lcd module diagram price

Factors that may influence the price of a certain type of LCD include: screen size, viewing angle, maximum brightness, color display,resolution and frame rate.

Screen size: larger size display more, and larger size cost more, these’re common sense. For example, in last year’s iPhone 8P which used a 5.5-inch LCD screen, the display (including touchscreen) cost 52.5 dollars, while a 43-inch LCD TV cost 128 dollars.

Viewing angle: it’s the maximum angle at which a display can be viewed with acceptable visual performance. It’s measured from one direction to the opposite, giving a maximum of 180° for a flat, one-sided screen. Early LCDs had strikingly narrow viewing angles, for now most of the manufacturers have improved them to more than 160°.

Color display: in early or simple LCDs, only two or very few colors can be displayed. As the technology advances, TFT LCD can display up to 65536 colors.

As the diagram shows above, LCD module covers the most part of the cost of a LCD TV. Within LCD module, there’re still many components. In the following diagram we’ll show you the price breakdown of these components.

The third quarter in the year is usually the demand season of LCD module, as a result the price will be the highest. However, situation varies in different market.

Due to the massive investment and low cost of Chinese mainland manufacturer, the capacity of LCD module for TVs increases significantly, so the price of these modules stay pretty low for the past year.

In another aspect, technology innovations keep push the price of high-end LCD to a higher level. For many users that are planning to replace their old TVs, these high-end LCDs are tempting choices.

Actually, though LCD screen has many advantages, its average price is keep decreasing in the past years. New technology brings lower cost is one reason, a strong competitor called OLED is another.

Main difference between OLED and LCD is OLED can give out light itself, that is to say OLED screen can run at a lower load compared to LCD screen, at least it doesn’t need a backlight system.

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved November 30, 2022, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed November 30, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: November 30, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited November 30, 2022)

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, digital watches use some kind of display to display the time.

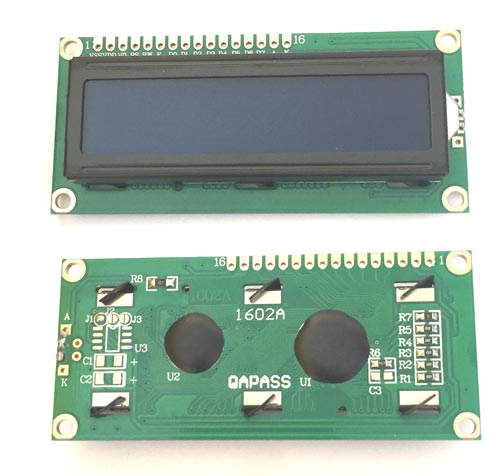

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates o a display 16 characters per line in 2 such lines. In this LCD each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for command register, whereas RS=1 for data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD it goes to the data register and is processed there. When RS=1, data register is selected.

Generating custom characters on LCD is not very hard. It requires the knowledge about custom generated random access memory (CG-RAM) of LCD and the LCD chip controller. Most LCDs contain Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

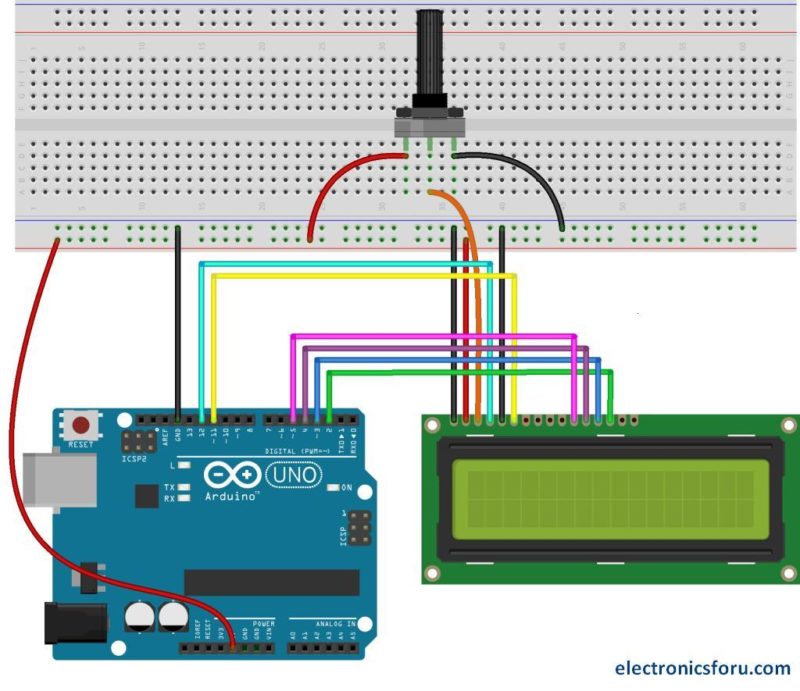

LCD modules form a very important in many Arduino based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customise the code easily. Any cost effective Arduino board, a 16X2 character LCD display, jumper wires and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED and some jumper cables. The circuit connections are below.

16x2 LCD modules are very commonly used in most embedded projects, the reason being its cheap price, availability, programmer friendly and available educational resources.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. but the most used one is the 16×2 LCD. So, it will have (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. A Single character with all its Pixels is shown in the below picture.

Now, we know that each character has (5×8=40) 40 Pixels and for 32 Characters we will have (32×40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels. Hence it will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780is used, which is mounted on the backside of the LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen. You can learn how to interface an LCD using the above mentioned links. If you are an advanced programmer and would like to create your own library for interfacing your Microcontroller with this LCD module then you have to understand the HD44780 IC working and commands which can be found its datasheet.

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

It may seem odd in the face of stalled economies and stalled AV projects, but the costs of LCD display products are on the rise, according to a report from Digital Supply Chain Consulting, or DSCC.

Demand for LCD products remains strong , says DSCC, at the same time as shortages are deepening for glass substrates and driver integrated circuits. Announcements by the Korean panel makers that they will maintain production of LCDs and delay their planned shutdown of LCD lines has not prevented prices from continuing to rise.

Panel prices increased more than 20% for selected TV sizes in Q3 2020 compared to Q2, and by 27% in Q4 2020 compared to Q3, we now expect that average LCD TV panel prices in Q1 2021 will increase by another 12%.

All that said, LCD panels are way less costly, way lighter and slimmer, and generally look way better than the ones being used 10 years ago, so prices is a relative problem.

Nowadays, we always use the devices which are made up of LCDs such as CD players, DVD players, digital watches, computers, etc. These are commonly used in the screen industries to replace the utilization of CRTs. Cathode Ray Tubes use huge power when compared with LCDs, and CRTs heavier as well as bigger. These devices are thinner as well power consumption is extremely less. The LCD 16×2 working principle is, it blocks the light rather than dissipate. This article discusses an overview of LCD 16X2, pin configuration and its working.

The term LCD stands for liquid crystal display. It is one kind of electronic display module used in an extensive range of applications like various circuits & devices like mobile phones, calculators, computers, TV sets, etc. These displays are mainly preferred for multi-segment light-emitting diodes and seven segments. The main benefits of using this module are inexpensive; simply programmable, animations, and there are no limitations for displaying custom characters, special and even animations, etc.

A 16×2 LCD has two registers like data register and command register. The RS (register select) is mainly used to change from one register to another. When the register set is ‘0’, then it is known as command register. Similarly, when the register set is ‘1’, then it is known as data register.

The main function of the data register is to store the information which is to be exhibited on the LCD screen. Here, the ASCII value of the character is the information which is to be exhibited on the screen of LCD. Whenever we send the information to LCD, it transmits to the data register, and then the process will be starting there. When register set =1, then the data register will be selected.

Thus, this is all about LCD 16×2 datasheet, which includes what is a 16X2 LCD, pin configuration, working principle, and its applications. The main advantages of this LCD device include power consumption is less and low cost. The main disadvantages of this LCD device include it occupies a large area, slow devices and also lifespan of these devices will be reduced due to direct current. So these LCDs use AC supply with less than 500Hz frequency. Here is a question for you, what are the applications of LCD?

Hello friends! Welcome back to ElectroDuino. This blog is base on What is 16×2 LCD Display Module Sensor | How 16×2 LCD Display Module Works. Here we will discuss the Introduction to 16×2 LCD Display Module, Module pin diagram, Working Principle, Features, and applications.

16×2 LCD is one kind of electronic device used to display the message and data. The term LCD full form is Liquid Crystal Display. The display is named 16×2 LCD because it has 16 Columns and 2 Rows. it can be displayed (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. These displays are mainly based on multi-segment light-emitting diodes. There are a lot of combinations of display available in the market like 8×1, 8×2, 10×2, 16×1, etc. but the 16×2 LCD is widely used. These LCD modules are low cost, and programmer-friendly, therefore, is used in various DIY circuits, devices, and embedded projects.

3VE (Contrast V)Adjusts the contrast of the LCD display. It is Connected to a variable POT that can provide 0-5V power supply. Connect it to the ground to get maximum contrast.

7D0 (Data Pin 0)These 8 Pins are used to sending commands or data to the LCD. These pins are connected in two-wire modes like 4-wire mode and 8-wire mode. In 4-wire mode, only four pins are connected to the microcontroller data pin 0 to 3. And in 8-wire mode, 8-pins are connected to microcontroller data pin 0 to 7.

These 16 x 2 LCD display modules are constant of 16 Columns and 2 Rows. The 1st row of this module has a total of 16 columns 0 to 15 and the position of the first row is 0. Also, the 2nd row has a total of 16 columns 0 to 15 and the position of the second row is position is 1. So the total numbers of the column are 16 x 2 = 32. Its means 16 x 2 LCD module can display 32 characters at the same time.

It will be a very complicated task to handle everything with the help of a microcontroller. So an Interface IC like HD44780 is used, which is mounted on the backside of the LCD Module. The function of this IC is to get the Commands and Data from the microcontroller and process them to display meaningful information onto the LCD Screen.

Vcc and Vss provide +5V and ground to our LCD, respectively, VEE is used for controlling LCD contrast i.e. dimming the brightness or increasing the brightness of LCD.

There are two very important registers inside the LCD. The RS pin is used for the selection of these registers. If RS=0, the instruction command code register is selected, which allows the user to send commands for the LCD such as clear display, cursor at home, and so on. If RS=1, the data register is selected. It allows the user to send data that is to be displayed on the LCD.

When data is supplied to the data pins, a high-to-low pulse must be applied to this pin in order for the LCD to latch in the data present at the data pins. This pulse must be a minimum of 450ns wide.

The 8-bit datapins, D0-D7 are used to send information to the LCD or read the contents of the LCD’s internal Registers. We send the ASCII codes is sent to the LCD to display numbers and letters for the letter A-Z, a-z, and numbers 0-9 to these pins while masking RS=1.

There are also instruction command codes that can be sent to the LCD to clear the display or force the cursor to the home position or blink the cursor.

The next table here incudes all the instruction command codes. To interface LCD to the AVR we can use 4-bit mode and 8-bit mode. The 8-bit data interfacing is easier to program but uses 4 more pins.

Monochrome character, graphic and static displays require different input voltages. All the different LCD voltage symbols can be confusing, but believe it or not, there is a system to the madness.

This LCD voltage terminology originated from the terminals of each type of transistor and their common connections in logic circuits. In other words, VCC is often applied to BJT (Bipolar Junction Transistor) collectors, VEE to BJT emitters, VDD to FET (Field-Effect Transistor) drains and VSS to FET sources. Most CMOS (Complementary metal–oxide–semiconductor) IC data sheets now use VCC and GND to designate the positive and negative supply pins.

Note: Most Segment, Character and Graphic displays will operate with a VDD of 5V or 3.3V. It may be possible to drive the display with as little as 3.0V, but the module may not perform very well in colder temperatures. The colder the ambient temperature, the more power is required to drive the segments.

Pin three (3) is Vo and is the difference in voltage between VDD and VSS. This LCD voltage is adjusted to provide the sharpest contrast. The adjustment can be accomplished through a fixed resistor or a variable potentiometer. Many products have firmware that monitor the temperature and automatically adjust the contrast voltage.

In a Liquid Crystal Display (LCD), V0 is used to vary the screen brightness or contrast. Contrast, simply put is the ratio of the light areas to the dark areas in a LCD. This is usually done in a production setting with values which are optimized for most users. Temperature can have an undesirable effect on the display brightness and for this reason a varying resister or potentiometer is used to accommodate the desires of the user.

Below is a data sheet of a 16x2 Character LCD module that shows various recommended driving voltages. The LCD voltage can range from MIN (minimum) to TYP (Typical) to Max (maximum).

If the supplied LCD voltage drops too low, the display is ‘under-driven’ and will produce segments that are ‘grey’. The lower the LCD voltage falls below the acceptable threshold, the lower the contrast will be.

If the LCD is over-driven, you may see ghosting. This is where segments that should not be ‘on’ are gray. They are not as dark as the segments that should be on, but they can be seen and may cause confusion for the end user.

There are times when a customer needs to replace a display that has been discontinued or EOL (End-Of -Life) by their previous LCD supplier. The previous LCD’s pin-outs may be different than Focus’ standard, off-the-shelf display. This is not a large problem to overcome.

The third option is to pull power from pins one and two. This is the same location from which the LCD is pulling its power. Focus does not recommend this option and can modify the PCB for the customer to connect the backlight from a different location.

Many LCD Modules will require more than one internal voltage/current. This may make it necessary for the customer to supply the needed inputs. They may need to supply 3V, 5V, 9V, -12V etc.

The solution for this is to integrate a charge pump (or booster circuit) into the LCD circuitry. This solution works in most applications, but if the product will be operating in an intrinsic environment, care must be taken with layout of the circuit board.

Intrinsically-safe LCDs are Liquid Crystal Displays that are designed to operate in conditions where an arc or spark can cause an explosion. In these cases, charge pumps cannot be employed. In fact, the total capacitive value of the display needs to be kept to a minimum.

Focus Display Solutions does not build a display that is labeled ‘Intrinsically safe’ but we do design the LCD to meet the requirements of the engineer. In meeting the design engineer’s requirements, the display may need to contain two or three independent inputs. Focus can redesign the PCB and lay out the traces to allow for these additional inputs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey