cut lcd panel manufacturer

Remember an ultra-wide display is produced by cutting down a standard display panel (Fig. 3) leaving the top portion of the panel to be used as the new ultra-wide display. Looking again at our model SSD2845 we see it has a resolution of 1920 x 357. The 1920 horizontal resolution informs us the SSD2845 display was cut from a standard high definition 16:9 aspect ratio panel which would have a resolution of 1920 x 1080.

If we divide the vertical resolution of the initial display by the resolution of the cut (ultra-wide) display we can determine the ultra-wide display is about 1/3 the height of the original 16:9 display.

Since ultra wide LCD so ubiquitous lately , because it has matured into a totally developed, versatile product that has adapted to several different applications and environments. As you know the applications are constantly diversifying and that we are now seeing bar LCD displays with multi-touch displays, video walls, and interactive. Which aims to offer consumers a more fun, educational and enhanced customer experience that helps drive sales.

As you know the monitor with conventional aspect ratios have limitations, in locations where they’re restricted tall or physical space, like on elevators, buses, or within the transportation and medical markets. However,The bar LCD is relatively new technology allows a resized LCD tube made to suit almost any application, yet it retains all its original performance and feature solution.

Resizing bar LCD consists of LCD disassembly, physically cutting the glass to a replacement size, sealing the sides. The technology also can be utilized in a good range of applications where standard sizes aren’t suitable, generally where there are height or width restrictions. Which use this technology are highly cost-effective solution for these low and medium volume demands. At the same time,the incorporates a sensible auto-scaling function so when users play their original content, the size are automatically modified to suit cutting LCD super-wide resolution.

Panel makers are cutting production by 16 percent on average from this month, Rong Chaoping, senior researcher at market research firm AVC Revo, told Yicai Global. Television panel makers are expected to ship 3.6 million less panels than last month.

Panel makers will reduce capacity by between 15 and 20 percent this month, said Wu Rongbing, chief analyst at Chinese semiconductor intelligence service Omdia.

TCL China Star intends to continue with its production cuts until September, while Beijing-based BOE and HKC Optoelectronics Technology have not yet decided how long they will reduce output, Rong said. None of the three companies responded when contacted by Yicai Global.

LCD TV display shipments from China’s five largest panel manufacturers accounted for 68.5 percent of the global market in April, a new high, and they were expected to exceed 70 percent this year, according to Omdia.

The global panel industry is expected to slash production by about 20 percent this year, according to Beijing-based Sigmaintell. It is the first time since 2013 that the worldwide sector has implemented such a large-scale and wide-ranging cut in manufacturing. But it should help to slow the fall in prices, Li said.

“Tumbling prices are squeezing profits,” Li said. “The price of a TV panel is now below cost price and that of some data panels is also below the manufacturing cost.”

“Panel makers are facing rising liquidity pressure and bigger losses as prices are now below cost price, so the display industry is likely to undergo another big reshuffle,” Rong said.

Excess supply will ease in the third quarter once output is cut, and prices will start to pick up and then flatten out, Li said. Demand for consumer electronic products is shrinking by far more than expected so it is too early to tell whether prices will rebound in the second half, she added.

Panel prices are likely to stop dropping this month or next as output falls, Wu said. Whether prices will start to pick up soon depends on when demand improves.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

![]()

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Alibaba.com offers 7665 cut lcd display products. About 2% % of these are lcd modules, 1%% are other machinery & industrial equipment, and 1%% are mobile phone lcds.

A wide variety of cut lcd display options are available to you, You can also choose from original manufacturer, odm and retailer cut lcd display,As well as from tft, ips cut lcd display.

Spectra-Physics is a leading supplier of lasers for the manufacture of flat panel displays (FPD) including OLED and LCD. Our lasers are proven in a wide range of FPD applications including glass cutting/drilling, ITO patterning, repair and marking. We deliver a broad portfolio of highly reliable, cost-effective lasers for 24/7 flat panel manufacturing backed by our industry-leading global support organization.

Spectra-Physics introduces ClearShape, a patent-pending femtosecond laser process for highest quality, fast cutting of chemically strengthened glass, unstrengthened glass, and sapphire. At speeds over 1000 mm/sec, the new process results in several-fold improvement in cut quality over other laser processes: no chipping, Ra <0.1 µm edge roughness, and as-cut bending strength of >650 MPa for chemically strengthened glass. Utilizing the widely deployed Spirit® family of industrial femtosecond lasers, the new process is ideal for 24/7 manufacturing of displays and windows for mobile devices, wearables, and other demanding applications.

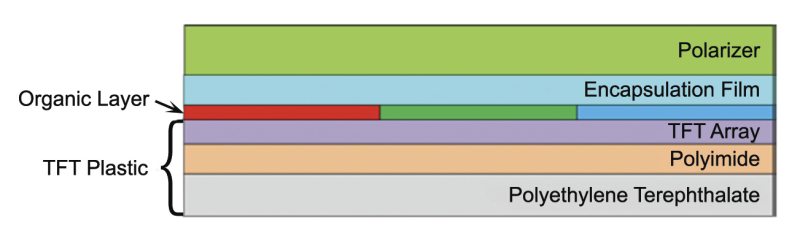

The Spirit 1030-100-SHG laser system operating at wavelengths of 515 and 1030 nm has been used for cutting 75 μm thick ribbons of PI and PET plastics, typically used for flexible OLED displays. Figure 1 shows microscope images of PI and PET plastics machined using the Spirit 1030-100-SHG laser. Cutting speeds exceeding 1 m/s for both plastics were achieved when operating the laser at 100 W average power at 1030 nm. It was also possible to achieve high machining quality with minimal thermal damage (HAZ < 50 .m). The demonstrated cutting speed and quality meets the requirements of OLED display manufacturers.. Please see Newport.com for additional information on Flat Panel Display Manufacturing.

Figure 1. PET (left) and PI (right) polymer 75 um thick films cut with a Spectra-Physics Spirit 100 W IR fs laser. Cutting speed was > 1 m/s for PET and 650 mm/s for PI. Results show minimal HAZ.

As the flat panel display market moves from liquid crystal display (LCD) to organic light emitting diode (OLED) display technology, laser structuring and cutting of heterogeneous materials (comprised of multiple organic material films) with high quality and accuracy is needed. Within OLED technology, substrate material is changing from glass to flexible plastics to create lighter, thinner and more durable displays. See Flexible OLED Manufacturing with High 42 Power Femtosecond Laser for additional information.

Flat panel displays use different backplane technologies. Small and medium OLEDs for mobile phones use a low temperature polysilicon (LTPS) backplane which is created by laser annealing amorphous silicon (a-Si). OLED TVs use a metal oxide backplane. Both backplanes use deposited thin films which must be highly uniform and contamination free to maximize electrical performance. The OLEDs are evaporated or deposited and encapsulated to reduce degradation caused by water vapor and oxygen exposure. Encapsulation uses either strengthened glass or thin films, depending on whether the OLED is rigid or flexible. Dissimilarity of materials within the rigid and flexible stacks make cutting and singulation of individual display devices a challenge. The highly complex nature of this process can induce defects, decreasing throughput and yield.

Our industrial femtosecond and picosecond display manufacturing lasers are excellent for glass and film cutting. For cover glass and rigid OLED, they provide flexible pulse and burst control with precision, resulting in a micro-crack, chip-free edge, making the glass stronger and less likely to break if dropped. This reduces the need for post-cut polishing, increasing throughput by reducing the number of manufacturing process steps. For flexible OLEDs, Spectra-Physics lasers with short pulse widths create a minimal heat affected zone and provide a clean cut through layers of dissimilar materials including various thin films, PET, and adhesives. Increased throughput is achieved from higher output power that speeds up the cutting process. The narrow kerf or cut and the low heat affected zone means more parts can be cut out of the same material.

Our high performance optics have various coatings that are optimized for different wavelengths, enabling tight beam delivery - important for tight radius corner cuts for both glass and film cutting. Combined with our linear stages that have high, stable velocity with on-off laser synchronization, MKS is uniquely positioned to provide a variety of solutions that enable precise radius cutting at the micron level for both film and glass.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

[1] The present invention relates to a cutting method of a large size TFT-LCD panel and a liquid crystal display unit to enhance a simplicity of process facility and a speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of respective sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size. Background Art

[2] Generally, it is well known that various flat panel display units replacing a cathode ray tube (CRT) which has been used so far are developed and being distributed as many interests are concentrated on a display unit of larger size and better quality as a medium for screen image information.

[3] It is also well known that a liquid crystal display unit, one of these flat panel display units, has developed in a level equal or better than CRT in screen color tone quality aspect.

[5] Most of all as an outline, one pixel (composed of R. G. B. three sub-pixels) in the thin film transistor (TFT) - LCD is approximately as fine as 0.3 mm wide.

TFT process, a color filter (CF) process, a cell process and a module process. The cell process makes one panel with two glasses undergone the TFT process and the CF process. Then, the module process completes the manufacturing process by mounting the one TFT-LCD panel undergone the cell process in a real monitor or TV.

process in the processes of manufacturing the TFT-LCD panel is necessary in the TFT process but also a similar pattern process is necessary in the CF process.

TFT-LCD panel formed as hereinabove, the TFT-LCD panel is completed by providing a polarized plate on a surface of the TFT substrate and the CF substrate.

[11] The TFT-LCD panel of size demanded by a user may be produced in a large amount but the other TFT-LCD panel of less demand may be produced in only a limited amount since various sizes of the TFT-LCD panels completed as hereinabove require a difference in production line and in each process of the production line dependent on the sizes of the TFT-LCD panels. Disclosure of Invention Technical Problem

[13] The cutting method of a large size TFT-LCD panel of the present invention, provided to solve the hereinabove problems, has an object of enhancing a simplicity of process facility and speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of different sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size.

[14] The cutting method of a large size TFT-LCD panel formed as hereinabove can devise a simplicity in process and a profitability through solving a spatial enlargement and other costs increase due to an increase of facilities by equipping a facility"s process dependent on a size according to a production of TFT-LCD panels in various sizes, having an advantage of possibly producing a various size of the TFT-LCD panel asked by a user purpose or a user taste in a simple and convenient way, and solving an abandonment and reduction of the facilities due to a change in consumption dependent

[18] FIG. 4 illustrates a state of a scribe line set into a mid-depth of a color filter substrate and a thin film transistor substrate by diamond wheel in the cutting method of a large size TFT-LCD panel of the present invention.

[20] FIG. 6 illustrates a state completed after processing sealing a cut portion in the cutting method of a large size TFT-LCD panel of the present invention.

[21] FIG. 7 is a cross sectional view illustrating a state of a light blocking tape attached on a surface above the cut portion of the color filter substrate and the thin film transistor substrate.

[22] FIG. 8 is a cross sectional view different from FIG. 7 illustrating a state of a light blocking tape attached on outer surfaces of the polarized plate bonded above the color filter substrate and the polarized plate bonded below the thin film transistor substrate at the respective cut portions.

[27] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate below the TFT substrate, a polarized plate stripping step that removes a portion of a predetermined width to be cut from the each polarized plate provided on a surface and an opposite surface of the large size TFT-LCD panel, a cutting location setting step that sets a portion not damaging a gate line and a data line of the TFT substrate through investigating a portion stripped in the polarized plate stripping step by microscope, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning

over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth in the stripped polarized plate portion along the portion set in the cutting location setting step which precisely corresponds with the set first scribe line using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step, and

[28] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth along the portion set in the cutting line setting step which precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may accomplish the present invention object.

[29] Further, the present invention comprises a scribe line setting step that sets scribe lines simultaneously cutting the CF substrate and the TFT substrate into their mid-depths along the portions set in the cutting location setting step using a diamond wheel.

[30] The cutting method of a large size TFT-LCD panel further comprises a blocking off a light illuminated from a backlight through attaching a light blocking tape along a cut portion selected between the CF substrate and the TFT substrate or the both substrates or between the polarized plates located above the CF substrate and below the TFT substrate or the both polarized plates.

[31] Further, the present invention comprising the cutting performed by using any one among a diamond needle, laser, and a diamond wheel in the first and second scribe line setting step or in the simultaneous scribe line setting step may accomplish the

LCD panel 100 is formed in structure sequentially coupled of, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14.

[36] In order to cut the large size TFT-LCD panel 100 completed as hereinabove, a polarized plate stripping step is initially performed that removes a portion of a predetermined width to be cut from the each polarized plate 10 provided on a surface above the CF substrate 11 and an opposite surface below the TFT substrate 13.

[38] The TFT substrate 13 is exposed if the polarized plates 10 and 14 around the cutting portion are removed by its lengthwise direction. Since gate lines transferring a scanning signal and data line transferring a screen image signal are configured by innumerably crossing with each other and difficult to perceive by naked eyes, a cutting location setting step sets a portion not damaging the gate line and the data line of the TFT substrate through investigating a portion stripped on the polarized plate stripping step by microscope.

[40] 1st scribe line setting step refers to a step of cutting the CF substrate 11 into its mid- depth along the portion set in the cutting location setting step using a diamond wheel. This step is very difficult and requires a skill of high precision determined by an experience of a technician.

[43] To process a side opposite from a side where a portion of the first scribe line is set, the present step turns over the large size TFT-LCD panel 100 after chucking one end of the large size TFT-LCD panel 100.

[45] The present step sets a 2nd scribe line setting step cutting the TFT substrate 13 into its mid-depth in the portion of the stripped polarized plate 14 bonded with the TFT substrate 13 below along the portion set in the cutting location setting step which

precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100. This step is also difficult and requires a skill of high precision to correspond with the set first scribe line.

[48] A natural crack is made if tempered for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100. Then, the air flows into a liquid crystal layer 12. If there is the air flow into the liquid crystal layer 12, the liquid crystal layer 12 is temporarily restricted from flowing out by the flowed in air.

[50] After the 30 minutes tempering step, the CF substrate 11 and the TFT substrate 13 are naturally cracked along the first scribe line and the second scribe line and the present step externally applies a certain amount of force in order to cut the large size TFT-LCD panel 100 along the scribe lines.

[52] The present step is the last step that applies a sealant 30 on a cut portion in the large size TFT-LCD panel 100 and the present invention is completed by applying the sealant 30.

[53] Through undergoing the process hereinabove, the large size TFT-LCD panel 100 is possible to be cut into a plural or multiple numbers without a many numbers of equipment and to meet a desired size of a demander or an operator.

[56] That is, in a large size TFT-LCD panel 100 completed of forming sequentially coupled, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14 below the TFT substrate 13, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate 11 into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel 100 to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel 100, a scribe line setting step that sets a second scribe line cutting the TFT substrate 13 into its mid-depth along the portion set in the cutting location setting step corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100, a tempering step that tempers for

30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100, a cutting step that cuts the CF substrate 11 and the TFT 13 substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may configure the present invention.

[59] For example, after undergoing the sequentially processed cutting location setting steps of the first or the second exemplary embodiments through the polarized plate stripping step that removes a corresponding portion of a predetermined width to be cut from the polarized plates 10 and 14 provided on a surface of the CF substrate 11 and an opposite surface of the TFT substrate 13 like the first exemplary embodiment or without the polarized plate stripping step like the second exemplary embodiment, a scribe line setting step sets scribe lines simultaneously cutting the CF substrate 11 and the TFT substrate 13 into their mid-depths along the portion set in the cutting location setting step using a diamond wheel.

[61] The present exemplary embodiment may or may not include the polarized plate stripping step like the first or second exemplary embodiment, and the subsequent steps may proceed in the same sequence as tempering step for the natural crack, cutting step cutting the CF substrate 11 and the TFT substrate 13 and sealing process step .

[62] Meanwhile, when a light from the backlight unit through the TFT-LCD panel 100 processed by the respective exemplary embodiments is illuminated to display a corresponding image, the image may be displayed with an image quality relatively unclear at a portion corresponding to the cutting portion.

[63] Considering this, a light blocking tape 20 may be provided to accomplish the object of the present invention by covering a certain region including the cutting portion against the light illuminated from the back light unit and realizing a clear screen quality at the display region corresponding to the cutting portion.

[64] Here, the light blocking tape 20 may be attached in a range covering any cut portions of the CF substrate 11 and the TFT substrate 13 or the both substrates 11 and 13 as shown in FIG. 7.

10 bonded above with the CF substrate 11 or at a periphery of the polarized plate 14 bonded below with the TFT substrate 14 which are removed with the set cutting portion, may maximize a clearness of the screen quality when the light from the back light unit is illuminated on the cut portion of the TFT-LCD panel 100 completed by cutting into a desirable size.

[70] Further, FIG. 10 and FIG. 11 illustrate an application of the TFT-LCD panel according to the cutting method provided by the present invention. FIG. 10 is a brief exploded perspective view of a liquid crystal display unit. FIG. 11 is a brief cross sectional view of FIG. 10.

[71] As shown in FIG. 10 and FIG. 11, the cut processed TFT-LCD panel 100 equipped with the backlight unit (not shown in drawing) below undergoes a series of course coupling a top sash 2 corresponding to an upper frame with an accommodating frame 3 accommodating the TFT-LCD panel 100 and the backlight unit to be used for the liquid crystal display unit.

[72] Here, when the TFT-LCD panel 100 cut processed in a desired size according to the present invention is received in the top sash 2 and the accommodating frame 3, a realization of a clear screen may be difficult since a slight difference may be produced, not accurately fixing the TFT-LCD panel 100, and producing a flowing phenomena because of the internal difference.

[74] Accordingly, in order to prevent the flowing phenomena, that is the flowing phenomena of the received TFT-LCD panel 100, attaching a plurality of both-faces tape 4 at the outer peripheral edge on the top sash 2 surface and attaching a plurality of both-faces tape 4 at the outer peripheral edge on the accommodating frame 3 surface as well is preferable to completely prevent the flowing phenomena.

[76] Therefore, since a large size TFT-LCD panel may be miniaturized for an application to various video games, monitors or cell phone liquid crystal displays through cut processing the large size TFT-LCD panel without a separate manufacturing line for manufacturing process according to present invention, an industrial applicability expecting an effective reduction of manufacturing facility and its value may be recognized.

After cutting processing, if the operation is improper or the cutting equipment itself has a problem, the processed bar screen display effect will be poor.

The cutting-edge G10 production line is a result of cutting-edge technology. To consistently manufacture LCD panels using the G10 glass substrates, each individual manufacturing process incorporates a range of unique know-how. Developed in collaboration with several world-leading production equipment manufacturers, SDP"s large-scale, one-of-a-kind manufacturing equipment delivers state-of-the-art accuracy and performance levels. One example is the photolithography machine, which is about the size of a tennis court. Our master-craftsmen operate and monitor this machine with the utmost care, to manufacture next-generation products.

Mimo Monitors can create a custom-size LCD monitor to almost any specification. Whether it is a minor modification to an existing design, or by utilizing our extensive experience in the industry, we can almost always build what you need.

Aspect ratio - The ratio of the width of the display to the height. Current televisions are 16:9, Old televisions are 4:3 – 16:9, 16:10 and 4:3 are the most popular. Every other aspect ratio is less popular, but any aspect ratio can be created by resizing a panel.

Viewing Angle - This will depend on the technology of the LCD panel. TN vs. VA vs. IPS. More here (http://www.tnpanel.com/tn-vs-ips-va/) . In general, the better the viewing angle, the more expensive the resulting display. Typical are 150x140, 170x170 and 179x179. Or more commonly wide viewing angle or standard viewing angle.

Brightness or Luminance - It is the level of light emitted by an LCD display monitor. Luminance is reported in nits or cd/m2. They are actually the same thing. This matters for indoor and outdoor viewing and also if you want to draw people toward the display for advertising. Typical indoor brightness is 150 nits, indoor advertising is 300, bright indoor advertising is 700 and outdoor panels are 1000+

Touch panel - Optional human interface for interactivity. Typical choices are Display Only, Resistive (4 or 5 wire), and Capacitive touch options. Our blog discusses the advantages and disadvantages of capacitive touchscreens. SAW is another touch technology that is becoming less and less common.

![]()

As far as the current mainstream display market is concerned, common display technologies include LCD (liquid crystal display), OLED (organic light-emitting diode display), and emerging Micro LED and Mini display technologies. The application scenarios of display panels are TV, mobile phone, PC, car, smart wearable devices. Laser technology is widely used in the display panel industry.

Keyun Laser is committed to the promotion and application of laser cutting and laser repair automation equipment in the display industry; and has established cooperative relationships with many panel manufacturers.

Keyun Laser"s automatic laser cutting equipment effectively improves cutting efficiency and cutting accuracy. Laser cutting equipment is used for Cell Cut in the Cell segment of LCD panels, POL Cut, Glass Chamfer Cut, and Glass Cut in the Module segment; Cell Cut in the Cell segment of OLED panels, Shape Cut, Pad Cut, Hole Cut in the Module segment, and flexible OLED cutting and cutting. Non-right-angled shaped cutting.

Keyun Laser’s laser repair equipment adopts Keyun’s advanced Cut, Cvd, Ink, BM, and DM technologies to repair process defects such as undesirable bright spots, dark spots, and flash points generated in different manufacturing processes of the panel. Laser repair equipment is used to repair the residual or missing metal lines of the OLED panel and the LCD panel Array segment, photoresist residue, or using Cut/Cvd/Ink technology; for the defective bright spots and poor bright spots of the Cell and Module segments of the LCD panel, use BM Technology to cover and prevent light leakage repair or use DM technology for carbonization to prevent light leakage repair; dark spot or normal repair for the bright spots in the OLEDCell and Module segments; remove and replace the defective chips of Micro LED and Mini LED. Keyun laser repair equipment is suitable for the defective repair of large, medium and small display panels. The repair success rate is as high as 99.99%, effectively improving the product yield of display enterprises and reducing production costs; providing customers with comprehensive and effective solutions.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey