tft display components quotation

Improve your product design by adding the DT010ATFT: a small, simple 1” TFT LCD with IPS technology. This mini TFT display is perfect as a status indicator presenting graphic icons or simplified information. The IPS technology included in this display allows your content to be crisp and clear no matter what angle your user is viewing it from. The ST7735S driver IC provides on-chip storage and power system. This IC allows for fewer components and a simple design to easily integrate the DT010ATFT into your next product.

The DT022BTFT uses the same connections as the DT022CTFT, with the exception of the backlight (which has connections shown in the Displaytech datasheet).

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function. Keep the default values for all registers in the ILI9341, unless changed by the example code provided.

Note that the WR pin becomes the D/CX signal in serial mode. CS is used to initiate a data transfer by pulling it low. At the end of the data transfer, pull the CS pin high to complete the transaction. The timing diagram indicates that you can pull the CS pin high in between the command byte and data bytes within a transfer, but it is unlikely needed if the display is the only device on the SPI bus. To keep things simple, we suggest to leave it low during the entire transaction.

The liquid crystal display (LCD) technology has been used in several electronic products over the years. There are more reasons for LCDs to be more endearing than CRTs.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

The display is a critical component in every project, impacting the case, firmware, electrical design, user interface, and even battery life. For these reasons, and because it is the most visible component of your product, it must be approved by the mechanical design team, management and marketing.Before these teams can approve, they need to see it in action. But it can take days or weeks to connect a display to your platform, initialize it and build a code library able to create believable demonstrations. Meanwhile, the whole project is on hold.Our 8051 development kit / demonstration board can solve this problem. Use it to get the display seen, demonstrated and approved for your project.

ER-DBT032-3 is a microcontroller 8051(80C51) demonstration and development kit for ER-TFT032-3.1 product that is 3.2 inch tft lcd display with ILI9341 controller.The kit includes MCU board controlled by STC12LE5A60S2,ISP(In System Programming) with USB port and cable to customize the demonstration that includes your own bitmap images,personalized fonts,symbols,icons and burn sketches,microSD card that is written graphic and text into it,the power adaptor,the adaptor board with various pitch dimension used to connect MCU board and display.Optional for 8080 8-bit,8080 16-bit parallel interface and 3-wire,4-wire serial interface.

For a digital picture frame i would like to use the MSP430 to connect a 20" TFT LCD display (Resolution 1600 X 1200) via SPI. Do you think this is doable? Is there a LCD controller that can support such a high resolution with SPI? In my research so far i have found some projects for small displays such as this:

This graphic display module is a 2.4" diagonal, full color TFT. Suitable for embedded applications, it is low-power, uses a white LED backlight, and has an integrated touch panel which has its connection brought out to the main TAB connector for the display.

It has an on-board controller and 3v single voltage for supply and logic (backlight not included), so you can easily use any modern microcontroller to interface with this display. It uses an 8 or 16 bit parallel interface, specified via connections to the display.

The connector on the CFAF240320K-024T-TS is a flex tail mated with a "COG" (chip on glass) display construction. This style of connector is designed to be soldered directly to corresponding pads on your PCB by using a hot-bar soldering machine. High volume contract manufacturers will be familiar with this type of construction and its assembly methods. There are hot-bar soldering machines made that are designed for prototype, rework or repair work of TAB connections.

We are changing our TFT part numbers to have them better describe the parts being ordered. The change should be complete for all TFT modules shipping within the next six months.

Displays have over time, emerged as one of the best ways to drive user interactions on any device. They make it easy to collect inputs and present information (outputs) to users in a graphical, easy to understand format. This usefulness has led to improvements in their quality, with improved resolution and low power features, but almost little has changed when it comes to the complexity of creating beautiful user interfaces for them. This is why the team at STONE Tech created the STVC035WT-01 intelligent Smart display which we will explore for today’s tutorial.

The STONE STVC035WT-01 display is a 16-bit, 3.5″ display with a 320×480 (RGB) resolution, has a 49.0 x 73.4mm viewing area, and pixel spacing of 0.1905mm×0.0635mm (H×V). The display is a Class A industry Panel with an Industry level 4 wire resistance based touch screen, all layered on an integrated CPU, driver, and flash memory with several communication interfaces to enable it to connect to data sources like microcontrollers. For communication with a microcontroller, the display supports serial communication protocols likeUART/TTL, RS232, and RS485, ensuring it can communicate with any kind of microcontroller or industrial computers. The UART/TTL pin on the Display supports both 3.3v/5v logic level which adds another layer of ease to the use of the display as users need not worry about the need for logic level shifters when building using a microcontroller that operates on either of the voltage level mentioned.

One of the major benefits of using this display is its compatibility with the STONE TOOL GUI Designer which allows the development of User Interfaces in a fast and easy manner.

To demonstrate the capabilities of the display, we will build a heart rate monitor using an Arduino Uno with the MAX30100 pulse oximetry and heart rate sensor. The Arduino will serve as the brain of the project and perform the simple task of obtaining the heart rate and blood oxygen data from the MAX30100, displaying it on the screen.

At the end of this tutorial, you would know how to interface Arduino boards with the STONETech displays, and also how to interface sensors like the MAX30100 with the Arduino.

Our development process for today’s project will follow this outline. We will first create the GUI for the project after which we will proceed to write the firmware to interface the microcontroller with the display.

As mentioned during the introduction, today’s tutorial will focus on creating a heart rate and Oxygen-level monitoring system using the display and to get things started, we create the GUI image (shown below) using Photoshop.

The design is quite simple, we illustrate label elements to hold the date, the project title, and the values from the microcontroller. The values from the microcontroller include; the status of the connection between the microcontroller and the display, the heart rate, and the oxygen levels.

1. With the software downloaded on your computer, launch it and go to File>New Project. This will launch the “New Project dialog box ” where you will be expected to fill in the details of your display, set the storage path, and the name of your project. Since we will use the STVC035WT-01 display which has a resolution of 320*480 and a default flash space size of 128Mbyte (expandable to 1024MByte), I have entered its details as shown in the image below. If you are using any of the other StoneTech displays, you will need to enter the details of that display instead.

4. Next, we add fonts to the project’s assets to determine how texts appear on the display. Right-click the “Font” file, and select the appropriate font to add to the project. For this tutorial, we will use the ASCII 24 by 48 font. With that done we are now ready to begin adding the GUI elements.

5. We will only use the “Text Display” GUI element since the display is only meant to display data from the MAX30100. The text display elements are capable of holding texts that can be changed programmatically by updating the data stored in their memory addresses. Add text displays on the lines as highlighted in the image below. Also, create a text display for the day-time section at the top of the display image to help users note the date/time each reading was observed.

6. Next, we set the properties of the text displays especially their memory addresses. The properties of each GUI element will be available on the right-hand side of your PC screen after clicking on the element. Note the memory address down as it will play an important role later.

7. With all of these done, we compile the GUI and upload it to the screen. To do this, click on button 1 in the image below to Compile the GUI design and click on button 2 to upload the GUI to your display.

Uploading the GUI display requires you either connect the display directly to your computer or you put the GUI on a flash drive and plug the flash drive into the USB port of the display. Because of the little complexity associated with the second option, we will be going with it.

Plug the USB flash drive into the computer then click the “Download to u-disk” button on the STONE GUI TOOL.With the “download to u-disk” process complete, pull out the USB flash disk, insert it into the USB interface of the display module and wait for the completion of the upgrade. When the upgrade is completed, there will be a prompt sound.

The model of the STONE display being used for this tutorial communicates via RS232, as such, to be able to interface the display with the Arduino, we have to connect it through a MAX3232 chip. This extra requirement can be avoided by using one of the STONE displays with a TTL interface.

Due to the simplicity embedded in the design of STONETECH displays, the microcontroller’s interaction with any of the GUI components is usually via the “memory address” of each component. for instance, to send a message to the display from the microcontroller (the Arduino in this case), the message has to be published to the memory address of the GUI Component (in this case, the text-display component). The same holds for GUI Components that are meant to send data to the microcontroller, as the microcontroller has to poll their memory address to obtain information from them. As a result of these, we need to obtain the memory address of all the GUI components before proceeding. For each GUI component, the memory address is usually listed among the properties of the component, under the property toolbar, at the right-hand side of the STONE TOOL interface.

With this obtained, we can now proceed to write the code for the project. One of the good things about using the STONETech displays is the fact that you don’t need a library to write code for them because of their simplicity, but since we will use serial communication, we will use the software serial library to avoid having to use the hardware serial

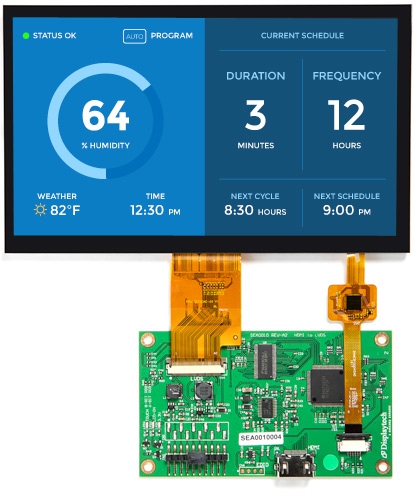

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

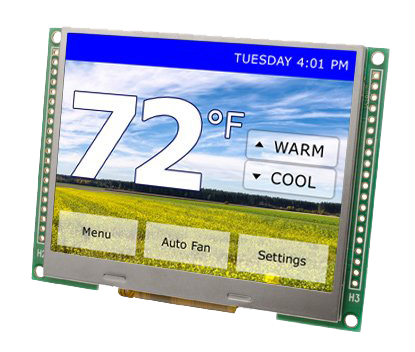

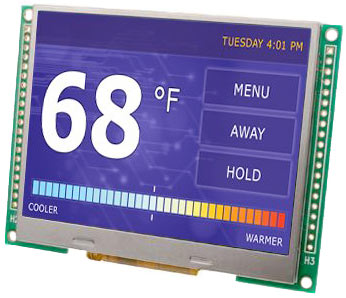

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

Eurocoin Components have been managing customers’ display requirements for over 40 years. We have a trusted history in guiding you to the best solution for your project. The Eurocoin display range has been specifically developed to provide the most up to date technology from the world’s best display manufacturers so you get the performance, reliability and longevity of supply you need for your requirements.

Thanks to DLC Display, Digimax is able to offer a wide range of display and digital signage accessories such as LVDS cables, connectors and touch controllers. Thanks to their advanced technology, the TFT DLC displays are able to operate at both low and high temperatures, so they are also suitable for sensitive applications such as in the military, medical and automotive sectors.

The SCD2365-Y is a 23.6 inch color TFT-LCD display with high brightness 1000 nits, special aspect ratio 1:1 and wide resolution 1920 x 1920. It is Litemax’s Circlepixel series product which designed for high brightness with power efficiency LED backlight. It provides LCD panel with specific aspect ratios and sunlight readable for digital signage, public transportation, exhibition hall, department store, and vending machine.

AZ Display’s new Monochrome TFT Module Solution ATM2412B (8 Bit Parallel) and ATM2412BS (SPI interface) series offer companies previously using a monochrome LCD (it fits most 240 x 128 pixel Monochrome Graphic LCD Modules) a way to update to the bold look of a TFT module without reprogramming the complete software and changing major components of the assembly.

ATM2412B and ATM2412BS interface like a traditional monochrome Graphic LCD Module, but perform like a TFT module (mono color). Content is brought to the display using the RA6963 controller.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey