adjusting backlight on lcd panel quotation

For the video display developer LCD panels are available in many sizes and resolutions, they are also available with many choices of maximum brightness. The following considers the topic of LCD panel brightness, the choices, the methods for adjusting brightness and some brightness adjustment scenarios.

LCD panels are generally rated as to their maximum brightness level which is expressed in Nits, it is equal to Candela/sqm (cd/m2), and this will be at a particular color temperature as noted in the specification, usually 10,000 K. In terms of a practical understanding, the following is a rough guide:

Outdoor displays range from a low end of 700 nits to typically 1,000 or 1,500nits and up with 2,000~2,500nits and even up to 5,000nits seen with some models. This may include standard LCD panels, custom LCD panels as well as custom cut LCD panels.

Virtually all LCD panels have a LED backlight these days, these are powered by an LED driver board. Brightness control via the driver board will be by one of two methods:

PWM (Pulse Width Modulation): This varies the duty cycle of the backlight “on time” – it is predominant in modern LCD panel LED backlight designs to enable support for digital brightness controls.

Analog: Uses a simple variable voltage to adjust brightness, for example this might be a dial or slider type potentiometer / variable resistor. To see how to enable analog backlight adjustment visit: https://www.digitalview.com/blog/brightness-adjustment/

One of the advantages of LED for the backlight is the range of adjustment that is possible, however it is important to note that the range varies significantly from model to model. Some industrial panels can be turned to very low light levels making them suitable for use in special environments such as at night. Lower cost panels limit the range of brightness to what might be required for typical usage, whereas panels with full range dimming from full off to full on require more complex backlight drivers.

Backlight lifetime: Many LCD panels have a backlight lifetime rating of 50,000 hours (typically measured to half brightness), this can be extended by running the LED backlight at a lower brightness level. Some panels may only offer 30,000 hours as a lower cost solution while other panels may offer up to 100,000 hours for high end applications.

An LCD panel backlight may be constructed so the LED’s are mounted directly behind a light guide diffuser, or they may be mounted along one or more edges of the light guide.

Active backlight: This is a function of some LCD panel backlights to automatically adjust the backlight brightness in response to the image. For more advanced systems there is an LED array making up the LED backlight, this adjusts the brightness in areas localized to the image being shown. This can greatly enhance the brightness across the display and is being used primarily with video, for example on consumer TV sets. It is not useful to all image types, for example a spreadsheet or content like maps or data is not likely to benefit.

Local dimming: Some LCD panels with direct LED may support local dimming so the LED’s are dimmed in response to the image close to them. This will not be at the same resolution as the LCD panel itself but will help greater contrast over the display by enhancing the brightness in bright areas of the image and darkening the image in dark parts of the image.

Both of the above techniques are likely to be more beneficial to certain types of content than others. For example a movie is likely to benefit more than a spreadsheet.

For the LCD monitor manufacturer it is important to consider that any covering over the LCD panel will reduce the brightness. For example the protective glass over a digital signage display, or a touch screen, or a semi-silvered mirror. So if a specific brightness is required the measurement should be taken with these in place.

There are various relatively low cost brightness meters available, typically in the couple of hundred dollars range. It is difficult to comment on the accuracy of these but we have found them to be within 5% of each other, though more importantly they do appear to be quite consistent in measurement so good for measurement comparisons. For more accurate measurement there are light meters from companies such as Minolta that can be calibrated, the cost may run into several thousand dollars.

Examples of light meters costing a few hundred dollars include SpyderX by Datacolor (needs a PC), a handheld meter is the SM208 by Sanpometer (search SM208 meter). Note: Many light meters, including smartphone apps, will be meters used for photography and not give readings in nits (or candelas). LCD panel specifications are typically measured using nits.

PWM and Analog: Most Digital View LCD controllers support PWM and Analog as a method for adjusting the backlight brightness level (this is noted in the column headed “Other” on the controller board summary table: https://www.digitalview.com/controllers/lcd-controllers-home.html. Also see https://www.digitalview.com/blog/brightness-adjustment/ for a guide to using a dial or slider type variable resistor to adjust the backlight.

DPMS (Display Power Management System): The backlight will be automatically turned off after a period if there is no valid video signal being received.

Ambient light sensor: The backlight is adjusted for brightness or powered off depending on ambient light conditions. This uses a light sensor attached to the LCD controller board, see https://www.digitalview.com/blog/light-sensor-app-note/ for more details.

The specifics of the backlight control are documented separately for each LCD controller model (product summary here) in the product manual available for download on the product page.

Note: There are two ways to adjust the perceived brightness of a LCD panel or LCD monitor, the backlight and the black-level. Very often, particularly in the past, the monitor brightness setting adjusted the black-level, this adjusts the LCD but not the backlight.

Color, color temperature etc: In addition to adjusting the brightness other settings may be adjusted as well. For example the color temperature or for example a switch to green monochrome for night vision.

Night-safe lighting (update) : Dual-rail backlights can also be supported. These special backlight enable normal brightness and extreme low level brightness with custom night-safe lighting. Contact us for details.

Note: We have a blog on methods for implementing an ambient light sensor with Digital View LCD controller boards to automatically adjust the backlight or system power, see: Ambient Light Sensor

Update March 2019: Most of the above remains unchanged except for the increased availability of high bright LCD panels of around the 1,000 nit to 2,500 nit range. AUO for example has a number of large size LCD panels with 1,500 nit brightness for the digital signage market. Tianma has panels under 20″ with 1,000 nit to 1,500 nit brightness for various outdoor applications.

The other change is that high bright panels are now increasing edge-lit, this makes the panels thinner and these panels tend to use less power than the previous models. One of the benefits for monitor designers is easier heat management and reduced overall display system costs.

Choosing a backlight system for LCD screen displays is a major consideration. It will determine a lot about your experience of the display and requirements during production. Different backlight options provide widely different effects in the contrast and brightness of the display. Also, depending on which backlight option you choose, it will affect some or all of the following: the cost of the overall product; how many products you will have to order due to manufacturing constraints; and how environmentally friendly the component parts are that make up the product.

The word LCD has been used to describe many display technologies. Often people believe that LCD screen displays are the same as a CRT (Cathode Ray Tube), an LED Display (Light Emitting Diode) or a Plasma display. This is not the case! Let’s discuss what an LCD is and what it is not.

Think of the liquid crystal display (LCD) as a window blind. Positioned in one direction the blinds allow light to pass through, or turned another direction they block the light. Just like a window blind, the LCD does not create its own light, it only blocks or allows it to pass through.

As you know, you can adjust the blinds to alter the amount of light desired. When fully closed, the blinds block light completely; when open, all light passes through; and when angled, partial light comes in. An LCD works similarly to this, with one significant enhancement: an LCD has the ability to block light in some areas and allow light to pass in other locations of the glass. An example of this is the display used on a gas pump. The customer sees numbers where the light is blocked, and a clear area where the light is allowed to pass through.

LCD’s are not CRT’s, LED’s, nor are they Plasma displays. Each of these types of displays produces their own light and are called emissive displays. Emissive displays require more power than an LCD.

Emissive displays have a distinct advantage in that they can be seen clearly at night whereas LCD’s cannot. However, the solution to this problem of low-light visibility is to install a backlight behind the LCD. Backlights do require more power than the LCD itself, but they can be turned on only when necessary. Many products that are powered by batteries will have the backlight dim or shut off after a certain amount of time. This can be seen on cell phones and watches. Consequently, even though a little more power is used for the backlight than used in a stand-alone LCD, because it is not constantly on, the LCD’s with backlights wind up using less power than their emissive display competitors. LCD screen displays using backlights become the clear choice.

This option is the most popular for products that have a lower power budget. Products that run on battery need to conserve power and the lowest powered backlight available is to have no backlight at all.

The Amazon Kindle is a perfect example. The Kindle makes use of a display technology called ‘e-paper’, which looks more like a printed page than any other device on the market currently. This specific e-book reader does not contain a backlight. Because it omits the backlight it can operate up to one month without recharging. Imagine, you could take it on a cruise to Fiji and back and never have to worry about recharging it!

Thinking back to your product, not all products can omit a backlight; in fact it may require one. If it does need a backlight the most popular option is an LED.

A light emitting Diode (LED) is a semiconductor that produces light when current is passed through the device. Light is created from the energy conversion that takes place in the LED die. The advantages of an LED are:LED lights are much more rugged and can handle shock much better than other types of lights.

LED backlights are made up of an array of LED’s. They come in a variety of colors including red, green, yellow, amber, blue, white and R/G/B (Red/Green/Blue). From the R/G/B trio any color in the rainbow can be made.

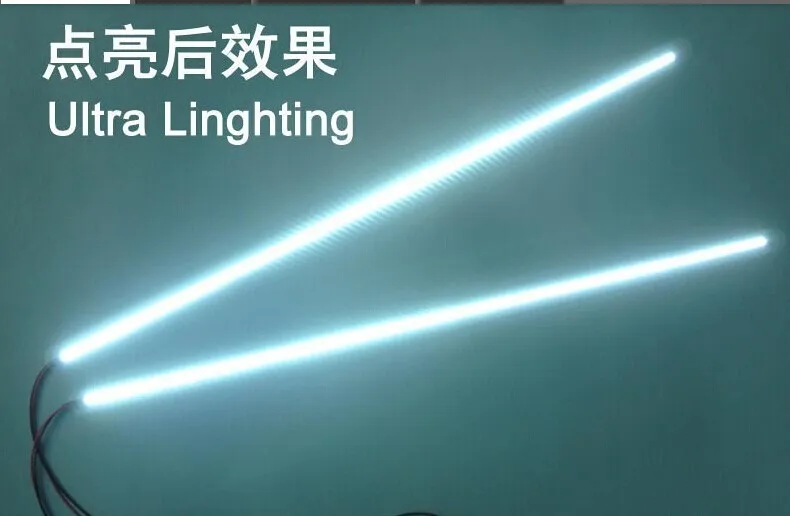

The majority of the LED backlight colors will operate with a half-life of 50K to 70K hours. (Remember, half-life is when the light will be half as bright as when it was first turned on. This is not when the LED will burn out.) Blue and white LED’s do have a shorter half-life than other colors. Presently, they are rated at 30K hours. That means that if you turned them on today and left them on, in 3.4 years they would be half as bright as they are today! One thing to take into account is that as technology improves, the lifetime of the LED’s will become longer, which will also increase the half-life. Below is a photo of a blue LED backlight.

To make LED’s display correctly, they are placed behind the LCD screen display in an array pattern. The challenge is that LED’s, similar to a light bulb, project a beam of light which can show spots of light. These spots are called hot spots. This can be an issue with LED’s since they will make the display look like it has polka dots. Below is a photo of a LED behind the LCD glass. This problem will be solved with the use of a diffuser.

A diffuser is like a lamp shade and is placed between the glass and the LED’s. The goal is to disperse the light or make it more even. Below is a photo of a diffuser. At the bottom of the diffuser you will see the LED’s. This is where you can see hot spots. But as the light travels further into the diffuser, the light becomes more even. The diffuser solves the issue with hot spots and makes LED’s a very attractive option.

EL (Electro Luminescent) backlights, also known as ELP’s (Electroluminescence Panel), have been used as a backlight for LCD’s for several years. They are available in a range of colors with white being the most popular. EL technology makes use of colored phosphors to generate light. They require AC (alternating current) rating of 100VAC @ 400Hz.

In the last three to four years, EL backlights have decreased in popularity. There are several reasons for this drop in popularity.The EL backlight requires an inverter to convert DC to AC. The cost of the inverter increases the cost of the overall LCD Display.

The half-life of an EL is an estimated 3,000 to 5,000 hours. (Once again, half-life is when the backlight is half as bright as when it was first turned on.)

LCD screen display manufacturers now require an MOQ (Minimum Order Quantity) of no less than 500 displays for orders that include EL backlights. This MOQ number is likely to increase in the future as this type of backlight becomes less popular. Additionally, as the demand drops the price will naturally increase.

A Cold Cathode Fluorescent Lamp (CCFL) is similar to the long fluorescent light bulbs you see in the ceilings of offices. Below are photos of various types.

This technology has been in use for many years, but in the last few years the popularity of this type of backlight has decreased. There are a few reasons why this is so.Similar to EL backlights, this technology operates on AC.

The majority of LCD screen display manufacturers no longer offer CCFL as an option. There are too many negatives and not enough positives to their use. The suppliers that do offer this now require a very high MOQ (Minimum Order Quantity).

When choosing the type of backlight for your LCD screen displays it is important to keep in mind MOQ’s and future availability. Make sure you are choosing a technology with a future so that your product has one too!

If you are having difficulty reading the information displayed on the LCD, try changing the contrast setting. Adjusting the contrast will give the information a sharper and more vivid appearance.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Backlight circuit failure can also occur from damage to the electrical traces on the circuit board. If the electrical traces buried in the board are inadvertently severed—for example, from trying to fasten the board with too large a screw—the backlight circuit will not conduct power to the backlight LEDs.

A screen that gets gradually dimmer, a monitor that flickers when you turn it on, or a display that flashes before going dark are all indicative of an LCD with a failing backlight. Most LCD screens require a third-party backlight, so at some point, you’ll need to deal with lamp failure for your screen.

Generally, replacing the backlight on your Samsung TV will cost you between $100-$200. Usually, this is significantly less than what you paid for the TV, so it is definitely worth it, especially if nothing else has gone wrong.

TV backlight repair costs $100 to $122, including replacement parts and labor, at a repair shop. In-house repair costs are more due to trip fees. The price of backlight replacement parts averages around $2.50 for each LED and between $20 and $25 for each CCFL strip.

To replace one LED backlighting strip, the price ranges from $100 to $125, including parts and labor. Older televisions cost more to repair. Parts for these TVs may be difficult to find. Also, parts for TVs that are 42 inches or bigger are more expensive.

Be very careful with the panel as it is extremely fragile! Now that LCD panel is removed, we can remove the bezel that maintain the backlight diffuser and access the backlight itself. Here we can see that the backlight system is made of LEDs which is pretty simple to replace when being the cause of the failure.

From a component standpoint, this TV features a lot of parts, but generally, the LEDs in its backlight are probably going to fail first. The average lifespan of an LED at maximum or close-to-maximum brightness is 40,000 to 60,000 hours, or roughly 4.5 to 6.8 years.

A Vizio TV can last you about 7 years on average, but you can extend their life up to a possible 10 years with a little sensible care. Vizio are great TVs that you can enjoy for a long time and today we’ll tell you all about how you can do that.

Replace the HDMI cable as it may have a short or another defect which causes the black screen issue. Unplug the TV for 5 minutes to attempt a reset. Unplugging the TV will reset the television and clear any temporary issues. Factory reset of the TV to resolve the issue.

If it’s a backlight or power supply problem, it can be fixed. Usually, the problem stems from the high voltage inverter circuitry, either bad power transistors, capacitors, or thermal stress on the circuit board leading to broken solder joints. But fixing these problems can often be a short term solution.

The average lifespan of a television varies between 4 and 10 years (approximately 40,000 – 100,000 hours) depending on usage and maintenance. Turning off your TV is one of the simplest things you can do to extend its lifespan.

More importantly, you can do so without having to worry whether or not you have to buy a fully new TV! If your TV panel is still in one piece, meaning a brick hasn’t gone through the screen there is a good chance it can be repaired!

So, when should you upgrade? Some people are unlikely to upgrade until their current set becomes faulty or fails entirely. However, those who are keen to enjoy the latest TVs may upgrade more frequently. Ideally, any television should last for at least ten years before brightness and other features begin to suffer.

But despite being advanced systems, Vizio TVs sometimes fail to work, and you get many errors when using them. Many Vizio TV user complaints revolve around the device screen flickering constantly, SmartCast failing to load, and the TV turning on but not showing pictures.

Most Vizio TVs have a power light in the lower left corner of the TV. It lights up whenever the power button is pressed. It is normal for the power indicator to light up then turn off after a few moments. The power light might still light up even if the rest of the TV is not on.

A Vizio TV screen may go black due to features such as ‘Screen Mute’ or ‘Sleep Timer’. It may also be a result of a loose/faulty connection, power issues, software error/bug or broken hardware. Most issues can be fixed by updating or resetting the TV, securing all cable or changing the TV settings.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

One of my relatives had this exact symptom happening all of a sudden. This problem on low-end TVs often occurs within the first couple years. As the repair costs for that kind of TV is pretty low, considering repairing it yourself might be a good idea!

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

Using a multimeter, we can confirm that the strips are indeed set in series, so now we have to test each strip individually. Professionals use LED testers such as this one (about 40$ on amazon) but as I didn’t had one at the time, I decided to make one, McGyver style!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey