flexible display screens free sample

Free sample for Flexible Display Programmable Transparent Led Curtain Wall. #transparentledcurtaindisplay #transparentledpanel #transparentledposter #transparentledvideoscreen #leddisplaytransparent #glasswindowleddisplay #transparentleddisplayglass #transparentledfilmdisplay #transparentledtv, www.szradiant.com , email:info@szradiant.com skype:radiant-led , wechat:+86-13902918225

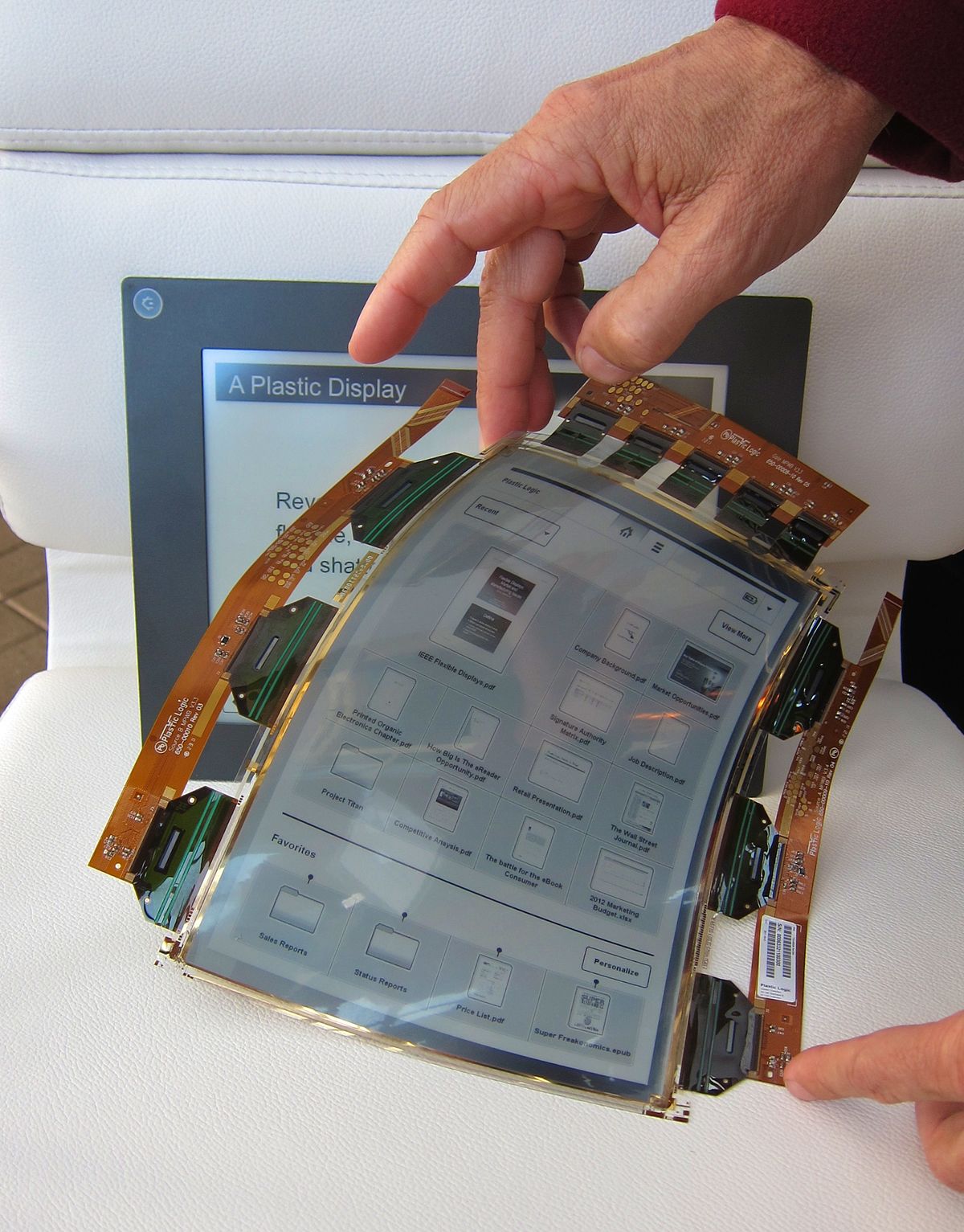

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

![]()

At the heart of every great digital signage display is this: content. Make it look good and people will stop to look at it. Make it look bad or outdated, and chances are they won’t be looking at your screen again.

The most obvious is social media. If you invest your efforts in social media, why not use this to bring your digital screens to life too? You can also utilize user-generated content.

Walls.io offers a unique feature to showcase sponsored ads from brands you partner with. This feature is called Sponsored Posts, and they are special posts on your social wall that aren’t filled with regular social content from your sources. Instead, you can upload specific images (or videos or just text) that you want to display there and have it show up on your wall in regular intervals.

If you need to create a quick notice, perhaps detailing a room change or a meeting time, there are a wealth of apps to make that happen. Like Noticeboard - an app that can be found in the ScreenCloud App Store. It allows you to create a quick and easy display in seconds, and also allows for real-time edits.

This type of content works well as ‘filler’ content in between video, ads and social media displays to stop your viewers from getting digital-overload.

Food is such a big part of our lives, it’s natural that we’re drawn to images, descriptions and menu boards showing it. Enter the digital menu board digital signage display.

This is one of the most important content displays you’ll create if you work in a restaurant, fast food chain or bar. It also works in an office cafeteria, an event setup or even as a fun noticeboard where you can swap menu items out for things you’re working on or fun descriptions of your team members. If you’re a franchise, this works especially well as you can change the price of an item across all screens and locations from one ScreenCloud login.

Data-driven companies are more likely to succeed – because they can easily see the areas that need attention. But most of the time this business-critical data is siloed and not seen by the teams that can make an immediate impact. Historically this data hasn’t been shown on screens due to security fears, which is why ScreenCloud developed Dashboards.

We love Slack at ScreenCloud. Like many startups, it’s how we do about 90% of our communication. So when a room’s really crucial to what we do, like our #praise room, we share it on our digital signage screens. This is made really easy with the Slack app.

How much time do you think your reception staff spend directing people to the right floor or meeting room? We love using the building directory app to share details of where everything is through our digital signage screens. The best part? If a room changes, you can update the screen easily unlike your static signs. Here are some non-obvious benefits of wayfinding in retail.

Imagine having a method of internal communication that allowed you to broadcast to your entire company, at the click of a button… That’s exactly what ScreenCloud Broadcast can do for you. This makes it easy to share company broadcasts that go out to all screens simultaneously with news, praise or health and safety announcements. Broadcast can securely live-stream meetings or announcements to screens in your office, and also onto the mobiles or desktop screens of remote or deskless workers, making sure everyone gets the news.

Everyone likes to see where they are in a leaderboard, whether that’s in sales or counting reps in the gym. Use your digital screens to show off this leaderboard and add an additional layer to your customer/employee experience. You can create it easily using Google Slides, or for something more automated, check out a tool like Bonusly, as shown below.

In the same way you might use your digital signage to share leaderboards, you could also entice employees or customers in with competitions. Promoting giveaways or asking them to submit something (like an Instagram image) for the chance to win, is a great use of your digital screens. Create a poster using Canvas and add a QR code to link through to a competition landing page.

Screens are great for all of the good stuff we like to put out into the world, but they’re also a good vehicle when you need to make an emergency notice that needs to reach a lot of people. For (planned) fire drills, you can schedule the alert to pop up on your screens, otherwise, have a template at the ready to push live should you need to display it in the moment.

Ever had a bad meeting room experience? Someone waiting awkwardly outside? Knocking before you’re finished to ask ‘how long’? Same. It’s why using small screens, iPads or tablets you have laying around is an awesome use of digital signage. We wrote more about how to set this up here.

Among the various improvements that smartphones and tablets have received over the last decade, flexible displays are undoubtedly one of the most interesting propositions and one with a huge potential to change the market. The technology is still relatively new, despite several companies exploring the tech for more than a decade.

After seeing several new devices successfully integrate flexible displays with varying levels of success, it"s clear that this tech is here to stay. The only question right now is how long it will take for flexible displays to become commonplace. Let"s take a look at how modern flexible displays work and future considerations for this corner of the market.

Smartphone displays are traditionally rigid due to the glass layer used in their production. However, modern OLED-based designs have successfully removed the need for that, instead implementing the screen in a very thin layer, to the point where it becomes flexible. The screen is then covered with a thin plastic layer, which is unfortunately susceptible to scratches.

In some cases, flexible displays are just an illusion. Some devices feature two or more displays lined up next to each other, with special emphasis placed on removing the border between them. These devices are usually more versatile in terms of the kinds of upper layers they support, in some cases including a full glass cover.

Flexible displays have been around for a decade now. Initial designs were rather underwhelming—but some of them ended up being repurposed into other devices. For example, the Galaxy Note Edge"s curved screen actually started as a prototype for a flexible display device.

The Galaxy Z Flip 3 is a notable example of a device that incorporates a flexible display, and some claimed that it should set some new trends on the market. Unfortunately, other manufacturers haven"t tried to follow the trend, so it remains to be seen whether the idea has any true potential. The device sold well enough, which is a good sign.

And in some cases, flexible displays were used to achieve a different effect. The iPhone X, which started the trend of screens with curved corners, actually used a flexible display to accomplish that without sacrificing any real estate around the bezels.

Flexible displays remain relatively expensive compared to their regular counterparts and often sacrifice visual quality. This is especially noticeable when the screen is folded at a particular angle. At the same time, flexible screens tend to have a more limited lifetime compared to traditional ones.

For most user"s needs, current designs should be able to last a very long time. But this is still a point that needs to be addressed by most manufacturers, especially in the context of the higher prices attached to flexible display devices.

It"s also important to note that flexible displays have huge potential outside of the smartphone market. Other devices can utilize them to improve their usability. Furthermore, with wearable gadgets increasing in popularity, new gadgets coming out in the future are likely going to take advantage of this technology.

Smartwatches are a good candidate for flexible display technology. Their designers already go to great lengths to make their displays as compact as possible, and flexible displays offer some direct advantages in this regard. They tend to be thinner than traditional displays, which makes them a good fit for devices of this kind.

Then there are medical devices and other specialized use cases. Even if flexible displays don"t immediately take off, they will find a place in other areas. It will be interesting to see what kinds of changes they facilitate in other markets.

Gaming is also shaping up to be a field where these devices could have a viable place. Between virtual reality and the new features being introduced in modern consoles and their controllers, we might see some approaches that integrate flexible displays.

With all that said, the main question remains—will this eventually become a common trend on the market as a whole? As we mentioned above, there are specialized cases where bendable or flexible displays have potential.

But at the same time, it"s questionable how fast this tech will be adopted in general, depending on price, application, and other availability factors. New developments in the field have made the production process more affordable, but it will probably take a while until foldable displays establish a permanent presence on the market and become commonplace.

LG Disply has developed a 12-inch stretchable display that can be extended in size to 14 inches, the company announced. The displays could one day be used in materials with irregular surfaces like clothes and wearables to display messages on the uniforms of first responders, for example.

Stretchable displays, or free-form displays as LG Display calls them, can be pulled, bent and twisted. They go a step farther than the flexible displays used in Samsung"s Galaxy Fold and other smartphones, which can be folded and bent but not stretched.

To make the display so stretchy, LG Display built the base substrate material from a silicon similar to that used in contact lenses. It also micro-LEDs smaller than 40-micrometers for the light source, allowing for high resolution and durability. And finally, the company used circuits shaped like springs to accommodate bending and folding.

"The stretchable display’s revolutionary technology offers next-level versatility for various daily scenarios," LG Display wrote. "Easily attachable to curved surfaces such as skin, clothing, furniture, automobiles and aircraft, this unique innovation expands the potential of the display in various industries including fashion, wearables, mobility and gaming."

We"ve seen stretchable displays in the past from Samsung and others, but the best you could do with those was put a small dent in them. This one appears to go much farther, showing the potential for displays with real potential for wearables. LG Display has been working on the technology since 2020 in collaboration and the research is expected to conclude in 2024.

The North America region is expected to reach USD 46.03 billion by 2030 with a CAGR of 33.5% in North America flexible display market. The term "flexible display" refers to any visual output surface that is constructed to be able to withstand being folded, bent, or twisted in any direction. OLED displays are commonly used in screens that use flexible displays. Flexible displays are becoming more common in foldable technology, such as smartphones that can be folded or closed like a book.

Flexible displays are helpful because they permit the device to be stored in a smaller space, like a pocket, while also providing a screen size that is more enjoyable for the display of media. This is a useful combination. Flexible displays in mobile devices can improve multitasking. Foldable displays on smartphones may one day make it unnecessary for some people to carry around a tablet in addition to their primary device. The cache of something new and futuristic is the main draw of a folding display.

Mobile phones, PDAs and laptops, a display that is permanently conformed to fit snugly around the wrists, a kid"s mask for Halloween and other occasions & an unusually shaped display built into a steering wheel or automobile.

It is anticipated that the primary manufacturers in the market would have prospects for expansion as a result of the growing demand for flexible displays in a variety of industries, including healthcare and automotive, amongst others. The incorporation of flexible screens into the interiors of vehicles is a primary goal for car manufacturers.

In recent years, improvements in manufacturing techniques for flexible organic light emitting diodes (OLED) have led to growth in the flexible display business. It is anticipated that the market penetration of flexible glass in a variety of consumer electronics goods would increase over the course of the projection period. These desirable characteristics include mobility, low weight, lack of brittleness, and flexibility.

The technology that is utilised in the production of these displays is considered to be one of the primary benefits of flexible organic LEDs. The OLED displays have a competitive advantage thanks to the use of organic components such as phosphorescent dye and conductive polymer. They emit more light, weigh less, and offer a greater degree of flexibility in terms of how they can be integrated with other electrical devices. In addition to this, they are quite resourceful and have a low impact on the environment in terms of energy consumption.

In the past few years, the value of the OLED sector has increased rapidly; the majority of this gain can be attributed to the segment of the industry that is responsible for manufacturing smartphones. The use of organic light-emitting diode (OLED) technology in smartphones has become increasingly widespread because the displays it enables users to create may be folded into a more portable and manageable form when not in use.

The customer can experience a higher resolution, greater sense of immersion, and a larger field of view thanks to the use of flexible OLED displays, which are also a component in curved TVs.

The manufacturing process for FOLEDs is extremely demanding and necessitates the introduction of stress via heat. The production of flexible plastics and the bending process necessitate very precise and intense heat, which can result in thermal and residual stress. This can reduce the device"s quality and longevity, making it less durable in the long run.

When significant stress is applied to the FOLED display panels, they are also weakened. This rigorous manufacturing process may make the FOLED more prone to natural wear and tear, discouraging consumers from purchasing them for long-term utility. The repetitive folding and unfolding that occurs when using these devices adds to the burden. Other drawbacks include poor outdoor visibility, oversaturation of images, vulnerability to water-related damage, and so on.

The market for flexible displays in the North America region may be broken down into three distinct categories: the component utilised, the technology & the application.

Display technology and display manufacturing technology are the two subcategories that are included in the technology segment"s further subdivisions. OLED, E-paper, LCD, and LCOS are some of the technologies that are used in display technology. The technologies used in display manufacturing include plasma display technology as well as flat panel display technology.

Apple utilised flexible displays in order to achieve a distinct effect in their products. The iPhone X, which kicked off the trend of screens with curved corners, actually used a flexible display to accomplish this without giving up any of the screen real estate that was previously occupied by the bezels.

Visionox announced the launching of China"s first 1Hz low-power AMOLED display on February 22, 2022. This display, which utilises Hybrid-TFT technology, is capable of achieving a dynamic refresh rate of 1-120 Hz. Concurrently, mobile phones that include Visionox"s 1Hz low-power AMOLED display will also be available for purchase in the not-too-distant future.

Backplanes are the most essential component of electronics because they can connect in parallel with each other and control the electrical signals of devices. As opposed to the passive-matrix form, the active-matrix backplane allows selective access to each component with a rapid response while maintaining a high-circuit density by sharing electrode lines. Despite many advantages of active-matrix backplanes, the realization of deformable active-matrix backplanes with reliable operation is very challenging. This is because three electrodes (gate, source, drain) of each component are connected to different word and bit lines and grounds, and the failure of only one single component can lead to the failure of the whole backplane. Therefore, it is important to minimize stress during deformations of thin-film transistor (TFT)-based electronics. The deformability of backplanes is commonly obtained by modifying device materials and structures to accommodate most of the strains induced by bending, folding, and even stretching. These modifications can be classified into two approaches: one uses intrinsically flexible materials (e.g., ultrathin or elastomeric materials) and the other uses an engineered substrate.

The most basic method of obtaining flexibility or bendability is the adoption of ultrathin materials as the TFT backplane components.2a, b. In addition, no fracture was found on the oxide semiconductor TFT regions due to the thin thickness of the backplane (~2 µm) and the improved flexibility of the TFT regions. Javey and coworkers have demonstrated a flexible display that is composed of a flexible carbon nanotube (CNT)-based backplane and flexible organic light-emitting diode (OLED) pixels as depicted in Fig. 2c, d (ref. 3). The flexible display was fabricated on a 24-µm-thick PI film, and the total thickness of the devices (excluding the substrate) was <2 µm. Therefore, the flexible backplane showed stable electrical characteristics even during the bending states (where the bending radius was 4.2 mm), and the OLED pixels also performed with negligible degradation from the deformations (where the bending radius was 4.7 mm). Consequently, this fabricated display also demonstrated flexibility because of the deformability of the devices.

Flexible backplane for display fabricated by a thin-film process. a Photo (left) of the TFT array sample made by graphene–AuNT hybrid electrodes on a transparent polyimide substrate. Scale bar: 1 cm. A schematic diagram (right) of the TFT layout. b Photos of the TFT arrays transferred onto: a leaf, eyeglasses, and the skin of human hand. All scale bars: 1 cm. a–b Reproduced with permission from ref. 8. Copyright 2014, American Chemical Society. c Photo (left), optical micrograph (middle), and scanning electron micrographs (right) of flexible backplane. d Photos of operating flexible display combined with backplane and OLED pixels. c–d Reproduced with permission from ref. 3. Copyright 2013, Nature Publishing Group

Many studies have demonstrated flexible electronics with various methodologies. However, in the case of the aforementioned methods, mechanical stresses continue to be induced on the brittle electronic materials, even though the stresses are relieved. Therefore, the mechanical stresses generate fatigue on the electronics during repetitive or constant deformations, and the accumulated fatigue causes severe problems that deteriorate the performance and reliability of flexible TFT backplanes. Consequently, reducing fatigue becomes a key challenge to realizing highly flexible and stable backplanes or electronics. The typical method of reducing mechanical fatigue on the TFT backplane is the adoption of device islands-interconnect designs. These designs are based on engineered substrates that are composed of materials with different values of elastic modulus.3a.1 summarizes the recent advances in stretchable interconnect technology.3b). The stretchable conductors showed high stretchability at over 200% strain as plotted in Fig. 3c. Based on these systems, the stretchable backplane also demonstrated superb stretchability up to the strain of 110% (Fig. 3d). In addition, Kim et al. have also demonstrated a reversibly foldable TFT backplane based on the oxide semiconductor (indium oxide (In2O3)), which shows high performance and is used in the conventional backplane.3e). The designed stretchable conductors exhibited stretchability up to the strain of 100% and also exhibited stability against cyclic tests (10,000 times with the 80% strain), as shown in Fig. 3f. Because of these superior interconnects and engineered substrates, the oxide semiconductor TFT backplane also showed high stability during the folding states without any degradation (Fig. 3g). In addition, Park and his team have also studied stretchable TFT backplanes based on these two systems Fig. 3h. Their TFT backplanes also provided reproducible performances up to the strain of 25%, as shown in Fig. 3i, and showed high stability against fatigue (5000 times with the 20% strain), as shown in Fig. 3j. The reliability of the stretchable TFT backplane is affected by the strain isolation effect of engineered substrates and the high stability of stretchable interconnects (Au film on AgNWs-embedded elastomer).

Device islands-interconnect design for highly flexible TFT backplane. a Simulation of strain manipulation at the top surface of the engineered substrate. Reproduced with permission from ref. 9. Copyright 2013, American Institute of Physics. b Schematic illustrations of OTFT backplane on engineered substrate. c Conductivity dependence on tensile strain in printed elastic conductors with and without surfactant. d Transfer characteristics of OTFT according to the tensile strain. b–d Reproduced with permission from ref. 12. Copyright 2015, Nature Publishing Group. e Schematic images (top) and scanning electron micrographs (bottom) of stretchable conductor (Au film on AgNWs-embedded elastomer) before and after stretching. Scale bars: 5 μm. f Resistance dependence on tensile strain (left) and cyclic numbers (right) of the stretchable conductor (Au film on AgNWs-embedded elastomer). g Images (top) and output characteristics (bottom) of foldable TFT backplane on engineered substrate before and after folding. Scale bars: 5 mm (black) and 100 μm (red). e–g Reproduced with permission from ref. 13. Copyright 2016, Royal Society of Chemistry. h Illustration and photograph (inset) of stretchable TFT backplane on engineered substrate. i Electrical properties of device in h according to the mechanical strain (up to a strain of 25%). j Electrical properties of device in h according to the number of cycles

The research activities for developing TSP technologies at UNIST have been devoted mainly to exploring new materials, device structures, and device fabrication processes for multi-functional flexible and stretchable TSPs. One noticeable achievement is the development of the highly flexible capacitive TSP with AgNW diamond-pattern electrodes and transparent bridge structures formed on a polycarbonate film.4 shows the structure and touch-sensing capability of the fabricated TSP. As shown in the Fig. 4, the bridge structure is composed of an epoxy polymer (SU-8)-based bridge insulator and an Al-doped zinc oxide (AZO) bridge electrode. In order to secure the stable and robust connection between the AZO bridge electrode and the AgNW diamond-pattern electrodes over the bridge insulator, the side-wall slope of the bridge insulator is made as low as possible with our unique photolithography process, in which the exposure time is extended beyond the optimized value for forming vertical side-walls. With the extended exposure time, the lower part of the SU-8 layer immediately adjacent to the direct exposure region can be sufficiently exposed to the stray ultraviolet (UV) light scattered from the substrate, leading to the formation of a bridge insulator with a low side-wall slope. The fabricated TSP sample was found to be highly flexible and transparent and also showed good touch-sensing performance. The measured capacitance changes by ~22.7% with the finger touch.

Based on their superb operational performances and functionalities, the flexible and stretchable TSP devices developed at UNIST, including the two introduced above, are expected to significantly enrich the information communicated between humans and machines. Thus, it is quite probable that these devices will be used extensively in various future information technology applications.

Flexible light sources are important parts in flexible display applications because they determine long-term stability and commercial value of practical flexible displays under continuous mechanical stress. Thus, flexible light sources should have sufficient light-emission efficiency and mechanical stability. Generally, OLEDs have been mostly spotlighted candidates for flexible light sources because OLEDs consisted of organic materials and they have outstanding mechanical flexibility compared with inorganic LEDs.

Following constituent materials of flexible OLEDs, there are four major research issues (substrates, electrodes, light-emissive materials, and encapsulation) to be perfectly developed for practical future applications; flexible substrates, electrodes, light-emissive materials, and encapsulation. Here, we briefly introduce technical research issues with four sections and suggest future research directions of flexible OLEDs.

Almost all of the macroscopic flexibility of flexible OLEDs comes from substrates. The important properties of flexible substrates are mechanical flexibility, thermal stability, optical transparency, and gas barrier properties.

Highly conductive poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) have been investigated for flexible electrodes with highly smooth surface, optical transparency, easy processes, and enhanced electrical conductivity up to 4380 S/cm by doping with polar solvents or concentrated sulfuric acid.6. In addition, hybrid flexible electrodes composed of PEDOT:PSS and AgNWs were said to be mechanically durable and robust OLED characteristics were said to be obtained.

a Schematic illustration of thermal annealing and LPEB irradiation of AgNWs. b Schematic illustration of fabrication process for AgNW/PEDOT:PSS composite electrode and the PLED structure, and photograph of light-emitting flexible PLEDs with AgNW/PEDOT:PSS electrode

Most components of flexible OLEDs are organic materials that can easily react with oxygen and moisture because plastic substrates and other components have low gas barriers. The water vapor transmission rate (WVTR) is strongly related to the long-term stability and feasibility of practical flexible OLEDs. OLEDs generally require a WVTR of approximately 10−6 g/m2∙per day, which is a very low value compared to inorganic LEDs.−3 g/m2∙day, as shown in Fig. 8.

For next-generation displays, flexible and light-weight OLEDs are an appropriate candidate because of their excellent light emission, and mechanical flexibility. Currently available components of flexible OLEDs including substrates, electrodes, emissive materials and encapsulation layers, are still insufficient to achieve practical flexible OLEDs with stable performance under mechanical deformation. Consequently, achieving reliable components of flexible OLEDs such as (1) flexible substrates and encapsulation layers with good barrier properties, (2) transparent electrodes that are mechanically robust under deformation and have low sheet resistance, and (3) flexible materials that emit light efficiently, remains to be solved for commercial applications.

Recently, flexible display devices have attracted widespread attention as an alternative to rigid devices because of their portability and comfort for long time wearing. For the relevant applications, when the devices undergo mechanical deformations such as bending and stretching, the thicknesses of the constituent materials usually decreases and all layers suffer a tensile stress at the outside of each layer.

Flexible display devices contain many laminated structures composed of sub-micrometer-scale thin films. At UNIST, we evaluated the mechanical properties of one of these components using modified hole-nanoindentation. PDY-132 (Merck, Germany, commercially sold as “Super Yellow”) is a ‘‘high-performance polymer’’ that emits yellow light. In our evaluation, PDY-132 was spin-coated on a clean glass substrate. The sacrificial layer was selectively dissolved to fabricate free-standing films with the same dimensions as the actual devices. We fabricated hole-patterned Si wafers using the deep reactive ion etching method. The patterned hole size was proportional to each film thickness, so that the diameter of a hole was less than 1% of the film thickness.11. The elastic modulus of the hole-indentation was found to be 4.89 GPa, and its fracture strength was 1.19 GPa.

Uchic et al.12. Tensile testing is the most fundamental method of evaluating a material’s inherent mechanical properties, such as yield strength, strain-hardening exponent, ultimate tensile strength, etc. As mentioned above, in-situ testing enables precise observations of sample deformations in real time, with simultaneous imaging during testing. Various indenters are also expected to enable stretching and bending tests of constituent materials in flexible display devices.

Flexible display devices contain many organic materials, such as polymer films, active materials, and electrodes. However, mechanical tests of organic materials in high vacuum conditions in SEM and transmission electron microscopy are limiting in that organic materials are (in real environments) highly affected by surrounding environmental conditions such as humidity and temperature; it is important to measure mechanical properties in actual operating environments. A nano-UTM can be used to control environmental conditions using a controlled humidity chamber and heating block because the machine is based on an optical microscope, as shown in Fig. 13. Images of gauge sections during tensile tests are observed by a charge-coupled device camera in real time, and strain is analyzed from the images based on digital image correlation. Constituent materials in flexible display devices are macroscopically visible and their thicknesses are generally in the nanometer-scale range. PEDOT:PSS is widely used for organic transparent conducting electrodes, and PEDOT:PSS thin films are fabricated by natural drying after drop casting on a substrate. A tensile sample was fabricated by a mechanical press, and the gauge length and gauge width were 4 and 1 mm, respectively, as in the standard ASTM E8 test. We performed tensile tests of PEDOT:PSS in three different humidity conditions by nano-UTM, and the results are summarized in Fig. 13. The yield strengths of the samples tested in the lowest humidity environment were greater than those of other samples, and the fracture strain decreased as humidity increased.

In recent years, fingerprint mutual capacitive TSPs with flexible displays fabricated from flexible plastic materials have attracted much attention because of the development of transparent fingerprint sensors embedded in flexible displays that are also thin and impact-resistant. As security protections for electronic devices such as smart phones become increasingly important, a fingerprint sensor has been integrated on the device’s home button because the fingerprint sensor is not transparent. However, a mutual capacitive transparent fingerprint TSP must be developed on the display itself because a wearable device does not have a home button, and the screen sizes of smart devices must otherwise be enlarged.

To make a flexible TSP, a flexible and transparent material must be used for the TSP electrode. However, variation in load becomes a concern when the flexible electrodes of the fingerprint TSP are bent or stretched, which can interfere with capturing the fingerprint image. Because the capacitance difference of the mutual capacitive fingerprint TSP from the ridge to the valley is several hundred atto-farads, the effect of the load variation due to a bent or stretched TSP will be very critical.

Both the flexible fingerprint TSP and post-processing are required to capture the fingerprint image in the fingerprint TSP on the flexible display. A readout IC for the flexible fingerprint TSP is required to distinguish the atto-farad capacitance difference in the fingerprint TSP noise environment on the flexible display. Post-processing is also necessary to compensate for the load variation due to the bent or stretched display.

When the thickness of the covered glass of the flexible display is almost 0.2–0.3 mm, the mutual capacitance difference from the valley to the ridge is almost 50–150 atto-farad. As the thickness of the display panel increases, the mutual capacitance difference is reduced. The thickness of the rigid glass is larger than that of the flexible display panel, which induces a capacitance difference between the valley and the ridge of only several atto-farad.

A low-noise, low-offset, and fast-response receiver is required to acquire a fingerprint image in the mutual capacitive fingerprint TSP on the flexible display. In addition, the post-processing is also required to compensate for the load variation issues that occur because of the flexible TSP’s unique characteristics. A readout IC with high accuracy and a fast response and an effective algorithm for cancelling the offset due to the load variation are both required to achieve an effective fingerprint TSP on the flexible display.

Display products are frequently used for the purposes of task efficiency or leisure. Because long-term and/or frequent use of visual display terminals (VDT) is harmful to our health, ergonomic interventions including ergonomic displays are essential. Users of VDTs suffer from headaches, nausea, visual fatigue, and/or musculoskeletal disorders, which are comprehensively called VDT syndrome or computer vision syndrome. Recently, curved displays have been adopted as a new form of display for several types of commercialized visual display products (smartphones, smart watches, smart bands, TV, and computer monitors). Visual display products that adopt bendable, foldable, or rollable displays are expected in the near future. Existing guidelines for performing visual tasks on flat or convex displays (e.g., ISO 9241) require that characteristics of new displays be evaluated from the perspective of the health of the human user. New types of display are different from conventional displays in terms of optical characteristics, and ergonomic investigations should thus be more focused on visual perception, comfort, and fatigue, among other factors in the ergonomics field.

Visual ergonomics is one prominent research area in terms of ergonomics related to display and visual perception. Visual ergonomics is defined as the multidisciplinary science concerned with understanding human visual processes and the interactions between humans and other elements of a system. Visual ergonomics applies theories, knowledge and methods to the design and assessment of systems, optimizing human well-being and overall system performance. Relevant topics include, among others: the visual environment, such as lighting; visually demanding work and other tasks; visual function and performance; visual comfort and safety; optical corrections and other assistive tools.

New forms of display are characterized by optically different properties, which consequently affect visual perception (Fig. 17). Curved displays have been reported to have advantages

When determining ergonomic display curvatures, several factors should be considered, including the viewer, media content, task, and environment. Regarding the viewer, general characteristics of visual perception as well as age-related factors should be considered. It is also important to consider the effects of media content (static, dynamic, 2D, or three-dimensional) on the viewer’s perception and ocular health. Task duration and the work-rest schedule are also important to promote ergonomic conditions during VDT tasks. Finally, the viewing environment is important in terms of its illumination, light reflection, humidity, viewing distance, viewing angle, and lateral viewing position.

When evaluating visual displays, the following measures can be used. Many diverse subjective rating scales are available to assess perceived visual comfort or discomfort, visual fatigue, and cyber-sickness (e.g., ECQ, SSQ). In addition, the concept of presence, or immersive feeling, has become more important as an essential element of a satisfactory viewing experience through any media. Objective measures related to the viewing experience include critical fusion frequency to assess mental stress and visual fatigue, change in pupil size, and eye blink frequency and duration.

It is also important to understand how our visual perception operates to better inform our visual display designs. Related concepts include the just noticeable difference (JND), horopter, and depth perception. For example, JND values for display curvature can be used to determine a specific display curvature within the JND range, within which our perception is regarded equal. The horopter concept contributes significantly to the advantages offered by curved displays in comparison with flat displays. Horopter is “the locus of points in space which project images onto corresponding points in each retina”.

To summarize, it is necessary to consider human factors, task factors, and environmental factors all together during the display research and development process. Otherwise, the resulting visual display product may be technologically feasible, but adversely affect our health.

New York, United States, July 19, 2022 (GLOBE NEWSWIRE) -- The global flexible display market had a market share of USD 13.34 billion in 2019, according to the new report of Straits Research. It is predicted to grow at a CAGR of 34.83% from 2022 to 2030. The global flexible display market is expected to grow owing to the rising innovations in consumer electronics and increased demand for a high-quality picture. Integrating smart sensors into residential devices has lengthened the replacement cycle for new consumer electronics. Displays are increasingly being used to control and communicate with devices.

Based on display type, OLED accounted for the largest market share of 73.65% in 2020. The OLED segment is predicted to grow at a CAGR of 35.87%, generating revenue of USD 175.95 billion by 2030.

The growing trend of smart homes and buildings and the increasing demand for connected technologies are some of the major factors driving the adoption of connected and innovative solutions across the consumer electronics sector. Effective data storage is becoming critical, with so many viewers consuming media from OTT platforms such as Netflix, Amazon, and others. Thus, the demand for TVs is expected to boost the flexible displays market.

Further, the growing demand for greater picture quality bolsters the demand for flexible displays. The number of 4K televisions sold has increased exponentially in recent years. According to JEITA, the number of 4K TVs shipped in Japan in 2020 will be 3.05 million, up from 2.58 million the previous year. The increase in demand is expected to be driven by the change in resolution and quality of the contents.

Lastly, more exciting and demanding technology, such as virtual reality and 4K displays, is now available. As a result, PC gamers are expected to upgrade their equipment, which is one of the factors driving sales of gaming-specific PCs and their accessories, such as gaming screens. As a result, increased need for picture quality has increased the demand for flexible displays. Report MetricDetails

Key Companies Profiled/VendorsLG Display Co. Ltd | Samsung Electronics Co. Ltd | Royole Corporation | e-ink Holdings | BOE Technology Group Co. Ltd | Guangzhou Oed Technologies Co. ltd | Flexenable | Chunghwa Picture Tubes Ltd |

Due to the global shutdown, production of flexible displays fell precipitously in 2020 due to the global supply chain disruption. COVID-19 had an impact on the operations of not only flexible display manufacturers but also their suppliers and distributors.

In the short term, the failure of export shipments and poor domestic semiconductor demand compared to pre-COVID-19 levels are expected to impact negatively and slightly stagnant demand for semiconductor devices, affecting the flexible display market.

As a result of the ongoing COVID-19 outbreak, several major economies have been placed on lockdown. Sales of electronic products have been hampered, and supply networks have been disrupted. Furthermore, many economies are losing a significant amount of revenue due to manufacturing plant closures. As a result, the general scenario has hampered the demand for flexible displays in 2020.

Market News December 29th, 2021, LG Display, launched its newest OLED TV technology ‘OLED EX’. This next generation OLED EX display implements LG Display’s deuterium and personalized algorithm-based ‘EX-Technology’.

Ultrasound Devices Market:Information by Product Type (Diagnostic), Device Display (Color, Black), Device Portability (Trolley/Cart-Based), and Region — Forecast till 2030

Automotive Head-Up Display Market: Information by Type (Windshield, Augmented Reality HUD), Vehicle Type (Passenger Vehicles, Commercial Vehicles), End-User, and Region — Forecast Till 2029

Virtual Reality Market: Information by Device Type (Head-Mounted Display), Application (Consumer), Technology (Non-Immersive, Semi and Fully Immersive) and Region — Forecast till 2029

A flexible display or rollable display is an electronic visual display which is flexible in nature, as opposed to the traditional flat screen displays used in most electronic devices.e-readers, mobile phones and other consumer electronics. Such screens can be rolled up like a scroll without the image or text being distorted.electronic ink, Gyricon, Organic LCD, and OLED.

Electronic paper displays which can be rolled up have been developed by E Ink. At CES 2006, Philips showed a rollable display prototype, with a screen capable of retaining an image for several months without electricity.pixel rollable display based on E Ink’s electrophoretic technology.flexible organic light-emitting diode displays have been demonstrated.electronic paper wristwatch. A rollable display is an important part of the development of the roll-away computer.

With the flat panel display having already been widely used more than 40 years, there have been many desired changes in the display technology, focusing on developing a lighter, thinner product that was easier to carry and store. Through the development of rollable displays in recent years, scientists and engineers agree that flexible flat panel display technology has huge market potential in the future.

Flexible electronic paper (e-paper) based displays were the first flexible displays conceptualized and prototyped. Though this form of flexible displays has a long history and were attempted by many companies, it is only recently that this technology began to see commercial implementations slated for mass production to be used in consumer electronic devices.

The concept of developing a flexible display was first put forth by Xerox PARC (Palo Alto Research Company). In 1974, Nicholas K. Sheridon, a PARC employee, made a major breakthrough in flexible display technology and produced the first flexible e-paper display. Dubbed Gyricon, this new display technology was designed to mimic the properties of paper, but married with the capacity to display dynamic digital images. Sheridon envisioned the advent of paperless offices and sought commercial applications for Gyricon.

In 2005, Arizona State University opened a 250,000 square foot facility dedicated to flexible display research named the ASU Flexible Display Center (FDC). ASU received $43.7 million from the U.S. Army Research Laboratory (ARL) towards the development of this research facility in February 2004.demonstration later that year.Hewlett Packard demonstrated a prototype flexible e-paper from the Flexible Display Center at the university.

Between 2004–2008, ASU developed its first small-scale flexible displays.U.S. Army funds ASU’s development of the flexible display, the center’s focus is on commercial applications.

This company develops and manufactures monochrome plastic flexible displays in various sizes based on its proprietary organic thin film transistor (OTFT) technology. They have also demonstrated their ability to produce colour displays with this technology, however they are currently not capable of manufacturing them on a large scale.Dresden, Germany, which was the first factory of its kind to be built – dedicated to the high volume manufacture of organic electronics.plastic and do not contain glass. They are also lighter and thinner than glass-based displays and low-power. Applications of this flexible display technology include signage,wristwatches and wearable devices

In 2004, a team led by Prof. Roel Vertegaal at Queen"s University"s Human Media Lab in Canada developed PaperWindows,Organic User Interface. Since full-colour, US Letter-sized displays were not available at the time, PaperWindows deployed a form of active projection mapping of computer windows on real paper documents that worked together as one computer through 3D tracking. At a lecture to the Gyricon and Human-Computer Interaction teams at Xerox PARC on 4 May 2007, Prof. Vertegaal publicly introduced the term Organic User Interface (OUI) as a means of describing the implications of non-flat display technologies on user interfaces of the future: paper computers, flexible form factors for computing devices, but also encompassing rigid display objects of any shape, with wrap-around, skin-like displays. The lecture was published a year later as part of a special issue on Organic User InterfacesCommunications of the ACM. In May 2010, the Human Media Lab partnered with ASU"s Flexible Display Center to produce PaperPhone,MorePhone

Research and development into flexible OLED displays largely began in the late 2000s with the main intentions of implementing this technology in mobile devices. However, this technology has recently made an appearance, to a moderate extent, in consumer television displays as well.

Nokia first conceptualized the application of flexible OLED displays in mobile phone with the Nokia Morph concept mobile phone. Released to the press in February 2008, the Morph concept was project Nokia had co-developed with the University of Cambridge.nanotechnology, it pioneered the concept of utilizing a flexible video display in a consumer electronics device.London, alongside Nokia’s new range of Windows Phone 7 devices.

Sony Electronics expressed interest for research and development towards a flexible display video display since 2005.RIKEN (the Institute of Physical and Chemical Research), Sony promised to commercialize this technology in TVs and cellphones sometime around 2010.TFT-driven OLED display.

In January 2013, Samsung exposed its brand new, unnamed product during the company"s keynote address at CES in Las Vegas. Brian Berkeley, the senior vice president of Samsung"s display lab in San Jose, California had announced the development of flexible displays. He said "the technology will let the company"s partners make bendable, rollable, and foldable displays," and he demonstrated how the new phone can be rollable and flexible during his speech.

During Samsung"s CES 2013 keynote presentation, two prototype mobile devices codenamed "Youm" that incorporated the flexible AMOLED display technology were shown to the public.OLED screen giving this phone deeper blacks and a higher overall contrast ratio with better power efficiency than traditional LCD displays.LCD displays. Samsung stated that "Youm" panels will be seen in the market in a short time and production will commence in 2013.

The Flexible Display Center (FDC) at Arizona State University announced a continued effort in forwarding flexible displays in 2012.Army Research Lab scientists, ASU announced that it has successfully manufactured the world"s largest flexible OLED display using thin-film transistor (TFTs) technology.

In January 2019, Chinese manufacturer Xiaomi showed a foldable smartphone prototype.Xiaomi demoed the device in a video on the Weibo social network. The device features a large foldable display that curves 180 degrees inwards on two sides. The tablet turns into a smartphone, with a screen diagonal of 4,5 inch, adjusting the user interface on the fly.

Flexible displays have many advantages over glass: better durability, lighter weight, thinner as plastic, and can be perfectly curved and used in many devices.glass and rollable display is that the display area of a rollable display can be bigger than the device itself; If a flexible device measuring, for example, 5 inches in diagonal and a roll of 7.5mm, it can be stored in a device smaller than the screen itself and close to 15mm in thickness.

Flexible screens can open the doors to novel and alternative authentication schemes by emphasizing the interaction between the user and the touch screen. In “Bend Passwords: Using Gestures to Authenticate on Flexible Devices,” the authors introduce a new method called Bend Passwords where users perform bending gestures and deform the touch screen to unlock the phone. Their work and research points to Bend Passwords possibly becoming a new way to keep smartphones secure alongside the popularization of flexible displays.

Flexible displays using electronic paper technology commonly use Electrophoretic or Electrowetting technologies. However, each type of flexible electronic paper vary in specification due to different implementation techniques by different companies.

The flexible electronic paper display technology co-developed by Arizona State University and HP employs a manufacturing process developed by HP Labs called Self-Aligned Imprint Lithography (SAIL).

The flexible electronic paper display announced by AUO is unique as it is the only solar powered variant. A separate rechargeable battery is also attached when solar charging is unavailable.

Many of the e-paper based flexible displays are based on OLED technology and its variants. Though this technology is relatively new in comparison with e-paper based flexible displays, implementation of OLED flexible displays saw considerable growth in the last few years.

In May 2011, Human Media Lab at Queen"s University in Canada introduced PaperPhone, the first flexible smartphone, in partnership with the Arizona State University Flexible Display Center.

At CES 2013, Samsung showcased the two handsets which incorporates AMOLED flexible display technology during its keynote presentation, the Youm and an unnamed Windows Phone 8 prototype device.Galaxy Note Edge,Samsung Galaxy S series devices.

LG Electronics and Samsung Electronics both introduced curved OLED televisions with a curved display at CES 2013 hours apart from each other.The Verge noted the subtle curve on 55" Samsung OLED TV allowed it to have a "more panoramic, more immersive viewing experience, and actually improves viewing angles from the side."

Crawford, Gregory P., ed. (2005). Flexible flat panel displays (Reprinted with corrections. ed.). Chichester, West Sussex, England: John Wiley & Sons. p. 2. ISBN 978-0470870488.

Thryft, Ann R. (7 June 2012). "All-Plastic Electronics Power Flexible Color Display". Design News. Archived from the original on 31 March 2019. Retrieved 24 April 2013.

Lahey, Byron; Girouard, Audrey; Burleson, Winslow and Vertegaal, Roel (May 2011). PaperPhone: Understanding the Use of Bend Gestures in Mobile Devices with Flexible Electronic Paper Displays, Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Pages 1303–1312.

Gomes, A., Nesbitt, A., and Vertegaal, R. (2013) MorePhone: A Study Of Actuated Shape Deformations for Flexible Thin-Film Smartphone Notifications. In Proceedings of ACM CHI’13 Conference on Human Factors in Computing. ACM Press, 2013, pp. 583–592.

Lee, Reuben (10 January 2013). "Samsung shows off flexible display phones at CES keynote". CNET. Archived from the original on 17 February 2013. Retrieved 12 February 2013.

Sasaoka, Tatsuya; Sekiya, Mitsunobu; Yumoto, Akira; Yamada, Jiro; Hirano, Takashi; Iwase, Yuichi; Yamada, Takao; Ishibashi, Tadashi; Mori, Takao; Asano, Mitsuru; Tamura, Shinichiro; Urabe, Tetsuo (1 January 2001). "24.4L: Late-News Paper: A 13.0-inch AM-OLED Display with Top Emitting Structure and Adaptive Current Mode Programmed Pixel Circuit (TAC)". SID Symposium Digest of Technical Papers. 32 (1): 384. doi:10.1889/1.1831876. S2CID 59976823.

Drzaic, P.; Comiskey, B.; Albert, J. D.; Zhang, L.; Loxley, A.; Feeney, R.; Jacobson, J. (1 January 1998). "44.3L: A Printed and Rollable Bistable Electronic Display". SID Symposium Digest of Technical Papers. 29 (1): 1131. doi:10.1889/1.1833686. S2CID 135723096.

Lowensohn, Josh (9 January 2013). "Eyes-on: Samsung"s Youm flexible-display tech at CES 2013". CNET. Archived from the original on 26 November 2013. Retrieved 12 February 2013.

For decades displays have been simply flat pieces of glass or plastic that dictated the design of technology. But recently, engineers and manufacturers have been coming up with curved screens, more and more of which can be found on computer monitors, televisions and phones.Samsung Galaxy S7 Edge and LG G Flex are among the devices featuring bendable display.

With bendable display, manufacturers are looking to advance technology. In fact, flexible displays have the potential to become one of the biggest technological breakthroughs in the decade, encouraging designers to create devices we have never seen before.

Although curved screens are impressive, these are not the same as the ones that are bent. Traditionally, liquid-crystal displays (LCDs) are sandwiches with materials that include backlight, polariser, thin-film transistor, liquid crystals and filter glass. LCDs are usually flat, but several companies like Samsung have managed to produce curved LCDs.

The recently released organic LED ecosystem (OLED) has gained popularity, thanks to its simplified design, better image quality and flexibility. OLED displays do not require backlighting, so these can be thinned and moulded into specific shapes such as the curved display on Samsung Galaxy S7. Flexibility, thinness and excellent image quality make OLED a better choice for curved screens, and it is clear that the OLED will overthrow LCD TVs in the future. However, OLEDs are currently too expensive to produce for large screens such as televisions and computer monitors, but their prices will eventually fall.

Although LCDs contain more layers than OLEDs, these screens may still be bent. Apple Japan Display is developing a 14cm (5.5-inch), full HD LCD. The display will use plastic for the substrate, which has traditionally been made of non-removable glass. This will enable it to flex and bend.

The biggest advantage of flexible displays is durability. Because the screen can be bent and manipulated, it can also absorb impact better than solid glass structures we currently have. So broken screens can be a thing of the past. However, it will take some time before we reach that point. It is assumed today that bendable screens will use plastic instead of glass, but the plastic itself can still crack under extreme stress.

Manufacturers like Corning are currently working on a flexible glass called Willow, which is planned to be put into everything from telephones to televisions to carry devices. Willow is as thin as a piece of paper and can be bent too. But it will still break if it gets too much rounded up.

The three largest mobile manufacturers are reportedly experimenting with flexible displays. According to Samsung, the most important feature of Galaxy X is that its display can be folded outside, allowing users to convert their phones into 12.7cm (7-inch) tablets. LG is also said to have come out with a smartphone that folds outside to form a tablet. Patent drawings represent a conceptual LG phone that has a foldable display which can be used even after bending. Apple is considering the use of bendable displays on the iPhone in 2018.

Other technologies could also benefit from flexible displays. For example, flexible displays could be used as clothing that changes colour or pattern instantly as per the environment, making these particularly useful for soldiers.

Phones can also take a new format, similar to the Lenovo Cplus prototype, which starts as a thin handset but folds into a wristband. Samsung experimented with the introduction of curved displays on its original Galaxy Gear S smartphone, but moved to a more traditional flat, rounded Galaxy Gear S3. With curved displays, intelligent observers can theoretically have massive screens that surround their wrist to display even more information at once.

Cars could also use curved screens as more and more dashboards are going digital. For example, Mercedes E-Class displays infotainment indicators and infotainment data on a 31cm (12.3-inch) HD display that extends on the dashboard. Tesla and X models have a huge 43cm (17-inch) central display, but you can use a curved screen to make the outline look natural on the car’s dashboard.

The concept of bent displays is not new, because gadget manufacturers appear to be displaying them on large shows like CES (Consumers Electronics Show in Las Vegas, USA) and MWC (Mobile World Congress in Barcelona, Spain) annually, but no one has brought a flexible display to the market yet. Why?

Growing use of flexible displays in the consumer electronics industry for smartphones, wearable devices, laptops, and its peripherals is expected to boost the category.

Due to their expanding use in flexible displays, wearable electronics, smart cards, and various other applications, flexible batteries are growing in popularity. A flexible display is also a rapidly growing technology, with applications of flexible display in areas such as media, aircraft, and transportation. Research on flexible display predicts increasing usage of this display technology in medical display systems.

The surge in demand for flexible display technology for a variety of applications such as digital signage, smartphones and tablets, and smart wearable devices is likely to drive the global flexible display market. The growing prominence of quantum dot (QD) display technology presents manufacturers with new revenue prospects and is likely to emerge as one of the important types of display technology.

Key Findings of Market ReportOver the next few years, the market is expected to be driven by the increasing use of flexible displays in different industries such as co

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey