lcd panel timing controller free sample

Different displays use different types of TCONs. In this article we will be talking about TCONs for the IT market: LCD (Liquid Crystal Display) notebook PCs and monitors.

An LCD panel has millions of Red, Green, and Blue (RGB) liquid crystals that are used to block a white backlight when electrical voltage is applied to them. High voltage signals to each individual pixel control how much of the backlight to block. A white display means nothing is being blocked. A black display means all three colors are blocked at maximum effort.

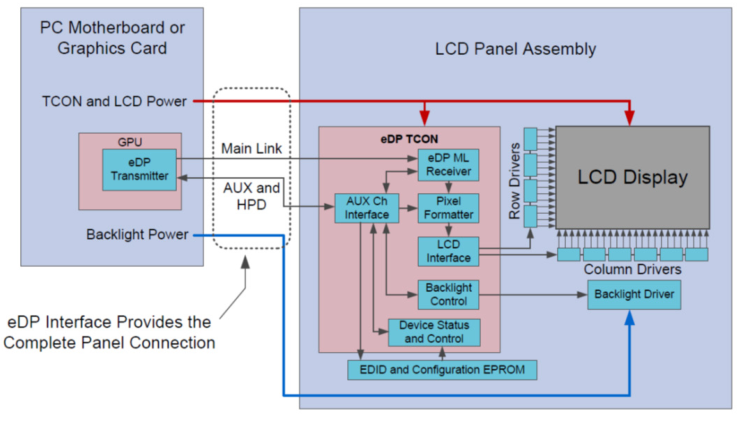

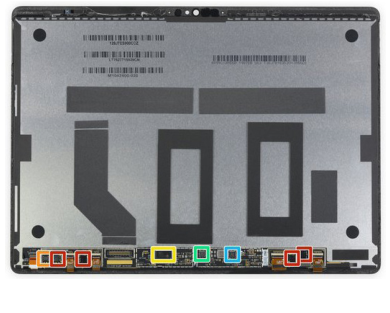

TCONS direct the high voltage driver chips that move the color filters and are usually found on a circuit board that sits below the glass panel (Fig. 1).

eDP connections are fast, use few wires, and are flexible for size, bandwidth and adding features eDP provides all panel connections in one plug, including power, data, and control signals. This is Analogix’s specialty.

While the GPU is responsible for transforming mathematical equations into individual pixels and frames, a TCON takes the individual frames generated by the GPU, corrects for color and brightness, then sends out parts of the image to each individual driver at the panel’s specific timing.

The human eye has an incredible dynamic range. That means we can see both very dark images and very bright images, at the same time. However, neither camera sensors nor display panels can display that range. Your camera generates HDR images by using images from multiple exposures to combine the brightest and darkest parts of the picture. This increases the contrast (dynamic range) between light and dark, pulling out details from darkened or washed out areas.

HDR accurately maps real world color and luminance to a display panel. VESA DisplayHDR™ standard specifies HDR quality, including luminance, color gamut, bit depth, and rise time.

Display panels have difficulty displaying a wide range of brightness. Normal sunlight can reach 10,000 nits, but the backlight on most notebooks today is around 250 nits

VESA DisplayHDR requires the panel to meet minimum brightness, contrast, and color. No panel can reach 10,000nits of natural light. The brightest a 250nit notebook panel can produce is 250nits and any image above 250nits is washed out. Also, no details from 250 nits to 10,000nits can be seen.

The HDR400 specifications require a dimmable backlight which helps with both producing darker blacks and lowering the power consumption. Tone mapping is used to map the whole range of 10,000 nits down to what the panel can handle, so the details can be seen. Tone mapping does not increase the brightness of the panel; it only makes the details visible.

VESA DisplayHDR600 Requires local dimming. No LCD panel can reach the VESA DisplayHDR600 requirement of 6000:1 contrast ratio. However, this can be overcome with local dimming.

For example, a 750:1 contrast panel requires 8 different backlight power settings to reach 6000:1 contrast ratio. However, unless there are thousands of separate regions, local dimming always produces halos around the bright areas. In order to reduce the halos, the following are recommended:

Monitors can use a direct backlight with many regions. An extra layer of liquid crystal can be used to dim the backlight at a specific location but this often results in a panel that is too thick for a notebook.

Notebook backlights use LEDs on the edge of the panel to reduce panel thickness. These can be on 1 side, 2 sides, or all 4 sides. Each edge adds to cost and bezel size.

Global Dimming Power Savings - Figure 6 shows a 15.6” UHD panel with 400nit maximum brightness. Figure 7 shows a comparison of backlight power consumption values between 400nit, 50nit and, respectively 5nit.

The primary goal of color management is to obtain a good match across color devices; for example, the colors of one frame of a video should appear the same on a computer LCD monitor, on a TV screen, and as a printed poster. Color management helps to achieve the same appearance on all of these devices, provided the devices are capable of delivering the needed color intensities. Color management cannot guarantee identical color reproduction, as this is rarely possible, but it can at least give more control over any changes which may occur.

A PC in HDR and SDR modes use different color gamut but the same screen. Dual-panel phones and notebooks need the color of the two sides to match perfectly. Graphic artists for web sites, movies, video games, etc., need to know what they are creating looks the same on their screen as on their customers’ screens.

As panels improve, the color space of new panels may exceed the color space from Windows. This results in displays which look oversaturated. There is a trend towards low blue light or “night shift” panels, while still retaining color accuracy for the other colors. Today, low blue light panels are created by measuring each individual panel, then hoping that the yield is high enough.

Analogix’s Advanced Color Blocking (ACB) technology is used to create consistent image quality across different panels and change color space for different usage modes (Fig. 8). It allows for 3D color gamut rotation in the optical color domain rather than the RGB domain and color space change on the fly, such as color mapping of BT.2020 source to sRGB or DCI-P3 panels. It includes LUT shadow registers and hardware transition calculations (to smooth changes).

Color conversion in the TCON can dynamically and continuously adjust the incoming signal from the GPU for a low blue light color space. This way, no individual panel measurement is needed and yields should increase. While this can also be done by the GPU itself, that takes GPU bandwidth and 500x more power.

Panel Self-Refresh (PSR) – frame buffer in a TCON can maintain a display image without receiving video data from the CPU. For a still image, this allows the GPU to enter a low-power state and the eDP main link to turn off. Allowing the GPU to power down between display updates will save significant power and extend battery life.

Panel Self-Refresh with Selective Update (PSR2) is a superset of the panel self-refresh feature and it allows the transmission of modified areas within a video frame with obvious benefits when watching a movie or playing a game. PSR2 identifies when only a portion of the screen is static, which is a selective update. In PSR2, when the full screen is static, the refresh rate can be lowered for further power savings as done by Intel Low Refresh Rate (LRR). Intel LRR lowers the refresh rate by changing pixel clock or by changing vertical blank depending on the scenario such as idle, playing video, browsing, etc. All Analogix TCONs support Intel LRR.

In-Cell Touch embeds the touch function in the display itself, the panel including all the touch sensors, controllers, and needed processing. This simplifies the production process and reduces weight and reflection by removing the cover glass. It also allows for thinner bezels as there is no need for daughter cards and no separate wires for touch, as well as lighter devices as the cover glass is removed.

Analogix has pioneered the in-cell touch notebook panel TCONs. About 15% of notebooks support touch and we expect the touch attach rate to increase as more active pen support is introduced.

Although Digital View LCD controller boards have multiple LCD panel timings pre-programmed and selectable via mini-dip switch there are always new LCD panels being released. We provide a service to add the required panel times but this may (but not always necessary) require providing a LCD panel sample.

Alternatively users can use the Panel Timing function in the Controller Utility, a free for download application to set the LCD panel timing themselves.

For more details regarding firmware updating see the manual for the specific controller (follow the link to the specific model’s webpage here). Also check the Controller Solution Generator to ensure there isn’t already a timing and cable solution for the panel.

The backlight controller creates the necessary signals for the backlight driver, also the on the scaler board, which, in turn, generates the necessary

The timing controller (TCON) chip on the TCON board receives the pixels from the scaler in serial format and does whatever is necessary to drive the individual

The TCON sends pixels to the source or column drivers of the panel. These are the chips that will finally drive the TFT matrix that is used to make pixels

Typical LCDs are edge-lit by a strip of white LEDs. The 2D backlighting system in Pro Display XDR is unlike any other. It uses a superbright array of 576 blue LEDs that allows for unmatched light control compared with white LEDs. Twelve controllers rapidly modulate each LED so that areas of the screen can be incredibly bright while other areas are incredibly dark. All of this produces an extraordinary contrast that’s the foundation for XDR.

With a massive amount of processing power, the timing controller (TCON) chip utilizes an algorithm specifically created to analyze and reproduce images. It controls LEDs at over 10 times the refresh rate of the LCD itself, reducing latency and blooming. It’s capable of multiple refresh rates for amazingly smooth playback. Managing both the LED array and LCD pixels, the TCON precisely directs light and color to bring your work to life with stunning accuracy.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey