adjusting backlight on lcd panel price

For the video display developer LCD panels are available in many sizes and resolutions, they are also available with many choices of maximum brightness. The following considers the topic of LCD panel brightness, the choices, the methods for adjusting brightness and some brightness adjustment scenarios.

LCD panels are generally rated as to their maximum brightness level which is expressed in Nits, it is equal to Candela/sqm (cd/m2), and this will be at a particular color temperature as noted in the specification, usually 10,000 K. In terms of a practical understanding, the following is a rough guide:

Outdoor displays range from a low end of 700 nits to typically 1,000 or 1,500nits and up with 2,000~2,500nits and even up to 5,000nits seen with some models. This may include standard LCD panels, custom LCD panels as well as custom cut LCD panels.

Virtually all LCD panels have a LED backlight these days, these are powered by an LED driver board. Brightness control via the driver board will be by one of two methods:

PWM (Pulse Width Modulation): This varies the duty cycle of the backlight “on time” – it is predominant in modern LCD panel LED backlight designs to enable support for digital brightness controls.

Analog: Uses a simple variable voltage to adjust brightness, for example this might be a dial or slider type potentiometer / variable resistor. To see how to enable analog backlight adjustment visit: https://www.digitalview.com/blog/brightness-adjustment/

One of the advantages of LED for the backlight is the range of adjustment that is possible, however it is important to note that the range varies significantly from model to model. Some industrial panels can be turned to very low light levels making them suitable for use in special environments such as at night. Lower cost panels limit the range of brightness to what might be required for typical usage, whereas panels with full range dimming from full off to full on require more complex backlight drivers.

Backlight lifetime: Many LCD panels have a backlight lifetime rating of 50,000 hours (typically measured to half brightness), this can be extended by running the LED backlight at a lower brightness level. Some panels may only offer 30,000 hours as a lower cost solution while other panels may offer up to 100,000 hours for high end applications.

An LCD panel backlight may be constructed so the LED’s are mounted directly behind a light guide diffuser, or they may be mounted along one or more edges of the light guide.

Active backlight: This is a function of some LCD panel backlights to automatically adjust the backlight brightness in response to the image. For more advanced systems there is an LED array making up the LED backlight, this adjusts the brightness in areas localized to the image being shown. This can greatly enhance the brightness across the display and is being used primarily with video, for example on consumer TV sets. It is not useful to all image types, for example a spreadsheet or content like maps or data is not likely to benefit.

Local dimming: Some LCD panels with direct LED may support local dimming so the LED’s are dimmed in response to the image close to them. This will not be at the same resolution as the LCD panel itself but will help greater contrast over the display by enhancing the brightness in bright areas of the image and darkening the image in dark parts of the image.

Both of the above techniques are likely to be more beneficial to certain types of content than others. For example a movie is likely to benefit more than a spreadsheet.

For the LCD monitor manufacturer it is important to consider that any covering over the LCD panel will reduce the brightness. For example the protective glass over a digital signage display, or a touch screen, or a semi-silvered mirror. So if a specific brightness is required the measurement should be taken with these in place.

There are various relatively low cost brightness meters available, typically in the couple of hundred dollars range. It is difficult to comment on the accuracy of these but we have found them to be within 5% of each other, though more importantly they do appear to be quite consistent in measurement so good for measurement comparisons. For more accurate measurement there are light meters from companies such as Minolta that can be calibrated, the cost may run into several thousand dollars.

Examples of light meters costing a few hundred dollars include SpyderX by Datacolor (needs a PC), a handheld meter is the SM208 by Sanpometer (search SM208 meter). Note: Many light meters, including smartphone apps, will be meters used for photography and not give readings in nits (or candelas). LCD panel specifications are typically measured using nits.

PWM and Analog: Most Digital View LCD controllers support PWM and Analog as a method for adjusting the backlight brightness level (this is noted in the column headed “Other” on the controller board summary table: https://www.digitalview.com/controllers/lcd-controllers-home.html. Also see https://www.digitalview.com/blog/brightness-adjustment/ for a guide to using a dial or slider type variable resistor to adjust the backlight.

DPMS (Display Power Management System): The backlight will be automatically turned off after a period if there is no valid video signal being received.

Ambient light sensor: The backlight is adjusted for brightness or powered off depending on ambient light conditions. This uses a light sensor attached to the LCD controller board, see https://www.digitalview.com/blog/light-sensor-app-note/ for more details.

The specifics of the backlight control are documented separately for each LCD controller model (product summary here) in the product manual available for download on the product page.

Note: There are two ways to adjust the perceived brightness of a LCD panel or LCD monitor, the backlight and the black-level. Very often, particularly in the past, the monitor brightness setting adjusted the black-level, this adjusts the LCD but not the backlight.

Color, color temperature etc: In addition to adjusting the brightness other settings may be adjusted as well. For example the color temperature or for example a switch to green monochrome for night vision.

Night-safe lighting (update) : Dual-rail backlights can also be supported. These special backlight enable normal brightness and extreme low level brightness with custom night-safe lighting. Contact us for details.

Note: We have a blog on methods for implementing an ambient light sensor with Digital View LCD controller boards to automatically adjust the backlight or system power, see: Ambient Light Sensor

Update March 2019: Most of the above remains unchanged except for the increased availability of high bright LCD panels of around the 1,000 nit to 2,500 nit range. AUO for example has a number of large size LCD panels with 1,500 nit brightness for the digital signage market. Tianma has panels under 20″ with 1,000 nit to 1,500 nit brightness for various outdoor applications.

The other change is that high bright panels are now increasing edge-lit, this makes the panels thinner and these panels tend to use less power than the previous models. One of the benefits for monitor designers is easier heat management and reduced overall display system costs.

TV repair costs between $60 and $350 with most spending $207 on average for LCD, LED, plasma, and 4K TVs; costs are higher if repairing older DLP, projection, and HD TVs. TV problems like display issues, powering-on problems, or sound issues can be fixed. Pickup and delivery fees may apply.

The cost to repair a TV will include the price of parts and labor costs, plus other associated costs. Additional charges include a trip fee for a technician to come to your home, a fee to transport your TV to and from a repair shop, and the diagnostic fee to determine what needs to be replaced.

The cost to repair a TV screen can be significantly more than the cost of purchasing a new TV. For this reason, replacing or repairing a broken TV screen is not considered feasible.

For example, the price of a new Samsung 40-inch LED TV is about $400, yet the cost of a replacement display panel for this model is about $380. This price is only for the replacement part and does not cover diagnostic costs, labor costs, or travel or shipping fees.

Broken TV screen repair is not a service offered by most TV or electronics repair companies. For example, BestBuy"s 90-day warranty, does not list broken TV screen repair as one of the problems they service.

Unless you are trying to fix a TV from the ’80s or earlier, cracked TV screen repair is not feasible; the entire display panel must be replaced instead. The cost of a replacement TV display panel is more than the cost of buying a new TV, and that’s before labor and other service costs.

The cost of TV screen replacement is generally the same as or more than the cost of buying a new TV. Therefore, replacing a broken or malfunctioning TV screen is not considered a viable option. If the TV is under the manufacturer’s warranty, the manufacturer may replace the entire unit.

TV manufacturers do keep replacement TV screen panels on hand to support products under warranty in case the screen malfunctions, due to manufacturer defect.

If you still want to replace a damaged or malfunctioning TV screen, your best option is to find a used replacement panel or a broken TV of the same model on which the screen is still functional. You might find one on eBay, and you can hire a technician to change out the panel.

The cost of a used replacement TV panel ranges from $50 to $350 or more, excluding shipping, depending on the brand and size. Note that the chances of finding exactly the part you need in excellent condition are slim, and the cost excludes the cost of installation by a repair shop.

Whether your TV is LCD, LED, plasma screen, or 4K (Ultra HD), the cost to fix common problems ranges from $60 to $350, depending on the repair type and the brand of TV being repaired.

These repair problems could have more than one possible source, so a technician should take time to narrow down the exact problem. TVs are repaired by replacing faulty components.

TV motherboard replacement costs between $200 and $350, including parts and labor, or about $275 on average. Motherboard replacement parts range from $35 to $199and labor costs from $60 to $125.

A TV inverter repair costs $104 to $171, including parts and labor, with an average cost of $138 for a TV with one inverter board or $178 for two. Parts range from $7 to $74, and the average labor cost for TV inverter repair is $97 per hour.

The function of an inverter board in a TV is to power the backlight of the screen. The inverter board requires a few hundred volts of power. If the inverter board goes bad, this would cause the TV to power on and have sound but no picture.

When an inverter component goes bad, it is usually replaced rather than repaired. In some cases, the capacitors on a converter board fail, and a technician can fix it by replacing the capacitors rather than replacing the entire inverter component. However, if an entire inverter board replacement is not available for the model of TV being repaired, replacing the capacitors may be the only option for TV inverter repair.

If an older model LCD TV or projection TV powers on and has sound but no picture, this may be due to lamp burnout, which is both common and expected. In this case, replacing the bulb will fix the problem. An experienced technician should be able to replace the bulb quickly and easily.

TV backlight repair costs $100 to $122, including replacement parts and labor, at a repair shop. In-house repair costs are more due to trip fees. The price of backlight replacement parts averages around $2.50for each LED and between $20 and $25 for each CCFL strip.

If the CCFL strips for your TV are no longer available, a technician can convert the backlight from CCFL to LED using the same number of backlighting strips. Each strip of LEDs costs between $12 and $30.

A new inverter may be needed to power the LEDs, costing between $7 and $74before labor, or an average of $40. In some cases, a repair shop can convert a CCFL backlight to LED without installing a new inverter.

Backlight failure in a TV may also be due to failure of the power inverter that supplies power to the backlight. In rare cases, both the inverter and the lighting components fail.

Repairing a TV power supply board costs $23 to $234 for parts alone. Completely replacing the power supply board costs $250 for parts and labor. If one capacitor has failed, the cost for replacement capacitors is low. However, it’s more cost-effective for the technician to replace the entire board rather than spend time trying to diagnose and replace faulty capacitors one by one.

The cost to fix an HDMI port on a TV is $93 to $302. In some cases, the input circuit board that the HDMI port connects to may be damaged and need to be replaced. The cost for replacing this input circuit board, including labor, ranges from $200 to $350.

TV capacitor repair costs $60 to $129, including parts and labor. The cost for the replacement part ranges from $0.06 to $14, with the labor portion ranging from $60 to $125 per hour. TV capacitors protect the circuit from getting too much power, filter signals, and facilitate changing channels.

It is not possible to fix a TV capacitor when it fails; it needs replacing. If your TV stops working while you are using it and you notice a smell similar to ammonia or bleach, this is a sign that a capacitor has blown. However, some capacitors do not make any noticeable smell when they blow.

Flat screen replacement glass is not available. The only option for flat-screen TV glass repair is to try optical glass glue, which costs $1.70 for a 5-ml. tube. This may be an option for TV glass repair if the crack is only a few inches or less. TV panels are built as one unit at the factory, with the glass adhered to the display panel.

A TV fuse repair costs between $61 and $136, with most spending $99 on average. The cost of the replacement fuse itself is $1.50 to $11, while labor ranges from $60 to $125 per hour. Additional fees may apply.

LCD flat-panel repair is not considered cost-effective. If the glass is cracked or the display is physically damaged, it is cheaper to replace the entire TV than to repair or replace the display panel.

Estimating TV repairs costs by brand is not something TV repair shops offer, however, there are general prices by type. When looking for specific repair costs for your TV, you’ll find them in the common repairs price list above. Pricing applies to brands such as Samsung, LG, Sanyo, TCL, Insignia, HiSense, Sony, Toshiba, Pioneer, and Vizio.

The cost of flat-screen TV repair ranges from $42 to $359. You cannot fix a broken screen, but the price of a new flat-panel TV starts from around $249 for a 1080-mp (non-4K) LED TV from LG to as much as $14,999 for an 85-inch 8K LED TV from Samsung. A TV referred to as a “flat TV” or “flat-screen” TV might be any of the following:

LCD TV repair typically costs $60 to $85 for diagnostics testing, and $200 to $300 to perform repairs. LCD TVs use backlighting, which may fail. Newer LCD TVs use LED strips for backlighting. Older ones might use CCFL. If CCFL backlighting fails, a technician can replace it with LED backlighting.

An LED TV is just an LCD TV that uses LED backlighting, which all newer models do (older models use CCFL backlighting). The cost to replace one LED backlighting strip ranges from $100 to $122, including parts and labor.

The cost to replace the motherboard, inverter, or LED"s in a 4K TV ranges from $100 to $275 or more depending on the brand and model. The cost for screen repair for a 4K TV is irrelevant because it cannot be fixed or replaced at a cost that is lower than the cost of a new 4K TV.

Digital light processing (DLP) TVs are also known as projection TVs. DLP big screens have not been made since 2012, and DLP TV repair is usually not worth the cost except for a lamp burnout, in which the bulb can be replaced. The cost to replace bulbs ranges from $60 to $115.

TV repair shops charge an average $60 to $125 per hour, or a flat rate of $50 to $250, which includes the diagnostic fee. Additional costs after that depend on the repairs needed and the brand and type of TV. However, most stores will have a minimum charge of about $90.

Best Buy TV repair is provided through the Geek Squad TV & home theater service. Geek Squad TV repair starts at a base cost of $100 for a diagnostic fee. TV repair is covered under Best Buy’s protection plan, which costs $280 per year when you purchase a TV from Best Buy at the time of purchase, or within the return period printed on your receipt.

The brand and model of your TV will dictate the final repair cost, with more expensive brands and larger TVs costing more to repair. Consider the remaining lifespan of the TV before paying for repairs. You can now buy bigger TVs with more features and better displays for a TV that won’t need repairs for a while and probably comes with a warranty.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery. When sending your TV into a service center for repair, you will be contacted regarding the associated costs and asked to process payment before the repair is completed, which usually takes two weeks including the shipping time.

Many TV repair shops charge a diagnostic fee that ranges from $20 to $60, depending on whether it is done in your home or the repair shop. Some shops charge a flat fee that ranges from $50 to $250that covers both the diagnostic cost and labor cost. In many cases, the initial diagnostic fee will be applied to the repair cost if you have the shop do the repair.

The more expensive a TV is, the more sense it makes to purchase an additional warranty to defray the potential for costly repairs. Best Buy offers an $89 five-year extended warranty for entry-level TVs. On larger TVs such as the 85-inch Samsung QLED 8K TV, which costs $14,998, the five-year warranty from Geek Squad costs an additional $1,699—11.33% of the cost of the TV.

With modern TVs, repair entails component replacement or replacement of capacitors, for which high levels of certification are not necessary. Generally, TV repair shops will let you know if their employees have certification.

First, check that the connecting cable is securely in the socket on both ends. If that doesn’t work, try substituting another data cable if you have one, or test it with a replacement cable.

The cost of mounting a TV ranges from $149 to $199, with most people paying around $174 for the labor. The mounting hardware costs between $20 and $500 depending on the brand of mounting hardware and the size of your TV.

There are various ways you might be able to save money on TV repair. These include transporting your TV to a repair shop, using a shop that charges in 15- or 30-minute increments, diagnosing the problem yourself, using salvaged parts, and doing the repair work on your own.

You can also consider the cost of TV repair when purchasing a new TV. More popular TV models are less expensive to repair because repair shops buy parts for the most common TVs in bulk and are therefore able to get them at lower prices.

Plug - If the TV is not powering on and no status LEDs are lighting up, start by plugging the TV into a different outlet. If the TV is too challenging to move, you can run an extension cord from another nearby outlet.

Circuit breaker - Check the circuit breaker for the power outlet that the TV plugs into. You can check the breakers by opening the door to your breaker panel and looking for circuit breakers that are in the OFF position.

Remote control - If the TV is not powering on with the remote control, you should try replacing the batteries. For remote controls with a status LED light, there could be enough power to light the LED but not enough power to send a signal to your TV.

Inverter is bad -It is possible that the inverter, which powers the backlights, has gone bad and needs to be replaced. It’s also possible that one or more capacitors on the inverter have gone bad, in which case a technician may be able to replace capacitors more cheaply than replacing the entire inverter.

Lamp burnout -In a projection TV or older LCD TV, no picture may be caused by lamp burnout. In this case, a technician can replace the bulb quickly and easily.

Plug headphones into the headphone jack. If sound comes from the headphones plugged into the headphone jack, this indicates a problem with the TV speakers.

The primary way to save money on TV repair would be to perform the work yourself. This may require you to purchase and get familiar with various tools such as soldering tools, and methods for replacing a capacitor or some other component.

The right parts - It can be complicated to determine which component of a TV is failing and causing the TV not to work correctly. If you buy a replacement part and perform the repair yourself, the TV may still not work, either because you replaced the wrong part, the part was old and not working properly to begin with, or you did not perform the work correctly. Buying multiple replacement parts can become costly.

Lack of experience – you might cause more damage to the TV due to your lack of knowledge and experience, and you might also end up causing a fire with your soldering iron or being electrocuted.

The cost of repairing a TV could be as much as $500 if multiple repairs are needed. Consumer Reports recommends not to spend more than 50% of the cost of a new TV repairing the old one.

If you have a newer TV that cost thousands of dollars, having it repaired would most likely be cost-effective. If the TV only cost a few hundred dollars to begin with, replacing the TV is more likely to be the best option.

Not included in these prices from Best Buy are 1080P screens, which range from $249 to $279 for 43-inch TVs from brands like Samsung, Sony, and LG. On the upper end, Sony and Samsung both have 95-inch 8K LED TVs for $69,999.

In most cases, a flat-screen TV can be fixed. The exception is a physically damaged display panel or screen. Most other issues including failing speakers, backlights, or power supply. Burned out fuses and damaged input ports can also be repaired.

If the screen is not physically damaged but is not showing a picture or is displaying “snow’” or vertical or horizontal lines, a technician can repair the TV by replacing failed components. If the screen is physically damaged, it cannot be repaired.

You cannot replace a broken flat-screen display. New TVs costs anywhere from $249 for a 1080P (non 4K) LED TV from LG to as much as $14,999 for an 85” 8K LED TV from Samsung.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery.

Choosing a backlight system for LCD screen displays is a major consideration. It will determine a lot about your experience of the display and requirements during production. Different backlight options provide widely different effects in the contrast and brightness of the display. Also, depending on which backlight option you choose, it will affect some or all of the following: the cost of the overall product; how many products you will have to order due to manufacturing constraints; and how environmentally friendly the component parts are that make up the product.

The word LCD has been used to describe many display technologies. Often people believe that LCD screen displays are the same as a CRT (Cathode Ray Tube), an LED Display (Light Emitting Diode) or a Plasma display. This is not the case! Let’s discuss what an LCD is and what it is not.

Think of the liquid crystal display (LCD) as a window blind. Positioned in one direction the blinds allow light to pass through, or turned another direction they block the light. Just like a window blind, the LCD does not create its own light, it only blocks or allows it to pass through.

As you know, you can adjust the blinds to alter the amount of light desired. When fully closed, the blinds block light completely; when open, all light passes through; and when angled, partial light comes in. An LCD works similarly to this, with one significant enhancement: an LCD has the ability to block light in some areas and allow light to pass in other locations of the glass. An example of this is the display used on a gas pump. The customer sees numbers where the light is blocked, and a clear area where the light is allowed to pass through.

LCD’s are not CRT’s, LED’s, nor are they Plasma displays. Each of these types of displays produces their own light and are called emissive displays. Emissive displays require more power than an LCD.

Emissive displays have a distinct advantage in that they can be seen clearly at night whereas LCD’s cannot. However, the solution to this problem of low-light visibility is to install a backlight behind the LCD. Backlights do require more power than the LCD itself, but they can be turned on only when necessary. Many products that are powered by batteries will have the backlight dim or shut off after a certain amount of time. This can be seen on cell phones and watches. Consequently, even though a little more power is used for the backlight than used in a stand-alone LCD, because it is not constantly on, the LCD’s with backlights wind up using less power than their emissive display competitors. LCD screen displays using backlights become the clear choice.

This option is the most popular for products that have a lower power budget. Products that run on battery need to conserve power and the lowest powered backlight available is to have no backlight at all.

The Amazon Kindle is a perfect example. The Kindle makes use of a display technology called ‘e-paper’, which looks more like a printed page than any other device on the market currently. This specific e-book reader does not contain a backlight. Because it omits the backlight it can operate up to one month without recharging. Imagine, you could take it on a cruise to Fiji and back and never have to worry about recharging it!

Thinking back to your product, not all products can omit a backlight; in fact it may require one. If it does need a backlight the most popular option is an LED.

A light emitting Diode (LED) is a semiconductor that produces light when current is passed through the device. Light is created from the energy conversion that takes place in the LED die. The advantages of an LED are:LED lights are much more rugged and can handle shock much better than other types of lights.

LED backlights are made up of an array of LED’s. They come in a variety of colors including red, green, yellow, amber, blue, white and R/G/B (Red/Green/Blue). From the R/G/B trio any color in the rainbow can be made.

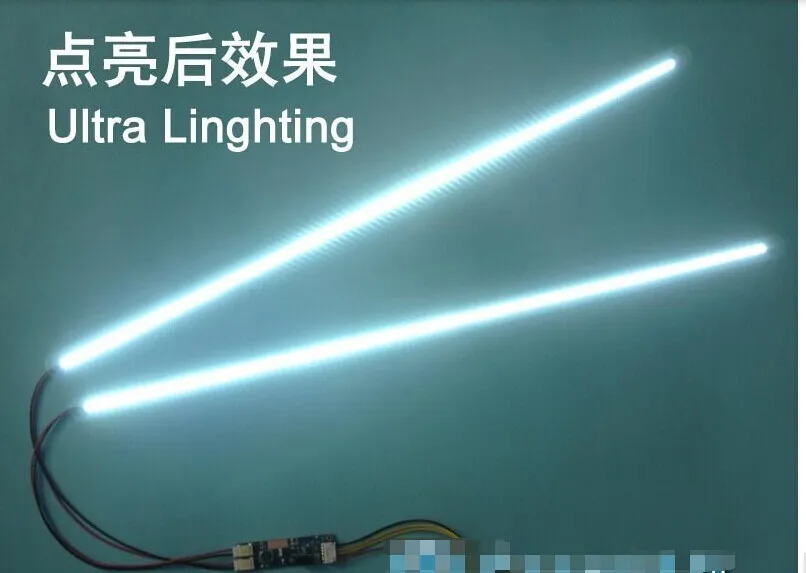

The majority of the LED backlight colors will operate with a half-life of 50K to 70K hours. (Remember, half-life is when the light will be half as bright as when it was first turned on. This is not when the LED will burn out.) Blue and white LED’s do have a shorter half-life than other colors. Presently, they are rated at 30K hours. That means that if you turned them on today and left them on, in 3.4 years they would be half as bright as they are today! One thing to take into account is that as technology improves, the lifetime of the LED’s will become longer, which will also increase the half-life. Below is a photo of a blue LED backlight.

To make LED’s display correctly, they are placed behind the LCD screen display in an array pattern. The challenge is that LED’s, similar to a light bulb, project a beam of light which can show spots of light. These spots are called hot spots. This can be an issue with LED’s since they will make the display look like it has polka dots. Below is a photo of a LED behind the LCD glass. This problem will be solved with the use of a diffuser.

A diffuser is like a lamp shade and is placed between the glass and the LED’s. The goal is to disperse the light or make it more even. Below is a photo of a diffuser. At the bottom of the diffuser you will see the LED’s. This is where you can see hot spots. But as the light travels further into the diffuser, the light becomes more even. The diffuser solves the issue with hot spots and makes LED’s a very attractive option.

EL (Electro Luminescent) backlights, also known as ELP’s (Electroluminescence Panel), have been used as a backlight for LCD’s for several years. They are available in a range of colors with white being the most popular. EL technology makes use of colored phosphors to generate light. They require AC (alternating current) rating of 100VAC @ 400Hz.

In the last three to four years, EL backlights have decreased in popularity. There are several reasons for this drop in popularity.The EL backlight requires an inverter to convert DC to AC. The cost of the inverter increases the cost of the overall LCD Display.

The half-life of an EL is an estimated 3,000 to 5,000 hours. (Once again, half-life is when the backlight is half as bright as when it was first turned on.)

LCD screen display manufacturers now require an MOQ (Minimum Order Quantity) of no less than 500 displays for orders that include EL backlights. This MOQ number is likely to increase in the future as this type of backlight becomes less popular. Additionally, as the demand drops the price will naturally increase.

A Cold Cathode Fluorescent Lamp (CCFL) is similar to the long fluorescent light bulbs you see in the ceilings of offices. Below are photos of various types.

This technology has been in use for many years, but in the last few years the popularity of this type of backlight has decreased. There are a few reasons why this is so.Similar to EL backlights, this technology operates on AC.

The majority of LCD screen display manufacturers no longer offer CCFL as an option. There are too many negatives and not enough positives to their use. The suppliers that do offer this now require a very high MOQ (Minimum Order Quantity).

When choosing the type of backlight for your LCD screen displays it is important to keep in mind MOQ’s and future availability. Make sure you are choosing a technology with a future so that your product has one too!

Backlight circuit failure can also occur from damage to the electrical traces on the circuit board. If the electrical traces buried in the board are inadvertently severed—for example, from trying to fasten the board with too large a screw—the backlight circuit will not conduct power to the backlight LEDs.

A screen that gets gradually dimmer, a monitor that flickers when you turn it on, or a display that flashes before going dark are all indicative of an LCD with a failing backlight. Most LCD screens require a third-party backlight, so at some point, you’ll need to deal with lamp failure for your screen.

Generally, replacing the backlight on your Samsung TV will cost you between $100-$200. Usually, this is significantly less than what you paid for the TV, so it is definitely worth it, especially if nothing else has gone wrong.

TV backlight repair costs $100 to $122, including replacement parts and labor, at a repair shop. In-house repair costs are more due to trip fees. The price of backlight replacement parts averages around $2.50 for each LED and between $20 and $25 for each CCFL strip.

To replace one LED backlighting strip, the price ranges from $100 to $125, including parts and labor. Older televisions cost more to repair. Parts for these TVs may be difficult to find. Also, parts for TVs that are 42 inches or bigger are more expensive.

Be very careful with the panel as it is extremely fragile! Now that LCD panel is removed, we can remove the bezel that maintain the backlight diffuser and access the backlight itself. Here we can see that the backlight system is made of LEDs which is pretty simple to replace when being the cause of the failure.

From a component standpoint, this TV features a lot of parts, but generally, the LEDs in its backlight are probably going to fail first. The average lifespan of an LED at maximum or close-to-maximum brightness is 40,000 to 60,000 hours, or roughly 4.5 to 6.8 years.

A Vizio TV can last you about 7 years on average, but you can extend their life up to a possible 10 years with a little sensible care. Vizio are great TVs that you can enjoy for a long time and today we’ll tell you all about how you can do that.

Replace the HDMI cable as it may have a short or another defect which causes the black screen issue. Unplug the TV for 5 minutes to attempt a reset. Unplugging the TV will reset the television and clear any temporary issues. Factory reset of the TV to resolve the issue.

If it’s a backlight or power supply problem, it can be fixed. Usually, the problem stems from the high voltage inverter circuitry, either bad power transistors, capacitors, or thermal stress on the circuit board leading to broken solder joints. But fixing these problems can often be a short term solution.

The average lifespan of a television varies between 4 and 10 years (approximately 40,000 – 100,000 hours) depending on usage and maintenance. Turning off your TV is one of the simplest things you can do to extend its lifespan.

More importantly, you can do so without having to worry whether or not you have to buy a fully new TV! If your TV panel is still in one piece, meaning a brick hasn’t gone through the screen there is a good chance it can be repaired!

So, when should you upgrade? Some people are unlikely to upgrade until their current set becomes faulty or fails entirely. However, those who are keen to enjoy the latest TVs may upgrade more frequently. Ideally, any television should last for at least ten years before brightness and other features begin to suffer.

But despite being advanced systems, Vizio TVs sometimes fail to work, and you get many errors when using them. Many Vizio TV user complaints revolve around the device screen flickering constantly, SmartCast failing to load, and the TV turning on but not showing pictures.

Most Vizio TVs have a power light in the lower left corner of the TV. It lights up whenever the power button is pressed. It is normal for the power indicator to light up then turn off after a few moments. The power light might still light up even if the rest of the TV is not on.

A Vizio TV screen may go black due to features such as ‘Screen Mute’ or ‘Sleep Timer’. It may also be a result of a loose/faulty connection, power issues, software error/bug or broken hardware. Most issues can be fixed by updating or resetting the TV, securing all cable or changing the TV settings.

First, the display screen on a sunlight readable/outdoor readable LCD should be bright enough so that the display is visible under strong sunlight. Second, the display contrast ratio must be maintained at 5 to 1 or higher.

Although a display with less than 500 nits screen brightness and a mere 2 to 1 contrast ratio can be read in outdoor environments, the quality of the display will be extremely poor. At i-Tech, a truly sunlight readable display is typically considered to be an LCD with 1000 nits or greater screen brightness with a contrast ratio greater than 5 to 1. In outdoor environments under the shade, such a display can provide an excellent image quality.

Luminance is the scientific term for hotopic Brightness?which specifies the visual brightness of an object. In layman"s terminology, it is commonly referred to as brightness? Luminance is specified in candelas per square meter (Cd/m2) or nits. In the US, the British unit Foot-lamberts (fL) is also frequently used. To convert from fL to nits, multiply the number in fL by 3.426 (i.e. 1 fL = 3.426 nits).

Luminance is a major determinant of perceived picture quality in an LCD. The importance of luminance is enhanced by the fact that the human mind will react more positively to brightly illuminated scenes and objects. Users are typically more drawn to brighter displays that are more pleasing to the eye and easier to read. In indoor environments, a standard active-matrix LCD with a screen luminance around 250 nits looks good. However, a sunlight readable LCD with a screen luminance of 1,000 will look even more beautiful.

Contrast ratio (CR) is the ratio of luminance between the brightest �white� and the darkest �black� that can be produced on a display. CR is another major determinant of perceived picture quality. If a picture has high CR, you will judge it to be sharper and more crisp than a picture with lower CR. For example, a typical newspaper picture has a CR of about 5 to 7, whereas a high quality magazine picture has a CR that is greater than 15. Therefore, the magazine picture will look better even if the resolution is the same as that of the newspaper picture.

A typical AMLCD exhibits a CR between 300 to 700 when measured in a dark room. However, the CR on the same unit measured under ambient illumination is drastically lowered due to surface reflection (glare). For example, a standard 200 nit LCD measured in a dark room has a 300 CR, but will have less than a 2 CR under strong direct sunlight. This is due to the fact that surface glare increases the luminance by over 200 nits both on the white and the black that are produced on the display screen. The result is that the luminance of the white is slightly over 400 nits, and the luminance of the black is over 200 nits. The CR ratio then becomes less than 2 and the picture quality is drastically reduced.

i-Tech sunlight readable LCDs with 1500 nits screen brightness will have a CR over 8 with the same amount of glare under the same strong sunlight, making the picture quality on these units extremely good. For further reading on contrast ratio, please see Tech Note 0101, Page 2, the Display Contrast Ratio.

The viewing angle is the angle at which the image quality of an LCD degrades and becomes unacceptable for the intended application. As the observer physically moves to the sides of the LCD, the images on an LCD degrade in three ways. First, the luminance drops. Second, the contrast ratio usually drops off at large angles. Third, the colors may shift. The definition of the viewing angle of an LCD is not absolute as it will depend on your application.

Most LCD manufacturers define viewing angle as the angles where the CR (contrast ratio)^3 10. For LCDs designed for less demanding applications, the viewing angle is sometimes defined as the angles where the CR^3 5.

For LCDs used in outdoor applications, defining the viewing angle based on CR alone is not adequate. Under very bright ambient light, the display is hardly visible when the screen luminance drops below 200 nits. Therefore, i-Tech defines the viewing angles based on both the CR and the Luminance.

All LCD backlights powered by cold cathode fluorescent lamps (CCFL) require inverters. An inverter is an electronic circuit that transforms a DC voltage to an AC voltage, which drives the CCFLs. i-Tech Technology manufactures inverters for all its products. Additionally, Applied Concepts and ERG also provide inverters for our products as well.

The dimming range or dimming ratio of an inverter specifies its capability of performing backlight luminance adjustment. For inverters used in notebook computers and LCD monitors, the backlight luminance can be adjusted typically over a dimming range of less than 10:1. That is, the luminance is adjusted from 100% down to about 10%.

For very high brightness backlights used in i-Tech Technology sunlight readable LCD modules, the inverters must be able to provide a much wider dimming range. Otherwise, the LCD screen will be too bright during nighttime conditions. Therefore, our inverters provide a typical dimming ratio of 200:1, meaning that the luminance can be adjusted from 100% down to 0.5%.

Dimming capabilities are beneficial because lowering the backlight luminance will result in a lengthening of the backlight life. It also lowers the power consumption and the related thermal management issues.

Any high brightness backlight system will consume a significant amount of power, thereby increasing the LCD temperature. The brighter the backlight, the greater the thermal issue. Additionally, if the LCD is used under sunlight, additional heat will be generated as a result of sunlight exposure. Temperature issues can be handled through proper thermal management design.

We provide TFT LCD with reflective mode of illumination without compromising its transmissive illumination. With the imposed reflective function, the modified LCD can reflect the ambient light passing the LCD cell and utilize the reflected light beams as its illumination. The stronger the ambient light is, the brighter the LCD will appear. As a result, the modified LCD is viewable under all lighting conditions including direct sunlight regardless the LCD"s original brightness.

The market demands for outdoor LCD applications are expanding, such as mobile navigator/video systems, PDA, personal organizer, Tablet PC, notebook computer, and Kiosk display etc. However, a regular transmissive LCD is very difficult to read under strong ambient light. This limits the outdoor applications of a conventional transmissive LCD.

The high bright LCD and the transflective LCD are the solutions generally utilized for outdoor applications. However, both solutions have some shortcomings. Because of the added lamps, high bright LCD creates some undesirable problems, which include high power consumption, excessive heat generation, increased dimensions, electrical circuit alterations, and shortened LCD lifetime. Thus, it is usually troublesome and costly to accommodate a high bright LCD in systems. Though giving good performance under the direct sunlight, the transflective LCD trades of its indoor performances.

Problems noticed in transflective LCD include narrow viewing angle, discoloration, low brightness, and loss of contrast. Moreover, the transflective LCD is currently limited in choice of sizes and resolutions.

On the other hand, a Transflective LCD is readable everywhere including outdoor environments without extra power consumption and excessive heat generation. The indoor viewing qualities are also enhanced. The modified unit fits right back into its original system with no need of any alteration and extra effort. Thus in your choice of size, resolution, and model, a direct sunlight readable LCD is conveniently incorporated into your device.

i-Tech is a premier supplier of optical bonding and performance added passive enhancements for all flat panel . i-Tech Optical Bonding process produces an optical bond between any display cover glass or touch panel, and any size LCD.

In the world of LCD"s, i-Tech takes display enhancement to a new level above all others. Utilizing advanced proprietary optical bonding technology; i-Tech overcomes optical challenges for display product manufacturers at an affordable price. In a wide range of applications, standard liquid crystal appear to "washed out" in high ambient lighting conditions. This wash out is due to excessive reflections and glare caused by bright light.

Commercially available LCDs, especially when protected by a separate cover glass or plastic shield, can not deliver enough brightness to make the display functional in outdoors or in other high ambient light applications. The exclusive Optical Bonding process from i-Tech provides a significant reduction of ambient light reflections at an affordable price, compared to other display enhancement technologies.

Optical Bonding seals either a top cover glass or touch screen directly to the face of the display bezel. Our bonding process eliminates the air-gap between the display and the cover glass, vastly reducing reflective light, which causes visual washout of the display image. Optical Bonding also enhances structural integrity by supporting the LCD assembly with the cover glass. The bond maintains perfect display uniformity while providing shock protection, unlimted humidity protection, and elimination of fogging caused by trapped moisture accumulating in typical air-gap assemblies.

Sunlight viewability of a display depends on the differences between "lumination" and "illumination" of the display. The lumination of the display is its brightness. A display"s brightness, typically referred to as a Nit (Candela per meter/2) is the amount of light energy coming out of the display. Illumination is the amount of ambient light shining onto a display. The readability of a display is dependant on the amount of light that is being reflected off of the display.

Light travels through a variety of transparent materials; such as air, glass, plastic, and even water. These material"s abilty to transmit light is measured by their "indices of refraction". As light transfers from one material to another, such as air to glass, the differences the index of refraction will cause reflection. In the case of an air-to-glass interface, the reflection will be slightly less than 5% of the ambient light. All surfaces that have an index mismatch will reflect and the reflection is cumulative. In the case of a standard glass or plastic window, there are three surfaces with an index mismatch which will create a total relfection of nearly 15% of the ambient light. If the total reflection (in nits) is close to the displays brightness, the contrast of the display will be reduced to the point where the display"s readabilty is reduced to unacceptable levels.

Optical Bonding from i-Tech is a solid, transparent bond which optically couples the front cover glass or touch screen directly to the face of the display. This internal bond eliminates reflection from the two internal layers. The outer surface of the window is treated with anti-reflecting coatings which matches the front surface of the glass with the index of refraction of air. This combination reduces the total reflection of the display and front cover glass to less than 2% of the ambient light. A reduction of reflection of this level, all but eliminates reflective loss in most ambient lighting conditions. With reductions of this level, displays with 300-500 nits of brightness will be viewable in daylight or indirect lighting conditions. At 500-800 nits brightness, most displays will be completely sunlight viewable.

Aside from the optical quality, Optical Bonding elminates the air-gap which prevents heat build-up from the "greenhouse" effect and prevents fogging from moisture or contamination from dirt or particles. It also offers shock protection and other damage to the LCD itself.

iTech IP65 Front and Full IP66 Chassis are designed for those applications require IP ( Ingress Protection ) feature, like chemical industry, food industry and medical industry. However, the IP65 Front and Full IP66 chassis might get moisture condensation issue for the applications under direct sunlight.

We provide two different choices of optical enhancement solutions that include anti-reflective coated and/or anti-glare protection glass. These technologies can be widely used in outdoor and indoor environment by enhancing optical performance of displays.

The anti-reflective coatings on the protection glass have excellent performance in tough ambient light conditions. With the normal glass, the strong reflection of the ambient light diminishes visibility and causes problems for viewer. Our special anti-reflective coated protection glass can increase contrast by enhancing light transmission rate over 95% (light reflectance rate less than 5%) and can effectively diminish the mirror images. The multi-layer vapor deposition coating either on one side or two sides of glass is designed to minimize reflectance and maximize transmittance.

Another solution, with an anti-glare (AG) coated protection glass, a microscopically rough surface laminated onto the topmost of display can diffuse glare. The chemically etched glass that has a slightly textured finish can reduce reflection by scattering light directed on its surface. It can soften the image of direct light sources visible in the reflection of the viewing area.

Clearing Point - The temperature at which the liquid crystal fluid changes from a nematic into an isotropic state. In practice, a positive image LCD will turn totally black at this temperature and will therefore be unreadable. Because the clearing point is different for every fluid type, ask for design assistance from your supplier if high temperature operation is critical in your application.

Also, for most cases, both TN, HTN and STN utilize the phase known as nematic for display purpose. Within this phase, the liquid crystal has a "rod shape" exists within the solution which has fast response and has excellent electro-optic properties. This phase, however, only exists within a limited temperature range. The higher end of this temperature range is known as clearing point, above which, the liquid crystal lost its birefrigerance properties and cannot bend the light path anymore. Thus the polarizer will then be the only factor which affect incoming and out coming light. When the LCD is cooled down to below its clearing point, the display should be working again. The temperature for the clearing point varies greatly from material to material and you should contact our engineers regarding what you have. Normally a safe margin should be used to avoid clearing point when designing the display.

Isotropic Stage The point where the fluid heats or cools to where it is no longer in the twisted nematic state. Since the molecules can no longer twist light, all incoming light is absorbed.

The lighter sensor measures the outside brightness according to different environments and sends the information to display. Display will adjust the brightness automatically.

With lighter condition (Outdoor/Sun-light) the brightness will increase; in the opposite condition, the brightness will be decreased to fit darker environment.

Light sensor detect the change of illumination outside, then it send the signal to MCU via I�2C interface. MCU will ask inverter to switch the brightness if the outside illumination was change over the default. MCU will transmit PWM signal to the inverter, amd the inverter will change the brightness of panel.

Each step has its own illuminate range according different environment illumination. This technology makes the use of visual application more friendly and intelligently.

Winmate �light sensor� technology are now available for 8.4�, 10.4�,12.1�, 15�, 17�, and 19� LCD with specific panel option. Please contact with sales for more detail information.

TouchScreen Solutions is a specialist manufacturer of touchscreens, optical filters to enhance the performance of electronic displays, and transparent composites.

By utilising TouchScreen Solutions�s traditional lamination expertise, touchscreens are designed to provide the highest levels of light transmission, excellent readability and unsurpassed protection against a wide range of physical threats. The touchsacreens are accurate, highly dependable and have a rapid response time

The electronic controls effectively divide the screen into pixel sized sensing cells, using microfine wires which are not visible on a powered display. These wires are connected to a controller board, and an oscillation frequency is established for each wire. Touching the glass causes a change in the frequency of the wires at that particular point, the position of which is calculated and identified by the controller. Unlike other capacitive systems where the operator touches the actual conducting surface of the sensing panel, the active component of the sensor can be embedded up to 25mm from the touch surface ensuring long product life and stability.

The touchscreen can be supplied with the options of anti�glare or anti-reflection coatings, thermal toughening or chemical strengthening and privacy or contrast enhancement filters. The front glass of the touchscreen acts as a dielectric and enhances the capacitance of the touchscreen.

The driver software allows the touchscreen to interface with the host computer�s operating system by emulating the behaviour of a computer �mouse� and translates taps on the touchscreen surface into mouse clicks.

Touchscreen is proven to meet today�s demanding requirements for ATM�s, web phones, ticket machines, medical displays, industrial displays, pay-at-the-pump gas machines, and interactive kiosk systems. The touchscreen is durable and dependable, its construction protects against damage caused by moisture, heat and even vandalism.

The touchscreen comprises a laminated glass sensor, which encompasses the sensing medium, and the control card which connects to the communications port of the computer.

Female D9 serial connector on a 3 metre long, 3 wire, lead. Maximum length of lead - 10 metres. Power supply components in connection -2 diodes, 1 resistor and 1 capacitor .

Simple calibration and set-up with Windows 98, NT, 2000, XP and Linux. Mouse emulation with Select on Touch, Select on Dwell, Select on Release and Drag and Drop.

Recently there many end customer was mislead believing high brightness (over 2000nits, even up to 5000nits) is the better solution. But there are few concerns that the so called extreme high brightness (3000nits to 5000nits) panel manufacturer don"t tell you:

1. How much power consumption is the extreme high brightness LCD? It is very important because all of our outdoor LCD is in completely sealed enclosures keeping it cool is a very huge Challenge. Not mentioned the hot temperature around 40-50C area.

2. Also, you need to determine how far is viewer distance. Because high brightness (3000-5000nits LCD) might Damage eyesight if the viewer is too closed. LCD is design with high resolution for people to see it very closely, so extreme high brightness doesn"t make sense for outdoor LCD. If they want to put on extreme high brightness LCD on roof top to attract audience which LCD is not even big enough for seeing from far away. Most case customer will use LED which is more reliable and cost effective if it is larger than 82".

3. High chance rejection from city sign official. Many LED billboard brightness can goes up to 5000-7000nits, but the local government agency will not approve this brightness, because it is traffic distraction for driver or other people. So, it doesn"t make sense to spend a fortune on extreme high brightness but need to dim it down back to 1000-1500nits.

4. Viewable under sunlight is not just brightness only, it involve contrast ratio, reflection of the front glass and content graphics contrast such as (red and white). Sunlight readable is combination of all above, not just brightness only.

4. Viewable under sunlight is not just brightness only, it involve contrast ratio, reflection of the front glass and content graphics contrast such as (red and white). Sunlight readable is combination of all above, not just brightness only.

3. All the major branded LG and Samsung LCD manufacturer the most brightness that they do is only 1000-2000nits because we believe this major LCD maker already done a study on what is the most feasible and comfortable LCD brightness for outdoor. That"s why all the high brightness (3000-5000nits) maker is after market vendor without any study about the what is most suitable brightness for different applications, only advertising high brightness is not the solution. If you ask these vendor for outdoor enclosure which they will not provide or guaranteed it will work because they know it is a huge Challenge to cool down the display. Just like you are buying a 800 horse power car, but you still need to design the car frame and cooler to make this engine run safely on the road, which this extreme high brightness won"t help you to design that.

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

Visibility is the ease with which a viewer can detect an object, or in more scientific term: the relationship between luminance contrast and human eye’s threshold. Therefore, the higher an object’s contrast is, the better is its visibility.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

What causes light reflection? When light traveling in one transparent medium encounters a boundary with another transparent medium, a portion of the light bounces off the border. Through the simplest version of Fresnel’s equation, we can calculate the amount of reflected light.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

The quick and easiest thing we can do to reduce air-glass interface reflectance is to use an Anti-Reflection and Anti-Glare film or apply AR coating. An external film with AR properties not only reduces reflected light, but also brings other benefits.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

A wide variety of lcd backlight options are ava

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey