full meter competition lcd panel manufacturer

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

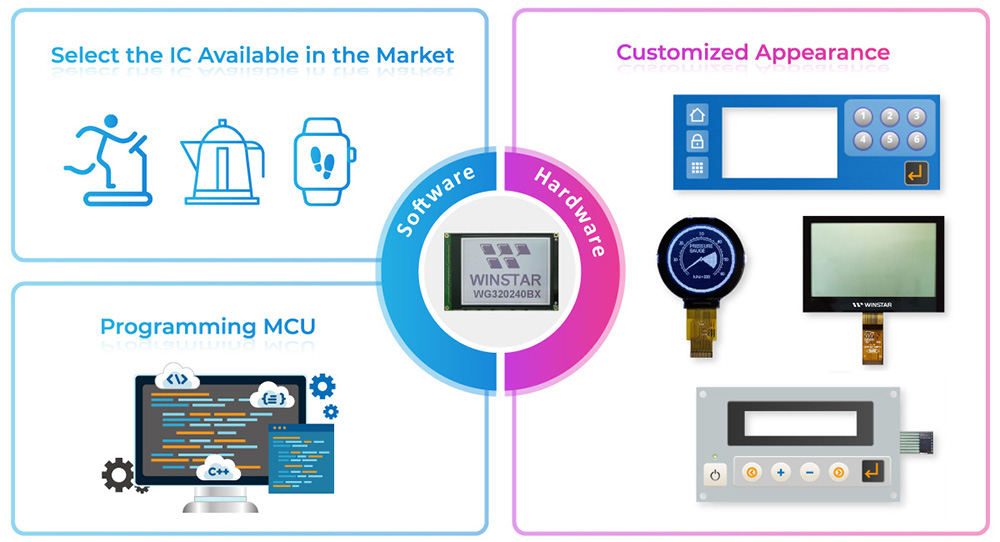

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Powertip has grown to become a leading manufacturer of small to mid-size full color TFT and monochrome displays as well as resistive and capacitive touch panels. Powertip is headquartered in Taichung, Taiwan with production facilities located in Taiwan and Nanjing, China. Powertip’s product offerings address major industries to include medical, industrial, automotive, consumer, white goods, communications, test and measurement and gas pumps / parking meters.

Powertip’s manufacturing capabilities comprise Surface Mount Technology (SMT), Chip-On-Board (COB), Chip-On-Glass (COG), Chip-On-Flex (COF), Tape Automated Bonding (TAB) and screen printing. Production of a typical LCD panel would require Powertip to take Mother Glass, scribe, cut, fill the cells with liquid crystal and then seal the two sandwiched glass panels. Powertip would then add polarizers, color filters and all other required backend manufacturing processes to create a completed LCD module to specification.

If product is deemed defective the customer will receive a replacement part after it is deemed so by Maverick Man Inc. and / or the Manufacture. NO REPLACEMENT WILL BE SENT UNTIL THE PRODUCT HAS GONE THOUGH THE FULL RMA PROCESS with Maverick Man Inc. or the Manufacture. Each Manufacture has their own policy for warranties and time frame for processing and must be considered in the process.

AutoMeter recommends contacting our tech agents at (866)248-6357 prior to purchase for any questions or concerns regarding this product, installation, use, or accessories related to this product.

The AutoMeter Competition LCD Display is the next evolution of driver communication and data acquisition. Designed specifically for the harshest of environments, the carbon composite housing is IP65 sealed against water and dust intrusion and will easily withstand 20g of continuous vibration and 50g of shock. Our 7” LCD panel ensures easy visibility under all circumstances with a retina level pixel density, unmatched brightness and an optically bonded lens for extreme glare suppression. The display layout is fully configurable to your individual specifications. The system will accommodate four programmable data bus channels (2 CAN and 2 serial) in conjunction with a nearly limitless amount of discrete analog sensors and its integrated 3 Axis Accelerometer. Data collection can occur at up to 1 kHz and the internal memory allows for practically infinite recording time. User definable warnings take advantage of super bright, multicolor LEDs placed around the perimeter of the chassis to alert the driver to critical onscreen information.

7.0” TFT LCD panel, 1000 nit brightness for unmatched daytime and nighttime visibility with 800x480 resolution. Onboard photo sensor for automatic brightness control

12 analog inputs for discrete sensors ideal for parameters not supported on the vehicle communication bus or ECU. Expansion modules available separately for additional input

Fully user configurable from display via integrated 4 button interface for at track changes. Optional external switch set can be mounted within driver reach for easy access

Initial release supports 6 layers or screens selected from user- configurable templates (screens/instrument cluster designs/layouts), additional configurability supporting team selected graphics, parameter/instrument type and location, and size will be made available with future firmware and PC software releases

Display features perfectly rendered virtual analog needles, value display bands, digital value indicators for vehicle parameters and configurable full color text warning messages

With a 1.5 inch (38 mm) high LED display, Red Lion’s LPAX displays are modular panel meters that work with various input modules to provide flexibility. Plug-and-play output cards add additional functionality such as setpoint, retransmitted analog and communication options.

Red Lion’s EPAX provides a 4 inch (101 mm) high LED display for easy viewing from distances up to 180 feet. These modular panel meters work with various input modules to provide flexibility. Plug-and-play output cards add additional functionality such as setpoints, retransmitted analog and communication options.

Segmented By Type (Totalizers, Multi-Input Indicators and Scanners, Temperature and Process Panel Meters, Others), By Display Technology (LED, LCD, Sunlight Readable, Dual Line, Single Line, Bar Graph, Others (Large Display, Etc.

New York, Dec. 05, 2022 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Digital Panel Meter Market –Global Industry Size, Share, Trends, Opportunity, and Forecast, 2018-2028" - https://www.reportlinker.com/p06370183/?utm_source=GNW

)), By Display Type (Numeric, Alphanumeric, Combination), By End User (IT and telecom, Manufacturing, Government, Healthcare, Retail, Transportation, Others), By Applications (Display Current, Display Voltage, Displays Temperature, Others), By Region, By Competition

Global Digital Panel Meter Market is anticipated to grow robustly in the forecast period, 2022-2028.Digital panel meters are the meters that are used to display the data output from signals in digital numbers.

The rising demand from the electronics sector is known to drive the digital panel meter market.It is also anticipated to fuel the development of the global market over the forecast period.

The demand for digital panel meters is driven mainly by consumer electronics due to the widespread usage of these meters in the electronics sector.Today, the utilization of digital displays to show output results in digital data format is becoming more and more prevalent in many commercial processes.

Manufacturing, pharmaceuticals, healthcare, and other industry utilize these digital display meters to monitor the desired output from the data signals such as current, time, voltage, and others in the form of digital numbers on the screen.

The displays used in LCDs or LEDs are the primary aspects responsible for the ever-increasing demand for display panel meters in the consumer electronics market. They show only the needed units instead of the needle and device used in the analog meters.

This remarkable accuracy of the constant calculation done by the digital panel meters is a significant driving factor in the demand for digital display meters during the forecast period.The signal to the digital panel meter can be in many different forms, including resistance, Temperature, AC voltage, DC voltage, AC, and AC power.

These meters are frequently used in electronic instruments, especially in consumer electronics.Several factors are considered when choosing a digital panel meter.

. Digital panel meters are preferred over traditional ones since the numbers are displayed on the screen. The number of digits, size, and color of the displayed number are some of the characteristics responsible for its rapid growth.. Thus, digital panel meters are simpler and more convenient than their analog version, and the data shown is more accurate. Owing to this, its market is expected to grow with a high CAGR in the forecast period.

A digital panel meter is commonly used in electronic applications such as microwave ovens and instrument panels containing panel meters that measure time, weight, and power.Medical centers use digital meters such as glucometers, digital thermometers, and oximeters, indicating various parameters.

Furthermore, a water pump works a pressure gauge panel meter and a motor RPM panel gauge to monitor water flow in a tank and swimming group.Moreover, digital panel meters are also used in cars and sports bikes to translate motion into digital indications such as time, speed, total distance in kilometers or miles, etc.

For instance, in June 2019, Trumeter declared the launch of a single split, three-phase digital APM power meter with features such as a color-changing display, Modbus connectivity, and compact size.

Digital panel meters are employed in multitude industries with different parameters and dimension, contributing to the increasing demand of the digital panel meter market through 2028.For instance, the United Nations conference on trade developments FDI investments in Asia-Pacific developing countries reached USD 619 Billion in 2021.

Price of the digital panel meters is higher than that of analog panel meter besides increased cost of implementation acts as a potential barrier for adoption of digital panel meters in end use industries.

Global Digital Panel Meter Market is segmented into type, display technology, display type, end-user, and application.Based on type, the market is segmented into totalizers, multi-input indicators and scanners, Temperature and process panel meters and others.

Based on display technology, the market is segmented into LED, LCD, Sunlight Readable, Dual Line, Single Line, Bar Graph, and others (Large Display), etc.Based on display type, the market is divided into Numeric, Alphanumeric and Combination.

Major market players in the Global Digital Panel Meter Market are Siemens AG, Murata Power Solutions, Inc, Red Lion Controls, OMRON Corporation, The Danaher Corporation, Phoenix Contact, PR Electronics, Precision Digital Corporation, PR Electronics, OMEGA Engineering Inc.

• In June 2019, Murata Power Solutions introduced its DMS01 Series wide format digital panel meter. It was designed for industrial applications such as factory automation and laboratory instrumentation. The product series provide a wide variety of process voltage and current measuring capabilities.

In this report, the Digital Panel Meter Market has been segmented into the following categories, in addition to the industry trends which have also been detailed below:

Global Digital Panel Meter Market report with the given market data, Tech Sci Research offers customizations according to a company’s specific needs. The following customization options are available for the report:

Attendees visit the booth of TV panel maker Shenzhen China Star Optoelectronics Technology during an international exhibition in Shanghai on July 11, 2019. [Photo by Lyu Liang/For China Daily]

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

The pandemic will accelerate reshuffling in the display industry as supply has surpassed demand in the past few years and competition has become very fierce, he added.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan ($6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Chen Lijuan, an analyst at Sigmaintell, said panel manufacturers should not just invest in production lines, but also pay more attention to the establishment of the whole supply chain, including raw materials, equipment and technology.

Bian Zheng, deputy director of research at AVC Revo, a unit of market consultancy firm AVC, said China will have a 51 percent market share in global TV shipments in 2020, while South Korea will have 25 percent, adding that large-screen TV panels will bolster healthy development of the industry.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

- 7.0” TFT LCD panel, 1000 nit brightness for unmatched daytime and nighttime visibility with 800x480 resolution. Onboard photo sensor for automatic brightness control

- 12 analog inputs for discrete sensors ideal for parameters not supported on the vehicle communication bus or ECU. Expansion modules available separately for additional input

- Fully user configurable from display via integrated 4 button interface for at track changes. Optional external switch set can be mounted within driver reach for easy access

- Initial release supports 6 layers or screens selected from user- configurable templates (screens/instrument cluster designs/layouts), additional configurability supporting team selected graphics, parameter/instrument type and location, and size will be made available with future firmware and PC software releases

- Display features perfectly rendered virtual analog needles, value display bands, digital value indicators for vehicle parameters and configurable full color text warning messages

Latest research from Omdia has found that Chinese display maker BOE has led the market in shipments of large area TFT LCD displays in December 2021, both in units and total area shipped. This accounts for nearly one-third of whole unit shipments, as the industry set new records for shipments for the month and year.

Pandemic restrictions impacted demand for and spending across home entertainment products with display shipments of TV and IT devices experiencing a growth surge. The total of large area TFT display shipments rose to a record 89.4 million square meters in December, reflecting a 4 percent month-on-month increase over November, as well as 5 percent Year on Year growth (YoY), Omdia reported in its latest Large Area Display Market Tracker.

For the full year, large area TFT LCD shipments increased with 9 percent YoY by units and 4 percent YoY by area, reaching 962.7 million units and 228.8 million square meters shipped in 2021, both historical highs and marking the first time the industry has ever shipped more than 900 million units in a year.

Among display makers, China"s BOE took the largest shares for both units and total area shipped in 2021. BOE took 31.5 percent for units shipped and 26.2 percent for area shipped, marking the first time one maker has captured over 31 percent market share for whole unit shipments and 26 percent share for whole area shipments in large area TFT LCD history.

Beyond BOE, Innolux took 15.4 percent market share for large area TFT LCD unit shipments, followed by LG Display with 13.4 percent in 2021. For total area shipped, China Star took 15.8 percent as second largest maker after BOE, followed by LG Display in third with 11.9 percent in 2021.

Strong demand particularly for mobile PC LCD during the pandemic increased notebook PC LCD unit shipments in 2021, rising 26 percent YoY. Tablet PC LCD unit shipments also rose 7 percent YoY last year. On the other hand, the LCD TV display segment saw unit shipments fall 4 percent YoY due to a slowdown in demand in 3Q21. But ongoing LCD TV size migration in favor of larger screens meant that total LCD TV display area shipped increased 2 percent YoY in 2021 despite the drop in unit shipments.

Large area TFT LCD revenue increased 34 percent YoY in 2021 and reached US$85.2 billion, also setting a record and the first time large area TFT LCD revenue has ever exceeded $80 billion. Strong demand and size migration to larger screens during COVID-19 pandemic combined with display price hikes up until 3Q21 to drive the high revenue number.

YoonSung Chung, senior research manager for large area displays and supply chain at Omdia, commented: "Display makers waited for results from Black Friday sales to set their early 2022 sales and pricing strategies. However, results seem to fall short of expectations for LCD TVs. LCD TV display buyers will price LCD TV displays more aggressively in the coming months.

"While demand for IT displays is weakening, panel makers’ supply plans are ambitious. Unless panel makers adjust their fab utilisation, price erosions could imminently worsen for large area display applications, including monitor and notebook PC LCDs. Omdia expects the LCD TV panel prices to reach the price bottom in 1H 2022 and then gradually rebound based on the market demand recovery."

Sycamore, IL – The Auto Meter LCD Competition Race Dash is the next evolution of driver communication and data acquisition. The carbon composite housing is IP65 sealed against water and dust intrusion and will easily withstand 20 g of continuous vibration and 50 g of shock. Our 7” LCD panel ensures easy visibility under all circumstances with unmatched brightness and an optically bonded lens for extreme glare suppression. The display layout is configurable to your individual specifications. The system will accommodate four programmable data bus channels (2 CAN and 2 serial) in conjunction with discrete analog sensors and its integrated 3 Axis Accelerometer. Data collection can occur at up to 1 kHz and the internal memory allows for practically infinite recording time. User definable warnings take advantage of super bright, multicolor LEDs placed around the perimeter of the chassis to alert the driver to critical onscreen information.

Display features perfectly rendered virtual analog needles, value display bands, digital value indicators for vehicle parameters and configurable full color text warning messages.

20 layers / screens / pages selected from 6 user-configurable templates (screens/instrument cluster designs/layouts), additional configurability supporting team selected graphics, parameter / instrument type and location, and size will be made available with future firmware and PC software releases.

Auto Meter is a leading developer and manufacturer of specialty automotive instrumentation systems as well as battery and electrical system test and charging equipment. The company operates out of a 93,000 square foot facility in Sycamore, Illinois and distributes its products to over 600 active customers within the specialty warehouse distributor, retailer and OEM channels. Auto Meter products are used through out the world and are relied upon by professional racers from NASCAR, to NHRA, to Formula teams as well by sportsmen racers and by street enthusiasts. Auto Meter Test equipment is used by the worlds leading automotive retail and service organizations. To learn more about Auto Meter, please visit www.autometer.com

In 2007, a young company SPL-LAB was created from the group of engineers, after six months of development, the first sound pressure meter in Russia was presented with a dynamic range up to 180 dB - USB Bass Meter. In parallel with the development of the instrument, the first version of the Measuring Center software for Windows was created. Many car audio competition formats have chosen USB Bass Meter and other Bass Meter devices as official gauges.

2009 was the year of the first measurement USB microphone for measuring the frequency response - USB RTA Meter. Since then, Spl-Lab has entered the market of professional audio systems for high-quality sound.

In the following years, Spl-Lab was actively developing new sound pressure meters and microphones for measuring the frequency response, improving and expanding the functionality. The versions of the Measuring Center software for Android and iOS platforms were released.

In 2013, we added the Smart Voltmeter automotive voltmeter and the Smart Monitor volt-ampere voltage meter to the product range. Thus began to produce electrical measuring instruments.

In 2018, after a long and complicated development, the first car acceleration meter was released - the Race Meter, which has already managed to establish itself with the best side among race drivers and tuning fans.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey