liquid crystal display screens without lightin for sale

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

As Figure 6 depicts, there are two types of surface reflections. The first one is from a direct light source, i.e., the sun or a light bulb, denoted as A1. Its reflection is fairly specular, and in practice, we can avoid this reflection (i.e., strong glare from direct sun) by simply adjusting the display position or viewing direction. However, the second reflection, denoted as A2, is quite difficult to avoid. It comes from an extended background light source, such as a clear sky or scattered ceiling light. In our analysis, we mainly focus on the second reflection (A2).

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

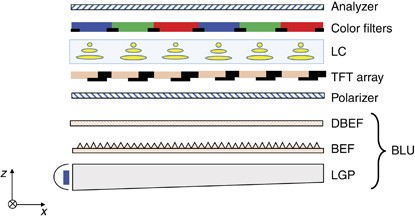

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

Flexible displays have a long history and have been attempted by many companies, but this technology has only recently begun to see commercial implementations for consumer electronics

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

Through improvements in LCD parts and materials, monitor weight has been reduced over earlier models, making it easier to transport and install the display.

Heavy-duty carrying handles are included with each monitor to ensure safe handling. These handles may be detached when the display is installed. All models additionally incorporate a VESA-compliant mounting hole configuration to help ensure a safe and secure installation with compatible third-party mounting hardware.

* Rewards 3% back excludes taxes and shipping. Rewards are issued to your online Dell Rewards Account (available via your Dell.com My Account) typically within 30 business days after your order’s ship date. Rewards expire in 90 days (except where prohibited by law). “Current rewards balance” amount may not reflect the most recent transactions. Check Dell.com My Account for your most up-to-date reward balance. Total rewards earned may not exceed $2,000 within a 3-month period. Outlet purchases do not qualify for rewards. Expedited Delivery not available on certain TVs, monitors, batteries and adapters, and is available in Continental (except Alaska) U.S. only. Other exceptions apply. Not valid for resellers and/or online auctions. Offers and rewards subject to change without notice, not combinable with all other offers. See Dell.com/rewardsfaq. $50 in bonus rewards for Dell Rewards Members who open a new Dell Preferred Account (DPA), or Dell Business Credit (DBC) account on or after 8/10/2022. $50 bonus rewards typically issued within 30 business days after DPA or DBC open date.

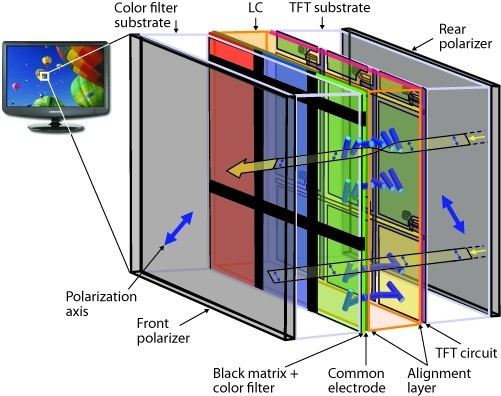

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

In the idle state, the liquid twists the plane of polarization of the incoming light by 90° so that it can pass the analyzer unhindered. The LCD is thus transparent. If a specific voltage is applied to the metallic film coating, the crystals rotate in the liquid. This twists the plane of polarization of the light by another 90°, for example: The analyzer prevents the light getting through, and the LCD thus becomes opaque.TN, STN, FSTN, blue mode, yellow-green mode

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

12°° displays (top view, TV) are best built into a table-top unit. All displays can be read vertically from the front.Reflective, transflective, transmissive

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

However, the lighting also determines the optical impression made by the display, and the display mode; blue or yellow-green – does not always have an influence. Below you can see the EAP162-3N display with different types of lighting by way of example:Lighting

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

Text displays require what is known as a dot matrix, an area consisting of 5x7=35 dots, in order to display all of the letters in the alphabet as well as various special characters. Graphics displays have a similar structure to text displays. In this case, however, there are no spaces between the lines and characters.Display drivers and controllers

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Pure display drivers work in a similar way to a shift register. They generally have a serial input. They require an external pulse, and in multiplex operation with high frequency they require new display data continuously in order to achieve a refresh frequency that is as high as possible (MSM5219, UPD7225, HD44100, LC7942, etc.). An example of a genuine controller is theHD44780 for dot-matrix displays: Once it has received the ASCII code, the controller manages its character set, memory and multiplexing entirely on its own. The following controllers are widely used for graphics displays: HD61202/3, HD61830, SED1520, SED1330, T6963.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

Figuring out which type of display is right for you doesn’t need to be arduous. We’ve rounded up a number of considerations to help you make the most informed decision.

Technically, LED displays are just LCD displays. Both use Liquid Crystal Display (LCD) technology and a series of lamps placed at the back of the screen to produce the images we see on our screens.

The main difference between the two technologies is that for LCD displays, the lamps at the back of the screen are fluorescent, whereas LED displays use Light Emitting Diodes.

There are two types of LED backlighting technologies; edge lighting and full array lighting. In edge lighting – as the name suggests – the LEDs are placed along the edge of the screen whereas in full-array lighting, an array of LEDs spans the back of the LED screen. In both cases, local dimming may or may not be used. The majority of LED displays are edge-lit without local dimming.

Image quality is one of the most contentious issues when it comes to the LED vs. LCD video wall debate. LED displays generally have better picture quality compared to their LCD counterparts. From black levels to contrast and even colour accuracy, LED displays usually come out on top. Among LED screens, full-array back-lit displays with local dimming provide the best picture quality. There is usually no difference in terms of viewing angle. This instead depends on the quality of glass panel used.

It’s generally accepted that LED displays have the lowest energy consumption levels of all displays. LCD displays commonly consume more energy than plasma and CRT displays, neither of which are in production.

In their research, CNET found that “No question, LED LCDs have the lowest energy consumption” in a comparative test between plasma, LCD and LED displays.

LED displays also win in terms of thickness, or lack thereof The reason, once again, being the advanced lighting technology. To start with, light emitting diodes are much smaller compared to the fluorescent lamps used in LCD displays.

Secondly, when the LEDs are placed at the edges as opposed to the back end of the display, the resulting screen will obviously be thinner. This explains why edge-lit LED screens are the slimmest displays available.

If your main concern is budget, then LCD is the obvious choice. As this article points out, you can usually buy a much bigger LCD display for vastly less money than an LED. LCD video walls are generally much cheaper compared to similar sized LED displays.

LCD software allows you to select the right amount of output for a video wall. You can plug a media player into a video wall processor or a daisy chain of displays. With LED displays, however, all cabinets have to plug directly from the video encoder or player. Either that or all cabinets have to be daisy chained together.

Having considered all of these factors, you should now be excellently equipped to pick a display for your video wall. Be sure to take good care of your screen for maximum longevity.

Shopping for a new TV is like wading through a never-ending pool of tech jargon, display terminology, and head-spinning acronyms. It was one thing when 4K resolution landed in the homes of consumers, with TV brands touting the new UHD viewing spec as a major marketing grab. But over the last several years, the plot has only continued to thicken when it comes to three- and four-letter acronyms with the introduction of state-of-the-art lighting and screen technology. But between OLEDs, QLEDs, mini-LEDs, and now QD-OLEDs, there’s one battle of words that rests at the core of TV vocabulary: LED versus LCD.

Despite having a different acronym, LED TV is just a specific type of LCD TV, which uses a liquid crystal display (LCD) panel to control where light is displayed on your screen. These panels are typically composed of two sheets of polarizing material with a liquid crystal solution between them. When an electric current passes through the liquid, it causes the crystals to align, so that light can (or can’t) pass through. Think of it as a shutter, either allowing light to pass through or blocking it out.

Since both LED and LCD TVs are based around LCD technology, the question remains: what is the difference? Actually, it’s about what the difference was. Older LCD TVs used cold cathode fluorescent lamps (CCFLs) to provide lighting, whereas LED LCD TVs used an array of smaller, more efficient light-emitting diodes (LEDs) to illuminate the screen.

Since the technology is better, all LCD TVs now use LED lights and are colloquially considered LED TVs. For those interested, we’ll go deeper into backlighting below, or you can move onto the Local Dimming section.

Three basic illumination forms have been used in LCD TVs: CCFL backlighting, full-array LED backlighting, and LED edge lighting. Each of these illumination technologies is different from one another in important ways. Let’s dig into each.

CCFL backlighting is an older, now-abandoned form of display technology in which a series of cold cathode lamps sit across the inside of the TV behind the LCD. The lights illuminate the crystals fairly evenly, which means all regions of the picture will have similar brightness levels. This affects some aspects of picture quality, which we discuss in more detail below. Since CCFLs are larger than LED arrays, CCFL-based LCD TVs are thicker than LED-backlit LCD TVs.

Full-array backlighting swaps the outdated CCFLs for an array of LEDs spanning the back of the screen, comprising zones of LEDs that can be lit or dimmed in a process called local dimming. TVs using full-array LED backlighting to make up a healthy chunk of the high-end LED TV market, and with good reason — with more precise and even illumination, they can create better picture quality than CCFL LCD TVs were ever able to achieve, with better energy efficiency to boot.

Another form of LCD screen illumination is LED edge lighting. As the name implies, edge-lit TVs have LEDs along the edges of a screen. There are a few different configurations, including LEDs along just the bottom, LEDs on the top and bottom, LEDs left and right, and LEDs along all four edges. These different configurations result in picture quality differences, but the overall brightness capabilities still exceed what CCFL LCD TVs could achieve. While there are some drawbacks to edge lighting compared to full-array or direct backlight displays, the upshot is edge lighting that allows manufacturers to make thinner TVs that cost less to manufacture.

To better close the local-dimming quality gap between edge-lit TVs and full-array back-lit TVs, manufacturers like Sony and Samsung developed their own advanced edge lighting forms. Sony’s technology is known as “Slim Backlight Master Drive,” while Samsung has “Infinite Array” employed in its line of QLED TVs. These keep the slim form factor achievable through edge-lit design and local dimming quality more on par with full-array backlighting.

Local dimming helps LED/LCD TVs more closely match the quality of modern OLED displays, which feature better contrast levels by their nature — something CCFL LCD TVs couldn’t do. The quality of local dimming varies depending on which type of backlighting your LCD uses, how many individual zones of backlighting are employed, and the quality of the processing. Here’s an overview of how effective local dimming is on each type of LCD TV.

TVs with full-array backlighting have the most accurate local dimming and therefore tend to offer the best contrast. Since an array of LEDs spans the entire back of the LCD screen, regions can generally be dimmed with more finesse than on edge-lit TVs, and brightness tends to be uniform across the entire screen. Hisense’s impressive U7G TVs are great examples of relatively affordable models that use multiple-zone, full-array backlighting with local dimming.

“Direct local dimming” is essentially the same thing as full-array dimming, just with fewer LEDs spread further apart in the array. However, it’s worth noting that many manufacturers do not differentiate “direct local dimming” from full-array dimming as two separate forms of local dimming. We still feel it’s important to note the difference, as fewer, further-spaced LEDs will not have the same accuracy and consistency as full-array displays.

Because edge lighting employs LEDs positioned on the edge or edges of the screen to project light across the back of the LCD screen, as opposed to coming from directly behind it, it can result in very subtle blocks or bands of lighter pixels within or around areas that should be dark. The local dimming of edge-lit TVs can sometimes result in some murkiness in dark areas compared with full-array LED TVs. It should also be noted that not all LED edge-lit TVs offer local dimming, which is why it is not uncommon to see glowing strips of light at the edges of a TV and less brightness toward the center of the screen.

Since CCFL backlit TVs do not use LEDs, models with this lighting style do not have dimming abilities. Instead, the LCD panel of CCFL LCDs is constantly and evenly illuminated, making a noticeable difference in picture quality compared to LED LCDs. This is especially noticeable in scenes with high contrast, as the dark portions of the picture may appear too bright or washed out. When watching in a well-lit room, it’s easier to ignore or miss the difference, but in a dark room, it will be, well, glaring.

As if it wasn’t already confusing enough, once you begin exploring the world of modern display technology, new acronyms crop up. The two you’ll most commonly find are OLED and QLED.

An OLED display uses a panel of pixel-sized organic compounds that respond to electricity. Since each tiny pixel (millions of which are present in modern displays) can be turned on or off individually, OLED displays are called “emissive” displays (meaning they require no backlight). They offer incredibly deep contrast ratios and better per-pixel accuracy than any other display type on the market.

Because they don’t require a separate light source, OLED displays are also amazingly thin — often just a few millimeters. OLED panels are often found on high-end TVs in place of LED/LCD technology, but that doesn’t mean that LED/LCDs aren’t without their own premium technology.

QLED is a premium tier of LED/LCD TVs from Samsung. Unlike OLED displays, QLED is not a so-called emissive display technology (lights still illuminate QLED pixels from behind). However, QLED TVs feature an updated illumination technology over regular LED LCDs in the form of Quantum Dot material (hence the “Q” in QLED), which raises overall efficiency and brightness. This translates to better, brighter grayscale and color and enhances HDR (High Dynamic Range) abilities.

There are more even displays to become familiar with, too, including microLED and Mini-LED, which are lining up to be the latest head-to-head TV technologies. Consider checking out how the two features compare to current tech leaders in

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

:max_bytes(150000):strip_icc()/LG-22-28-LG4540-LED-LCD-TV-AMZN-xxx-58ceff565f9b581d726af2ca-b12a1544bfda41418aaaf0afb6aa0375.jpg)

LCDs are made by a number of companies across Asia. All current OLED TVs are built by LG Display, though companies like Sony and Vizio buy OLED panels from LG and then use their own electronics and aesthetic design.

Take this category with a grain of salt. Both TV types are very bright and can look good in even a sunny room, let alone more moderate indoor lighting situations or the dark rooms that make TV images look their best. When it comes down to it, no modern TV could ever be considered "dim."

Here"s where it comes together. Contrast ratio is the difference between the brightest and the darkest a TV can be. OLED is the winner here because it can get extremely bright, plus it can produce absolute black with no blooming. It has the best contrast ratio of any modern display.

Contrast ratio is the most important aspect of picture quality. A high contrast-ratio display will look more realistic than one with a lower contrast ratio.

Nearly all current TVs are HDR compatible, but that"s not the entire story. Just because a TV claims HDR compatibility doesn"t mean it can accurately display HDR content. All OLED TVs have the dynamic range to take advantage of HDR, but lower-priced LCDs, especially those without local-dimming backlights, do not. So if you want to see HDR content it all its dynamic, vibrant beauty, go for OLED or an LCD with local dimming.

If you want something even brighter, and don"t mind spending a literal fortune to get it, Samsung, Sony, and LG all sell direct-view LED displays. In most cases these are

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

As light strikes the first filter, it is polarized. The molecules in each layer then guide the light they receive to the next layer. As the light passes through the liquid crystal layers, the molecules also change the light"s plane of vibration to match their own angle. When the light reaches the far side of the liquid crystal substance, it vibrates at the same angle as the final layer of molecules. If the final layer is matched up with the second polarized glass filter, then the light will pass through.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

LCDs are made by a number of companies across Asia. All current OLED TVs are built by LG Display, though companies like Sony and Vizio buy OLED panels from LG and then use their own electronics and aesthetic design.

Take this category with a grain of salt. Both TV types are very bright and can look good in even a sunny room, let alone more moderate indoor lighting situations or the dark rooms that make TV images look their best. When it comes down to it, no modern TV could ever be considered "dim."

Here"s where it comes together. Contrast ratio is the difference between the brightest and the darkest a TV can be. OLED is the winner here because it can get extremely bright, plus it can produce absolute black with no blooming. It has the best contrast ratio of any modern display.

Contrast ratio is the most important aspect of picture quality. A high contrast-ratio display will look more realistic than one with a lower contrast ratio.

Nearly all current TVs are HDR compatible, but that"s not the entire story. Just because a TV claims HDR compatibility doesn"t mean it can accurately display HDR content. All OLED TVs have the dynamic range to take advantage of HDR, but lower-priced LCDs, especially those without local-dimming backlights, do not. So if you want to see HDR content it all its dynamic, vibrant beauty, go for OLED or an LCD with local dimming.

If you want something even brighter, and don"t mind spending a literal fortune to get it, Samsung, Sony, and LG all sell direct-view LED displays. In most cases these are

LCD display screens are everywhere. You probably own one or more devices with an LCD display screen at home and at work. This includes your TV, computer monitor, watches, clocks, smartphones, and even calculators.

But have you ever wondered about how your LCD display screen works, its lifespan, components, and how it holds up to other emerging display technologies today?

Knowing all these things about your LCD display lets you appreciate your screen all the more. Caring for your device becomes easier when you’re armed with this knowledge.

LCD display screens make use of Liquid Crystal Display technology. The screen is embedded with liquid crystals, a substance that has properties in between a conventional liquid and a solid crystal. Liquid crystals can flow, but their molecules carry a crystal-like solid orientation.

Liquid crystals are responsible for producing an image flashed onto the LCD screen. They don’t emit light, though. Backlights are used to illuminate these crystals.

A display screen is made up of several tiny color blocks called pixels. The term is a portmanteau of “picture” and “element”, denoting pixels as little elements making up an entire screen picture. A screen is typically made up of millions of pixels.

Every pixel on the display screen is made up of red, blue, and green light. These lights can be quickly turned on or off to create an overall moving picture or image.

Now, in LCD displays, pixels are regulated by using liquid crystals for rotating polarized light. Polarized light denotes light waves with vibrations occurring in a single plane. In LCDs, this is achieved by using polarized layers.

Each pixel has polarizing filters on both its front and back. Tiny nematic (twisted) liquid crystals are placed in between these filters. The liquid crystals can be switched on or off electronically through tiny electronic transistors.

When the liquid crystal is turned off, electricity controlled by the transistor stops flowing. The pixel is then turned on, brightening up due to the 90-degree twisting of the nematic liquid crystal. This allows light to pass through both polarizing filters on the pixel, illuminating the pixel by letting light pass through.

When the liquid crystal is turned on, electricity flows through the nematic liquid crystals. They completely straighten out from their twisted state. The polarizing filter in front of the liquid crystal blocks out the light, resulting in the pixel turning off and becoming dark.

A single LCD contains millions of pixels, nematic liquid crystals, polarizing filters, and transistors. They all work together to create images on the screen.

The backlight’s life expectancy is the biggest factor in determining the LCD display lifespan. It’s because liquid crystals do not give off light from themselves. The liquid crystals depend on the backlight for illuminating them. Hence, the LCD screen wears off when the backlights dim as it reaches its maximum lifespan.

The backlight serves as the illuminator of the entire LCD display device. Without a backlight, the LCD device remains darkened and hard to use. Backlights are installed directly behind the LCD panel to lighten up the display.

Simple devices such as pocket calculators don’t use a backlight for their LCD screens. Users rely on natural light to see the numbers displayed on such calculators. However, the majority of modern LCD screens such as televisions, computer monitors, smartphones, aviation screen panels, outdoor signages, and medical monitoring devices use backlights as their internal light source.

Edge-Lit White LED (EL-WLED)– One or more LED rows are placed on the screen’s edge. A special light diffuser is used to scatter the light evenly across the entire display screen. Computer monitors, laptops, notebooks, and even HDTVs are now lit in this way.

ELP uses electroluminescent materials such as colored phosphors instead of heat to create light. This material is placed in between two conductor layers. The material emits light as a result of an electric current flowing through it. ELPs are mostly used in small LCD screens.

Computer monitors and TV screens predominantly used CCFLs for backlights. However, modern manufacturers opt for LED technology instead of CCFL for their devices’ backlights.

Liquid crystals are the heart of an LCD display. This unique substance flows like a liquid but retains many characteristics of solid crystals. They have long and cylindrical-shaped molecules that can twist when changes in molecular orientation happen.

Different liquid crystal families are used in LCD displays. One requirement of such liquids is to exhibit mutual attraction. Also, the molecules in the liquid crystal need to be anisotropic. This means that the liquid crystal molecules have that average structural order along a molecular axis.

Liquid crystals are often sandwiched in between the color filters and the polarizers. They twist and straighten in response to electrical currents applied to them. The movement of liquid crystals controls whether polarized light will pass through the filters or not.

The nematic phase is characterized by the crystal molecules freely moving around the liquid. However, these molecules point themselves to one direction only, making it unique from pure liquid molecules. Nematic liquid crystals are the most common liquid used in LCD screens.

In the smectic phase, the liquid crystals keep their similar orientation and direction. But the molecules are now lining themselves into layers. The smectic layers have restricted movement, creating a solid-like state in the liquid crystals.

Also known as the chiral nematic phase, the cholesteric phase happens when the liquid crystal molecules align themselves at a slight angle to each other. The molecules become stacked in very thin layers as well. The cholesteric phase also allows molecules to change color from exposure to different temperatures.

Now, molecules in liquid crystals move as a reaction to an electric field. Their arrangement changes as a voltage are applied to them. This allows liquid crystals to control polarized light, which, in turn, defines which pixels on a screen will be illuminated or not.

Color filters are found in between the liquid crystals. These filters determine whether the pixel shows red, green, or blue colors when activated. The filters work by independently controlling the pixel’s red, green, and blue sub-pixels. With this, the LCD screen can reproduce all possible colors found in the color space.

The color filters aren’t active elements, though. It’s the liquid crystal molecules that control the light passing through the filters. The color filters simply determine the color the pixel shows based on how much light is passing through them, as determined by the applied electric voltage and the movement of the liquid crystal molecules.

An LCD cell is made up of two polarizing filters. They enclose the LCD display and color filters. One polarizing filter is located in front of the backlight and is horizontal in orientation. The other one is found just beneath the pixel in front and is vertical in orientation. Polarizing filters are typically made of transparent crystals or glass substrates.

The role of polarizing filters is to control which light patterns can pass through the LCD screen. Without these filters, visual images generated by the LCD panel will have a poor contrast ratio and an inferior quality image.

Now, light emitted by your panel’s backlight source enters the first horizontal polarizing filter. It then passes through the liquid crystals. The polarized light vibrates vertically if the liquid crystals are in a twisted state. Hence, these light waves can then pass through the second vertical polarizing filter. The pixel on the screen turns on and is illuminated properly.

Meanwhile, if the LCD display is arranged in a straightened way, the horizontal light waves that came from the first polarizing filter will be blocked from entering the vertical polarizing filter. The pixel is then turned off and no light illuminates it.

The two polarizing filters need to be vertical and horizontal in orientation, respectively. If the filters are oriented in the same way (ie; both horizontal or both vertical) will block all the light passing through, displaying nothing on the screen.

TFTs are responsible for providing electrical voltage to the LCD display. Each screen pixel has a corresponding transistor, enabling the pixels to easily be controlled in unison through changes in electrical current.

Using TFTs requires less charge and less power to operate the LCD display screen successfully. TFT use also leads to sharper images because each pixel has its own transistor controlling it. The charge given to a certain pixel can be actively maintained even if the screen is refreshed to display another image.

That’s all the basic information you need to know about LCD display screens. Now, you know how an LCD screen works, its possible lifespan, its components, and how it compares to other display technologies.

Armed with this information, you can better appreciate and take care of your LCD display devices. And in case you’re planning to add display devices to your business, the information you’ve learned will help you make educated choices regarding the display technologies you’ll utilize.

Effects of direct sun-light exposure to Touchscreen equipped Liquid Crystal Display monitors and mitigation techniquesIntroductionLiquid crystal, at room temperature, is neither a liquid nor a solid. This state allows liquid crystal to be usable as a light controlling device – i.e.: Liquid Crystal Display (LCD). However, liquid crystal can be adversely affected by temperature changes causing undesirable results. Low temperature environments can cause the crystal to transition more to a solid thus causing the crystal to be less responsive to changes needed to properly control light. In a LCD this can be observed as slow transition time from frame to frame (choppy video or memory of previous image). Higher temperature environments cause the liquid crystal to transition more to a liquid state, again causing the crystal to not perform correctly when controlling light. This effect can be seen in an LCD as a lowering of contrast ratio (darkening) or in extreme heat conditions melting the crystal resulting in a completely dark LCD image. Direct sun-light exposure typically does not cause LCD to internally heat enough to reach the liquid crystal’s melting point. However, touch monitors have a glass overlay and air barrier on top of the LCD. This can cause a greenhouse effect causing the air temperature between the touch sensor and LCD to become much hotter than the ambient temperature.Preventive measures

Films and Coatings: Films designed to block light can be applied to some touchscreen technologies to slow the greenhouse effect. APR, resistive, capacitive, Infra-Red, and Optical all would be candidates for addition of films. The below experiment shows the results of three APR screens with various films and no film applied.

TestingTesting was performed on three Elo ESY15B1-APR products, outdoors in direct sunlight for 4-hours. A white background was displayed and a burn-in was test running to load the processor.

Note: The product with NU405RA film also appeared clearer in normal conditions than the one without a film applied, however the touchscreen was a little more difficult to activate with the shield verses without the shield.

LED LCD backlights are small light strips, or light sources, contained i

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey