tn lcd panel polarized glasses supplier

A wide variety of lcd polarized options are available to you, such as machinery repair shops, manufacturing plant and home use.You can also choose from apple iphone, lcd polarized,As well as from 1 year, {2}, and {3}. And whether lcd polarized is provided, {2}, or {3}.

custom lcd glass with tn provide the touch interface in smartphones, which are vital for them to function. Alibaba.com stocks a stunning range of high-tech custom lcd glass with tn with vibrant color depictions. Truly crystal-clear displays of custom lcd glass with tn are available covering various brands and models such as the Samsung Galaxy Edge 2, OnePlus 7T, Samsung Galaxy C5, and many more.

custom lcd glass with tn are the most commonly used displays, as they produce great image quality while consuming low power. Rather than emitting light directly, they use back lights or reflectors to produce images, which allows for easy readability even under direct sunlight. custom lcd glass with tn are energy-efficient, and are comparatively safer to dispose of, than CRTs. custom lcd glass with tn are much more efficient when it comes to usage in battery-powered electronic equipment, due to their minimal power consumption.

Some other advantages of custom lcd glass with tn over the CRT counterparts are - sharper images, little to no heat emission, unaffected by magnetic fields, narrow frame borders, and extreme compactness, which make them very thin and light. Some types of custom lcd glass with tn are transmissive, reflective, and transflective displays. Transmissive displays provide better image quality in the presence of low or medium-light, while reflective displays work best in the presence of bright light. The third type of custom lcd glass with tn, transflective, combine the best features of both the other types and provide a well-balanced display.

Whether as an individual purchaser, supplier or wholesaler, browse for an extensive spectrum of custom lcd glass with tn at Alibaba.com if you don"t want to stretch a dollar yet find the best fit.

TN displays have a 90° or less twist (the rotation of the molecules from one plane of the display to the other). All passive direct drive, active matrix, and most passive low level (x2 to x32) multiplexed LCDs have a 90° twist.

The basic Twisted Nematic (TN) LCD consists of a layer of liquid crystal material supported by two glass plates. The liquid crystal material is a mixture of long, cylindrically shaped molecules with different electrical and optical properties, depending on direction.

The TN technology comes in a single coloration; it is Black characters on a gray background. It is the least expensive, but has the lowest visual quality, primarily in viewing angle.

When searching for a liquid crystal display (LCD), consideration of the device’s display technology is essential. Screen technology companies such as Apple and Samsung search for the best possible display panels and panel technology in order to offer their customers the best image quality. In competitive gaming, gaming monitors must be able to provide great image quality but also fast refresh rates so that gamers can play at a fast pace.

Before diving into how exactly liquid crystals affect display features, it is necessary to understand their general role in an LCD monitor. LCD technology is not capable of illuminating itself, so it requires a backlight. The liquid crystals are responsible for transmitting the light from backlight to the computer monitor surface in a manner determined by the signals received. They do so by essentially moving the light differently through the layer’s molecular matrix when the liquid crystals are oriented or aligned in a certain manner, a process which is controlled by the LCD cell’s electrodes and their electric currents.

The methods of alignment, however, can vary between panel types, offering different features and benefits. Two common and popular liquid crystal alignment techniques are twisted nematic (TN) and in-plane switching(IPS).

TN panels offer the cheapest method of crystal alignment. They also are the most common of the alignment methods and have been used for quite a long time in the display industry, including in cathode ray tubes (CRTs) that preceded the LCD.

In TN displays, the electrodes are positioned on either side of the liquid crystal layer. When a current is sent between the back and front electrode, something called an electric field is created that shifts and manipulates the orientation of the molecular matrix.

If no electric field is applied to the specific cell, the crystals experience a 90 degree twist in the alignment. As light from the backlight passes through this twist, the light waves are polarized, allowing them to pass through the polarizer that sits on the surface of the TN monitor.

If an electric field is applied, it can either untwist the TN liquid crystal layer partially or in full, depending on the strength of the field. The structure of TN crystals will typically straighten out when this happens, and some, if not all, light waves will not be polarized properly to pass through to the surface.

Each LCD cell composes a pixel of the display, and in each pixel are subpixels. These subpixels use standard red green blue (sRGB) colors to create a variety of colors to make the pixel display the necessary color to play its role in the overall display. If beneath the subpixel the liquid crystal fully polarizes the light, that subpixel’s specific color would be very bright in the pixel as a whole. But if the light is not polarized at all, then that color will not show up. If partially polarized, only a limited amount of that color is used in the mixture of RGB colors in the final pixel.

A more complex method of alignment is IPS. IPS monitors, unlike the TN, place both electrodes on the same level, behind the liquid crystal layer. When the electric field is applied, this forces the liquid crystal molecules to align themselves parallel to the IPS device layers instead of perpendicularly like the TN molecules.

Opposite of the TN, when the electric field is applied, IPS technology will polarize the light to pass, whereas when the electric field is not applied, the light will not be polarized to pass. Because of the orientation of the crystals, IPS displays require brighter, more powerful backlights in order to produce the correct amount of brightness for the display.

An important consideration is viewing angles. The TN offers only a limited viewing angle, especially limited from vertical angle shifts, and so color reproduction at these angles will likely not look the same as from a straight-on viewing; the TN’s colors may invert at extreme angles. The IPS counters that and allows for greater and better viewing angles that consequently offer better color reproduction at these angles than the TN. There is one issue with extreme viewing angles for IPS devices: IPS glow. This occurs when the backlight shines through the display at very wide angles, but typically is not an issue unless a device is looked at from the side.

In terms of color, as mentioned, TN devices do not have very strong color reproduction compared to other alignment technologies. Without strong color reproduction, color banding can become visible, contrast ratio can suffer, and accurate colors may not be produced. Color gamut, or the range of colors that the device can reproduce and display, is another feature that most TN displays do not excel in. This means that the full sRGB spectrum is not accessible. IPS devices, on the other hand, have good quality black color reproductions, allowing the device to achieve a deeper, richer display, but it is still not the best option if a customer is in search of high contrast (discussed further in a couple more paragraphs).

While TNs may not have the best color quality, they allow for high refresh rates (how often a new image is updated per second), often around 240 Hz. They also have the lowest input lag (receiving of signals from external controllers) at about one millisecond. TN panels often attract gamers because of the need for minimal lag and fast refresh rates in a competitive or time-sensitive setting. In consideration of moving displays like in video game displays, it is also important for fast response times (how fast a pixel can change from one amount of lighting to another). The lower the response time (the higher the response rate), the less motion blur will be shown as the display changes to show motion. TNs also offer these low response times, but it is important to remember that a powerful graphics processing unit, commonly called a GPU, is still needed to push these displays to meet the fastest refresh and response rates.

Another common consideration of customers is the price of each display. TN, though it does not offer as high quality of a display, offers the lowest cost and best moving displays, making it useful if the intended use of the LCD monitor is simple and not too demanding. However, if you intend for something that calls for better color production or viewing angles, the IPS and other methods are viable choices, but at much higher costs. Even though IPS motion displays have reached the speed and rates of TNs, the price for such technology is much more expensive than the TN option.

There are other options besides the TN and IPS. One option is known as vertical alignment (VA) and it allows for the best color accuracy and color gamut. Compared to a typical IPS contrast ratio of 1000:1, VA panels can often have ratios of 3000:1 or even 6000:1. Besides improved contrast ratio, the VA is in between the TN and IPS. To compare the TN vs IPS vs VA, the VA does not have as great a viewing angle as IPS but not as poor as the TN. Its response times are slower than TN but faster than IPS (though at fast refresh rates, the VA displays often suffer from ghosting and motion blur). Due to the contrast ratio benefits, VA technologies are most often desirable for TVs.

And lastly, there is an option quite similar to IPS that is called plane to line switching (PLS). It is only produced by Samsung, who claims the PLS offers better brightness and contrast ratios than the IPS, uses less energy, and is cheaper to manufacture (but because it is only created by Samsung, it is hard to judge pricing). It also has potential in creating flexible displays.

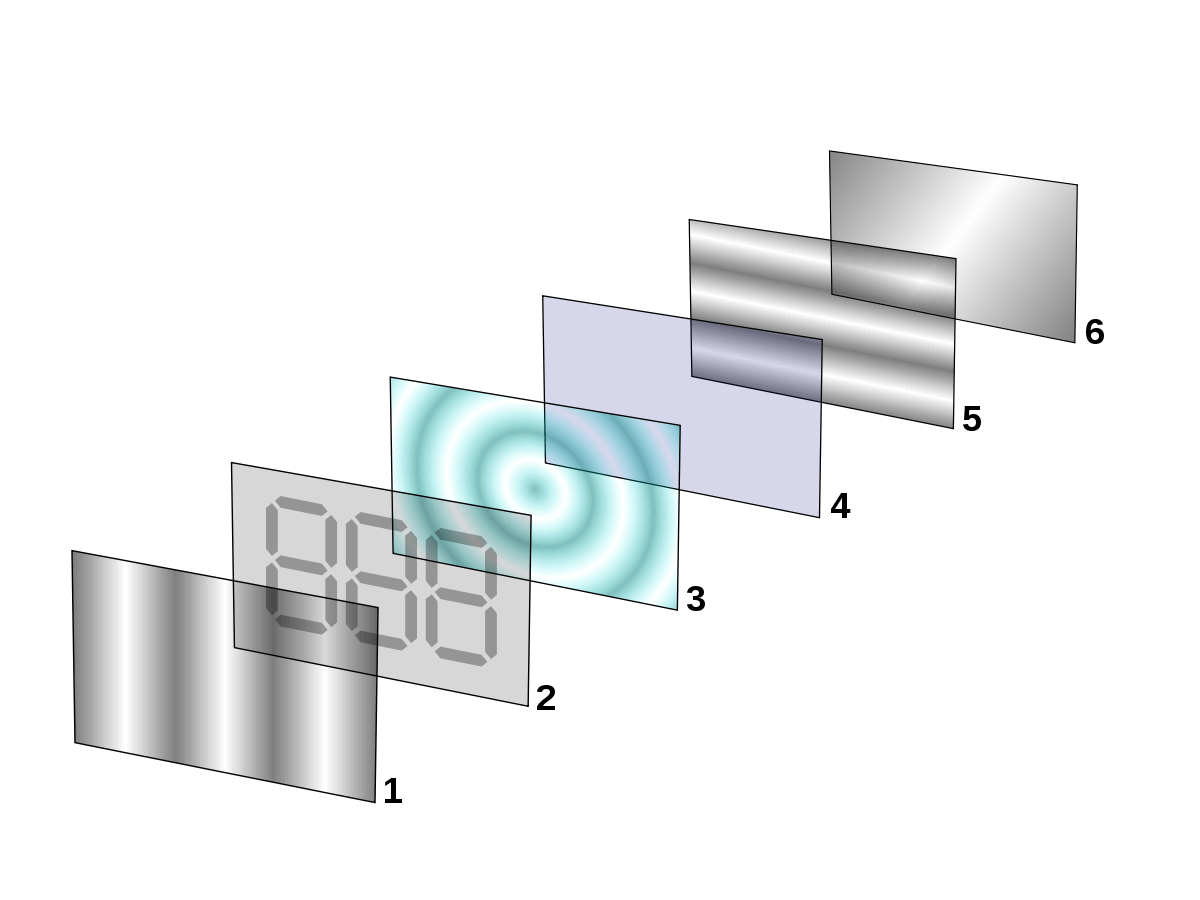

Polarizer is one of the main raw materials of liquid crystal display (LCD), accounting for about 20%-30% of its manufacturing cost. However, since the manufacturing technology of polarizer has been monopolized by Japan, South Korea and other countries, there is very little information to introduce polarizer in details . Taking the polarizer for TN LCD as an example, we will explain some issues that many LCD polarizer users are very concerned about.

Polarizer is a kind of optical film with the function of generating polarized light, which is composited by multi-layer polymer materials. According to the different application in the LCD screen, it can be roughly divided into surface sheet (also called transparent sheet) and negative plate (also known as reflector plate).

It can be divided into reflective film side adhesive and seperate film side adhesive. The role of the reflective film side adhesive is to firmly bond the reflective film to the TAC film, and re-peelability is not allowed. The peeling film side adhesive is a pressure-sensitive adhesive, which determines the adhesion performance of the polarizer and the processing performance of the patch. Its performance is one of the most concerned issues for LCD polarizer users.

It is a PET (ethylene terephthalate) film coated with a silicon coating on one side. It mainly protects the pressure-sensitive adhesive layer. At the same time, its peeling force is very important for the LCD patch.

Generally, the size of the polarizer for TN-type LCDs in the market is fixed, and the direction of the absorption axis is fixed. If a polarizer with a special size and shape is provided to the LCD manufacturer, the absorption axis should be marked or stated.

The transmittance index of the polarizer can be divided into three items: single, parallel , and Crossed. It is usually measured with an integrating sphere spectrophotometer . Among them, the monomer transmittance refers to the transmittance of a single polarizer. the parallel transmittance (H0 ) refers to the transmittance of two polarizers with parallel absorption axes. And the crossed transmittance (H90) refers to the transmittance of two polarizers with crossed absorption axes. Among these three indicators, H0 and H90 affect the brightness (H 0) and contrast (H 0/H 90) of the LCD screen, which is very important for LCD manufacturers. In order to obtain a good display effect with high brightness and high contrast, it is desirable that H0 could be as high as possible and H90 be as small as possible.

Polarizing Co-Efficiency (ν) is a calculated value used to express the overall efficiency of polarized light produced by the polarizer. The formula can be transformed into H 0/H 90 = (1+ν2) /(1-ν2) . It can be seen that the closerνvalue is to 100%, the higher the contrast (H 0/H 90 ).

The peeling force of the polarizer is further divided into three items: protective film peeling force, peeling film peeling force, and peeling force against glass substrate. The three kinds of peeling force are measured with a tensile testing machine . The peeling force of the protective film and the peeling force of the peeling film are measured in the 180° direction, and the glass substrate is in the 90°direction. For LCD manufacturers, the peeling performance of the polarizer to the glass substrate is very important. If it is difficult to peel off within a short period of time (4-6 hours) after pasting, or there is residual glue on the glass plate after peeling, the polarizer will have poor reworkability, and poor placement will cause the entire LCD screen to be scrapped. However, if the peeling force is too small, it is easy to decrease the durability and moisture resistance of the pressure-sensitive adhesive after the polarizer is laminated on the glass substrate. And the surface of the peeling film is dented, which also affects the performance of the polarizer.

The durability test of the polarizer is to peel off the peeling film and the protective film of the polarizer and attach it to the glass substrate. After defoaming under pressure, it is placed in a constant temperature and humidity box to observe the changes before and after the experiment. The foaming and peeling index is mainly to assess the durability of the adhesive, and the optical change index is to assess the durability of the PVA layer. The durability requirements of the polarizer should be determined according to the design requirements (use environment) of different types of LCD products. The imaging of LCD must rely on polarized light. All liquid crystals have two front and rear polarizers attached to the liquid crystal glass to form a total 1mm thickness LCD. If any polarizer is missing, the liquid crystal film cannot display images. The reason why the polarizer need to be replaced is that the polarizer facing the eyes of the ordinary liquid crystal display is frosted. It dissipates the surface reflection and scatter the light to increase the viewing angle of the liquid crystal display. For the projector, any scattering will cause the loss of light. The ideal state of the liquid crystal film used in the projector should be a 0 degree viewing angle. That is, when viewing the liquid crystal film from the vertical direction , there will be no light. Of course, this is impossible to achieve, but the closer the viewing angle is to 0 degree, the higher the utilization rate of light. So after replacing the frosted polarizer with a flat polarizer, the brightness of a projector on the wall will be greatly improved, probably by 50-80%, which is why the polarizer should be changed.

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

In the idle state, the liquid twists the plane of polarization of the incoming light by 90° so that it can pass the analyzer unhindered. The LCD is thus transparent. If a specific voltage is applied to the metallic film coating, the crystals rotate in the liquid. This twists the plane of polarization of the light by another 90°, for example: The analyzer prevents the light getting through, and the LCD thus becomes opaque.TN, STN, FSTN, blue mode, yellow-green mode

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Many ask themselves, "What is the difference between an LCD display and a TFT display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey