tft lcd vs led lit quotation

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

The liquid crystal display (LCD) technology has been used in several electronic products over the years. There are more reasons for LCDs to be more endearing than CRTs.

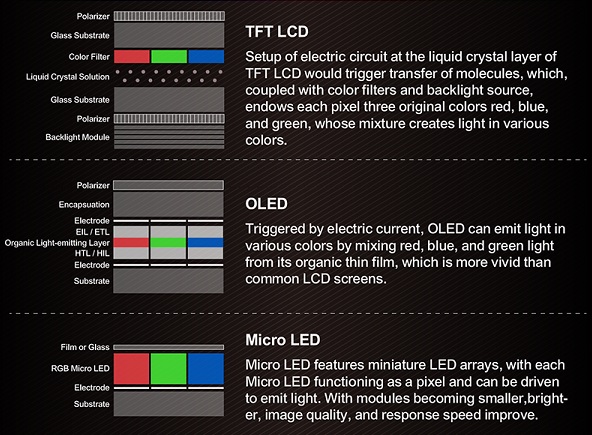

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

We have over two dozen TFT LCD display modules to choose from. All of them are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for imaginative user experiences. Thin and light, these are ideal for handheld devices, communications equipment, information displays, and test and measurement equipment.

Listed by the diagonal size of the active area (the usable area for lit pixels), our TFT display sizes range from 1.3 inches to 10.1 inches. Choose from six different interfaces, many of our TFT modules have more than one interface available. Arduino users should select modules with SPI for fast and easy communications to add color graphics to their projects.

Contrast ratio is the difference between a pixel that is lit or dark. Standard STN LCD displays typically have a 10:1 contrast ratio while TFT displays are 300:1 and up, so details stand out and text looks extra sharp. For standard STN displays, you must choose a display limited to a specific viewing angle (12, 3, 6 or 9 o"clock) while TFTs can have a viewing cone greater than 160 degrees.

Technology can be confusing because it evolves quickly, and there are complex acronyms for almost everything. If you are thinking ofbuildinga monitor or want to learn about the technology, you will encounter the term TFT Monitor at some point.

A lot goes on behind the glass surface, and we will look at this in comparison to other technologies to paint a clear picture of what TFT is and how it evolved.

TFT is an acronym for Thin Film Transistor, and it is a technology used in Liquid Crystal Display screens. It came about as an improvement to passive-matrix LCDs because it introduced a tiny, separate transistor for each pixel. The result? Such displays could keep up with quick-moving images, which passive-matrix LCDs could not do.

Also, because the transistors are tiny, they have a low power consumption and require a small charge to control each one. Therefore, it is easy to maintain a high refresh rate, resulting in quick image repainting, making a TFT screen the ideal gaming monitor.

The technology improved on the TN (Twisted Nematic) LCD monitor because the shifting pattern of the parallel, horizontal liquid crystals gives wide viewing angles. Therefore, IPS delivers color accuracy and consistency when viewed at different angles.

Both TFT and IPS monitors are active-matrix displays and utilize liquid crystals to paint the images. Technically, the two are intertwined because IPS is a type of TFT LCD. IPS is an improvement of the old TFT model (Twisted Nematic) and was a product of Hitachi displays, which introduced the technology in 1990.

The monitors can create several colors using the different brightness levels and on/off switches. But unlike OLED, both TFT and IPS do not emit light, so most have bright fluorescent lamps or LED backlights to illuminate the picture. Also, neither of them can produce color, so they have an RGB color filter layer.

Easy to Integrate and Update: By combining large-scale semiconductor IC and light source technology, TFTs have the potential for easy integration and updating/development.

Wide Application Range: TFTs are suitable for mobile, desktop screens, and large-screen TVs. Additionally, the technology can operate at a temperature range of -20°C to +50°C, while the temperature-hardened design can remain functional at temperatures not exceeding -80°C.

Impressive Display Effect: TFT displays use flat glass plates that create an effect of flat right angles. Combine this with the ability of LCDs to achieve high resolutions on small screen types, and you get a refreshing display quality.

High Resolution: The technology combines high brightness, color fidelity, contrast, response speed, and refresh rate to ensure you get a high resolution.

Good Environmental Protection: The raw materials used to make TFT displays produce zero radiation and scintillation. Thus, the technology does not harm the user or the environment.

Mature Manufacturing Technology: TFT technology came into existence in the 60s. Over time, its manufacturing technology has matured to have a high degree of automation, leading to cheaper, large-scale industrial production.

Wide View Angle: One of the main advantages of IPS screens is their wide viewing angle due to the horizontal liquid crystals. They do not create halo effects, grayscale, or blurriness, but these are common flaws with TFTs.

Better Color Reproduction and Representation: The pixels in TFTs function perpendicularly after activation with the help of electrodes. However, IPS technology makes the pixels function while parallel horizontally. Thus, they reflect light better and create a more original and pristine image color.

Faster Frequency Transmittance: Compared to TFT, IPS screens transmit frequencies at about 25ms, which is 25x faster. This high speed is necessary to achieve wide viewing angles.

Liquid Crystal Display (LCD) is a front panel display that utilizes liquid crystals held between two layers of polarized glass to adjust the amount of blocked light. The technology does not produce light on its own, so it needs fluorescent lamps or white LEDs.

As explained earlier, TFT improved on the passive-matrix LCD design because it introduces a thin film transistor for each pixel. The technology reducescrosstalkbetween the pixels because each one is independent and does not affect the adjacent pixels.

LED screens are like the new kids on the block in the display market, and they operate very differently from LCDs. Instead of blocking light, LEDs emit light and are thinner, provide a faster response rate, and are more energy-efficient.

Since IPS is a type of TFT, when comparing the two, we are essentially looking at the old Thin-Film Transistor technology (Twisted Nematic) vs. the new (IPS). Even though TN is relatively old, this digital display type has its advantages, a vital one being the fast refresh rate. This feature makes such screens the preferred option by competitive gamers. If you have any inquiries about the technology,contact usfor more information.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

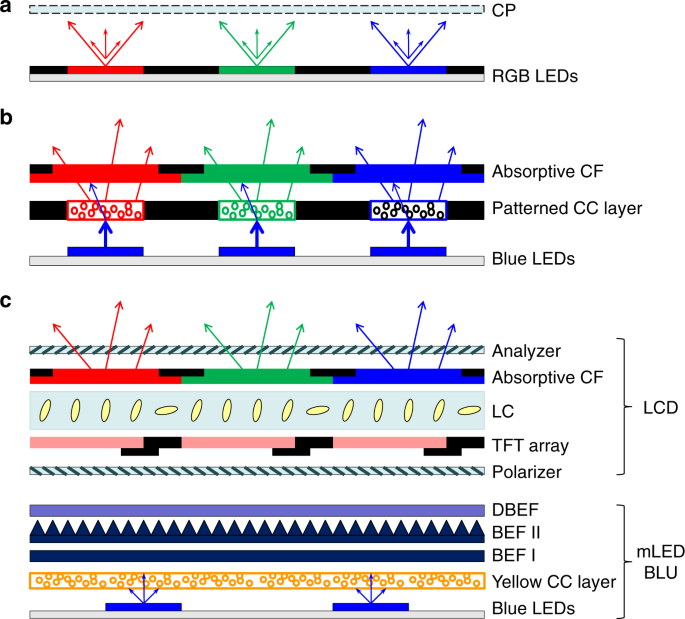

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

A fast response time helps to mitigate motion image blur and boost the optical efficiency, but this statement is only qualitatively correct. When quantifying the visual performance of a moving object, motion picture response time (MPRT) is more representative, and the following equation should be used

where Tf is the frame time (e.g., Tf=16.67 ms for 60 fps). Using this equation, we can easily obtain an MPRT as long as the LC response time and TFT frame rate are known. The results are plotted in Figure 5.

From Figure 5, we can gain several important physical insights: (1) Increasing the frame rate is a simple approach to suppress image motion blur, but its improvement gradually saturates. For example, if the LC response time is 10 ms, then increasing the frame rate from 30 to 60 fps would significantly reduce the MPRT. However, as the TFT frame rate continues to increase to 120 and 240 fps, then the improvement gradually saturates. (2) At a given frame rate, say 120 fps, as the LC response time decreases, the MPRT decreases almost linearly and then saturates. This means that the MPRT is mainly determined by the TFT frame rate once the LC response time is fast enough, i.e., τ≪Tf. Under such conditions, Equation (1) is reduced to MPRT≈0.8Tf. (3) When the LC response is <2 ms, its MPRT is comparable to that of an OLED at the same frame rate, e.g., 120 fps. Here we assume the OLED’s response time is 0.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

High CR is a critical requirement for achieving supreme image quality. OLEDs are emissive, so, in theory, their CR could approach infinity to one. However, this is true only under dark ambient conditions. In most cases, ambient light is inevitable. Therefore, for practical applications, a more meaningful parameter, called the ACR, should be considered

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Transmission spectra of color filters and emission spectra of (a) YAG WLED, (b) KSF WLED, (c) QDEF and (d) Vivid Color LED. KSF, potassium silicofluoride; QDEF, quantum dot enhancement film; WLED, white light-emitting diode; YAG, yttrium aluminum garnet.

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

A color filter array is another effective approach to enhance the color gamut of an OLED. For example, in 2017, AUO demonstrated a 5-inch top-emission OLED panel with 95% Rec. 2020. In this design, so-called symmetric panel stacking with a color filter is employed to generate purer RGB primary colors

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

The next type of lifetime is operational lifetime. Owing to material degradation, OLED luminance will decrease and voltage will increase after long-term drivingT50) can be as long as >80 000 h with a 1000 cd m−2 luminanceT50, half lifetime) with an initial luminance of 1000 nits. However, this is still ~20 × shorter than that of red and green phosphorescent OLEDs

To further enhance the lifetime of the blue OLED, the NTU group has developed new ETL and TTF-EML materials together with an optimized layer structure and double EML structureFigure 10a shows the luminance decay curves of such a blue OLED under different initial luminance values (5000, 10 000, and 15 000 nits). From Figure 10b, the estimated T50 at 1000 nits of this blue OLED is ~56 000 h (~6–7 years)

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

Power efficiency of white, red, green and phosphorescent blue and fluorescent/TTF blue OLEDs over time. Data are compiled from Refs. 41, 45, 114, 115, 116, 117, 118, 119, 120, 121, 122, 123, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

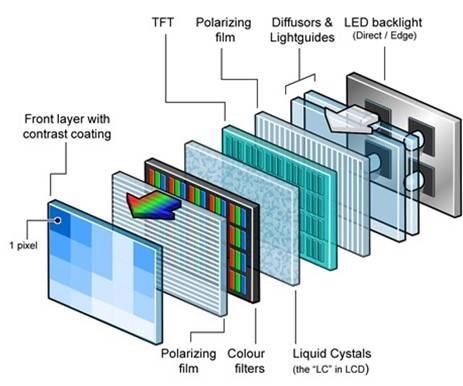

Before answering the questions below, it would be helpful to provide a simple overview of how a TFT LCD works. Every monitor or touchscreen computer includes an LCD panel. The LCD panel is the component that you are viewing at this very moment. This panel includes a thin layer of TFT LCD pixels, where each pixel includes a red, blue, and green rectangle. You can actually see the individual pixels on a display if you place a drop of water on it. The drop will magnify the pixel area and reveal a pixel with a red, blue, and green rectangle. Each red, blue, and green rectangle is a small lens that can be adjusted to allow varying amounts of light to pass through. The colors you see on your screen are determined by how much light is passing through each adjustable red, green, and blue element of each pixel.

The light that you see does not come from the pixels themselves, but from the backlight behind the pixels, which is a series of carefully placed LEDs that emit white light that projects through the LCD pixels. You cannot see the individual backlight LEDs when you look at your monitor, because there is layer of light diffusing material between the LED backlight and the LCD pixel layer. The light diffusing material scatters the light from each individual backlight LED, so they do not show up as bright spots on your monitor.

To summarize, the three layers of an LCD panel are the TFT LCD pixel layer, the diffuser layer, and the LED backlight layer. Note that some LCDs have edge-lit backlighting, but there is no need to go into detail about this, as the same principles apply. That completes LCD panel course 101. Now, what makes a display sunlight readable?

There are two general ways to make an LCD brighter and therefore readable in sunlight. The first and simplest way is to increase the brightness of the backlight. LCD brightness is measured in Nits. Typical LCD panels have a screen brightness between 250 Nits to 450 Nits. LCD brightness of 800 Nits or higher is generally considered sunlight readable, but most sunlight readable displays are 1000 nits. Increasing the brightness of the LCD panel backlight is the most common method of making an LCD panel sunlight readable. Most of Teguar’s industrial panel PCs and touchscreen monitors are available with this type of high brightness LCD.

Another way to make an LCD sunlight readable is to change the diffuser material between the LED backlight and the LCD pixels to a “transflective” material. The transflective material is similar to reflective sunglasses or a one way window, where the shiny side is facing the LCD surface. When transflective material is used, the sunlight entering the LCD panel travels through the pixels, bounces off the transflective material, and is reflected back through the pixels to your eyes. In this case, the sunlight has much less of an impact on viewability than a traditional LCD panel, as the sunlight is reflecting back through the LCD pixels and contributing to the LCD brightness. One drawback of transflective diffuser LCDs is that they don’t allow for as much of the backlight to pass through the diffuser material, so in low light conditions the LCD does not appear as bright. Transflective diffuser LCDs are not as common as high brightness backlight LCDs.

Optical bonding improves viewability of touchscreen PCs in sunlight or other high-bright environments. In a touchscreen computer, the touchscreen sensor and the LCD panel are separate components. The touchscreen is mounted in front of the LCD surface and there is a small air gap between these two components. When sunlight passes through the touchscreen layer, some amount of the light is reflected between the LCD surface and the touchscreen; this reflection reduces LCD viewability.

Optical bonding is a process where a clear adhesive gel is placed between the LCD to the touchscreen. The gel hardens and bonds the touchscreen to the LCD to eliminate the air gap, improving contrast and clarity. Optical bonding is available on many of Teguar’s touchscreen computers and industrial monitors.

The brightness of a sunlight readable display may be overwhelming at night, when there is little or no ambient light. Most industrial computers with sunlight readable LCDs are available with an optional auto-dimming feature. With this feature, an ambient light sensor on the front bezel measures incoming light and adjusts the backlight brightness to match the current light conditions. This is typically a requirement for industrial touchscreen computers that are used in both sunlight and moonlight.

Most of our products can handle a few hours of direct sun exposure per day, but full exposure to direct sunlight will cause damage to most touch screens in around 1 year. Contact a knowledgeable Teguar sales rep to discuss the details of your own environment and we can help determine the best solution.

Touchscreen computers in vehicles commonly require high brightness LCDs, because of the ambient sunlight coming through the windows. Sunlight readable LCDs are also used in many indoor applications surrounded by windows, such as air traffic control centers, railroad cars, marine vessels, agriculture machinery, and public kiosks.

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

The other configuration for LED backlights is edge lit. An edge lit configuration is the most commonly used construction for LED backlights. This configuration mounts the LEDs along one edge of the light box. The layout results in a thin design. Edge lit also uses less LEDs overall and therefore consumes less power than an array configuration.

Another type of backlight options is the use of fiber optic technology. Fiber optic backlights use sheets of fiber optic woven cloth and are bundled by a ferrule (metal cap) to an LED or halogen light source. Advantages for the fiber optic technology includes low voltage, low power, and a very uniform brightness. This type of backlighting is ideal for custom display shapes or sizes however it is priced at a higher cost compared to other technologies available.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

In this research thermal and fluid fields of a 32-inch commercial thin film transistor liquid crystal display (TFT-LCD) TV panel were investigated numerically and experimentally. The new trend in the production of TFT-LCD, TV panel is to have slimmer screen displays. The original design with 180 LEDs (light emitting diodes) placed at the top and bottom edges of the panels was modified. In the new design, the panels were illuminated using only 72 LEDs placed underside and inside the panels. By this modification an important cost reduction has been achieved alongside having slimmer screen displays. Heat dissipated by these 72 LEDs must be removed in order to assure good image quality and long service life. Hence an appropriate thermal management is indispensable. To analyze temperature distribution at steady state condition a CFD (computational fluid dynamics) computer code “FloEFD” was used. The results obtained from the computational analysis have been validated by using experimental techniques. For this purpose thermocouples were attached on the panel and after the steady state has been reached, temperatures have been recorded in order to compare them to the distribution obtained by “FloEFD”. Furthermore, a thermal camera image of the panel by FLIR Thermacam SC2000 test device was obtained as another validation for temperature distribution.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

Everything from the environment your display will be used in, your budget, to the lighting conditions and the required durability will play a part in this decision.

Contrast refers to the difference between the lightest and darkest parts of an image. High contrast will produce sharper images and more easily readable text. It’s a crucial quality for high fidelity graphics and images or to make sure that a message on a display is very visible.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

Compared with ordinary LCDs, TFT LCDs provide very clear images/text with shorter response times. TFT LCDs are increasingly being used to bring better visual effects to products.

TFT stands for “thin film transistor”. The transistor of a color TFT LCD is composed of a thin film of amorphous silicon deposited on glass. It acts as a control valve to provide the appropriate voltage to the liquid crystal for each sub-pixel. This is why TFT LCDs are also known as active matrix displays.

TFT LCDs have a liquid crystal layer between a glass substrate formed by the TFT and transparent pixel electrodes and another glass substrate with a color filter (RGB) and a transparent counter electrode. Each pixel in the active matrix is paired with a transistor that includes a capacitor, which gives each sub-pixel the ability to retain its charge without sending a charge every time it needs to be replaced. This means that TFT LCDs are more responsive.

To understand how a TFT LCD works, we must first grasp the concept of a field effect transistor (FET), which is a transistor that uses an electric field to control the flow of current. It is a component with three terminals: source, gate and drain. fet controls the flow of current by applying a voltage to the gate, thereby changing the conductivity between the drain and source.

Using the FET, we can build a circuit as follows. The data bus sends a signal to the source of the FET, and when SEL SIGNAL applies a voltage to the gate, a drive voltage is generated on the TFT LCD panel. A sub-pixel is lit. A TFT LCD display contains thousands or millions of such driver circuits.

Color TFT LCD from 1.8 inch ~ 15 inch, there are different resolutions and interfaces. How to choose the right TFT LCD, you can refer to the previous article “LCD | How to choose a liquid crystal display module

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey