make any lcd touch screen manufacturer

Remanufacturer and distributor of liquid crystal, panel and touch screen displays. Available with 100 VAC to 240 VAC power supply. Features include front bezels, USB support, windows, auto-adjust buttons, built-in power supply and USB cable brackets. AutoCAD files accepted. Most items available in stock. 24/7 services provided. RoHS compliant. UL and cUL listed. CE certified. Two year warranty.

Manufacturer of custom rugged displays for military, marine, industrial, avionic, medical, transportation, commercial and other applications. Diverse engineering team able to design to fit any enclousure. Many types of touch screen technologies available, including surface capacitive, projected capacitive, resistive, SAW, infrared, optical, DST. Other features include sunlight readable, NVIS, waterproof, flip-up, flip-down, rack mount drawer, panel or rack mount, and much more. All sizes are available, from small to large. Suitable for workstations, cockpits, medical devices and other safety- or mission-critical applications. Manufactured, serviced, and supported in the USA.

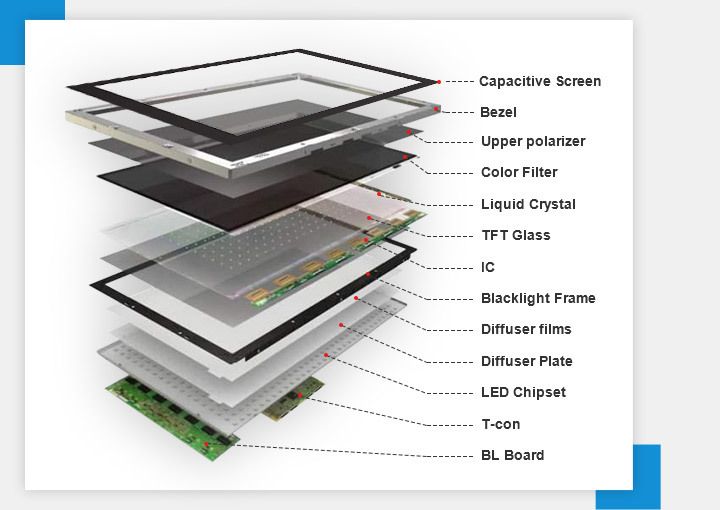

Manufacturer of standard and custom liquid crystal display (LCD) displays. Thin film transistor (TFT) and graphical displays are available. Offered with LED backlight and integrated capacitive or resistive touchscreen. Suitable for medical devices, embedded systems, airplanes, amusement parks, golf carts and vehicles. Serves automotive, automation, gaming, security and OEM industries.

Distributor of touch screen panel liquid crystal displays (LCDs). Available in 10.1 in. sizes. Inventory management services are also offered. Serves the electronics, computer, telecommunications, aerospace, aviation, medical, automotive and transportation industries. ITAR registered. Stock items available.

Manufacturer of optically bonded, non-touch and touchscreen displays. Features vary depending upon model, including vision 2 display controllers with quad-core multimedia processors, liquid crystal displays, auto-dimmable display backlights, housings with powder-coated die-cast front, horizontal and vertical viewing angles, membrane keyboards, internal temperature sensors, programmable software and resistive touch screens. Meets ASME and OHSAS 18001 standards. CSA and NFPA approved. API registered. CE certified.

Manufacturer of flat-panel industrial monitors and displays rated for Division 1 and Division 2 environments. Custom engineered, designed, and manufactured to handle the dust, dirt, debris and chemical exposure common to rugged and hazardous applications in the oil and gas, pharmaceutical and food processing, manufacturing and chemical industries. Types of monitors include military grade, LCD, rugged, washdown, high definition, wide screen, panel mount, rack mount, flush mount, gas purged, and more.

Manufacturer of resistive touchscreen HMI displays with anodized aluminum housings, USB and Ethernet. Available in four screen sizes, 6.102 to 11.535 in. width, 2.283 in. depth and 5.315 to 8.78 in. height. Surrounding air operating temperature ranges up to +55 degrees C. Serves the automotive, railway system, power engineering, building, lighting, marine, offshore and process industries. Most items available in stock. RoHS compliant. UL listed. CE certified. JIT delivery.

Distributor of integrated touch screen displays. LCD, sunlight readable TFT, monochrome, chip on glass, TFT LCD, LED, automotive rear seat and OLED displays are also available. Vendor managed inventory (VMI) programs and stock items available. Meets AS9100 Rev C standards. Kanban and JIT delivery.

Manufacturer of Industrial touchscreen displays suitable for railway sign, airport control tower, digital signage, agriculture, factory automation, kiosk and retail applications. Available in 10.4 to 21.5 in. display size, -10 to 60 degrees C operating temperature and 9 to 50 volts DC voltage. Some monitors are offered with fanless and rugged design, LCD display, front panel IP65 waterproof, dual speakers, resistive and capacitive (PCAP) touch options available. EPA registered.

Manufacturer of standard and custom thin film transistor liquid crystal displays (LCD) including human machine interface diagonal touchscreens. Available in 5 VDC power at 200 mA current, 4.3 in. screen sizes, 0.92 in. depth, 4.75 in. width and 3.70 in. height. Features include programmable, graphical operating systems, front panel mountable enclosures, protective overlays, built-in copy protection options and power management controllers. Serves the pharmaceutical packaging identification, instrumentation, emergency response service, recording and bioprocessing industries. Made in the USA.

Manufacturer of touchscreen panel displays for medical and industrial applications. Available in 10.1 to 27 in. display sizes. Features vary depending upon model, including LED backlights, plastic design, USB, flat, power connectors, optional side brackets, input video signal interfaces and terminals. Accessories such as power adaptors, cords, cables and stands offered. Meets EN 60601-1-2 standards. Custom options depending upon applications are also provided.

Manufacturer and distributor of touchscreen, sound, video and theatrical displays. Types include counter top, back-up, extension, dual USB charger, heads up and four sided color changing displays. Available in a variety of configurations. Features vary depending upon model and include LED light strips, wireless remote control, LCD widescreen rear view mirrors and license plate cameras.

Manufacturer of touchscreen displays for home automation, video intercom and door entry system. Features include up to 16 control functions, intuitive operation and capacitive touch display. Lifecycle management, engineering, consulting, installation, maintenance, replacement and training services are provided. Serves the automotive, chemical, marine, metal, food, beverage, mining, power generation or distribution, solar power, printing, aluminum, cement, automation, water, wind power, pulp and paper industries.

Manufacturer of alphanumeric, touchscreen and LCD displays. Features vary depending upon model, including built-in Ethernet ports, hand-held versions, single port multi access (SPMA), integrated simulation functions, analog resistive touch, multiple communications, compact flash memory cards and FTP web interfaces. Serves the automotive, food/packaging, electronics, life sciences, material handling, machine tool, oil and gas, water, wastewater, security, detection, entertainment and other industries. 24/7 predictive maintenance services also provided.

ISO 9001 certified worldwide manufacturer of touchscreen terminals, monitors & displays. Graphics touchscreen terminals enable operating, monitoring & control of large scale projects with different PLC"s simultaneously. Features include plain text messages & graphical overview screens for user-friendly diagnostics. Touchscreen terminals are available in sizes of 5.7 in., 6.5 in., 10.4 in. 12.1 in. & 15 in. Terminal features also include Microsoft Windows ® CE.net operating system, USB interfaces, serial interfaces, Ethernet interface, IP65 front, IP20 back & PCMCIA slots.

Six Sigma capable, ISO 9001:2008 & ISO 14000 certified manufacturer of touchscreen displays including flat panel monitors. Types of flat panel monitors include DVI/RGB and hazardous location compatible. Flat panel monitors feature front USB interface, 256K or 16 million color display, analog resistive touch panel, serial/USB touch interfaces, on-screen-display menu for brightness & contrast control, & VESA standard wall mounts. Available with a 2-year warranty. Markets served include industrial, automotive, oil & gas, water/wastewater, semiconductors & agriculture. Modbus-IDA, OMAC & ODVA affiliated. Products are UL® listed, CSA® approved, and ATEX & CE certified. Products are RoHS compliant.

Custom manufacturer of touchscreen displays for stationary storage, equipment, electric and hybrid vehicles. Battery management systems and vehicle control systems are offered. Fleet management software is also provided. Consulting is available as value added service. Serves the e-mobility, automotive and mobile robotics industries.

Precision CNC machining, sheet metal fabrication and assembly services. Repair services are also provided. Fiber optic junction boxes, converters, latches and switches are offered. Uninterruptible power supplies (UPS), liquid crystal displays (LCD), racks, consoles, multiplexers, control panels and quad-core processors and servers are also available. Serves aerospace and defense industries.

Manufacturer of 5.7 in. color graphic touchscreen displays. Operating temperature ranges from -4 to +158 degrees F. Features include programmable system setup, plug and play device display detection, programmable screen savers, LED backlights, dual power over Ethernet and high speed communication ports. Suitable for industrial facilities, commercial enterprises, government and public services and power utilities. RoHS and IEEE 1519 compliant. UL listed. CE certified.

Manufacturer of position and process LCD touchscreen multifunction displays. Available in 96 x 48 mm and 92 x 45 mm sizes and 18 to 30 VDC power supply. Working temperature ranges from -20 to +60 degrees C. Features include scalable analog outputs, four switching, two relay outputs and RS232 interfaces. Repair services are also offered. Serves the drive/elevator technology, mobile automation, heavy crane, steel, wind turbine, solar energy, packaging and bottling plant industries. RoHS compliant.

Manufacturer of LED/LCD displays for rugged, outdoor, touch embedded and industrial applications. Features vary depending upon model, including standard integrated frames, panel mount, USB interfaces, tempered smudge resistant protected glasses, backlights and LCD panels. Two year warranty.

Custom manufacturer of touchscreen LCD displays. Various capabilities include design, testing, engineering, cutting, plating and potting. Electronics, medical, telecommunications, gaming and other industries served. Meets IPC standards. JIT delivery.

The world is rapidly becoming a more technologically advanced place, with various devices now being developed by touch screen manufacturers to make things easier. One of the most popular forms of such devices is the touch screen technology.

The technology utilized by touch screen displays enables users to interact with a device simply by touching it – meaning that it does not require manual inputs such as a mouse or keyboard. As a result, there has been a huge surge in the manufacturing of touch screen technology, with a variety of commercial and industrial applications now using this form of touch technology.

At faytech, we are shaping the future of touch screen technology manufacturing and we believe the future of commercial and industrial applications will use touch screen solutions. As original equipment manufacturers, we continue to innovate in the realm of projected capactive touch screen technology, resistive touch screens, and LCD display technology.

In order to manufacture touch screen technology, it is necessary to begin with the basics – understanding what the technology is and its advantages over traditional input methods.

To put it simply, touch screen technology works by utilizing capacitive sensing to detect when a user interacts with a device. This happens when the user touches the device and the capacitive sensing technology detects an electrical field.

This in turn allows for an input from the user – turning electrostatic energy into actionable data for the device to respond to. As a result, users can benefit from an intuitive interface which allows them to interact with devices without needing any physical buttons or keyboards.

This level of user-friendly interaction has been made possible thanks to advances in touch screen technology manufacturing. It is now easier than ever for companies to source parts for their touch screen devices, allowing them to quickly and efficiently produce high quality units for their customers. Companies can also customize their touch screens – with various sizes, shapes, colors and materials available depending on their needs.

The increasing popularity of touch screen technology has meant that more and more commercial and industrial applications are now beginning to use these solutions.

One example of public use of touch solutions is in retail stores – where customers can now use touch screens to browse products and quickly complete transactions without having to wait in line or speak with someone at the checkout counter.

Other applications range from medical equipment, medical devices, self-service kiosks, industrial machinery, vending machines and more – all of which can be improved through the use of touch screen technology.

It is clear that touch screen technology is becoming increasingly relevant in many different industries – creating a huge potential for companies looking to capitalize on its benefits. In the future, we can expect even more businesses and organizations to begin using touch screen solutions in order to make their processes simpler and more efficient.

With that in mind, it’s clear that those involved in touch screen technology manufacturing should continue to invest in developing their products, ensuring that they remain ahead of the curve in providing reliable solutions for commercial and industrial customers who are looking for an easy way to interact with their products or services.

Overall, it’s clear that touch screen technology manufacturing has come a long way over recent years – enabling easier interaction between users and their devices.

If you are interested in adding touch screen solutions to your organization, but aren’t sure where to begin, we would be happy to answer and questions you might have and guide you to the best solutions for your needs and bugdet.

Elo is a global leader in,including modern point-of-sale systems and interactive digital signage, ranging in size from 7’’ to 65’’. Elo now has more than 200,000 retail and hotel facilities in more than 80 regions/countries. Its products are designed in California and come with a three-year standard warranty. The Elo touch screen experience always stands for reliability, innovation, and quality. Elo"s product portfolio includes various interactive touch screen monitors, OEM touch screens, touch screen computers, touch screen monitors, and touch screen controllers. You may have interacted with Elo touch screens in interactive kiosks, game consoles, hotel systems, Wayfinder displays, point-of-sale terminals, transportation applications, interactive retail displays.

3M Touch Systems, Inc. manufactures and supplies pen-sensitive and touch input systems. The company"s products include electronic whiteboards, touch screens, self-service kiosks, point-of-sale devices, information point displays, and entertainment and gaming systems. 3M Touch Systems provides services to customers worldwide. It was established in 1983 and is in St. Pual, USA.

DMC Co. Ltd. is a touch screen manufacturer with more than 20 years of experience, providing a series of touch screens from 3.8 inches to 46 inches diagonal for display panels.

· Available touch screen technology: resistive touch technology with multi-touch and single-touch function, and the newer capacitive touch technology, which has a lighter operating pressure.

Through unique technology development method, they successfully realized the mass production of glass resistive touch panel type, bringing the latest electronic components to advanced industries. They have made quite a lot of achievements in the automotive touch panels produced for the automotive industry; They have received overwhelming support in the areas of quality and service.

AMT focuses on providing high-quality touch technology for industrial, mission-critical, and medical applications. AMT was established in Taiwan in 1998. AMT have extensive experience in the development, design, and production of total touch solutions, and can provide one-stop production of PCAP and resistive controllers, touch panels, and device drivers.

Eagle Touchis a high-tech enterprise specializing in the design, manufacturing, research and development, and sales of touch screen displays and touch screens, providing complete touch solutions and high-quality touch screen products for the global touch market. As a Chinese touch screen manufacturer, Eagle Touch always uses the latest technology to update production line. Their current product line includes resistive touch screen 4/5 line (PCAP) projected capacitive touch screen. (EETi and Ilitek solutions). Eagle Touch established a touch display production line in 2010, and its main products include open displays, touch screen displays, custom displays and all-in-ones.

Zytronic has more than 2 years of experience in the field of digital display manufacturing company based in Newcastle and has now developed a global influence with the help of Zytronic Japan and Zytronic Inc. Committed to the future of touch interaction for self-service and public use, today"s multinational manufacturers continue to develop cutting-edge technologies, making them one of the fiercest competitors in the market.

Projected capacitive technology (PCT)experts make touch screens that are durable and of high quality-making these screens an ideal solution for all demanding work environments.

HIGGSTEC Inc is a Taiwanese company engaged in the research and development of touch technology. The company"s products include customized5-wire resistive touch solutions, standard 5-wire resistive touch solutions, and projected capacitive touch solutions and controllers. Its products are used in automotive, military, medical, gaming, and marine industries.

In addition to having a wide range of product applications and multi-faceted solutions, TPK is also equipped with industry-leading touch panel technology. Its products include various types of structures glass-film-film (GFF), such as glass-glass (GG), and single glass solution (SGS), including Touch-on-Lens (TOL)), single glass solution (OGS)), Glass-Film (G1F), etc. TPK goal is to improve the performance of TP products while making them lighter and thinner.

In addition, as an industry leader, through continuous research innovation, and development, TPK provide better multi-touch and large-size touch solutions and have obtained SITO structure (single indium tin oxide structure) and hundreds of other TP patents.

AD Metro is a leading supplier of touch screen solutions for original equipment manufacturers (OEM), system integrators and value-added resellers. Our touch screen solutions are designed to meet the requirements of industrial, commercial, and military applications. AD Metro products are embedded in control panels, displays, kiosks, all-in-one PCs and mobile computing devices. They are widely deployed in a wide range of applications in gaming, healthcare, aerospace, industrial, medical, marine, retail, transportation, and military fields. Millions of people around the world are exposed to A D Metro solution every day.

A D Metro’s patented ULTRA armored glass touch screen is the industry’s most durable resistive touch screen sensor and a fully proven solution that is ideal for harsh operating environments.

Our industrial display touch screen monitors can help your factory personnel and workshops handle complex industrial tasks on intuitive factory grade touch screens. Our wide range of rugged LCD displays with multi-touch and various touch technologies such as resisitive, SAW, optical imaging, projected capacitive and infrared are tough and suitable for virtually any industrial applications. We can help you choose the best touch screen technology and solution that fits best with your needs, and close the gap between your vision and implementation of the digital factory.

Viewsonic"s Touch Screen Solutions helped us simplify the hassle of operating complex machinery in our factory. It really helped us improve our factory line operations and reduced labor input.”

We"ve provided customers with innovative touch solutions for over 30 years. Our touch screen products are perfect for hospitals, schools, homes, kiosks, offices, and retail displays. Simple to connect and easy to use, touch screens allow you to turn any monitor into an interactive display.

Since 1990, AccuView is dedicated to delivering fully customized LCD display solutions for our customers. Our strength lies in understanding and meeting our customers" EXACT requirements coupled with AccuView"s comprehensive manufacturing capabilities and expertise to deliver the right LCD display solution. Let AccuView be your total video solution provider.

Touch screens offer ease of use, speed, accuracy, and negate the need to become proficient with a handheld device. General Digital offers the option of equipping your LCD monitor with a variety of touch technologies, such as:

In 1977, we created the world’s first touch responsive industrial terminal, the VuePoint™. It didn’t have a true touch screen; rather, the VuePoint was equipped with a circuit board onto which infrared LEDs were mounted. The LEDs were arranged to form a 12 x 40 grid and when the screen was touched, the infrared beams were broken, indicating the touch location to the terminal. Thus, an operator could control a system right at the terminal.

As touch screen technology evolved (along with monitor technology), we incorporated various touch panels into our LCD monitors, starting with our SlimLine™ series of flip-up LCD monitors. Over time and based on demand, our Saber RackMount, PanelMount and Standalone Series became the next logical candidates for touch integration. This was due to increased use of flat panel technology in human-machine interface applications.

Featuring pure glass construction, Surface Acoustic Wave (SAW) touch screens will almost never physically “wear out” due to a superior scratch-resistant coating. Excellent light transmission ensures that the image clarity of the display remains sharp and vibrant. The stable, “drift-free” operation means that the touch response is always accurate. They work well with a finger, gloved hand or a soft stylus. And SAW touch screens have a sensitive touch response—they recognize the touch location and the amount of pressure applied.

Being an all-glass design, light transmission of surface capacitive touch screens is improved, when compared to resistive touch screens. This improves display viewability and reduces eye fatigue. Featuring a scratch-resistant top coat, durability in heavy-use environments is easily maintained. This type of touch screen is ideally suited for rugged, industrial or military applications.

Infrared touch technology doesn’t rely on an overlay or a substrate to register a touch, so it cannot physically “wear out,” thus ensuring a long product life cycle. Possessing superior optical performance and excellent gasket-sealing properties, an infrared touch screen is ideal for harsh industrial environments and outdoor kiosks. They work with a finger, gloved hand, stylus, and most any object wider than 1/10". They adjust to changing light conditions, even direct sunlight. And they benefit from stable, no-drift calibration performance.

Working in tandem, two optical sensors track the movement of an object close to the surface by detecting the interruption of the touch screen’s infrared light source, which is emitted in a plane across the display surface and can be either active (infrared LED) or passive (special reflective surfaces).

Optical touch screens use a controller board that receives signals from the optical sensors, then compensates for optical distortions and triangulates the position of the touching object with extreme accuracy.

The infrared light source and optical sensors of the touch screen are synchronized using a sophisticated algorithm that also reduces the effect of ambient light, thus creating a very clear, accurate touch selection.

Developed specifically for interactive digital signage applications, Dispersive Signal Technology determines a touch point by measuring the mechanical energy (bending waves) within a substrate created by the pressure of a finger or stylus. As these bending waves radiate away from the touch location, the signal spreads out over time due to the phenomena of dispersion. The “smeared” signals are then interpreted by a complex set of algorithms to precisely pinpoint the exact touch location on the screen.

DST is a passive technology, waiting for a signal created by a touch impact. Therefore, contaminants such as dirt, grease, and other solids can accumulate on the surface and edges of the display screen without significantly affecting touch responsiveness. In addition, surface damage, such as scratches, has no significant impact on touch performance.

The sophisticated and optimized controller that continuously monitors for a touch impact is the fastest and most responsive technology available for large format displays, offering greater than 99% touch location accuracy.

General Digital’s Sales Engineers are quite knowledgeable at determining what will best suit your particular application. Contact us at 800.952.2535 today and we will be happy to take the time to understand your needs and make our recommendations.

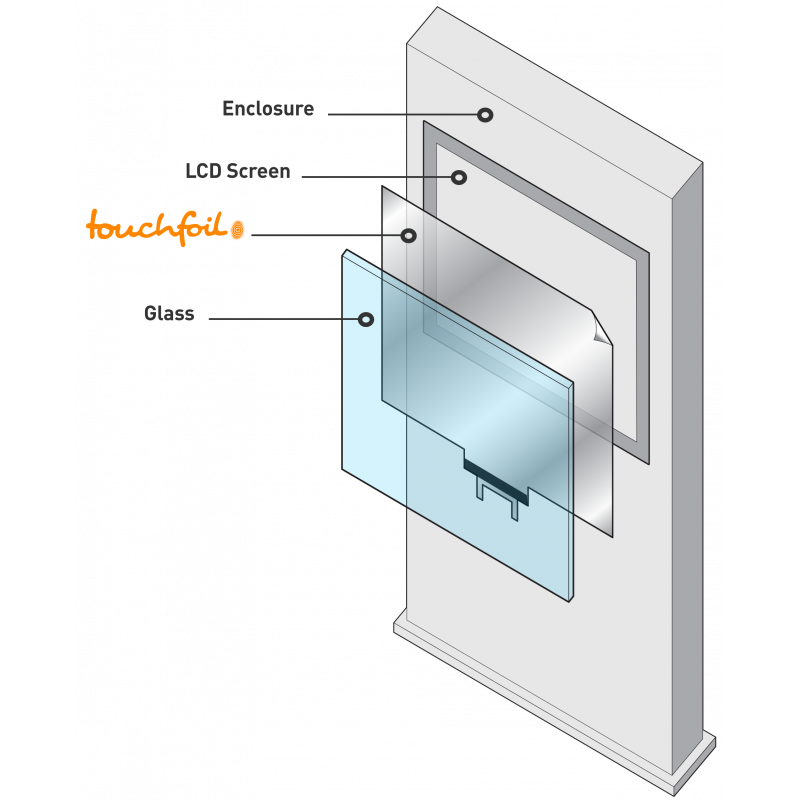

A 3D model of the custom oem touch screen monitor and display will be drawn and designed within 3 working days. After your approval a sample of the monitor will be produced within 10 to 15 working days, you can then test it and make any changes you’d like to the design. Once you are happy with the sample it will then be taken to production.

Ideally, oem touch screen display are produced and manufactured in low volumes to help control inventories and ensure that the market is subjected to testing before producing larger quantities. This means that feedback can be taken by the public your product can be improved upon to meet their desires. Customized touchscreen displays can be rapidly produced to meet your criteria.

When your requirement is received, we will get in touch with you as soon as possible. You only need to provide your needs, ideas or manuscripts, we will communicate with you about the size ,appearance, performance and the details about how to choose the touch screens and the displays. If it is necessary, our draft design can be provided. Meanwhile, Welcome to visit our facility and discuss your project face to face if you are convenient.

All the products we provide must go through 9 inspection tests. Screen aging test and high and low temperature test can improve the reliability of the product effectively. And we can provide you with the best quality.

Superior optics for use in high ambient light conditions and high accuracy are important characteristics of touch screens used in the medical industry. It is also important that these units are properly sealed to protect against ingress of water, saline, gels, cleaning solutions and other liquids the unit may be exposed to in the healthcare environment. Learn more about the benefits of DawarTouch solutions for the medical industry.

Excessive vibration and high temperatures are just a few of the extreme environmental conditions touch screens used in the military and aerospace industry experience. A ruggedized and durable product is a must in these industries alongside sunlight readability, low reflections and a robust seal to protect against dust, dirt, debris and liquids. Learn more about the benefits of DawarTouch solutions for the military and aerospace industry.

Touch screens used in Instrumentation and industrial type applications need to be reliable, accurate and highly responsive to touch with a bare finger, stylus or a thick work type glove. Durability and impact resistance is also an important feature as often times these applications are in factory or laboratory type environments and experience heavy use. Learn more about the benefits of DawarTouch solutions for the instrumentation/industrial industry.

In-vehicle control touch screens are used in numerous industries from emergency response vehicles to agricultural, construction and warehouse equipment. Many times these environments require a durable, impact resistant, lightweight or portable solution that can be used with finger, thick work glove or stylus. Durability and protection against shock and vibration is also an important feature for this industry. Learn more about the benefits of DawarTouch solutions for the in-vehicle controls industry.

Touch screens used in the POS/Kiosk market need to offer long life expectancy and high endurance for excessive public use. Sunlight readability, quick response and accuracy are other important features often required with these types of applications. Learn more about solutions for the POS/Kiosk industry.

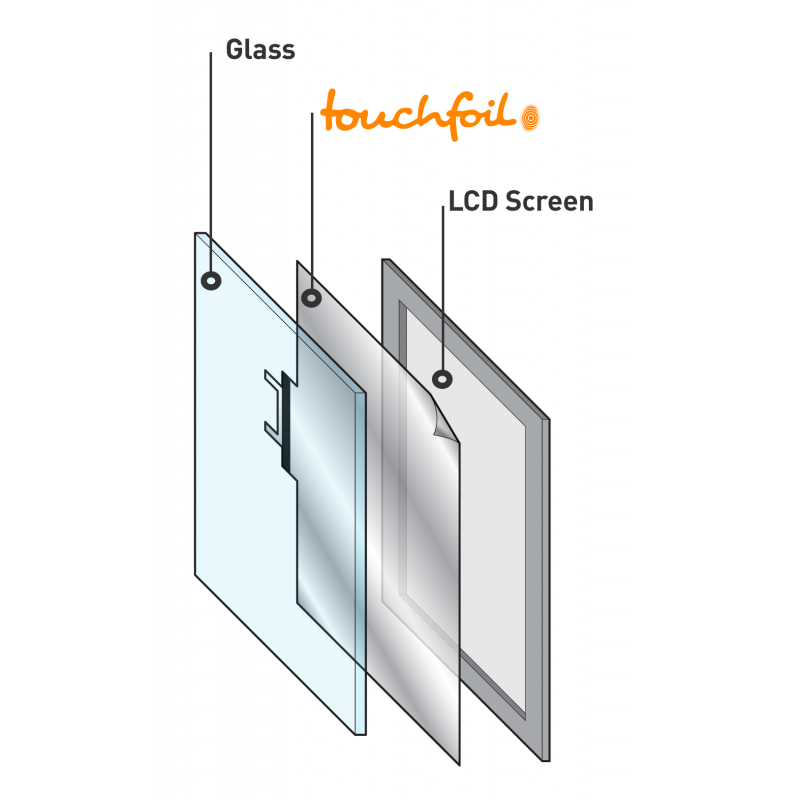

Touch screens used in the marine environment often require custom tuning to eliminate false touch occurrences from contact with salt water. A cover lens, film enhancement or optical bonding process may also be required for improved sunlight readability in these outdoor applications. Learn more about solutions for the marine industry

Top One Tech Ltd. is a touchscreen monitor manufacturer that integrates the design, manufacture, and sale service of open frame Touchscreens, touch display and touch All-in-one computers. Our vision is to serve all customers with heart and grow with you.

At Toponetech touch screen suppliers, we provide high-quality touchscreen monitor prototyping, fast production of samples and low volume manufacturing services to support the development of your monitors and low volumes launching needs. Toponetech touchscreen monitor manufacturer with a team of engineers work to make your touch display ideas a reality through manufacturing technologies like 3D designing, touchscreen selection, controller boards selection, plastic and metal frame CNC machining, a range of finishing services, display assembly, and FQC.

A touchscreen monitor incorporates the function of the pointing device into the display, replacing both mouse and keyboard. Interaction with the computer takes place via a system which detects contact with the screen surface.

Resistive screens are differentiated by the number of wires they have. The five-wire system compensates for their fragility, making them more durable and less prone to scratches and cracks.

Capacitive models respond to the transfer of electrical charges when touched, and cannot be used while wearing a glove. They are very bright, but have a fragile surface coating. Projected capacitive versions take advantage of the proximity transfer effect. Their surface is protected by reinforced glass.

Infrared technology uses light detection, the screen responding even before it is touched. However, it offers limited resolution and is prone to accidental activation. The most common type is the surface acoustic wave (SAW) screen. It responds to a wide variety of touch techniques, some screens even taking into account the amount of pressure applied. It is very bright and has excellent resolution.

In addition to size and resolution, choice of touchscreen will depend on the conditions under which it will be used and the possible need for multi-touch capability.

Our products are designed to eliminate the fuss of multiple wires, with only one USB connection powerful to accommodate both video and touch capability, and run everything you need. Supported under Windows, Mac, and Linux, and designed

Our touchscreens are used across industries ranging from hospitality, to entertainment, IT, medical and transportation, ideal for interactive POP digital signage, point-of-sale systems, hands-on kiosks, conference rooms and more.

Touch screens give the user control of a device through simple or multi-touch gestures. They enable the user to interact directly with what is displayed rather than using a mouse, trackpad, or other separate components.

To quickly install and maintain large machines or kiosks used in public places, most customers want to use modular semi-finished products, that is, open frame touch screen monitors. AMT understands that customers’ projects have a variety of needs, and some specifications of ready-made open frame touch screen monitor modules may not meet the requirements. Therefore, we provide a full range of design options to create a suitable open frame touch screen monitor for you.

One of AMT’s greatest strengths is the ability to customize our proprietary touch screen and touch controller technology. We also able to customize other elements of our open frame touch screen monitor to meet a wide range of customer applications. Thus, an AMT open frame touch screen monitor is incredibly customizable and most customers will find it easier to integrate a bespoke AMT product into their project rather than working with off the shelf models.

To facilitate installation, the AMT open frame touch screen monitor provides standard VESA holes and also a fixture that is easy to install in the chassis. For example, we can design side brackets on the four sides of the screen to adjust various installation depths to facilitate installation in any embedded application. In terms of mechanism, we will recommend that you choose the appropriate metal material (such as galvanized steel, stainless steel... etc.), whether it is a ruggedized mechanism design or an economical mechanism design, it is up to you!

In addition to providing basic dust-proof and water-repellent designs for the AMT open frame touch screen monitor, we can also provide corresponding certified designs in terms of impact resistance and water resistance according to customer needs for outdoor and industrial applications.

By using an open frame touch screen monitor that has been specially designed to fit your system, customers can save time and effort during project development, installation, testing, and operation. A customized AMT open frame touch screen monitor is easy to install in the field and can be designed to meets the specified requirements of different environments.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey