, I noticed that when using servo1.write(0);, the pulse width was only about 700microseconds, not 1000 which is the way the function should work when set at zero degrees. But when using servo1.writeMicroseconds(1000); the output was exactly 1000microseconds.

After uploading the compiled code, open the Serial Monitor on your Arduino. As you push on either button, the servo should increase or decrease as shown on the serial monitor. Initially, the code will set the servo at 90 degrees. Use the button connected to pin 3 to increase the angle. When you reach 180 degrees, the high end of the rotation, the LED connected to pin 5 will turn on. When you reach the low end of the range which is 0 degrees, the LED connected to pin 6 will turn on.

To determine the result of the button push, a whilestatement verifies the button and the angle of the shaft. while (digitalRead(pin3) == HIGH && pos < 180) determines that the button was pushed (HIGH) and the angle is less than 180, so the program adds one degree and loops on. The second button while (digitalRead(pin4) == HIGH && pos > 0) determines that the button was pushed (HIGH) and the angle is greater than 0. This causes the angle to decrease by one and loops on. The LedHi and LedLow level for LEDs are each controlled by anif statement that checks the angle to see if it’s 0 or 180. The LEDs are turned off as soon as the angle changes in each of the two while statements.

After uploading the code, open the serial monitor on your Arduino. As you adjust the potentiometer, the rotation of the servo will change accordingly. When you reach the lowerlimit of the range, the Low LED will turn on, and as you reach the upper limit, the High LED will turn on.

analogRead() takes in the voltage from the potentiometer as an analog signal. It accepts the values of the full range of input accepted in an Arduino (0-5V). It captures it as an integer in the range of (0-1023). So for example, a DC value of 0V would be captured as the integer 0; a full range value of 5V would be captured as the integer 1023, and half the input range of 2.5V would be captured as the integer 512, half of 1023.

The next line of code servo1.write(val); is the write() command that takes the integer stored in val as the argument and applies it to the servo. The servo receives a pulsefrom the servo1.write(val); and the pulse width is determined by the value of val. The servo uses the width of this pulse to determine its rotation.

Bright, 4 White-Led Backlight, On By Default But You Can Connect The Transistor To A Digital Pin For Backlight ControlThe minimum purchase order quantity for the product is 1

I wanted to put all the Arduino projects and ESP32 projects which can be used to display the messages. I am using a free Arduino simulator. Yes, Wokwi is a free Arduino simulator, that works straight out of the browser and is easy to share projects with others. Basically, it can be on a7 segment display,1602 LCD,2004 LCD,OLED,TFT displays, FastLED,matrix, PAL TV,LED bar graphmore much more. If you have any suggestions or projects to be added, kindly share the project link in the comments or direct message me.

Brief introduction:This project will show you how to display a simple text message on a 1602 Liquid crystal display. Here are the details of the components neededLCD1602 ( 2 rows, 16 columns)

Brief introduction:This project will show you how to display a simple text message on a 2004 Liquid crystal display. This LCD can accommodate more text and can hence function as a menu bar or even a good counter. Here are the details of the components neededLCD2004 ( 4 rows, 20 columns)

Brief introduction:This project will show you how to display a simple text message on an OLED. This LCD can accommodate more text and can hence function as a menu bar or even a good counter. Here are the details of the connectionSSD1306 display module

Brief introduction:This project will show you how to display a simple text message on a TFT display. This LCD can accommodate more text, graphics and can hence function as a beautiful or even a good image display. Here are the details of the connection.

Background: This project will show you how to display a simple text message on a MAX7219 display. Several MAX7219 displays are concatenated. Here are the details of the connection

BriefIntroduction: 7 segment display is not a quite favourite candidate but still you can manage to display large text. hence the project. Here are the components needed:4 digit, 7 segment display

Then for the number, if it can be more than one char, make a char array of three chars, and fill these until you receive a "\n", or more than three ASCII numbers. With atoi() you can parse ASCII to integers.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this tutorial we will learn how servo motors work and how to control servo motors with Arduino. Servo motors are very popular and widely used in many Arduino projects because they are easy to use and provide great position control.

Servos are great choice for robotics projects, automation, RC models and so on. I have already used them in many of my Arduino projects and you can check out some of them here:

You can watch the following video or read the written tutorial below. It includes several examples how to use a servo motor with Arduino, wiring diagram and codes. In additional, it has a guide how to control multiple servo motors with Arduino using the PCA9685 PWM driver.

A servo motor is a closed-loop system that uses position feedback to control its motion and final position. There are many types of servo motors and their main feature is the ability to precisely control the position of their shaft.

In industrial type servo motors the position feedback sensor is usually a high precision encoder, while in the smaller RC or hobby servos the position sensor is usually a simple potentiometer. The actual position captured by these devices is fed back to the error detector where it is compared to the target position. Then according to the error the controller corrects the actual position of the motor to match with the target position.

Hobby servos are small in size actuators used for controlling RC toys cars, boats, airplanes etc. They are also used by engineering students for prototyping in robotics, creating robotic arms, biologically inspired robots, humanoid robots and so on.

There are four main components inside of a hobby servo, a DC motor, a gearbox, a potentiometer and a control circuit. The DC motor is high speed and low torque but the gearbox reduces the speed to around 60 RPM and at the same time increases the torque.

The potentiometer is attached on the final gear or the output shaft, so as the motor rotates the potentiometer rotates as well, thus producing a voltage that is related to the absolute angle of the output shaft. In the control circuit, this potentiometer voltage is compared to the voltage coming from the signal line. If needed, the controller activates an integrated H-Bridge which enables the motor to rotate in either direction until the two signals reach a difference of zero.

A servo motor is controlled by sending a series of pulses through the signal line. The frequency of the control signal should be 50Hz or a pulse should occur every 20ms. The width of pulse determines angular position of the servo and these type of servos can usually rotate 180 degrees (they have a physical limits of travel).

Generally pulses with 1ms duration correspond to 0 degrees position, 1.5ms duration to 90 degrees and 2ms to 180 degrees. Though the minimum and maximum duration of the pulses can sometimes vary with different brands and they can be 0.5ms for 0 degrees and 2.5ms for 180 degrees position.

There are many different models and manufacturers of RC or hobby. The main consideration when choosing a servo motor is its torque, operating voltage, current draw and size.

Let’s put the above said to test and make a practical example of controlling a hobby servo using Arduino. I will use the MG996R which is a high-torque servo featuring metal gearing with stall torque of 10 kg-cm. The high torque comes at a price and that’s the stall current of the servo which is 2.5A. The running current is from 500mA to 900mA and the operating voltage is from 4.8 to 7.2V.

We simply need to connect the control pin of the servo to any digital pin of the Arduino board, connect the Ground and the positive wires to the external 5V power supply, and also connect the Arduino ground to the servo ground.

The S90 Micro Servo has lower current consumption, around 100-200mA no-load running current, but around 500-700mA stall current. On the other hand, the Arduino 5V pin can output only around 500mA if powered via USB, or up to 1A in powered via the barrel connector.

Even though it’s possible to run these 9g servo motors directly to Arduino, for more stable work I would suggest to always use an external power supply for them.

Now let’s take a look at the Arduino code for controlling the servo motor. The code is very simple. We just need to define the pin to which the servo is connect, define that pin as an output, and in the loop section generate pulses with the specific duration and frequency as we explained earlier.

After some testing I came up with the following values for the duration of the pulses that work with my servo. Pulses with 0.6ms duration corresponded to 0 degrees position, 1.45ms to 90 degrees and 2.3ms to 180 degrees.

I connected a multimeter in series with the servo to check the current draw. The maximum current draw that I noticed was up to 0.63A at stall. Well that’s because this isn’t the original TowerPro MG996R servo, but a cheaper replica, which obviously has worse performance.

Here we just need to include the library, define the servo object, and using the attach() function define the pin to which the servo is connected as well as define the minimum and maximum values of the pulses durations. Then using the write() function we simply set the position of the servo from 0 to 180 degrees.

The Arduino servo library supports controlling of up to 12 servos at the same time with most the Arduino boards, and 48 servos using the Arduino Mega board. On top of that, controlling multiple servo motors with Arduino is as easy as controlling just a single one.

So, we just have to create objects from the Servo class for each servo motor, and define to which Arduino pin is connected. Of course, we can set any servo to move to any position, at any time.

There’s also another way of controlling servos with Arduino, and that’s using the PCA9685 servo driver. This is a 16-Channel 12-bit PWM and servo driver which communicates with Arduino using the I2C bus. It has a built in clock so it can drive 16 servos free running, or independently of Arduino.

What’s even cooler we can daisy-chain up to 62 of these drivers on a single I2C bus. So theoretically we can control up to 992 servos using only the two I2C pins from the Arduino board. The 6 address select pins are used for setting different I2C addressed for each additional driver. We just need to connect the solder pads according to this table.

So first we need to include the libraries and define the PCA9685 object. Then using the Servo_Evaluator instance define the pulses duration or the PWM output of the driver. Note that the outputs are 12-bit, or that’s a resolution of 4096 steps. So the minimum pulse duration of 0.5ms or 0 degrees position would correspond to 102 steps, and the maximum pulse duration of 2.5ms or 180 degrees position to 512 steps. But as explained earlier these values should be adjusted according your servo motor. I had value from 102 to 470 which corresponded to 0 to 180 degrees position.

I connected a second servo to the driver, and as I expected, it wasn’t positioning the same as the first one, and that’s because the servos that I’m using are cheap copies and they are not so reliable. However, this isn’t a big problem because using the Servo_Evaluator instance we can set different output settings for each servo. We can also adjust the 90 degrees position in case it’s not precisely in the middle. In that way all servos will work the same and position at the exact angle.

So we should create separate PCA9685 object for each driver, define the addresses for each driver as well as set the frequency to 50Hz. Now simply using the setChannelPWM() and pwmForAngle() functions we can set any servo at any driver to position any angle we want.

This is a common problem with these hobby servo motors, the SG90 Micro Servo and the MG996R. The reason for this is that, as mentioned earlier, they can draw quite significant amount of current when they are at load. This can cause the Arduino board to reset, especially if you are powering the servo directly from the Arduino 5V pin.

In order to solve this issue you can use a capacitor across the GND and the 5V pin. It will act as a decouple capacitor which will provide additional current to the system at start up when the DC motor starts.

This is another common problem with these hobby servos. As we explained earlier, a pulse width of 1ms (0.5ms) corresponds to 0 degrees position, and 2ms (2.5ms) to 180 degrees. However, these values can vary from servo to servo and between different manufacturers.

In order to solve this problem, we need to adjust the pulse width we are sending to the servo motor with the Arduino. Luckily, using the Arduino Servo library we can easily adjust the pulse widths values in the attach() function.

The attach() function can take two additional parameters, and that’s the minimum and maximum pulse width in microseconds. The default values are 544 microseconds (0.544milliseconds) for minimum (0 degrees) angle, and 2400 microseconds (2.4ms). So by adjusting these values we can fine tune the moment range of the servo.

I made 3D models of the two most popular servo motors, the SG90 Micro Servo and the MG996R servo motor. You can download load them from the links below.

So, we have covered almost everything we need to know about using servo motors with Arduino. Of course, there are some many manufacturers and models of these type of hobby or RC servo motors, and each of them has its own unique features that might differ from what we explained above.

The possibilities for creating awesome robotics, automation and RC projects using motors are endless, however choosing the right model for your application is very important.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below, as well as make sure you can my Arduino Projects Collection.

Using a servo motor with Arduino is quite easy. The servo motor has just 3 wires, two of which are GND and 5V for powering, and the third wire is the control line which goes to the Arduino board.

We can run servo motors directly from Arduino, but we might have power problems. If the servo motor draws more than 500mA of current, the Arduino board might lose it’s power and reset. It’s better to always use a separate power source for the servo motors.

Using the Arduino Servo library we can control up to 12 servo motors with most Arduino boards, and up to 48 servo motors with the Arduino Mega board. Of course, we need to use a dedicated power source for the servo motors.

Arduino has a built-in function servo.write(degrees) that simplifies the control of servos. However, not all servos respect the same timings for all positions. Usually, 1 millisecond means 0 degrees, 1.5 milliseconds mean 90 degrees, and, of course, 2 milliseconds mean 180 degrees. Some servos have smaller or larger ranges.

For better control, we can use the servo.writeMicroseconds(us) function, which takes the exact number of microseconds as a parameter. Remember, 1 millisecond equals 1,000 microseconds.

In order to use more than one servo, we need to declare multiple servo objects, attach different pins to each one, and address each servo individually. First, we need to declare the servo objects—as many as we need:// Create servo objects

Connection-wise, the grounds from the servos go to GND on the Arduino, the servo power to 5V or VIN (depending on the power input), and in the end, each signal line has to be connected to a different digital pin. Contrary to popular belief, servos don"t need to be controlled by PWM pins—any digital pin will work.

There is a special breed of servos labelled as continuous rotation servos. While a normal servo goes to a specific position depending on the input signal, a continuous rotation servo either rotates clockwise or counter-clockwise at a speed proportional to the signal. For example, the Servo1.write(0) function will make the servomotor spin counter-clockwise at full speed. The Servo1.write(90) function will stop the motor and Servo1.write(180) will turn the motor clockwise at full speed.

There are multiple uses for such servos; however, they are really slow. If you are building a microwave and need a motor to turn the food, this is your choice. But be careful, microwaves are dangerous!

The ESPLORA Joystick Photosensitive Sensor Board is a microcontroller board compatible with Arduino & derived from the Arduino Leonardo. The ESPLORA Joystick Photosensitive Sensor Board differs from all preceding Arduino boards in that it provides a number of built-in; ready-to-use set of onboard sensors for interaction.

It’s designed for people who want to get up and running with Arduino without having to learn about the electronics first. For a step-by-step introduction to the Esplora; check out the Getting Started with Esplora guide.

The ESPLORA Joystick Photosensitive Sensor Board has onboard sound and light outputs, and several input sensors; including a joystick, a slider, a temperature sensor, an accelerometer, a microphone, and a light sensor. It also has the potential to expand its capabilities with two Tinker-kit input and output connectors, and a socket for a color TFT LCD screen.

Like the Leonardo board, the ESPLORA Joystick Photosensitive Sensor Board uses an Atmega32U4 AVR microcontroller with 16 MHz crystal oscillator. And a micro USB connection capable of acting as a USB client device like a mouse or a keyboard. In the upper left corner of the board, there is a reset push button, that you can use to restart the board.There are four status LEDs

The board contains everything need to support the microcontroller; simply connect it to a computer with a USB cable to get started. The Esplora has built-in USB communication; it can appear to a connected computer as a mouse or keyboard, in addition to a virtual (CDC) serial / COM port. This has other implications for the behavior of the board; these are detailed on the getting started page. You can find all the information you need to configure your board, use the Arduino Software (IDE); and start to tinker with coding and electronics.Input and Output

The design of the ESPLORA Joystick Photosensitive Sensor Board recalls traditional gamepad design with an analog joystick on the left and four push buttons on the right. The ESPLORA Joystick Photosensitive Sensor Board has the following onboard inputs and outputs :

Let’s take a look into a simple interfacing project this time. This is actuator interfacing with Arduino Uno and the actuator being servo motor, specifically SG90 servo motor. SG90 is a lightweight (just 9g) and tiny servo motor which has quite good output toque. We can use Arduino IDE to code this servo and control its movements precisely. We can rotate 180 with this servo motor.

This project uses SG90 servo motor interfaced with Arduino Uno which is programed to turn the servo motor from 0 degrees to 180 degrees and back to 0 degrees.

For demo purposes, with zero load on the servo motor, we are powering the servo motor using Arduino 5V pin. But it is important to keep in mind that the motor should be powered separately. This servo motor has input voltage of 4.8V to 6V DC. It is recommended that the servo motor should be powered externally (using a dedicated power supply) and the voltage should be within the accepted range. The maximum current draw from Arduino is 0.8A only. So when we use an external power supply, it will make sure that the Arduino board won’t be damaged due to excess current draw.

There is a common problem when dealing with SG90 (or even MG90S) that is the overshooting or undershooting. This is a problem has a bit to do with Control Systems. In general, we can say, the systems that are overdamped miss the target value, that causes the “undershoot”. This means, the servo would not really reach 0 to 180 degrees or other specified value. Whereas those systems that are underdamped go over the target. This causes the situation to “overshoot”. This is when the servo motor exceeds the specified degree and sweeps more area than it is supposed to do.

There are a couple of fixes available online for this overshoot/undershoot problem. You could use a better servo motor like “Tower pro MG 995” servos. This is not a micro servo like SG90 but it is more precise and it can also deliver more power. There are other servo motors that are used for model aircraft building; they are known to be more precise. They give very good results but are quite expensive. If you really want to use SG90 servo motor only and get precise degree turn, then, consider the following points to get better results:

The circuit connections for this project are very simple as the servo motor has only 3 pins. The red wire of the servo goes to 5V pin of Arduino Uno. The Black wire of the servo goes to Arduino Uno’s ground pin (GND). And the yellow wire (called the control pin of servo) goes to Arduino pin 8. This completes the circuit connections of the servo motor with Arduino Uno.

First, we need to include a library called “Servo.h” to be able to control various servo motors. If you don’t already have this library in your Arduino IDE, then you can go to “tools” à “Manage Libraries…” and type “Servo” in the Library Manager and install the one from “Michael Margolis, Arduino”.

Next, we declare a variable called “servo”. In void setup function, we use the servo.attach function to tell the Arduino board that the control pin of the servo motor is attached to pin 8 of Arduino (the function attaches the servo variable to the pin). The servo.write function is used to tell the servo the degree to which it should turn. At the beginning the default state of servo is considered as zero degree we keep this as origin position that is zero degrees. So we write servo.write(0). Then a delay function is used to create a delay of 2ms.

Next, in void loop, we use the servo.write function again to tell the servo to turn to 180 degrees and the delay function will hold this position for 1ms. Then the servo is instructed again to go back to 0 degrees, as we had initialized before. The delay function will hold this position for 1ms. This is repeated until the power is disconnected or servo is disconnected.

This is a beginner friendly project. It focuses on controlling an actuator, SG90 Servo motor, using Arduino Uno and Arduino IDE. It provides a strong basic foundation in dealing with actuators and helps beginners jump into more fun with actuators.

The idea of that particular servo shield is that it provides 16 PWM (pulse width modulation) channels. These are all operated simultaneously with no additional processing overhead on the Arduino.

The Arduino Uno itself does not offer 16 (or 18) hardware PWM channels but only 6 (see here). So driving 18 servos without an additional shield would require software PWM which requires some of the Arduino"s ressources to be devoted doing the calculations. This may or may not interfere with the rest of your program.

Furthermore the Uno does only provide 14 dedicated digital GPIO pins in total (+6 multiplexed digital/analog pins, as ZS6JMB"s answer points out), so additional hardware would* be required either way - or using an Arduino with more pins (such as the suggested Mega). The Mega however offers only 15 hardware PWM channels, leaving you with soft PWM again. (* assuming some pins will be needed for sensors or user interfacing).

An alternative is this board or, uhm, well, cheaper clones if you like. It features the same chip as the shield but with a PCB half the size and thus skipping the "free use area". I expect it to behave the same way like the shield and operate with the same libraries as the both the shield and this board communicate only via I2C. Both can be chained (or stacked for the shield if you will) for up to 992 PWM outputs (62 boards).

This article is a guide about the Ultrasonic Sensor HC-SR04. We’ll explain how it works, show you some of its features and share an Arduino project example you can follow to integrate into your projects. We provide a schematic diagram on how to wire the ultrasonic sensor and an example sketch with the Arduino.

The HC-SR04 ultrasonic sensor uses sonar to determine the distance to an object. This sensor reads from 2cm to 400cm (0.8inch to 157inch) with an accuracy of 0.3cm (0.1inches), which is good for most hobbyist projects. In addition, this particular module comes with ultrasonic transmitter and receiver modules.

The time between the transmission and reception of the signal allows us to calculate the distance to an object. This is possible because we know the sound’s velocity in the air. Here’s the formula:

This sensor is very popular among Arduino tinkerers. So, here we provide an example of how to use the HC-SR04 ultrasonic sensor with the Arduino. In this project, the ultrasonic sensor reads and writes the distance to an object in the serial monitor.

First, you create variables for the trigger and echo pin called trigPin and echoPin, respectively. The trigger pin is connected to digital Pin 11, and the echo pin is connected to Pin 12:

You also create three variables of type long: duration and inches. The duration variable saves the time between the emission and reception of the signal. The cm variable will save the distance in centimeters, and the inches variable will save the distance in inches.

In the loop(), trigger the sensor by sending a HIGH pulse of 10 microseconds. But, before that, give a short LOW pulse to ensure you’ll get a clean HIGH pulse:

The pulseIn() function reads a HIGH or a LOW pulse on a pin. It accepts as arguments the pin and the state of the pulse (either HIGH or LOW). It returns the length of the pulse in microseconds. The pulse length corresponds to the time it took to travel to the object plus the time traveled on the way back.

Then, define the trigger and echo pin. The trigger pin is connected to the Arduino digital Pin 11 and the echo to Pin 12. You also need to define the MAX_DISTANCE variable to be able to use the library.

In this post, we’ve shown you how the HC-SR04 ultrasonic sensor works and how you can use it with the Arduino board. For a project example, you can build aParking Sensor with LEDs and a buzzer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey