creating a pcb for lcd touch screen brands

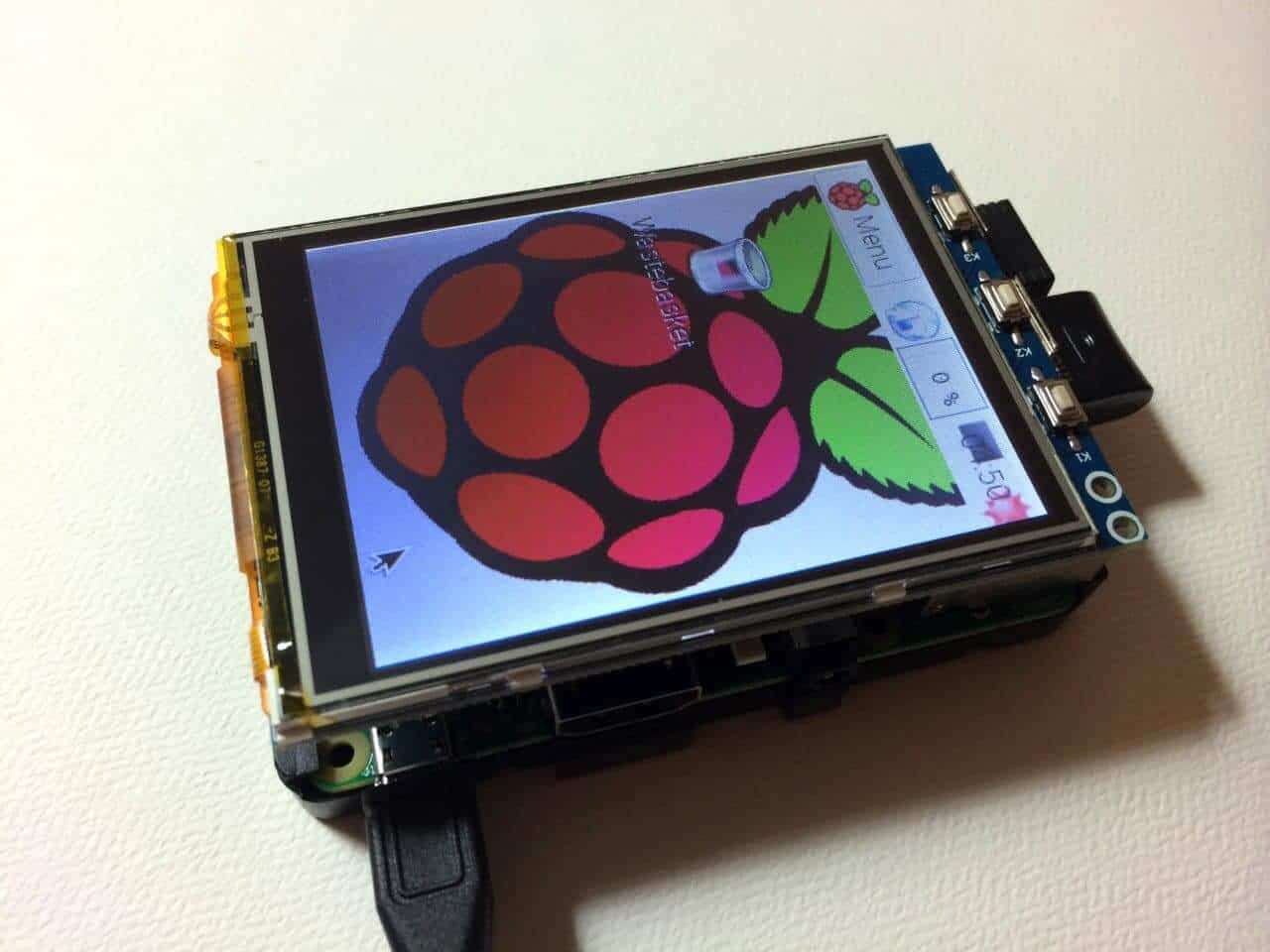

We worked with the client to determine what they wanted to have the touch-screen display do and what it should look like. We then picked an appropriate touch-screen based on the size, resolution, and availability.

As the electronics were being designed, we also started work on the software. This is where the software commands to control the display as well as the client"s graphical interface were created.

In addition to the previous steps, we also needed to create a mounting system for the display. Since the display we chose had no mounting holes of its own, we had to design in Solidworks a cradle that both held the display and the driver board to come. This cradle would then attach to the project case. Because we have two 3D printers in-house, we were able to quickly iterate plastic prototypes until we had the ideal cradle.

Once the cradle was designed, we then worked out what hardware was needed to mount everything together. Also, we needed to create a rubber gasket based on the design parameters of the cradle and the display. This was all done in Solidworks by creating a virtual assembly of the entire project.

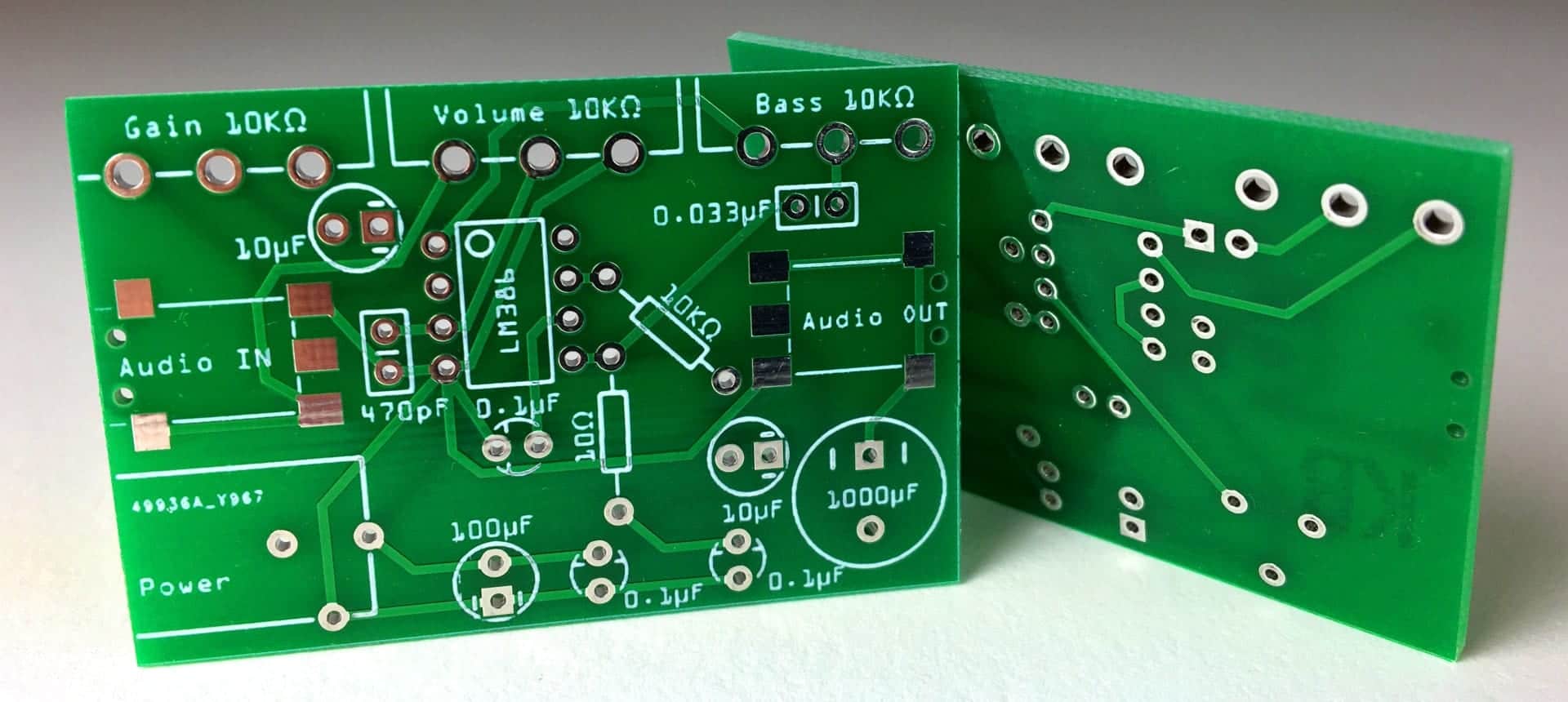

The cradle design dictated the size of the circuit board driver for the display. With that information now determined, the circuit board was designed.

And lastly, the display was built in-house using our surface-mount machinery and skilled technicians. Once assembled, the driver board was programmed with the custom software and tested.

A PCB is sort of like a layer cake or lasagna- there are alternating layers of different materials which are laminated together with heat and adhesive such that the result is a single object.

The base material, or substrate, is usually fiberglass. Historically, the most common designator for this fiberglass is "FR4". This solid core gives the PCB its rigidity and thickness. There are also flexible PCBs built on flexible high-temperature plastic (Kapton or the equivalent).

You will find many different thickness PCBs; the most common thickness for SparkFun products is 1.6mm (0.063"). Some of our products- LilyPad boards and Arudino Pro Micro boards- use a 0.8mm thick board.

Cheaper PCBs and perf boards (shown above) will be made with other materials such as epoxies or phenolics which lack the durability of FR4 but are much less expensive. You will know you are working with this type of PCB when you solder to it - they have a very distictive bad smell. These types of substrates are also typically found in low-end consumer electronics. Phenolics have a low thermal decomposition temperature which causes them to delaminate, smoke and char when the soldering iron is held too long on the board.

The next layer is a thin copper foil, which is laminated to the board with heat and adhesive. On common, double sided PCBs, copper is applied to both sides of the substrate. In lower cost electronic gadgets the PCB may have copper on only one side. When we refer to a double sided or 2-layer board we are referring to the number of copper layers (2) in our lasagna. This can be as few as 1 layer or as many as 16 layers or more.

The copper thickness can vary and is specified by weight, in ounces per square foot. The vast majority of PCBs have 1 ounce of copper per square foot but some PCBs that handle very high power may use 2 or 3 ounce copper. Each ounce per square translates to about 35 micrometers or 1.4 thousandths of an inch of thickness of copper.

The layer on top of the copper foil is called the soldermask layer. This layer gives the PCB its green (or, at SparkFun, red) color. It is overlaid onto the copper layer to insulate the copper traces from accidental contact with other metal, solder, or conductive bits. This layer helps the user to solder to the correct places and prevent solder jumpers.

In the example below, the green solder mask is applied to the majority of the PCB, covering up the small traces but leaving the silver rings and SMD pads exposed so they can be soldered to.

Soldermask is most commonly green in color but nearly any color is possible. We use red for almost all the SparkFun boards, white for the IOIO board, and purple for the LilyPad boards.

The white silkscreen layer is applied on top of the soldermask layer. The silkscreen adds letters, numbers, and symbols to the PCB that allow for easier assembly and indicators for humans to better understand the board. We often use silkscreen labels to indicate what the function of each pin or LED.

Silkscreen is most commonly white but any ink color can be used. Black, gray, red, and even yellow silkscreen colors are widely available; it is, however, uncommon to see more than one color on a single board.

Breadboards are great for prototyping circuits, but they aren’t so good for actually using the thing you’re building. At some point, you’ll probably want to make a project more permanent. The best way to do that is to put it on a PCB.

In this tutorial, I’ll walk you through the process of designing a PCB layout and getting it printed by a custom PCB manufacturer. The performance of your circuit will depend greatly on how it’s laid out on the PCB, so I’ll give you lots of tips on how to optimize your design.

You can always etch PCBs at home with a process that’s similar to developing prints from photographic film. But that method is messy and it uses a lot of chemicals. It’s much easier (and cheaper) to get your PCB made by a professional manufacturer. To demonstrate the process, I’ll use an online service called EasyEDA to design a PCB layout for an LM386 audio amplifier, then I’ll have it manufactured and show you the results. Their free online design software is easy to use and the rates are very affordable.

Before you start designing your PCB, it’s a good idea to make a schematic of your circuit. The schematic will serve as a blueprint for laying out the traces and placing the components on the PCB. Plus, the PCB editing software can import all of the components, footprints, and wires into the PCB file, which will make the design process easier (more on this later).

It’s best to place all of your schematic symbols on the canvas before drawing any wires. In EasyEDA, schematic symbols are located in “Libraries”. The default EasyEDA library has most of the common symbols, but there are also “User Generated Libraries” with lots of other symbols:

Each schematic symbol you use needs to have a PCB footprint associated with it. The PCB footprint will define the component’s physical dimensions and placement of the copper pads or through holes. Now is a good time to decide which components you’ll be using.

The schematic symbols in the EasyEDA library already have footprints associated with them, but they can be changed if your’re using a different size or style:

To change the footprint associated with a schematic symbol, search in the “User Generated” libraries for a footprint that matches the component you’re using. Once you find it, click on the heart icon to “Favorite” it:

Now click on the symbol in the schematic editor, and paste the name of the new footprint into the “package” field in the right sidebar menu (watch the video below for a demonstration):

Once all of your symbols are placed on the schematic and you’ve assigned footprints to each symbol, it’s time to start drawing the wires. Rather than explain the details of all that in this article, I’ve made a video so you can watch me draw the schematic for my LM386 audio amplifier:

After all the wiring is done, it’s a good idea to label the symbols. The labels will be transferred over to the PCB layout and eventually be printed on the finished PCB. Each symbol has a name (R1, R2, C1, C2 etc.) and value (10 μF, 100 Ω, etc.) that can be edited by clicking on the label.

The next step is to import the schematic into the PCB editor, but before we do that, let’s talk about some things to keep in mind when designing your PCB.

Identify what each part of your circuit does, and divide the circuit into sections according to function. For example, my LM386 audio amplifier circuit has four main sections: a power supply, an audio input, the LM386, and an audio output. It might help to draw some diagrams at this point to help you visualize the design before you start laying it out.

Keep the components in each section grouped together in the same area of the PCB to keep the conductive traces short. Long traces can pick up electromagnetic radiation from other sources, which can cause interference and noise.

The different sections of your circuit should be arranged so the path of electrical current is as linear as possible. The signals in your circuit should flow in a direct path from one section to another, which will keep the traces shorter.

Each section of the circuit should be supplied power with separate traces of equal length. This is called a star configuration, and it ensures that each section gets an equal supply voltage. If sections are connected in a daisy-chain configuration, the current drawn from sections closer to the supply will create a voltage drop and result in lower voltages at sections further from the supply:

It’s not uncommon to see round, triangular, or other interesting PCB shapes. Most PCBs are designed to be as small as possible, but that’s not necessary if your application doesn’t require it.

If you plan on putting the PCB into an enclosure, the dimensions may be limited by the size of the housing. In that case, you’ll need to know the enclosure’s dimensions before laying out the PCB so that everything fits inside.

The components you use will also have an effect on the size of the finished PCB. For instance, surface mounted components are small and have a low profile, so you’ll be able to make the PCB smaller. Through hole components are larger, but they’re often easier to find and easier to solder.

The location of components like power connections, potentiometers, LEDs, and audio jacks in your finished project will affect how your PCB is laid out. Do you need an LED near a power switch to indicate that it’s on? Or do you need to put a volume potentiometer next to a gain potentiometer? For the best user experience you might have to make some compromises and design the rest of your PCB around the locations of these components.

Larger circuits can be difficult to design on a single layer PCB because it’s hard to route the traces without intersecting one another. You might need to use two copper layers, with traces routed on both sides of the PCB.

The traces on one layer can be connected to the other layer with a via. A via is a copper plated hole in the PCB that electrically connects the top layer to the bottom layer. You can also connect top and bottom traces at a component’s through hole:

Some double layer PCBs have a ground layer, where the entire bottom layer is covered with a copper plane connected to ground. The positive traces are routed on top and connections to ground are made with through holes or vias. Ground layers are good for circuits that are prone to interference, because the large area of copper acts as a shield against electromagnetic fields. They also help dissipate the heat generated by the components.

Most PCB manufacturers will let you order different layer thicknesses. Copper weight is the term manufacturers use to describe the layer thickness, and it’s measured in ounces. The thickness of a layer will affect how much current can flow through the circuit without damaging the traces. Trace width is another factor that affects how much current can safely flow through the circuit (discussed below). To determine safe values for width and thickness, you need to know the amperage that will flow through the trace in question. Use an online trace width calculator to determine the ideal trace thickness and width for a given amperage.

If you look at a professionally designed PCB, you’ll probably notice that most of the copper traces bend at 45° angles. One reason for this is that 45° angles shorten the electrical path between components compared to 90° angles. Another reason is that high speed logic signals can get reflected off the back of the angle, causing interference:

If your project uses digital logic or high speed communication protocols above 200 MHz, you should probably avoid 90° angles and vias in your traces. For slower speed circuits, 90° traces won’t have much of an effect on the performance of your circuit.

The proximity of traces to components and adjacent traces will also determine how wide your traces can be. If you’re designing a small PCB with lots of traces and components, you might need to make the traces narrow for everything to fit.

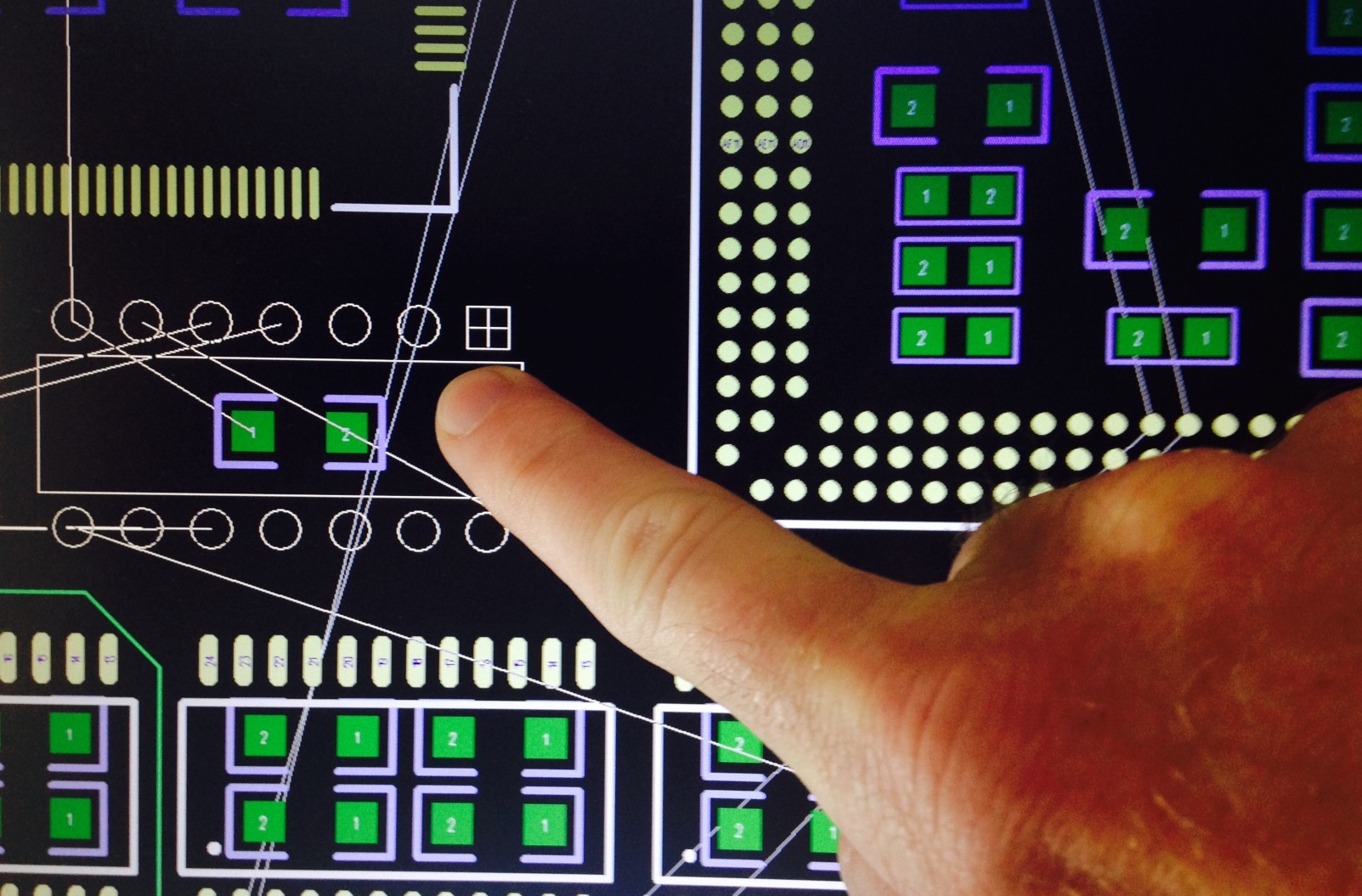

Notice the thin blue lines connecting the components. These are called ratsnest lines. Ratsnest lines are virtual wires that represent the connections between components. They show you where you need to route the traces according to the wiring connections you created in your schematic:

Now you can start arranging the components, keeping in mind the design tips mentioned above. You might want to do some research to find out if there are any special design requirements for your circuit. Some circuits perform better with certain components in specific locations. For example, in an LM386 amplifier circuit the power supply decoupling capacitors need to be placed close to the chip to reduce noise.

After you’ve arranged all of the components, it’s time to start drawing the traces. Use the ratsnest wires as a rough guide for routing each trace. However, they won’t always show you the best way to route the traces, so it’s a good idea to refer back to your schematic to verify the correct connections.

Traces can also be routed automatically using the software’s auto-router. For complicated circuits, it’s generally better to route traces manually, but try the auto-router on simpler designs and see what it comes up with. You can always adjust individual traces later.

The last thing to do before placing the order is to run a design rule check. A design rule check will tell you if any components overlap or if traces are routed too close together. The design rule check can be found by clicking the “Design Manager” button in the right side window:

Items that fail the design rule check will be listed below the “DRC Errors” folder. If you click on one of the errors, the problem trace or component will be highlighted in the PCB view:

You can specify your own settings for the design rule check by clicking the drop down menu in the upper right hand corner and going to Miscellaneous > Design Rule Settings:

At this point it’s a good idea to double check your PCB layout against your schematic to make sure that everything is connected properly. If you’re satisfied with the result, the next step is to order the PCB. EasyEDA makes this part really easy…

You can select the number of PCBs you want to order, the number of copper layers, the PCB thickness, copper weight, and even the PCB color. After you’ve made your selections, click “Save to Cart” and you’ll be taken to a page where you can enter your shipping address and billing information.

Gerber files are a set of image files that contain the patterns used to manufacture your PCB. All of the files are compressed into a single .zip file. There is a separate file for the copper traces, silk screen, and locations of drill holes and vias:

I ordered 15 PCBs for my LM386 audio amplifier circuit and the cost came out to about $15 USD. Manufacturing and shipping took about two weeks. The PCBs were well made, and I couldn’t find any defects. After I soldered on the components and tested the amplifier, it worked great. You can clone my LM386 amplifier schematic and PCB here if you want.

Making your own custom PCB is a lot of fun, and the results can be very rewarding. Hopefully this article will help you get your prototype circuit onto a PCB. Let us know in the comments if you have any questions, and let us know what PCB design projects you have planned. If you liked this tutorial and want to get more like it, be sure to subscribe!

There are mainly two types of module PCB in our company: Internet of things (IoT)/ communication module PCB and vehicle-to-everything(V2X) module PCB.

As the most basic perception layer of the Internet, the IoT/communication module PCB has continued to grow rapidly. Both long-term evolution vehicle-to-everything (LTE-V2X) and new radio vehicle-to-everything (NR-V2X) are important parts of self-driving, the development of the corresponding module board market is increasingly prominent.

Special design features: max 3-time compression design, back drilling(including blind hole back drilling) & POFV, the impedance control tolerance≤ 5%, HDI system board, copper inlay, etc.

Antenna PCB is widely used in the telecom field to receive and transmit signals. With the development of the 5G network, antenna PCB is perfect for expanding wireless networks and enhancing the broadcasting or receiving stations.

Where there is fiber-optic communication, there is a demand for electro-optical switching modules. The optical module is the key component to realize electro-optical-electro transmission of the signal in fiber-optic communication. We mainly manufacture 100G & 400G high-end high-speed optical modules.

As the mounting density of SMT increases, the effective heat dissipation area of electronic equipment decreases. Especially when the PCB temperature is greater than 70 , the reliability of the PCB decreases by 5% for every 1 increase. There are three ways of heat transfer: heat conduction, convection and radiation, and all of which are included in the thermal PCB.

A PCB with a finished copper layer greater than 2oz is defined as a heavy copper PCB. Heavy copper PCB can achieve efficient and reliable power distribution. As a special type of PCB, heavy copper PCB is suitable for high-current capacity products. The significant benefits of heavy copper PCB are that it reduces the chance of circuit failure and enhances the heat transfer from the layer to an external source.

The auto anti-collision radar is the most important part of the developing trends of future automotive technology. MMW radar has advantages in auto-collision avoidance technology.

All touch screen PCB is available in the wide range of sizes and capacities. For those in large commercialities, the touchscreen PCB is available in different sizes and won ’ t leave any customer interested in the matter of they are looking for the new touch in PCB or for other industrial. touchscreen PCb is available in a wide range of colors, and functionality. No matter the touch of PCB is for use, businesses in large commercialities and such places are need to have more options.

The touchscreen PCb assembly is one of the most popular types. It is scratch-resistant and easy to install in a variety of settings, and for the best performance, Alibaba.com has a wide range of touchscreen PCb assembly and types, touchscreen PCb assembly is also available. scratch-resistant and easy to repair without the degradable quality of the components, being one of the most popular types.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

These products are all widely used in various industries such as in medicine, home security, automotive, energy field solar charging, and domestic equipment use.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

The company started in 1983 as a corporate spin-off from the American oscilloscope company Tektronix. In 2015, Planar Systems became a subsidiary of the Chinese manufacturer Leyard Optoelectronics.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

ST cooperates with Riverdi because we believe that such partnership brings value to our joint customers. On top of this, we also discovered that we shared some business visions about how to make it easier and faster to go from the initial stages of designing a product embedding a graphical user interface to a production ready product. The conclusion was that combining the STM32 High performance microcontrollers, with the free STM32 graphics toolchain and Riverdi displays + PCB and then merge all of this into a board support package ready to run TouchGFX, would be a compelling offering.

Designing and developing a product with an embedded user interface (GUI), can be complex, as it involves many building block and disciplines, which all requires expert knowledge. Riverdi offer is covering a lot of them, allowing the customer to focus on the most important part of the development, the GUI Application itself. And remember that this is the face of your product. Choosing such solution, the customer does not need to worry about sourcing components like the display, microcontrollers, memory, etc. or even writing low-level drivers, development the board support package or porting TouchGFX. Its all ready done. What makes cooperation with Riverdi unique is that Riverdi has been able to drive a 1280*800 display resolution in high colors, with a STM32H7 microcontroller and a TouchGFX application showing a smart home UI. This shows that Riverdi is well aware of how to exploit all the capabilities of the STM32 Graphics offering combining hardware and software in a unique solution. From the first business meetings, it was clear that we shared visions of the market for embedded GUIs. And Riverdi proved that they can go from an idea and concept to actual working hardware, very fast.

In the pursuit of quality, our company"s products have won unanimous praise from customers at home and abroad, and is in a leading position in the industry of 17 Touch Screen Open Frame Monitor, Mall Advertising Lcd Display, Android Pos Terminal With Printer. We will follow the tenet of "owner first, abide by the contract, high quality service", and the enterprise spirit of "unity and cooperation, rigorous and realistic, high quality and high efficiency, innovation" and meticulously create excellent projects to provide satisfaction to new and old customers service. We try our best to build a modern enterprise with unique and quality products.

Since establishment, we have become the leader of Bluetooth Android PCB Board for Car LCD Display Media Player Tablet industry in China through constant pursuit of perfection, professional management team, most competitive price and excellent service. Customers" benefit and satisfaction are always our biggest goal. The products has a good reputation with competitive price, unique creation, leading the industry trends.

By continuing to use AliExpress you accept our use of cookies (view more on our Privacy Policy). You can adjust your Cookie Preferences at the bottom of this page.

First: There are several types of cheap touchscreens: resistive and capacitive (intro from 3m). And under touchscreen I mean touch panels (digitizers) - the thin multilayer panels which feels touches, but don"t display anything. Touchscreens can be combined with LCD/OLED screens to get display with touch capability. Resistive touchscreens are sensitive to pressure, and you can use any stick to press them, they also had problems with multitouch (sensing several touches at same time). Capacitive touchscreens are often used now in smartphones (since iPhone), and they sense capacitance of human body, working only with fingers or special conductive styli.

Resistive touchscreens usually have 4-wire or 5-wire analog interface (short description) to touchscreen controller. If you want to plug this directly into FPGA board, you need ADC (analog-to-digital converter, sometimes up to 10-12 bit precision) to measure coordinates of touch point.

Capacitive touchscreens usually have more complex interface with complex medium-frequency signals (25-200 kHz). Simplest panels still have 5 wires, but Cypress"s "Touchscreens 101" lists two more advanced panels with 11 and 20 pins. It will be very hard to implement (and calibrate) your own touch controller in FPGA even with good ADCs and DACs.

So, our second step is the touchscreen controller ASIC: the device between microcontroller or FPGA and the touchscreen. Controller will do all needed magic to detect touches and translate information about them into some digital protocol, like COM (RS-232) or USB in ancient controllers for PC, or simple SPI and I2C for microcontrollers and FPGAs (you should know how to implement SPI/I2C for FPGA; the fpga4fun site may help you: spi, i2c). Many small touchscreens sold now may include some controller, integrated into their PCB or flex wire.

Third step: if you want to make prototype with LCD display and touchscreen, especially with small size LCD (up to 6″), the touch panel may be already integrated into display. And because virtually all LCD have the controller to output some information to display (again, fpga4fun has some introduction into using LCD with FPGAs), they probably will have integrated touchscreen controller too.

Now we can start speak about your case: "what I could buy". If you already have FPGA board, you can search for some LCD+touchscreen for some popular hardware prototyping platform, e.g. for ardoino or raspberry pi. For example, adafruit shop has both separate touch panels, lines and buttons even without controller: http://www.adafruit.com/category/60. Also they have several LCD+touch like 2.8" TFT with STMPE610 touch controller (both SPI and I2C, selectable via pin). There are several on sparkfun.com too. Make sure that you understand how to connect the LCD to FPGA, both electrical and protocol requirements. Check is there touch controller, or you need to implement it in the FPGA with ADC (and there should be ADC on your FPGA board).

If you don"t have FPGA board or if you have no any FPGA experience, it can be better (and costly) to find FPGA kit with optional LCD+touch, but not from chinese vendors. There are lot of chinese kits in cheap section of ebay"s search "fpga touch", but they may have not so good tutorials and demo projects as right vendors. There are 7" kit from Terasic (2000 USD, VEEK-MT-C5SoC), or 7" 250USD LCD+touchpanel module for 1800 USD DE3 or 600USD DE2 FPGA boards. And for Digilent, there is 150 USD VmodTFT 4.3" TFT+touch (manual) compatible with Digilent boards with VHDCI connector, like 300 USD Nexys 3 board, 450 USD Atlys board, or 1100 USD Genesys superboard.

Projected capacitive (PCAP) touch screens are the latest iteration of a long history of touch sensor technologies dating back decades. The usage of PCAP touch screens has risen in conjunction with the proliferation of consumer electronics, medical device advancements and more sophisticated automotive applications, creating breakthrough specializations and use cases.

A PCAP screen’s conductive grid picks up changes in capacitance, which is the mechanism behind registering a touch. Paired with different bonding techniques, surface treatments and touch controller tunings, the ability to customize PCAP touch screens has led to endless permutations of highly successful touch display products.

Resistive touch sensors register a touch when force is applied to the screen. When pressed against the screen, a finger creates an indent on a top film, which makes a connection with electrodes at the bottom of the stack. This change in resistance is how touch is recognized.

PCAP screens use two layers of electrodes (X and Y) that form a capacitive electromagnetic field around them. When a finger, stylus or other conductive object hovers or touches the screen, it results in an electric charge that enables the processing system to identify, register and respond to the signal. A finger, for example, penetrates the electromagnetic field, creating a change in capacitance.

PCAP sensors have almost completely replaced resistive touch sensors over the years due to their numerous advantages. They can support multi-touch, gestures and 3D proximity sensing, and provide superior reliability and durability. This makes them ideal for automotive, consumer, medical, and industrial applications that require more functionality than buttons and single points of contact can offer.

PCAP technology is highly customizable and can be designed to individual customer needs. Engineers can tune PCAP touch sensors for application-specific sensitivity and accuracy, using custom touch controller algorithms. These capabilities make PCAP touch sensors an ideal solution for applications with rigorous requirements.

New Vision Display has decades of experience engineering high performance standards into integrated display products. Backed by its renowned PRECI-Touch® sensors, NVD is a leading designer of PCAP touch screen solutions for some of the world’s largest original equipment manufacturers (OEMs).

Touch sensors can be designed using various substrates and stack-ups based on the customer’s environment needs. Some of the stack-ups NVD can support include:

SITO touch sensor stacks have a single ITO layer with the X-Y pattern, usually a diamond pattern, on the top surface of the substrate (glass or film). The patterning has cross bridges, made of ITO or metal, that allow the X and Y electrodes to cross. They can be further customized with a glass lens with optional back printing, optically bonded to the sensor. This design eliminates the second layer of ITO present in DITO touch panel stacks and reduces the channel-routing margin outside the active area.

This is one of the most effective PCAP stack-ups, as it offers a high degree of accuracy as well as more control of charge time and sensitivity. SITO touch panels are the preferred solution for instrument clusters in automobiles, yacht navigation controls, and other applications requiring high sensitivity and control. They are also more accurate for rugged environments, water and salt-water immunity, and use with glove or stylus.

DITO touch panel stacks have ITO layers on both sides of a glass or film substrate, with Y-patterning on the top sensing surface, and X patterning is on the bottom surface. DITO sensors are customizable with a glass lens with optional back printing, optically bonded to the sensor. They are a low-cost solution, which provides high resolution and accuracy.

OGS stack-ups are newer to the market. The cover lens and the entirety of the touch stack-up itself are contained within one piece of glass, with all patterning completed on the back surface of the cover lens.

OGS is not often recommended for many industries, since the ruggedness of the stack is concentrated on the one and only piece of glass, increasing the chance of breakage. Additional layers, while adding mass to a stack-up, also help to make those options more durable. However, the slimmer and lighter construction can be attractive to customers and useful in certain (small-sized) applications. Also, the manufacturing costs are lower because of the reduced processing and fewer materials required.

A 2-layer film touch sensor stack has X and Y electrodes patterned on two different film layers, bonded together using OCA. The Y electrodes are patterned on the top film layer, and the X electrodes are patterned on the bottom film layer. This stack is customizable with additional protective cover lens optically bonded to the sensor, with optional back printing.

This option is often used in situations where cost is a critical factor, as film-based stack-ups are less expensive than those incorporating glass. It’s also useful in curved touch applications. However, applications where users might be expected to wear polarized sunglasses should be avoided, due to the birefringence characteristics of PET films.

A 2-layer glass touch panel stack has X and Y electrodes patterned on two different glass layers, bonded together using OCA. The Y electrodes are patterned on the top glass layer, and the X electrodes are patterned on the bottom glass layer. This stack is customizable with additional protective cover lens optically bonded to the sensor, with optional back printing. This was the initial structure used for PCAP stack-ups.

The high number of processes and materials involved in manufacturing this type of touch screen increases the rate of failure compared to other options, introduces more opportunities for external cosmetic defects, and increases the thickness and weight of the touch panel. Manufacturers have largely moved on to thinner and more efficient touch screen structures with better reliability and fewer manufacturing processes.

The most evolved ITO pattern is diamond-shaped pattern. Whether the pattern is two-layered or co-planar with cross bridges is dependent upon the stack-up used.2-layer patterns:DITO stack-ups have X and Y patterns on opposite sides of the same glass or film substrate

One final point of differentiation among PCAP touch panel designs is how and where the chip is mounted. Two methods can be used:COF (Chip-on-flex:) The controller and supporting electronics are on a flexible substrate. This is the primary chip integration method used for touch sensors due to it being slim and flexible, but may not be possible for sensors larger than 15 inches.

Bonding of touch sensor and display:Optical bonding: Using an optically clear adhesive (OCA) or liquid glue to bond the touch and display components together, called optical bonding, is the optimal solution for many applications. In an optical bonding stack, air gaps are eliminated, creating a moisture and dust barrier and near-perfect optical transmission with low reflectance. This process also offers greater resistance to impacts, meaning greater overall durability.

Air gap bonding: Another option for touch and display bonding is to use a double-sided tape around the perimeter of the display. Though lower in cost than optical bonding methods, this solution has lower optical performance, higher chance of dust and moisture penetration, and reduced shock and vibration resistance. There are ways to reduce system reflectance within an air bonded module by using anti-reflective (AR) films or coatings on the air gap surfaces and/or applying display polarizers.

Optical bonding of touch sensor and cover lens:Optical bonding:Touch sensor and cover lens components are always bonded together using an OCA film or liquid glue. Currently, air gap is not used to bond the two layers together because the air gap can cause uneven touch sensitivity on the surface. Optical bonding also provides near-perfect optical transmittance with reduced reflection.

NVD is one of the most trusted PCAP touch sensor manufacturers with decades of experience serving major OEMs across all markets. Our PRECI-Touch® solutions are known for their performance in some of the most challenging applications and can be customized to your unique application requirements. We also provide full integration with custom LCD/OLED displays, cover lenses, and peripherals.

For more information on our PCAP technology capabilities, or to discuss your project with our experienced sales and engineering staff, contact New Vision Display today.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

Many don’t realize that the electronics, devices, and items they own are built upon several internal components which work collaboratively to provide the necessary functionality and features they use. A mobile phone, for example, is more than just the casing, buttons, and display you see on the outside. Inside the device are several pieces that house and connect the necessary components. One of those core pieces is called a printed circuit board or PCB for short.

Printed circuit boards are the foundation of most electronics. By the end of 2018 alone, the global PCB product sales value is expected to reach 82 billion U.S. dollars. That should give you some idea of just how often PCBs are used in manufacturing.

Without them, many devices would simply cease to function entirely. In the event of a major failure or malfunction, it can cause some pretty serious issues. Circuit boards aren’t invulnerable either. Over time, they experience a great deal of wear and tear that can deteriorate their performance and functionality. Things such as the weather, humidity, age, and even elevation can affect the condition of a board.

Luckily, it’s possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

Of course, before any board can be repaired or reconditioned, engineers need to discern and understand why it failed in the first place. You can’t very well fix a problem if you don’t know what went wrong, can you?

It’s highly beneficial to know and identify some of the most common problems associated with PCBs, so that if and when a device does fail, you at least know what went wrong. We’re going to take a look at some of the most common printed circuit board problems, and explore ways in which they can be solved.

A printed circuit board or PCB is a core component of nearly all electronic devices. Everything except the simplest of electronics uses a board of some kind to connect and mechanically sync all elements of the product. A coffee maker, for instance, might have a small PCB inside to connect the electronic control system, heater element and display.

In the early days—way before design software was a thing—printed circuit boards were planned using Mylar sheets through manual hands-on development, and were often four times bigger than the circuit board itself. The designers would lay pin pads, traces and components out in a proposed design, which was used sort-of like a storyboard to test and explain circuits. Today, it’s all done via design and manufacturing software.

PCBs are mechanically necessary to support and connect all components within the device, which are synced using conductive tracks—this allows electricity to flow freely through the board and from component to component.

PCB components are soldered to the board, which electrically and mechanically fastens them to the overall circuit. Those “components” include things like the battery, resistors, LEDs, transistors, capacitors and more.

Boards are often produced in layers, which include various levels of conductive and non-conductive sheets. They can be one-sided with a single copper layer, two-sided with a double copper layer on both sides of a substrate layer, or multi-layer with differing layers of copper and substrate. It is worth mentioning that multi-layer boards provide a variety of benefits like an increased component density, however they are much harder to analyze, repair and modify.

It’s important to understand that circuit board repair parts and practices often consist of the same materials and components used to build the hardware in the first place. There are very few substitutes or alternatives, especially when talking about reliable and conductive materials. This highlights the need to find a proper, professional repair team with the right assets and connections.

PCBs are used in nearly every electronic device you may find, from smartphones and computers to televisions and vacuums. If a device requires an electrical connection to be passed through it to operate, it’s a safe bet that there’s some kind of circuit board inside, sometimes incredibly small and thin.

As technology has advanced over the years, so has the design and development of circuit boards allowing for smaller, more complex components, and thinner, less bulky boards. This makes the circuit board repair process particularly tricky because there are so many different types of varying sizes and design. You can’t go to just anyone to have a printed circuit board repair, modified or re-manufactured. It is crucial that you go to an authorized party who has both the experience and necessary gear to make it happen.

As with anything that deteriorates over time and extended use, printed circuit boards can run into a variety of problems. From trace damage which affects the conductivity of the board and circuit to component failure which sees capacitors or diodes dying, there are many points of contention on a circuit board.

It helps to identify and understand some of the most common PCB problems, that way you can deal with the problem in a relevant manner. This may also help people—who don’t have direct experience with circuit boards—keep them in better shape.

This is the more obvious choice when it pertains to the damage of a circuit board. In fact, the most common causes of PCB failures all stem from physical damage to a device or its internals. This can be just about anything pertaining to physical pressure or shock. The device in question might have been dropped from a great distance. Perhaps it was smacked or hit forcibly by another object? There’s also the possibility that the device was disassembled for whatever reason, and damage happened directly to the board.

So long as complete failure is not the scenario—the board fell upon the ground and shattered or broke completely—physical damage can be remedied through the remanufacturing process. Generally, this involves melting down the damage sections of the board or repairing through disassembly and reassembly. Due to the nature of most physical damage, it’s highly unlikely that this can be done as a DIY project by those without experience with printed circuit board repair. The repair of physical damage should only be done by a trained and experienced professional. In most cases, it calls for remodeling of the board, resoldering of components, and the reballing of conductive traces.

Aside from physical damage, faulty components are the other most common cause of printed circuit board problems. In fact, if and when there is no physical damage but a device has failed to operate or power on, you can almost guarantee it has to do with one of the components connected to the board.

The component itself could be anything from a capacitor to a diode or microprocessor. If the component is the issue and has died or failed to work, it may need to be replaced entirely. However, it’s not always the actual component that’s the problem. Sometimes due to aging, overheating and voltage sags the trace circuit may have deteriorated to a point where it’s no longer conductive. It’s also possible that a component—or several—have dislodged entirely from the board and need to be reseated.

You may be asking, how to fix a printed circuit board when a component fails? Again, the repair and remanufacturing process for faulty components is best left to professionals. There are voltage tools and various devices that can be used to test the conductivity of a board’s circuit. They can also be used to discern if there’s electricity flowing to a component, or if an element of the board has failed entirely. A lot of times, by just opening up the device you can see components that have failed. Their outer shell may seem burnt, cracked or broken, or the component is completely detached from the board and loose.

Traces on a circuit board are the conductive pathways comprised of silver or copper. Generally, you can see an issue with traces using the naked eye, but not always. If a trace suffers damage, whether through regular use or physical damage then it can cause significant issues with the printed circuit boards conductivity, components and the device in question.

Some of the more common reasons for trace damage include lightning strikes, severe power surges or shorts, metallic dust contamination, overheating and normal wear.

Provided the trace is not incredibly thin and difficult to see, you can usually discern damage simply by scanning the pathway. Copper and silver by nature are bright and shiny, which makes it easier to identify when there’s a break or damage. Keep in mind this is not always the case, but it’s a sure bet.

To repair faulty or damage trace pathways, you simply need to resolder or reball the board with the necessary material. This reconnects the broken circuit and allows electricity to flow freely throughout the board.

As much as we’d love to praise every single engineer or product developer in existence, that’s just not viable. Sometimes, for whatever reason, a team may cut corners when designing a board or manufacturing the necessary components. This can result in the poor design and construction of a board, which causes issues later down the line.

You’ll know as soon as you have a faulty or poor circuit board because your device will continue to fail time and time again, even after a repair or service session. The best solution for a shoddy circuit board is to replace it completely, by visiting an official or licensed repair center.

The easiest way to identify a poorly designed board is the number of failures or problems after extended use. Barring significant physical or electrical damage to the device, if you take the board to be repaired or analyzed somewhere and there are a handful of issues, there’s likely something wrong with the way the board was constructed. In some cases, this simply means the original manufacturer used cheap or unreliable components, but the board itself is fine.

In most cases, a power failure is remarkably similar to a component failure, it may even be one in the same. The ultimate issue stems from the fact that there was a major power failure to all or part of the board. One of the PCB components could have been exposed to higher voltages than normal, causing it to receive heat damage and explode. Or maybe there was a trace failure causing a short somewhere? Whatever the case, a power meter can be used to test each individual component and the general conductivity of the board.

All professional repair teams have a power or voltage meter that can be used to identify electrical issues with a board and its components. Voltage tools are really the only way to diagnose a problem outside of visible damage to a component. As for repair, the process is best left to professionals but generally involves reseating or replacing components.

There are several ways in which a printed circuit board can be repaired or serviced, with varying degrees of skill required. For the most part, however, anything to do with the internals of an electronic or device calls for knowledge of engineering and mechanics, and basic electrical circuits. For some of the larger devices on the market, you could seriously injure or even fatally wound yourself if you don’t know what you’re doing.

With traces and conductive pathways, you may need to coat, remove or replace the necessary material: be it copper or silver. Often, this relies on tools such as a soldering iron or heat gun.

For physical or visible damage to a board, base board repair is necessary. This may include melting down similar materials to reshape or modify the board, or can sometimes even call for complete disassembly.

For conductor and component repair, knowledge and skill of soldering, desoldering, BGA rework and pinpoint accuracy may all be necessary. If you’ve ever worked with or held a soldering iron before, it’s not so easy to retain a steady hand and spread the material evenly. You will want extensive experience with a soldering and desoldering iron, just to be sure the components and parts are seated properly to the board.

Of course, there are a variety of IPC and ICO standards necessary to follow for professionals, to ensure electronics and components are constructed and repaired using proper protocols. If you are not aware or don’t know enough about these standards, you may find yourself in hot water later.

An EMS, if you don’t know, is often a circuit board repair company that designs, manufactures, tests, distributes, and repairs electronic components and internal assemblies. They commonly service components and devices for OEMs or original equipment manufacturers. An OEM is the company that originally designed and owns the product in question.

As is to be expected, most repairs require the same materials—or improved materials—used in the official design of a board. It may call for copper or silver to be reseated to repair trace pathways. PCB substrates are often comprised of fiberglass or an epoxy resin with copper foil bonded to the conductive layer. They may also be comprised of reinforced phenolic resin, a more paper-like material that’s thinner than fiberglass.

The best service and repair teams can reassemble or fix a damaged board near enough to its original condition that there’s almost no difference in a previous version and the upgraded one. Certainly, this requires a great deal of finesse and experience that you won’t find outside of an experienced and professional setting.

An important part of researching and hiring a professional repair service is making sure they have the proper PCB repair materials and tools available to get the job done. Some service repair teams don’t have everything on property or on-site, which can balloon the time it takes to repair or reassemble parts. They have to wait to receive the requisite materials or tools.

It’s no secret that a lot of the materials used are not environmentally-friendly or conducive to safety. We’re a long ways off, but there are scientists and bleeding edge teams working on bio-degradeable PCBs that will break down naturally after being discarded.

For PCB repair and remanufacturing and industrial PCB repair service options you can’t do any better than EMSG Inc. (Electronic Manufacturing Services Group). We are well suited to handle board level and complete box build assemblies, including any custom packaging you may have created or utilized.

We have a highly advanced facilitywith the latest manufacturing and repair technologies, which allow us to be incredibly precise, yet efficient in our duties. This, coupled with our incredibly experienced personnel, modern equipment and great management team means we can be swift and reliable and get any repairs or development done within the schedule of your choosing.

At EMSG, our primary goal is to help you enter the market successfully, but also in a competitive, reliable setting. We understand every business is unique, and the design and specifications of their components entails personalized attention. We can and will afford you the absolute focus and dedication you need, to ensure any and all work exceeds your expectations.

We are highly confident that EMSG will play an integral role in the design and development of your product. The information presented here is merely scratching the surface of what’s necessary to conduct and perform a professional-grade repair and remanufacturing service. You can rest assured, we have the skills, experience and tools to get you to market as soon as possible.

If you’re interested in our manufacturing or repair services, please fill out this contact form and allow us to reach out to you. You can also give us a call, anytime, to speak to a company representative.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey