lcd panel meters are available in free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Selecting a panel meter for a particular application can be a daunting task, given the wide variety of products that are available today. There are many factors to consider when making a decision. Let’s look at a few of the major items.

Panel meters can be categorized by type, size, style or other criteria. One way to begin the selection process is to look at the meter’s function – what measurement is this meter making? Some common functions are ammeter, voltmeter, frequency meter, power meter, energy meter, counter, timer, temperature meter, process meter, and controller.

Panel meters are generally classified as either analog or digital. Does the application need a precise readout (digital meter) or a visible level indication (analog meter)? A hybrid of these is an analog/digital or digital bargraph meter, which provides both in a single instrument.

How much space is available in the panel? Both analog and digital meters come in a wide range of sizes. Analog meters from 1.5″ to 8.75″ are available from multiple manufacturers. Common digital meters vary from 1/32 DIN (24x48mm) to 4.25″ square ANSI. Smaller and larger meters of either type are less common, but still available. Bargraph meters go from 1/16 DIN up to 12″ high.

What meter style will properly indicate the reading and/or match other instruments in the panel? Analog meters come in round, square, rectangular, and edgewise styles. Edgewise models have a straight scale; the rest have a curved scale. Digital meters generally have a square or rectangular front panel, but vary in the number of displays and front panel controls. Bargraph meters have either straight or curved bars, similar to analog meter scales. For higher space utilization, dual or even triple display meters may be used. Examples of dual analog, digital and bargraph meters:

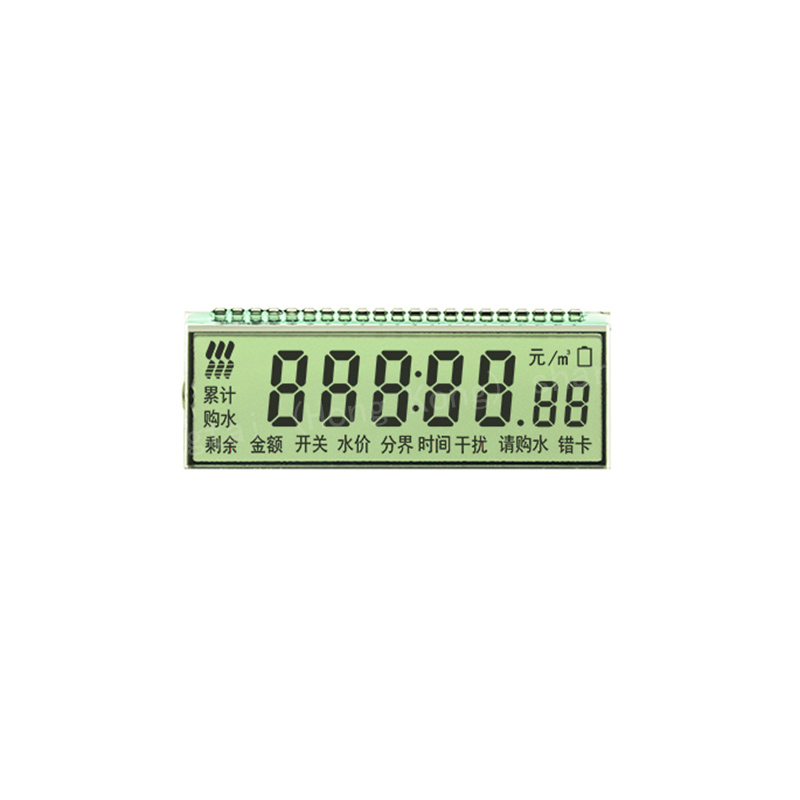

What is the preferred display? All analog meters have a pointer driven by a mechanical movement. Some models offer illumination for use in low light conditions. Typical digital displays are either LED (light-emitting diode) or LCD (liquid crystal). The most common LED color is red, but green, amber, or blue may be preferred in some installations. High brightness LEDs may be an option for use in sunlight. LCDs have either dark numbers on a light background or bright numbers on a dark background. Backlighting improves LCD visibility in low light areas. Digit height should be selected for readability at the expected viewing distance. Likewise for the height of scale markings on analog meters. On digital and bargraph meters, the number of digits and decimal position determine the reading resolution. Some digital meters use an alpha-numeric or graphical display to show setup prompts and additional information about the parameter being viewed.

Is the meter input an electrical signal or a sensor? For an electrical signal, select a meter with a matching function and level (e.g. 200V dc). Analog meters have a factory set function and range. The function and range on some digital meters can be changed by the user. For a sensor directly connected to the meter, select a meter compatible with the sensor type (e.g. thermocouple, RTD, strain gauge, RPM sensor). In some applications, a transducer may be used to convert a signal before it is sent to the meter. For these, a digital meter that can be set up to show a scaled or calculated value is desirable, so the readout appears in units of the signal source. Front panel markings on analog and bargraph meters can be customized to show the resulting scaled or calculated value.

Is a power source available in the panel to operate the meter? Most analog meters operate without external power. Digital meters usually require an external power supply, either AC or DC. Often the meter datasheet will list several power supply options to match the meter to the available panel supply voltage. An exception is loop-powered meters, which are powered from the 4-20mA DC input signal. Some AC power meters can also use the input signal to operate the internal circuitry.

Are meter outputs needed? Some applications use a panel meter to control external devices or interface to a SCADA system. Relays, either mechanical or solid-state, are an option on many meters. Care must be taken to match the relay specifications to the load characteristics (form, current rating, voltage rating, isolation, etc.). Note that analog meters with relay outputs are often called Meter Relays.

An analog output (aka analog retransmit) is a DC signal derived from the meter reading. It is typically a 0-1V, 0-10V, ±10V, 0-1mA or 4-20mA process signal used to drive a remote indicator or process controller. The output is usually set to cover the full range of the displayed value, but often can be scaled or modified to follow a narrower span or offset value.

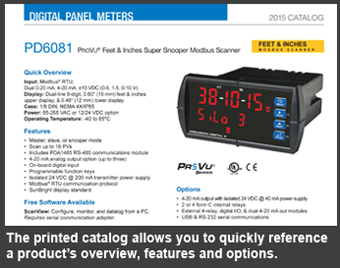

Will the meter interface to a computer or network? Many digital meters include or offer a communication interface for data export and/or meter setup. Typical hardware formats are RS-232, RS-485, USB and Ethernet. Common protocols are ASCII, Modbus RTU and Modbus TCP/IP. Specialized communication standards such as CANbus, Profibus, DeviceNet, and DNP3 are less common. Analog panel meters generally do not offer communication capability.

To select a meter for an application, rank the factors listed above in order of importance and begin to narrow down the available models. The Weschler website has selector tools in various panel meter categories to help do this across multiple brands. Then consider any special requirements such as shock, vibration, water resistance, extreme ambient temperature, sensor excitation, safety certification, etc. When several models meet the technical requirements, price and delivery can be assessed to make the final selection. For assistance at any point in this process please email a Weschler Meter Specialist or give us a call at 440-378-6580.

The EMA1710 panel meter features an analog-style LCD for the measurement of voltage. Fitted with a threaded stud that allows mounting of the product through a 5.5mm (7/32”) drill hole, this unique enclosure provides quick and easy mounting. A rubber seal provides splashproof protection when fitted between the meter and mounting panel. Connection is via wires.

A common application of a panel meter is motor current monitoring. A motor that runs fans or pumps in an industrial setting will have certain line parameters. For instance, the resistance of the fan may increase due to filter blockage, which if not treated, can lead to a cascade of problems, most notably halt in operations. Alternatively, a broken belt can lead to a drop-in motor output current, which must be dealt with immediately to regain productivity. A potential or current transformer can be used to measure the voltage and currents respectively, which can then be displayed on a panel meter.

Digital panel meters typically read an input signal, displaying it within a panel, examples being that of voltage, current and resistance. The signal comes from a sensor, whose input is converted into digital form and then displayed as a variable, e.g. temperature, pressure, etc. Depending on the functionalities, the meters can also act as controllers, generating a control signal that drives an actuator, relay, safety gate, etc.

Analog: the panel meter provides an analog output, i.e. variable current or voltage, proportional to the input signal, which can then be amplified to control output devices.

Numeric: this means that the panel displays only numbers; most products have this type of construction as the values that need to be displayed are mostly numbers.

Either LCD or LED is used as the display of a panel meter. An LED display consist of diodes that light up, usually following a N-segment algorithm. The benefit of an LED display is its visibility in the dark.

On the other hand, an LCD displays black digits over a gray/green screen. LCDs are less power consuming compared to LEDs but require a backlight for visibility in the dark.

The device’s physical compatibility with the panel is determined by the size of its panel face. Typically rated in millimeters or inches, the size is specified by both length and width, sometimes even depth. The display to be selected should have dimensions that can fit inside the control panel. Furthermore, the display should be large enough for operators to see, depending on the distance they would be standing at.

These are devices that measure analog signals and display them directly without any intermediate conversion. The values are displayed on a dial, usually with a scale, pointer and needle. Generally, an analog panel meter accepts a signal input, but based on the model can also accept multiple signals, such as pulsating frequencies. These are known as multiple channel analog panel meters. The introduction of digital panel meters has pushed out analog products, however, they are still used in some applications. Modern analog meters usually feature anti-glare and illuminated face displays.

Taut band: A moving pointer is suspended between two ribbons of metal that reduces friction and improves sensitivity. These devices can withstand randomly generated shocks, making them suitable for rugged environments.

Pivot & jewels: These can withstand shocks but are not as accurate as taut band panel meters. The operation method involves a coil & pointer being suspended by steel, fitted into two jewel bearings.

Furthermore, analog panel meters are available in more than one channels, having the capability to measure multiple variables in different units. They are commonly used to measure three phase power. Devices are also available that can measure radio frequency signals.

Most analog panel meters usually have a range of measurements that fall between 0 – 4 mA or 0 – 10 VDC. Face type, depth behind panel and dimensions are common specifications for an analog panel meter. The most common face types used are either round or rectangular. Round devices vary by front face diameter while rectangular devices vary in terms of front face height. For devices that have zero as a reference point, scaling methods that are commonly used are zero-right, zero-left and zero-center.

Totalizers:these panel meters take the sum of an input signal over a specified period of time. Totalizers are generally used to count pulse inputs or in flow measurement applications.

Temperature and process panel meters:this is the most common type of panel meter, and accepts a single channel input, displaying it digitally on the screen. Common inputs are those taken from temperature sensors such as RTDs and thermocouples.

Multi-input indicators:a type of digital panel meters, it can accept more than one input. Most meters have a switching button that displays the output of the subsequent channel, while there are others that can scan all channels automatically, switching its output periodically.

The summary of the product category, refine search conditions, and part number list (up to 300 part numbers) are output as simple catalogs. To change the number of columns to be output in the part number list, use the "Change Columns".

・An asterisk (*) and question mark (?) can be used as wild cards. When an asterisk (*) is entered in a character string where a portion of a part number being searched is unknown, products can be searched as a condition specifying any character string. A question mark (?) can be used as a condition specifying any character string.

・An asterisk (*) and question mark (?) can be used as wildcards. When an asterisk (*) is entered in a character string where a portion of a part number being searched is unknown, products can be searched as a condition specifying any character string. A question mark (?) can be used as a condition specifying any character string.

・An asterisk (*) and question mark (?) can be used as wild cards. When an asterisk (*) is entered in a character string where a portion of a part number being searched is unknown, products can be searched as a condition specifying any character string. A question mark (?) can be used as a condition specifying any character string.

Product used for applications(running, turning, stopping and safety devices)which particularly concern human life, such as in devices for automobiles.

These products are intended for use in implanted medical devices such as cardiac pacemakers, cochlear implants, insulin pumps and gastric electrostimulators .

This term refers to circuits in implanted medical devices that are not directly linked to life support, i.e. circuits that will not directly endanger the life of the patient should the functionality of the device be reduced or halted by failure of the circuit.

By making full use of the water repellence of the capacitor surfaces, this product minimizes Ion migration from the external electrodes (Terminations) that results from condensation.

Product used for applications(running, turning, stopping and safety devices)which particularly concern human life, such as in devices for automobiles.

These products are intended for use in implanted medical devices such as cardiac pacemakers, cochlear implants, insulin pumps and gastric electrostimulators .

This term refers to circuits in implanted medical devices that are not directly linked to life support, i.e. circuits that will not directly endanger the life of the patient should the functionality of the device be reduced or halted by failure of the circuit.

The electrodes of this 2 terminal capacitor are configured in the longitudinal direction (LT side) of the chip, unlike the electrode positions (WT side) of a common 2 terminal capacitor.

By making full use of the water repellence of the capacitor surfaces, this product minimizes Ion migration from the external electrodes (Terminations) that results from condensation.

Product used for applications(running, turning, stopping and safety devices)which particularly concern human life, such as in devices for automobiles.

These products are intended for use in implanted medical devices such as cardiac pacemakers, cochlear implants, insulin pumps and gastric electrostimulators .

This term refers to circuits in implanted medical devices that are not directly linked to life support, i.e. circuits that will not directly endanger the life of the patient should the functionality of the device be reduced or halted by failure of the circuit.

By making full use of the water repellence of the capacitor surfaces, this product minimizes Ion migration from the external electrodes (Terminations) that results from condensation.

We are now able to supply hour meters and battery indicators for the automotive industry. There are a veriety of products available, with LCD and electromechanical displays, with different housing options, dual channel units with hour/hour, count/count, and hour/count configuration.

Hoyt has resolved forever the question of choosing between digital or analog panel meters with the new Combo Series. For the first time, all of the advantages of both analog and digital panel meters are combined in one meter. The Combo Series features the same precision analog meter movement you expect from Hoyt, with the addition of a 3 ½ digit, bright red, digital display featuring 0.37" high digits. For all their innovation, the new Combo Series meters are completely compatible with existing analog-only or digital panel meter- applications.

With the addition of what amounts to a digital panel meter (DPM) in an analog panel meter case, questions immediately arise regarding input signal and power supply common, ground, “floating”-, single ended, or differential inputs. Hoyt resolves these questions too, very simply — the new Combo Series meters are self-powered, 2-wire meters. That means there are only two connections, the + and – leads of the input signal. The entire meter, both analog and digital displays, is fully powered by the signal being measured. There are never any grounding or signal- reference questions.

Regardless of whether you use analog or digital panels meters now, incorporating Hoyt’s Combo Series will provide a significant space savings in your next application. If you are using analog panel meters now, you can instantly achieve the added benefit of both by upgrading to a Hoyt Combo Series meter. It’s fast, easy, and the two-wire connections allow the Combo Series to upgrade virtually any analog meter application.

Large, bright red LED digital displays are available in Combo Series meters to monitor a wide variety of AC voltage, DC voltage, and frequency ranges. Hour meters are available in the Combo Series with LCD digital displays. With the most popular signals and ranges addressed, Hoyt has a Combo Series meter to meet your specifications.

The left number is the Display Number, which is 04 in this example. The right section shows the Register Read, which is 000753 in this example. You need both numbers to get your billing reads.

Although the meter may show more Display Numbers than listed, UI only needs a few for billing. If your meter does not show all of these Display Numbers, don’t worry. The missing Display Numbers won’t be needed for your bill.

/Digital%20Panel%20Meter%20(0%20to%20100V%20%200%20to%2010A)-1000x750.jpg)

The N1540 is a fast sampling (up to 50 samples per second) process indicator with a wide list of input types - thermocouples, Pt100 RTDs, voltage and current – the N1540 is capable of measuring the majority of the variables and sensors encountered in industrial processes.

The N1540 meter was designed with advanced technology for highest performance and reliability in the most demanding applications. Based on an advanced and robust hardware platform, the N1540 can be fully programmed via its front keypad or via a USB interface. The unique USB interface makes the programming task a simple one step fool proof operation. It allows, for example, the set up of several instruments with the same programming parameters with extreme ease while saving precious time.

This powerful but attractively priced panel meter contains two alarms (six functions), sensor offset, configuration of parameters protected by password, serial communication, indication in degrees Celsius (°C) or Fahrenheit (°F), among others.

With a very short 35 mm (1.34 inches) depth enclosure, the N1540 can be easily installed in panels and enclosures where space is at a premium. Dual alarm relays and a convenient 24 V auxiliary power supply are also available in this competitively priced process meter.

The meter configuration can be performed directly on the meters key panel or through the USB interface. We offer a free downloadable software, NConfig software, for configuration and monitoring through the USB port of a Windows computer.

The USB interface is used for CONFIGURING or MONITORING the panel meter. We offer NConfig software as a free download that must be used for the configuration. It makes it possible to create, view, save and open configurations from the meter or files in your computer. The software can be used for saving and opening configurations in files and makes it possible to transfer configurations between meters and to make backup copies.

For MONITORING purposes you can use any supervisory software (SCADA) or laboratory software that supports the MODBUS RTU communication on a serial communications port. When connected to the USB of a computer, the indicator is recognized as a conventional serial port (COM x).

Metal Surround Case. Cannot be used with the Panel Cutout Reinforcer and the Panel to Case Seal Adaptor. THE "OP-MTLCLIP" (2pc Screw mounting clips) BELOW WILL ALSO BE SELECTED, AS THEY ARE NECESSARY TO INSTALL THE METAL CASE.

This compact panel meter features a 3½ digit LCD with 12.5mm (0.5”) digit height and a low-profile bezel for mounting. With a 200mV d.c. full scale reading, auto-zero and auto-polarity this meter plugs directly into a single-in-line (SIL) socket or can be panel mounted using the snap-in bezel and window supplied.

This compact, 4-20mA loop powered panel meter features a 3½ digit LCD with 11mm (0.43") digit height, LED backlighting and one-piece snap-in housing. Calibration is by two multi-turn potentiometers and connection to the current loop is via two screw terminals.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Honestly, I really like the meter, BUT, the panelpilot system used to program these has left me in a sticky situation. I purchased a few of the OM-SGD-24-M meters along with the OM-SGD-ADPT-TC modules to allow me to monitor temp on our UV ovens. I was able to program these without any issue using panelpilot version 2.23. The next order of meters I ordered would not program, and I was instructed to update version 2.23 to version 2.27. After the update was complete I still was unable to program these meters. This has caused me to not be able to install any of the new system I have been working on during our July 4 shutdown, and have to postpone the installation of this system 6 months till Christmas shutdown. I realize that Omega"s hands, but I would not recommend buying any of these meters until they can get this issue resolved.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey