lcd display structure brands

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

Interface Devises Business includes Display and Senor, Sensor, and Application Solutions. As a leading company in the global semiconductor display industry, BOE has made the Chinese display industry develop from scratch to maturity and prosperity. Now, more than one-quarter of the global display panels are made by BOE, with its UHD, flexible display, microdisplay, and other solutions broadly applied to well-known worldwide brands.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

LG Display now operates back-end assembly plants in South Korea, China, and Vietnam. In addition, LG Display operates a sales subsidiary with a global network to effectively serve overseas markets.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Toshiba is a famous multinational company with a history of 130 years. It covers a wide range of businesses, including social infrastructure construction, home appliances, digital products, and electronic components. It covers almost every aspect of production and life. Toshiba has the largest research and development institution in Japan. Through unremitting innovation and development, Toshiba has been at the forefront of science and technology in the world.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

... glands. All versions have a smooth, seamless display surface for perfect cleanability. Its IP69K protection makes the new monitor also suited for washdown applications like high-pressure cleaning.

... and dusty conditions. Plus, the protective glass serves to protect the display against sharp foreign objects, meaning the screen is still operable even with scratches on the surface.

... with a complete digital advertising solution. The wall-mounted outdoor display combines a high-bright screen with a weatherproof body. The 1,500 NITS screen captures attention, and auto-dimming keeps ...

... engaging digital signage in any weather. The high-brightness LCD screen keeps your content clear in direct sunlight, for maximum customer engagement. An IP54/NEMA 4 enclosure protects the screen ...

... turn-key system solutions in a stainless steel enclosure as wall, floor or ceiling mounting versions. The screen of the POLARIS Remote 15"" is a TFT display with an XGA resolution (1024 x 768 pixels) ...

... the main display for applications requiring a small screen. End-cap shelf displays in retail settings or as personal gaming screens as part of a larger interactive gaming table benefit from the features and design of ...

The HANNspree HO105HTB 10.1’’ Open-Frame monitor delivers a high-performance display solution. Its rugged bezel with edge-to-edge glass makes it very suitable for applications like tabletop integration. The HANNspree ...

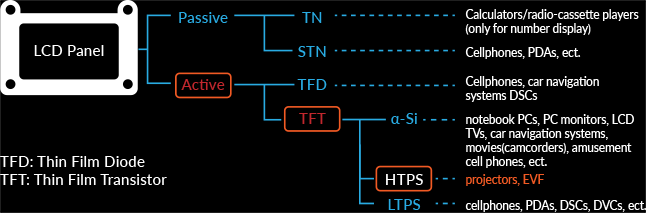

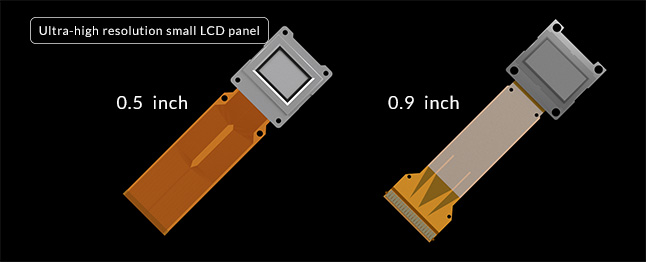

HTPS is an abbreviation of High Temperature Poly-Silicon, an active matrix transmissive LCD. It"s superior in that it is smaller, has higher resolution and higher contrast, and can embed drivers. The main function of HTPS is as a light valve for projectors.

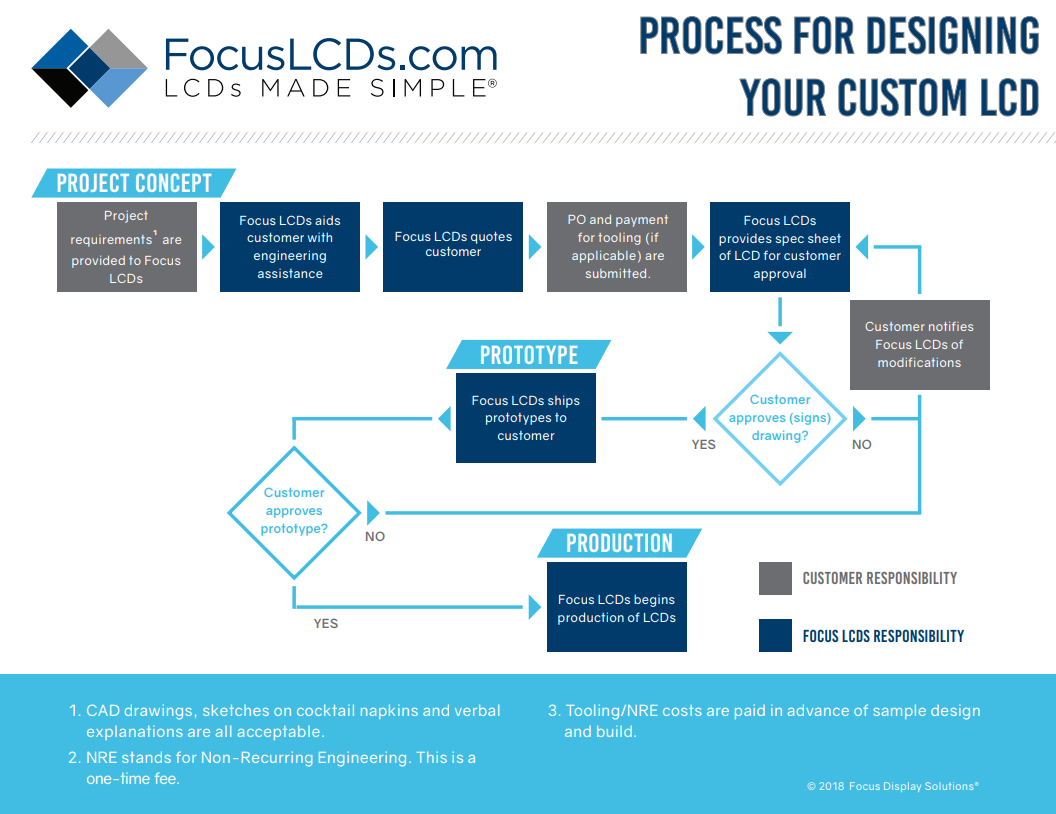

One of the advantages of designing a custom display is the ability to reduce your LCD display’s thickness by selecting a thin ITO glass; which is key to a thin LCD module.

Additional advantages to customizing segment displays include reduced unit cost, small tooling NRE (Non-recurring engineering) investment and low power consumption.

Other display technologies provided by Focus Display Solutions are… Thin Film Transistor ( TFTs), Vacuum Fluorescent Displays (VFDs) and Light Emitting Diodes (LEDs) do not use any type of fluid.

The structure of the LCD is very basic, but a special glass called ITO glass is used in constructing the display. Three sides of the ITO glass are glued together with an adhesive or epoxy. Both the ITO glass and the nematic fluid used are transparent. There is a small gap of one or two millimeters between the top and bottom layer of glass. A nematic fluid is then injected between the layers. Finally, a cap is placed on the fourth side to keep the fluid from leaking out.

A polarizer is applied on both the top and bottom layer of glass. The polarizer on the top layer is always Transmissive, whereas the bottom layer can be Reflective, Transflective or Transmissive. For more details on the different types of polarizers, please read our article: LCD Polarizers.

Indium Tin Oxide (ITO), also referred to as tin-doped indium oxide, is a standard piece of transparent glass with a conductive film applied to the surface. The job of the conductive film is to control the behavior of the nematic fluid when energized by an electrical field. ITO glass is used on all segment, character and monochrome graphic displays.

ITO glass can be cut to custom dimensions, but smaller sized glass can add a significant cost increase to the overall cost of the LCD. The reason for the increased cost is the amount of labor and time required to add a polarizer to the small piece of glass.

Many times customers require the display to be as thin as possible; one method to achieve a thin LCD module is to select a thinner ITO glass. Keep in mind that the thinner the glass, the more expensive and the higher the fallout rate.

Note:Fallout rate does not mean failures of the LCD’s in the field; fallout is when the display fails on the manufacturing line. If the display fails in production, it is discarded before it is shipped to the customer.Once the display passes QA (Quality Assurance) it will operate normally for the life of the product.

Note: The top piece of glass is smaller than the bottom piece of glass allowing for pin placement. This same design is also used for displays that use zebra or elastomeric contacts.

It is possible to add a backlight to the monochrome display to make the display readable in low or no light conditions. The challenge of adding a LED backlight is that it increases the thickness of the LCD by as much as 5mm to 9mm.

In the photo above, a segmented LCD is combined with a LED backlight and backlight diffuser. A printed circuit board (PCB) is used to hold the assembly together. As the backlights name suggests, a light is placed behind the bottom layer of ITO glass.

Note: A backlight diffuser’s job function is similar to the lamp shade used on a table lamp. It disperses the light from each led to provide a more uniform appearance. Without the diffuser, there would be hot and cold spots on the display. A hot spot is where the backlight is too close to the LCD glass and it is overly bright; the area around the hot spot is dimmer and is referred to as a ‘cold spot’.

If the backlight needs to be brighter while keeping an even flow of light, it is possible to use multiple LEDs evenly spaced below the back of the display to avoid hot spots.

There are four methods to reduce the thickness of the LCD display/backlight combination; thereby creating a thin LCD module. However, these solutions do not apply to TFTs, VFDs, LEDs or OLEDs (Organic Light Emitting Diodes).

In the integration the backlight is sandwiched between the LCD and PCB. The LCD’s leads (pins) are then soldered to the PCB securely holding the backlight in place. This helps to create a thin LCD module.

Advantages of a PCB mounted LED backlight:The PCB combines the backlight and the LCD; this is great in applications that operating in environments of heavy vibration.

Another way to combine the LCD and the LED backlight is to use either a plastic clip to bind them together, or to use an epoxy or adhesive. There are advantages and disadvantages to both, but we suggest the plastic clip solution.

This method requires a one-time tooling fee to design and prototype a small, flexible plastic clip that holds the backlight and display together. The clip only adds a few pennies to the overall cost of the LCD combination.

This method is accomplished without any tooling cost and only adds a penny or two to the overall cost of the LCD assembly, but we do not recommend this approach.

An edge-lit display means that the LEDs are not placed behind the bottom layer of glass, but along the edge between the two layers of glass. This alone helps to create a thin LCD module.

Disadvantages to an Edge-lit display:One of the Challenges of this solution is that it increases the size of the overall display in the X and Y directions (Length and Width). Which means the sides of backlight will stick out beyond the LCD.

Side-lit displays work well for smaller size LCDs, but create hot spots around the edges if the display is too large. This is more evident with a white LED edge-lit; since white LEDs are much brighter than other colors and sometimes need to be dimmed to reduce their starkness.

EL backlights are AC (Alternating Current) driven, this requires an inverter either on the LCD or on the customers’ board. Inverters add extra cost and labor.

LEDs are DC (Direct Current) driven and do not require an inverter. Many times the voltage for the LED backlight is the same as for the LCD which means one less power supply is required.

Liquid crystal refers to the intermediate status of a substance between solid (crystal) and liquid. When crystals with a high level of order in molecular sequence are melted, they generally turn liquid, which has fluidity but no such order at all. However, thin bar-shaped organic molecules, when they are melted, keep their order in a molecular direction although they lose it in molecular positions. In the state in which molecules are in a uniform direction, they also have refractive indices, dielectric constants and other physical characteristics similar to those of crystals, depending on their direction, even though they are liquid. This is why they are called liquid crystal. The diagram below shows the structure of 5CB (4-pentyl-4’-Cyanobiphenyl) as an example of liquid crystal molecules.

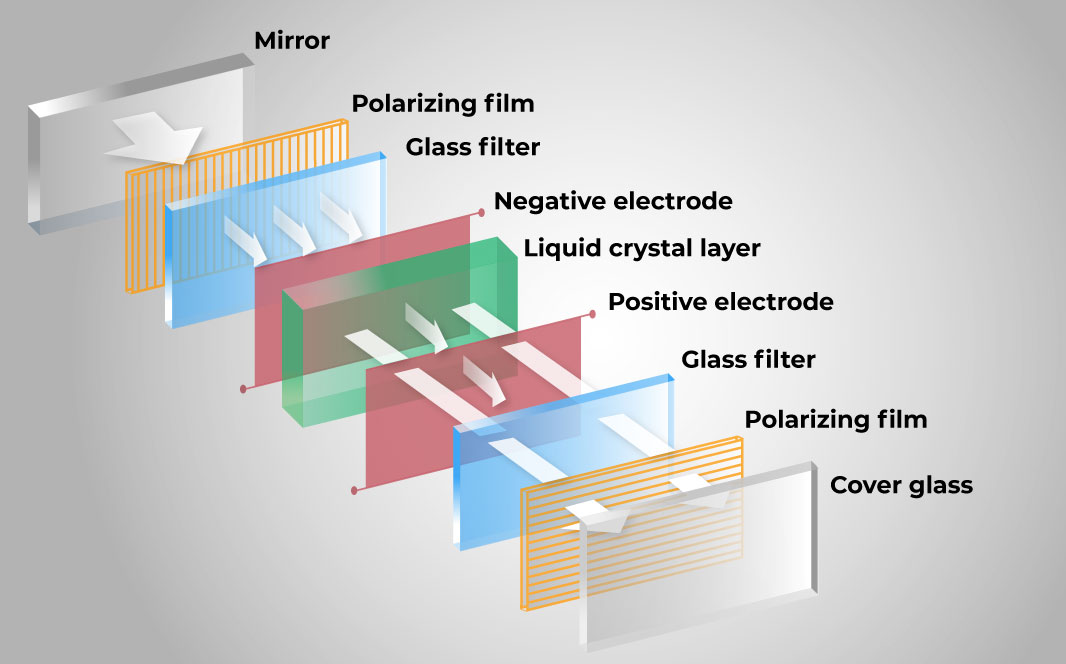

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

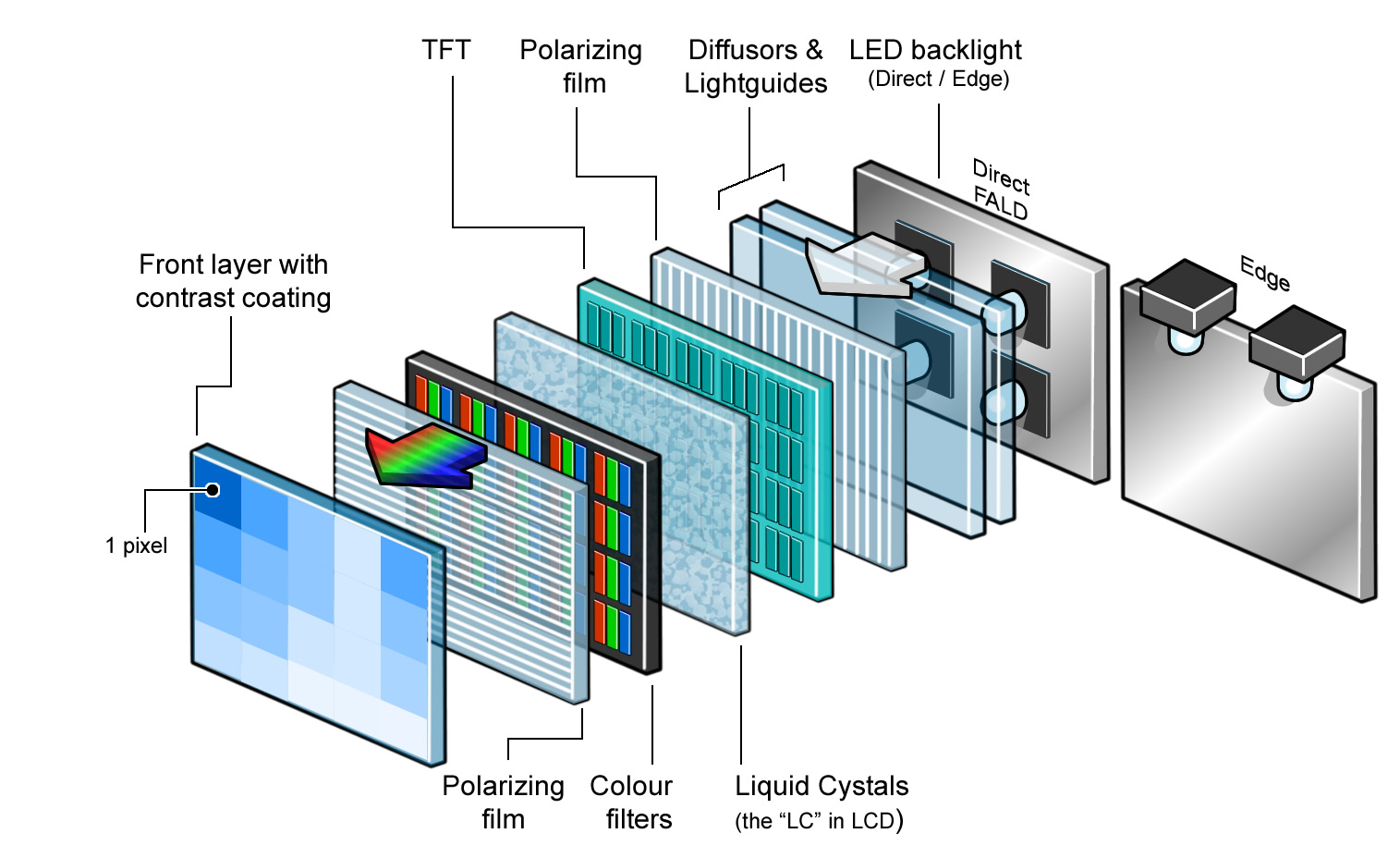

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

Through improvements in LCD parts and materials, monitor weight has been reduced over earlier models, making it easier to transport and install the display.

Heavy-duty carrying handles are included with each monitor to ensure safe handling. These handles may be detached when the display is installed. All models additionally incorporate a VESA-compliant mounting hole configuration to help ensure a safe and secure installation with compatible third-party mounting hardware.

A cholesteric liquid crystal display (ChLCD) is a display containing a liquid crystal with a helical structure and which is therefore chiral. Cholesteric liquid crystals are also known as chiral nematic liquid crystals.

KDI has world class manufacturing expertise in roll to roll manufacturing of liquid crystal films, face shield lenses, and other functional flexible materials in including the award winning flexible Boogie Board eWriter LCD films.

Liquid Crystal Display or LCD is a flat, electronic device generally used as a screen in televisions, computers, smartphones and display signs for producing still and movable images.

As the name goes, LCD is composed of liquid crystal particles. Liquid crystals generally do not emit light on their own rather they are illuminated by a fluorescent backlight.

Since liquid crystals do not produce light of their own, they need an external light source to work. An LCD panel has sets of polarised glass consisting of liquid crystal materials in between them. When the external light passes through one of the polarised glasses and electric current is applied on the liquid crystal molecules, they align themselves in such a way that polarised light travels from the first layer to the second polarised glass, causing an image to appear on the screen.

Here the LCD has a backlight, which passes through the LCD polarised glass to produce visible pattern. But because it uses backlight for working, the images displayed in such LCD types appear very dim when used under bright sunlight.

This LCD type has a reflective mirror layer and a backlight. It uses both outside light and backlight, making it suitable for indoor and outdoor conditions.

LCDs or Liquid Crystal Displays are flat, thin and lightweight, making them more usable and user friendly compared to CRTs. It uses liquid crystals and layers of polarised glass to produce images while consuming less power than CRT.

OLEDs or Organic Light Emitting Displays use a single glass with plastic panel and need no external light to work. Every pixel of this display is an LED light and an image is formed by controlling each of these LEDs. It is much thinner and lighter but expensive as compared to an Liquid Crystal Displays.

QLEDs or Quantum Light Emitting Displays are an advanced form of OLEDs in which nanometre size light particles known as quantum dots produce different colours of light that form an image. The technology helps in creating richer and stunning picture quality.

![]()

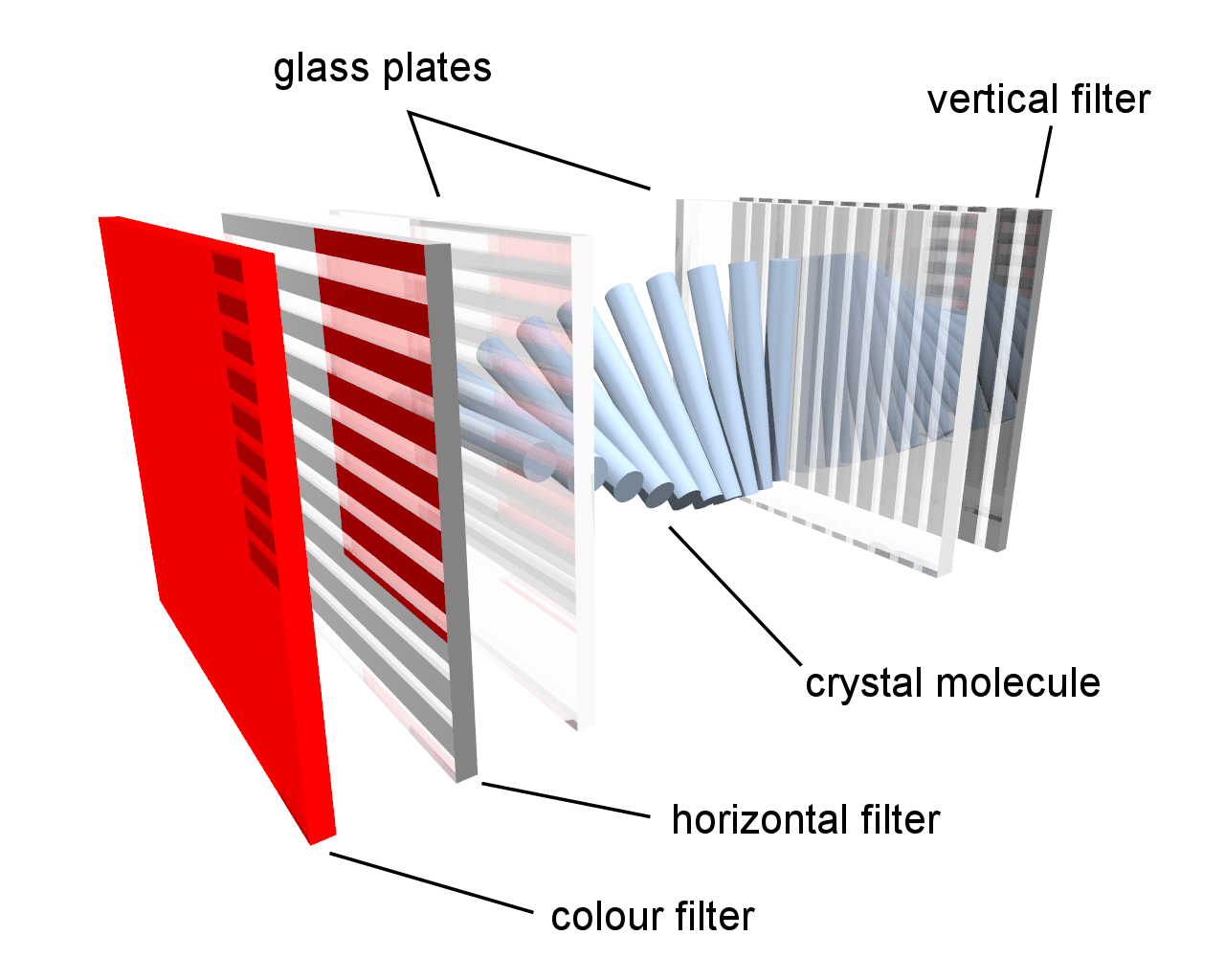

In order to express images colorfully, it is necessary to adjust the amount of light transmitted through the color filter. Here, the polarization of light becomes very important. LCDs possess several functions to adjust the polarization of light and are able to change the amount of light that is transmitted at will, therefore capable of expressing colorful images.

A polarizer is a plate that can polarize light. It is shaped like a fence and is equipped at both sides of a display just like the bread in a sandwich. The lights we usually see in nature are actually electromagnetic waves that are vibrating in many directions. In other words, the light is “unpolarized.” When unpolarized light is passed through a polarizer, only the light vibrating in a specific direction is able to get through. For example, when a polarizer is placed horizontally, only the waves of light that is vibrating in a horizontal direction are transmitted.

We can control the amount of light that is transmitted by combining two polarizers. For example, by putting the first polarizer horizontally and the second polarizer vertically (tilted 90 degrees), the light which passes the first polarizer is vibrating only horizontally, so it cannot pass the second polarizer. As a result, black is displayed on the screen. This way, we can adjust the brightness of the screen by changing the angle of the two polarizers.

However, in an actual LCD, the angles of the polarizers are fixed and cannot be rotated. So we need to adjust the polarization of light by controlling the liquid crystal layer located in the middle of the display.

First, the two polarizers set at both sides of the display will be set orthogonally (tilted 90 degrees to one another). With just this, the light emitted from the backlight (light source) cannot pass through the display. Therefore the alignment layer is used to change the polarization of the light. Two alignment layers attached on both sides of the liquid crystal layer are set orthogonally just like the polarizers. Here, the liquid crystal molecules between the alignment layers are arranged in a characteristic manner. The molecules near the first alignment layer are arranged in the same direction as the alignment layers furrows, but as the molecules become closer to the second alignment layer, they gradually tilt to match the direction of the furrows in the second alignment layer, forming a 90 degree helical formation between the two layers. As a result, the vibration of the wave of light passing through the liquid crystal layer is also twisted 90 degrees so it can pass through the second polarizer.

So far, all the LCD did was transmit light, but as we explained earlier, the role of the liquid crystal layer is to act as a “shutter” to control whether light is transmitted or not. Here, the crucial factor is the control of liquid crystal molecules by applying voltage. Since liquid crystal molecules line up parallel to the direction of an electric current, when voltage is applied to the liquid crystal molecules, the helical structure induced by the alignment layers dissolve and light cannot pass through the second polarizer. Therefore, when you want light to be transmitted, you just have to turn the voltage off and when you want light to be blocked, you only need to turn the voltage on. This way it is possible to express light and dark on the screen. Moreover, as we can adjust the helical formation of the molecules by adjusting the voltage, it is also possible to control the contrast density in each subpixel.

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

As Figure 6 depicts, there are two types of surface reflections. The first one is from a direct light source, i.e., the sun or a light bulb, denoted as A1. Its reflection is fairly specular, and in practice, we can avoid this reflection (i.e., strong glare from direct sun) by simply adjusting the display position or viewing direction. However, the second reflection, denoted as A2, is quite difficult to avoid. It comes from an extended background light source, such as a clear sky or scattered ceiling light. In our analysis, we mainly focus on the second reflection (A2).

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

To further enhance the lifetime of the blue OLED, the NTU group has developed new ETL and TTF-EML materials together with an optimized layer structure and double EML structureFigure 10a shows the luminance decay curves of such a blue OLED under different initial luminance values (5000, 10 000, and 15 000 nits). From Figure 10b, the estimated T50 at 1000 nits of this blue OLED is ~56 000 h (~6–7 years)

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

Flexible displays have a long history and have been attempted by many companies, but this technology has only recently begun to see commercial implementations for consumer electronics

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey