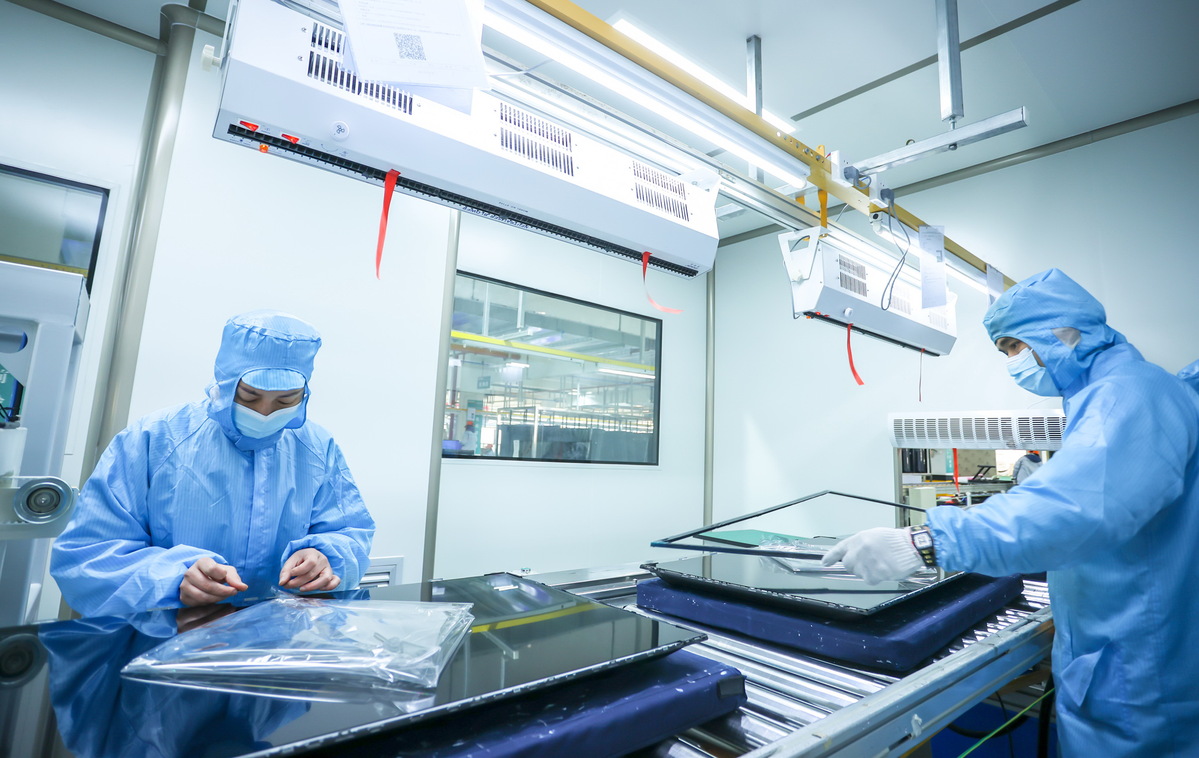

flexible display screens ready for mass production made in china

According to BOE officials, the 6th generation AMOLED (flexible) production line project in Chongqing has now officially commenced mass production. The company announced this at a mass production and customer delivery ceremony. BOE spent 46.5 billion yuan ($7.3 billion) to build this production line. At present, BOE has deployed 6 key projects in Chongqing, including the 6th generation AMOLED (flexible) production line. It also has the 8.5th generation TFT-LCD production line, and the BOE Chongqing Smart System Innovation Center. These production lines have a cumulative investment of over 86 billion yuan ($13.5 billion).

The mass production of the 6th generation AMOLED (flexible) production line in Chongqing is in Chongqing Liangjiang New District, covering an area of approximately 970,000 square meters. At the mass production ceremony, BOE President, Liu Xiaodong said that in the current information and digital age, new application markets such as smart mobile terminals, smart wearable devices, and smart connected cars are showing explosive growth trends. This is increasing the demand for high-end display technologies such as flexible displays.

This new production line is of great significance for enhancing BOE’s comprehensive strength in the global semiconductor display industry. It is accelerating the growth of the new terminal application market. Furthermore, this production line will promote the innovation and development of the global display industry.

Since 2021, BOE has continued to make breakthroughs in the flexible display market. It has also worked with many popular manufacturers like Huawei, Oppo, Honor, iQOO, and others. The new generation streamer four-curved screens of the Honor 60 Pro just released not long ago also come from BOE.

In the field of flexible display, BOE has deep technical accumulation. Its unique high-end flexible OLED technology solutions have outstanding advantages. Some of its display advantages include brilliant colors, variable shapes, and high functional integration.

The three-fold OLED product independently developed by BOE can achieve a zigzag folding form. Compared with ordinary folding products, it can switch from mobile phone to tablet by adding one folding operation. The display area is larger and the picture quality is excellent, which represents flexibility. This is the latest technological achievements in the field.

In addition, it has also continuously launched industry-leading flexible scrolling screens with up to 200,000 dynamic scrolling times, and 360° internal and external bidirectional folding screens, which greatly breaks the innovative application space of flexible displays. According to data from Sigmaintell, BOE’s flexible display shipments rank first in the Chinese industry and second in the world.

Korean media outlet Thelecreported on Monday that BOE, a Chinese electronic components firm, has recently converted the layout of its B12 OLED panel factory so that it can manufacture panels for IT products and automobiles, besides just smartphones. Rivals Samsung Display and LG Display are also at leading stages in the IT OLED panel technology field.

The phase three production line at the B12 facility in Chongqing, China will be able to manufacture OLED panels for smartphones, IT and automobiles. Phase three was initially designed to handle Gen 6 (1500x1850mm) flexible OLED panels for smartphones, as in phases one and two. The change of plan hints that BOE is likely aiming to supply OLED panels for Apple’s IT products, from tablets to PCs. The Chinese display giant has designed phase three of the B12 facility so that it can manufacture OLED panels of up to 15 inches in size, sources said.

BOE’s B12 factory started phase one operations last year during the fourth quarter; the second phase is expected to commence during the first half of this year. Equipment for phase three will enter installation in April.

On December 28, 2021, BOE’s official WeChat account showed that the company’s sixth-generation AMOLED (flexible) production line project in the southwestern city of Chongqing has now begun mass production.

This project further expands BOE’s flexible display technology reserves and production capacity and will round out the company’s link of flexible display production lines in Chengdu and Mianyang, two cities in nearby Sichuan Province.

At present, BOE has deployed six key projects in Chongqing, including the sixth-generation AMOLED (flexible) production line. It also has the 8.5-generation TFT-LCD production line, and the BOE Chongqing Smart System Innovation Center. These production lines have cumulative investment of over 86 billion yuan ($13.5 billion).

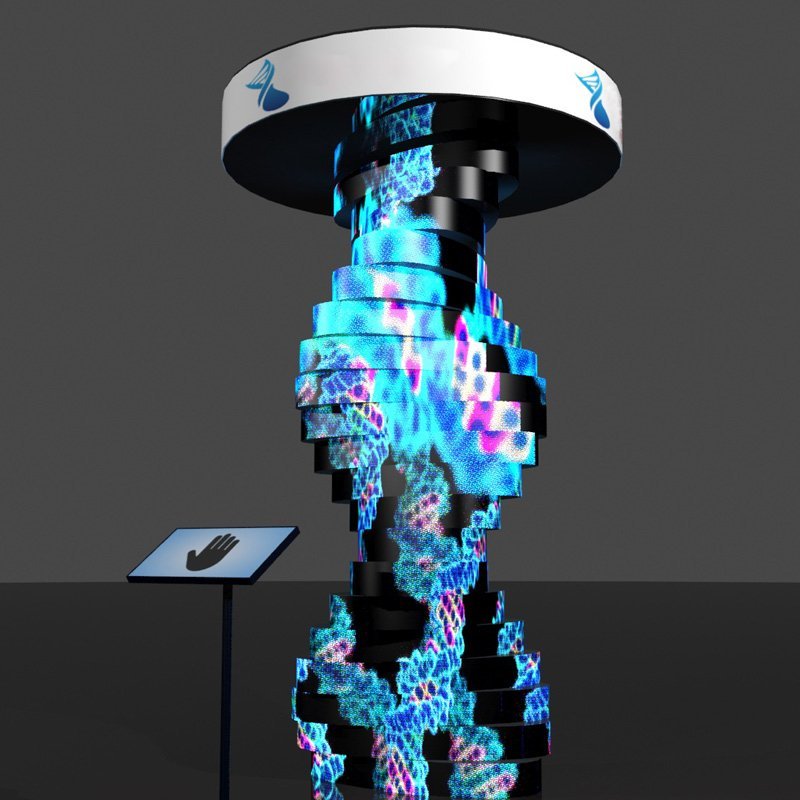

Founded by a Stanford PhD graduate, Royole has designed and is starting to mass-produce a super-thin flexible screen that could be used in everything from t-shirts to portable speakers.

It"s the stuff of science fiction, and plenty of tech trade shows — a screen so thin and flexible that it can be rolled up into a cylinder as small as a cigarette or hung on a wall like wallpaper.

Royole just opened a new factory in China that is already mass producing the displays, and the company is working with partners to get them installed in everything from t-shirts to automobiles to smartphones.

Royole"s screens are based on OLED technology, in which the lighting elements are built into the display itself. Unlike the OLED screens that are in some higher-end televisions, which are typically placed on a rigid base like glass, the lighting elements in Royole"s screens are placed on a flexible plastic base, so they can bend or roll up.

"The cool thing here is that we"re not limited by the form factor of the surface," said Liu, who founded Royole with some friends from Stanford after graduating from there with a PhD in electrical engineering. "They could be anywhere."

Royole, which was founded in 2012 and has raised $1.1 billion in funding, just brought its new factory online in June. The plant will be able to produce up to 50 million panels a year once it"s at full capacity, Liu said. That could help it feed a potentially burgeoning market for bendable gadgets.

Researchers have been trying to develop flexible screen technology since at least the early 1970s — first in the form of monochrome displays that were intended to replace printed pages, and then, much later, in the form of color ones that might replace the screens in TV or portable devices.

For much of the last decade, display makers including Samsung and LG have been showing off their flexible OLED screens and prototype of products made with them at trade shows.

Samsung"s Galaxy Round, a relatively obscure smartphone that came out that year, was one of the first gadgets that used a flexible screen way back in 2013. Because the display was placed behind a fixed plate of glass, so you couldn"t really tell that it was bendable. The only clue was that the front of the phone was concave.

Other smartphones since the Galaxy Round have also employed flexible displays, including the LG G Flex and the Edge versions of the Samsung Galaxy S and Galaxy Note lines. More recently, the screens have started to make their way into even mainstream devices. Apple"s iPhone X, for example, has a flexible display behind its famously notched screen.

They were "a disappointing application of what that the technology could do," said Raymond Soneira, CEO of DisplayMate, a consulting firm for the display and TV industries.

Neither businesses nor consumers were ready for bendable or foldable gadgets when the first flexible displays started rolling off production lines five years ago, analysts said. Electronics makers generally hadn"t set up their supply chains to accommodate them or figured out how they might be able to take advantage of the screens" properties in new products. Apps hadn"t been written specifically for devices with bendable screens. And nobody had laid the groundwork for new kinds of flexible gadgets by marketing them to consumers.

Things may be different now. Next year, Samsung will reportedly introduce a phone with a foldable screen that"s built around its flexible display technology. Apple reportedly has a foldable phone in the works, too.

"You can"t make [phones] much bigger … and have them be carried by most consumers," Soneira said. "So you"ve got to move up to foldable, even rollable screens."

The release of foldable screen phones and other gadgets from major manufacturers will likely spur developers to start making apps designed specifically around those features. It"s also likely to inspire demand for other devices that take advantage of the properties of bendable screens.

Flexible screens will likely get their start by replacing other screens in devices we already recognize, including not just smartphones, but computer monitors and laptop computers, allowing manufacturers to make models that are slightly more innovative or resilient, said Ryan Martin, a principal analyst at ABI Research. But eventually, manufacturers are likely to get a lot more creative with them.

A flexible display "changes the realm of design as well as design thinking," Martin said. "You"re no longer confined to the four corners of a screen. You can make things more abstract."

At CES, the giant electronics trade show held in Las Vegas every January, LG has shown off a prototype for a car dashboard in which the speedometer, tachometer and other other gauges and buttons are displayed virtually on flexible screens that could be shaped to the contours of a car"s interior.

Although the company is going up against some of the biggest electronics companies around in LG and Samsung, Royole"s got several advantages, Liu said. Its displays are built on its own proprietary technology for which it has filed numerous patents, he said. That technology allows it to build screens that are a tenth as thick as those of competitors.

What"s more, because it"s using a different methodology for building its screens, it was able to get its factory up and running for about $1 billion, which is far less than what it would cost its competitors, he said.

The first devices with Royole"s screens should start showing up later this year. The company plans to sell T-shirts and hats with its flexible displays built in. Soon thereafter, it expects marketers to start using its screens to display advertisements in elevators, airports, shopping malls, and other places.

From there, the screens should start making its way into other products, both traditional and new, Liu said. When purchased in volume, they should be competitive in price to other types of displays, he said.

Smartphone makers are pushing harder to expand their presence in foldable screens that could be used either as tablets or as pocket-sized phones in a bid to revive a market mired in an innovation lull and sales slump amid a global pandemic.

Neil Mawston, executive director at Strategy Analytics, said foldables pack a big screen into a small design, allowing users to surf rich content like video on larger displays, and then fold the device away neatly into a pocket or bag.

A string of manufacturers recently accelerated efforts to roll out foldable smartphones in a bid to grab a slice of the foldables pie in the world"s largest mobile phone market. South Korea-based Samsung Electronics Co Ltd unveiled the Galaxy Z Fold 2 5G, its latest foldable smartphone, in China last month.

Priced 16,999 yuan ($2,483), the gadget serves as a 7.6-inch tablet when fully opened. It transforms into a phone when folded, with a 6.2-inch display that fits snugly in one"s palm.

Choi Seungsik, president of Samsung Electronics China, said the smartphone boasts the most innovative foldable screen among the company"s offerings, and provides an immersive watching and gaming experience for consumers.

Priced at 12,499 yuan, the Razr is equipped with a 2.7-inch quick-view touchscreen display on the front, and a 6.2-inch organic light-emitting diode, or OLED, foldable display on the inside of the phone.

Meanwhile, Royole Corp, a Shenzhen-based startup developing flexible screens, launched its second-generation bendable phone last month. Priced at 9,988 yuan, the FlexPai 2 is the first 5G flexible phone to cost less than 10,000 yuan.

Wu Shuyuan, an analyst at Beijing-based market research firm Sigmaintell, said sales of foldable devices would be hampered by the supply chain, high costs and hinges-a mechanical design that allows the flexible panel to fold and unfold-thereby restricting them to a niche market position.

"Consumers need to spend more to buy foldable smartphones that have the same technical configurations compared with other handsets," said Jia Mo, an analyst at Canalys, a market research company. That is because foldables have low display yields and higher design costs as of now.

Worldwide smartphone shipments decreased by 16 percent on a yearly basis in the second quarter, according to market consultancy IDC. Huawei became the biggest smartphone player in the world in the second quarter for the first time.

With the arrival of foldable smartphones, demand for displays that use AMOLED technology is also surging. AMOLED displays are more flexible with faster response times, higher contrast ratios and wider visual angles compared to traditional liquid crystal display panels.

Domestic display panel suppliers such as BOE Technology Group Co Ltd, Visionox Technology Inc and China Star Optoelectronics Technology Co Ltd are doubling down on flexible screens used in smartphones and scaling up their production capacities in this segment.

"AMOLED technology is the future trend for smartphone panels," said Zhang Yu, vice-president of BOE. "At the moment, technological upgrades of display panels on smartphones concentrate on appearance, function and image quality."

BOE has three sixth-generation AMOLED production lines. It started mass production of flexible panels from its facility in Chengdu, Sichuan province, in October 2017. The panels have already been used by more than 10 smartphone manufacturers.

The company"s second line in Mianyang, Sichuan province, started mass production in July 2019, while work on a third facility commenced in Chongqing last year.

Xu Fengying, vice-president of Visionox, said the company has provided AMOLED technology for smartphone maker Xiaomi Corp"s under-screen camera since June 2019. Xiaomi"s prototype foldable phone also used an OLED display panel from Visionox.

The company"s AMOLED display screen production line in Gu"an, Hebei province, began operations in May 2018. It can turn out 30,000 glass substrates (1,500 mm by 1,850 mm) every month, and meet highend, foldable screen demand for 90 million smartphones.

CSOT announced its sixth-generation flexible AMOLED display panel production line in Wuhan, Hubei province, and achieved mass production on Jan 1. The company will make 48,000 modules each month.

According to research firm Omdia, the market for AMOLED smartphone displays is expected to expand by 9 percent this year despite the overall negative impact of COVID-19 on handset sales.

Global shipments of flexible AMOLED panels used in smartphones are set to soar to 513 million units this year, up from 471 million units last year, suggesting the product"s penetration is deepening rapidly, Omdia said.

Chinese smartphone makers are expected to increase the number of high-end smartphones integrating AMOLED panels this year, said Brian Huh, principal analyst of small and medium-sized displays at Omdia.

Li Yaqin, president of Sigmaintell, said demand for flexible OLED panels used in foldable smartphones is expected to surge 140 percent this year, buoyed by the commercial application of superfast 5G technology.

Visitors look at Visionox"s organic light-emitting diode or OLED foldable display at the China International OLED Industry Conference 2020 held in Guangzhou, Guangdong province, in October. WU WEIHONG/FOR CHINA DAILY

A customer tries out Galaxy Z Flip 5G, a foldable smartphone, at a Samsung store in Hangzhou, Zhejiang province, in September. LONG WEI/FOR CHINA DAILY

China’s first self-developed 8.5 generation TFT-LCD panel, or thin-film transistor liquid crystal display panel, rolled off the production line Wednesday in Bengbu, east China’s Anhui Province, paving the way for mass production.

TFT-LCD is a key strategic material of the electronic information display industry. An 8.5 generation TFT-LCD panel, with a length of 2.5 meters and width of 2.2 meters, can produce six screens of 55 inches, according to its manufacturer, the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group Co., Ltd.

China’s optoelectronic display industry has developed rapidly in recent years and the country has become the world’s largest manufacturing base for display terminals. Many Chinese TV panel manufacturers have established a number of 8.5 generation TFT-LCD production lines.

China’s annual demand for 8.5 generation TFT-LCD or above has reached 380 million square meters. The mass production of the self-developed TFT-LCD screens will end the country’s complete dependence on other countries for the technology and products, said its manufacturer. Xinhuanet

BOE, the biggest display manufacturer in China, is preparing to supply its OLED displays for Samsung Electronics’ smartphones for the first time. Particularly, the company’s OLEDs will be “flexible OLEDs” that are one of major products of South Korean display manufacturers. BOE’s supply of OLED displays is expected to have a significant impact on South Korea’s display industry as the industry is seeing a rapid growth of China’s display industry and as Samsung Electronics has chosen OLED panels from BOE that is the biggest competitor to South Korea’s display industry.

According to the industry on March 21, it is reported that Samsung Electronics plans to use BOE’s flexible OLEDs for part of the Galaxy M series models that are expected to be released in the second half this year.

It is almost certain that Samsung Electronics will use BOE’s flexible OLEDs as the specific standard has been set for displays that will be used for the models and Samsung Electronics also selected relevant components such as driver IC and touch IC. Schedule for production has also been set for July.

Flexible OLED indicates an OLED that is based on a flexible substrate. Instead of a rigid glass substrate, it uses a plastic material (polyimide) which allows the display to be bent. Flexible OLED is categorized as a premium product. Due to its light weight, thinness, and degree of freedom in design, it can be used for edge smartphones that have the edges bent or foldable smartphones that can have the screens folded and unfolded.

South Korean display manufacturers have been the leaders in flexible OLED. Samsung Display became the first in the industry to develop flexible OLED and commercialized it for the first time through Samsung Electronics’ smartphone “Galaxy Round” in 2013. LG Display also succeeded in mass-production of flexible OLEDs in 2017 which allowed the company and Samsung Display to be the leaders in the global market for small and medium-sized OLEDs.

Although BOE also entered the flexible OLED market, it has yet to succeed in making its brand known. As flexible OLED requires advanced techniques, the company had faced issues such as yield and quality despite making aggressive investments. BOE started to run its OLED business through Huawei. Its strategy was to gain competitive edge in its OLED business by working with other Chinese companies.

However, BOE faced another setback when the U.S. government imposed sanctions on Huawei. BOE needed an alternative and it turned to Samsung Electronics to find a breakthrough. Because Samsung Electronics is the world’s biggest smartphone manufacturer, it is the biggest customer for display manufacturers.

Supply of flexible OLEDs by BOE to Samsung Electronics is expected to have a huge impact on South Korea’s display industry. Although BOE’s OLEDs will be limited to few models of the M series, which is an economic smartphone series, BOE has now secured Samsung Electronics as its customer by supplying OLEDs. Also, because Samsung Electronics accepting BOE’s products indicates that BOE’s technical skills, quality, and price meet Samsung Electronics’ level, there is a great chance that there will be more transactions between the two companies in the future. There is also a chance that Samsung Electronics will expand its cooperation with BOE in order to secure competitive edge for its products’ prices.

All these possibilities are warning signs for South Korea’s display industry because Samsung Display has been the sole supplier of flexible OLEDs for Samsung Electronics. Samsung Electronics now has to compete with BOE to secure more orders from Samsung Electronics. Although Samsung Display’s technical skills, quality, and mass-production capability are all ahead of BOE, Samsung Display is concerned about a possible reduction in its profitability as it will be involved in a price war with BOE that is backed by the Chinese government.

While LG Display is not directly affected by this as it does not have any transaction with Samsung Electronics, it will have to compete against BOE once BOE improves its competitive edge in its OLED business based on its transaction with Samsung Electronics in order to secure other smartphone manufacturers such as Apple, OPPO, VIVO, and Xiaomi. BOE currently stands ahead of LG Display when it comes to flexible OLED production capacity and shipments.

“It is reported that BOE suggested a shocking offer to Samsung Electronics in order to secure an order from Samsung Electronics.” said one official from the industry. “There is a good chance that there will be more transactions between the two companies in the future.” In fact, BOE tried to supply its flexible OLED panels for Samsung Electronics’ Galaxy S series.

Regarding BOE’s supply of flexible OLEDs, Samsung Electronics said that it cannot confirm any information related to its future products and supply of parts.

China"s BOE introduced the world"s largest 8K organic light emitting diode (OLED) panel for the first time. China Star Optoelectronics Technology (CSOT), a subsidiary of TCL, also developed a 60-inch large OLED panel for the first time. China"s attacks has begun to break down the strongholds of LG and Samsung, the only companies in the world that mass-produced large OLEDs. In order not to follow in the footsteps of liquid crystal display (LCD) train that allowed China to take the leading spot, government-level support for the display industry is desperately needed.

At the Society for Information Display (SID) 2022 held in San Jose, California, U.S. for three days from the 10th (local time), Chinese display companies poured out a many new next-generation display technologies such as large OLEDs and micro LEDs.

An official at BOE said, "We have not yet ironed out a specific plan for large-scale OLED mass production, but at any time we may prepare for mass production."

CSOT also unveiled a large OLED panel. CSOT introduced a 65-inch 8K OLED panel for the first time. This product was manufactured using inkjet printing process technology. It is a method of printing OLED light emitting material on a substrate like an inkjet printer. CSOT also exhibited a large number of small and medium-sized low-temperature polycrystalline oxide (LTPO) OLED panels for mobile use. It is a stepping stone aimed at entering Apple"s iPhone supply chain.

Experts analyzed that China, which has become the world"s leader in display, is catching up quickly in the large OLED market thanks to aggressive investment and astronomical government support. The Chinese government is providing full support to display companies, including free land support, subsidies for manufacturing facilities, and corporate tax reductions. China is planning to mass-produce large-scale OLEDs from China in just one to two years.

Although there is still a technology gap with South Korean companies in the large OLED market, some point out that it is only a matter of time before China catches up with South Korea.

"The Chinese government is investing enormous benefits and support to provide subsidies when display companies make a deficit," said Jang-hyuk Kwon, a professor of information display at Kyung Hee University. "Our government should also widen the technology gap with full support in the display industry," he added.

Visionox Co Ltd, a leading Chinese manufacturer of organic light-emitting diode or OLED screens, is accelerating its expansion in smartphones, wearable devices, vehicle-mounted systems and intelligent homes due to the surging demand for flexible display screens.

"With the development of 5G, big data and cloud computing, the display panels will change peoples" lifestyles and enhance the visual experience," said Xu Fengying, vice-president of Visionox, adding that cutting-edge technologies will stimulate applications for flexible screens.

"The OLED industry is growing very rapidly. Visionox will focus on independent innovation and team with other companies in the industrial chain to produce flexible products," Xu added.With the development of 5G, big data and cloud computing, the display panels will change peoples" lifestyles and enhance the visual experience

The company official emphasized the flexible active-matrix organic light-emitting diodes or AMOLEDs will have wider applications in smartphones, computers, smart wearables, vehicles, smart homes, virtual reality and augmented reality.

AMOLEDs are more flexible with a faster response and have high contrast and wide visual angles when compared to traditional liquid crystal displays or LCD panels.

The company has provided AMOLED technology for smartphone maker Xiaomi Corp"s under-screen camera since June. Xiaomi"s prototype foldable phone also used an OLED display panel from Visionox, Xu said.

In April, another smartphone manufacturer, Nubia Technology Co Ltd, unveiled its first wearable watch-like smartphone called Alpha, which features a four-inch flexible screen manufactured by Visionox.

The firm currently has about 6,000 OLED patents. It grew out of the OLED project team of Tsinghua University and has been in the sector for more than two decades. It has two sixth-generation flexible AMOLED display screen production lines in Gu"an, Hebei province, and Hefei in Anhui province.

Its AMOLED display screen production line in Gu"an went into operation last year. It can turn out 30,000 glass substrates (1,500 mm by 1,850 mm) every month, and meet the high-end, foldable screen demand for 90 million smartphones.

South Korean companies such as Samsung and LG account for the majority of that revenue, but experts said more Chinese companies are entering the market.

The Beijing-based supplier of semiconductor display products now has three sixth-generation flexible AMOLED production lines. It started mass production of the panels from its facility in Chengdu, Sichuan province, in October 2017.

The panels are being used by more than 10 smartphone manufacturers such as Huawei, Oppo, Vivo, Xiaomi, ZTE and Nubia. The company"s second line in Mianyang, Sichuan province, started mass production on Monday. Work on the third facility began in Chongqing last year.

"China"s semiconductor display industry has taken large steps forward in the past decade, changing the display industry"s global competitive landscape. China has transformed into the world"s largest consumer market and manufacturing base for display terminals, with huge market potential," said BOE Vice-President Zhang Yu.

"AMOLED technology is the future trend for smartphone panels," Zhang said. "At the moment, technological upgrades of display panels on smartphones concentrate on appearance, function and image quality."

In addition, Shenzhen China Star Optoelectronics Technology Co Ltd announced a new production line for large-screen ultra-high definition 8K display products and OLED screens in November.

Spurred by growing demand, shipments of foldable AMOLED panels are expected to reach 50 million units by 2025 for the first time since their launch in 2018, global consultancy IHS Markit said.

"Chinese panel companies are developing rapidly in the flexible and foldable screens sector, but we still lag behind South Korean competitors in key technical talent, craftsmanship and product reliability," said Wang Jian, an analyst at Beijing-based market researcher Sigmaintell Consulting.

Wang said AMOLED technology will be very important for smartphone panels in the next few years and its future prospects are promising, while adding the flexible display technology will play a vital role in the small-and medium-sized display sector.

As China witnesses the phenomenal growth of its display industry, its global counterparts also face new challenges. Large-scale production of traditional LCD panels has fallen into a “dilemma of abundance”, where the current focus of display enterprises has shifted to how to best develop the potential of new technologies.

In recent years, panel makers such as JDI, Innolux, AUO, LGD and BOE have made significant efforts on the layout of the vehicle display industry, which shows immense market potential.

Previously, vehicle display pursued an integrated design with a relatively long life cycle. However, an increasing number of separation screen designs is emerging with a shorter life cycle, which demonstrates five major visible development trends in consumer electronics display.

Large screen – a major trend in vehicle display. With the nonstop development of intelligent driving technology, cars will become more interactive and intelligent. Akin to mobile phone screens, vehicle display size will also continue to expand. Moreover, vehicle screens can now be expanded horizontally and vertically so as to provide a wider display space. In fact, a multitude of vehicles has begun to carry large screens. For example, all Byton vehicles come equipped with a 48-inch LCD screen.

High-definition – as mobile phone screens continue on a path of development, consumers will continue to propose higher requirements for vehicle display resolution. Low-resolution display has lost the ability to meet market demand, leading vehicle display closer towards higher resolution. LTPS LCD has better electron mobility than a-Si LCD, which is capable of meeting higher-resolution requirements. Due to its advantages of narrow bezel, high brightness and In-cell, LTPS is now widely adopted by manufacturers. JDI and Innolux were the first to move into mass production of LTPS, according to Sigmaintell, while TIANMA, LGD and AUO are currently in the game. In addition, panel makers, led by JDI, have been recommending LTPS technology to vehicle manufacturers since 2017. In the same year, LTPS took up 2% of the market share in the vehicle display industry. In effect, in addition to resolution, high-definition vehicle display has also led to higher requirements in contrast, field of view, optical index and response speed.

Interaction - Like smartphones, touchscreens might very well become a must-have for vehicle display. Vehicle display has higher requirements for touchscreen, which should be lighter and more sensitive. At present, vehicle display has introduced a large number of capacitive touch applications. In 2017, the TP loading rate reached 22%, and by 2020 it is projected to reach 58%. If OLED were widely introduced into the vehicle display market, its touch technology would also be worthy of attention. OLEDs are classified into rigid OLEDs and flexible OLEDs. The former will be dominated by On-Cell, while in-Cell may prove prevalent in the latter. By 2020, In-Cell is expected to be the mainstream in the OLED market.

Multi-screen - In addition to dashboard and central-control displays, much more is coming in the vehicle display arena. TIANMA believes that multi-screen can be viewed from two angles. The first is “from 0 to 1”, which means vehicles, where no screen existed before, can now be equipped with one, such as a rear seat control display or vehicle key display. The second is “from 1 to an”". HUD and Mirror were previously only installed in high-end vehicles. Due to security demands and the introduction of AR technology, HUD and Mirror have since seen significant development.

Polymorphism- Unlike flat display, flexible display will bring even more possibilities to interior design. More and more anomalous screens, flexible screens and transparent screens are coming into play. These new possibilities leave much space to think about layout and design of interior space, which would provide users with a higher sense of technology. It’s worth mentioning that Samsung was the first to introduce OLED to the vehicle industry, and despite the fact that they had once give up , they restart to promote the technology at present.

CODA and Reed Exhibitions Kuozhan will be holding DISPLAY CHINA 2019 on June 26-28, 2019. Its show floor will feature a 180-square-meter area, namely the New Vehicle Display Innovation Display Area. Invitees will include professional visitors of all levels from the automotive electronics industry, together with touchscreen and display panel factories. The concurrently held Smart Cabin & Vehicle Display and Intelligent Interactive Technology Conference 2019 will be held in cooperation with New Energy Times on June 28. This conference will discuss hot topics such as next-generation, vehicle image display control technology and flexible OLED applications, the latest solutions in multi-screen integration, DLP projection technology, holographic technology, vehicle display full-fit processes (OCA, OCR full-fit technology, full-fit process and problem analysis, In cell/On-cell technology application in vehicle), as well as exploring and predicting the development and future trends of the smart cabin market.

The plethora of drivers in modern times has the ability to ramp up industry development. There is also immense demand for product innovation. Development potential in the panel industry is not only huge in vehicle display. Intelligence interaction and commercial display are also uncharted lands just waiting to be explored. At present, about 39.9% of all digital signage panels are used in the retail market. The commercial retail industry is experiencing rapid growth. Consequently, last year saw its sharpest growth in commercial display panel shipments, at a year-on-year increase of nearly 27%. It is expected that the entire commercial display panel market will reach an annual revenue of $2.88 billion by 2020.

The organizers of DISPLAY CHINA long foresaw these trends, along with the struggle to promote industry development. To that end, they have striven to create an exclusive commercial platform dedicated to intelligent and interactive display, where buyers and industry leaders from commercial display, digital sign factories, vending machine manufacturers and interactive machine manufacturers can experience and purchase the latest touch display technology. The concurrently held Intelligent Interactive Development Summit will discuss the future development model of digital cities with, among others, industry experts, panel exhibitors and logo production buyers, who’ll be sharing their experiences and insights with a focus on the aspects of new framework materials, environmental protection and sustainable development to new display technologies, new software integration solutions and current commercial space solutions.

Looking back at DISPLAY CHINA 2018, the three-day event boasted an exhibition area that stretched across 12,000 square meters and attracted nearly 200 industry brands and a total of 12,710 visitors, including 1,160 professional visitors from 31 industry companies.

DISPLAY CHINA 2019 is projected to attract nearly 20 thousand professional visitors, 1,000 invited buyers, 2,000 visitor groups and 3,500 overseas buyers. Well-known enterprises such as BOE, JNC, TIANMA, ELC, Jingkun, LTMS, Edwards, KOSAN, Yangpu Industrial, Sunlonge, Youji Guangxian, Jspacktech, Huiguang, Naibo, Hangzhou Guangli, Maolian will be taking part in this year’s event.

Seoul, Korea (Oct. 7, 2013)– LG Display [NYSE: LPL, KRX: 034220], the world’s leading innovator of display technologies, today announced that it will start mass-production of the world’s first flexible OLED panel for smartphones. This state-of-the-art panel represents another milestone following the company’s commercial rollout of the world’s first 55-inch OLED TV display earlier this year.

“LG Display is launching a new era of flexible displays for smartphones with its industry-leading technology,” said Dr. Sang Deog Yeo, Executive Vice President and Chief Technology Officer of LG Display. “The flexible display market is expected to grow quickly as this technology is expected to expand further into diverse applications including automotive displays, tablets and wearable devices. Our goal is to take an early lead in the flexible display market by introducing new products with enhanced performance and differentiated designs next year.”

LG Display’s flexible OLED panel is built on plastic substrates instead of glass. By applying film-type encapsulation technology and attaching the protection film to the back of the panel, LG Display made the panel bendable and unbreakable. The new display is vertically concave from top to bottom with a radius of 700mm, opening up a world of design innovations in the smartphone market. And only 0.44mm thin, LG Display’s flexible OLED panel is the world’s slimmest among existing mobile device panels. What’s more, it is also the world’s lightest, weighing a mere 7.2g even with a 6-inch screen, the largest among current smartphone OLED displays.

In March 2012 LG Display developed the world’s first 6-inch Electronic Paper Display (EPD) based on e-ink which utilizes a plastic backplane. Having previously showcased the world’s first curved 55-inch OLED TV panel at CES 2013, today’s announcement highlights the company’s leading position in advanced flexible display technologies.

According to research firm IHS Display Bank, the global flexible display industry will see dramatic growth and become a USD 1.5 billion market by 2016, exceeding USD 10 billion by 2019. LG Display plans to advance flexible display technologies and bring innovation to consumers’ daily lives with the introduction of rollable and foldable displays in various sizes.

LG Display Co., Ltd. [NYSE: LPL, KRX: 034220] is a leading manufacturer and supplier of thin-film transistor liquid crystal display (TFT-LCD) panels, OLEDs and flexible displays. The company provides TFT-LCD panels in a wide range of sizes and specifications for use in TVs, monitors, notebook PCs, mobile products and other various applications. LG Display currently operates nine fabrication facilities and seven back-end assembly facilities in Korea, China, Poland, and Mexico. The company has a total of 56,000 employees operating worldwide. For more news and information about LG Display, please visit www.lgdnewsroom.com.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Chinese tech giant BOE recently announced its mass production of flexible displays in Chengdu, Sichuan Province, making China the second country to acquire the technology after South Korea, CCTV reported.

Utilizing active-matrix organic light emitting diode (AMOLED) technology, the flexible displays can be used on mobile phones, wearables, and other portable electronics, allowing the device screen to be only 0.03 mm thick, bendable and even foldable.

The entire production line was designed, developed and established solely by BOE, and will be able to roll out 70 million flexible AMOLED displays annually.

Flexible displays use organic light-emitting diode (OLED) material, a self-lighting material that allows the screens to have better definition, fineness and color than ordinary liquid crystal display (LCD) screens without needing a backlight.

The wide use of flexible AMOLED displays is expected to become a trend across the world. Chen predicted that the company"s production growth will exceed 30 percent within three to five years.

Previously, South Korean company Samsung monopolized the field and with the production of AMOLED displays fair below the demand. The mass production of the display in China breaks that monopoly and markedly increases the supply. At a ceremony to celebrate the first batch of flexible displays produced, over ten Chinese phone makers, including Huawei, Xiaomi, Oppo, and Vivo, have received samples, Yan said.

Other Chinese businesses are also jumping into the smartphone display business. Tianma Micro-electronics Co., Ltd., for instance, has plans to increase investment.

Across China"s entire display sector, investment in assembly lines planned or under construction for screens for TVs, computers, smartphones and other devices has reached 800 billion yuan. Industry associations predicted the country will overtake South Korea as the world"s largest producer of display screens as early as 2019.

LG Display’s new OLED TV panel fab in Guangzhou, China, is ready to start production next month in a move that will double the world’s OLED display manufacturing capacity.

LG Display is the world’s only maker of OLED TV panels at present, and the vast majority of these are built at its original fab in South Korea. Construction of the plant in Guangzhou was announced back in 2017, with LG saying the facility would cost around $4.2 billion (£3.3 billion).

The company confirmed to Business Korea that the new plant is currently doing production test runs ahead of its full launch next month. Once the facility is up and running, its OLED production capacity will almost double, from 70,000 to 130,000 substrates per month.

Those substrates will be used to make panels ranging from 55-inches, 65-inches, 77-inches and 88-inches, LG Display said. It also has plans to begin manufacturing smaller, 48-inch OLED panels in the near future. The company forecasts that it will produce 3.8 million OLED TV displays this year, up from 2.9 million in 2018. By 2021, it’s aiming to produce up to 10 million OLED TV panels a year.

The new fab will employ a new production technique known as multi-model glass, which will enable it to build multiple panels from a single substrate. This should have the effect of reducing wastage, and therefore production costs, by around 10% to 20%. LG Display may also have plans to manufacture soluble OLED displays using the Inkject process at the new facility, which could potentially further reduce its costs.

The move will help LG to fulfill its ambition of shifting away from LCD panel production, which is less profitable, to focus more on OLED. Currently around 20% of the TV display panels it manufactures are OLED, and the aim is to increase this to 30% by the end of the year.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey