anti glare coating lcd monitors manufacturer

The biggest challenge to achieving high optical performance in digital TV, advertising and signage is the glare and reflection that occurs when light hits a screen. The solution to this issue is by the incorporation of an AR coating.

The use of an anti reflective coating ensures that advertising displays and television screens are fully visible and digital signage is fully readable in daylight.

This application of an anti reflective coating involves applying a film or coating of a specific thickness to the surface. The film reduces the reflections on the surface by cancelling out a specific wavelength of light as it is reflected back to the consumer.

When a specific wavelength of light passes through the AR coating, some of it is reflected back to the consumer and some of it is reflected at the surface. The thickness of the AR film causes the reflected wavelengths to be reflected so that they cancel each other out.

Using an ITO coating has the additional benefit of protection from damage as they increase resistance to impact damage, protecting the LED screen further.

DIAMOND AR anti reflective coating has similar spectral properties to the DIAMOX + coating and is available on polycarbonate, acrylic and glass substrates. There are a variety of different AR coatings available in the DIAMOND AR range. The most suitable coating can be ascertained to meet our customers needs.

For an uncoated glass component, typically 4% of incident light would be reflected at each surface. When an anti-reflective optical coating is used, reflection can be reduced to less than 0.1%

Resistive touch screens were launched about 20 years ago with a lower cost-benefit and a pressure-sensitive surface to react with various objects such as your finger, glove, pencil or specialist tools. Resistive touch technology remains the popular choice for factory automation. Some drawbacks for resistive touch technology include the need for calibration from time to time, a driver is needed for new installations, and the surface of the resistive touch display has a limited lifetime. The resistive touch technology also suffers from reduced light transmittance in comparison with PCAP, therefore, decreases the sought-after high brightness of the underlying TFT-LCD.

Assured Systems provide 3 different surface coatings for PCAP touch screen computers; Anti-Reflection, Anti-Glare and Anti-Fingerprint. These surface coatings can be utilised in both indoor and outdoor environments by enhancing the optical performance of displays.

A chemical-based surface treatment, otherwise known as a chemical AG process, is applied directly to the glass display surface to form micro asperities and give the glass an anti-glare effect under the likes of sunlight. It does not generate any of the minute flaws or micro-cracks that are characteristic of mechanical AG processes and therefore maintains the high surface strength of the glass.

The other way for AG treatment is manufactured by a controlled acid etching process yielding uniform diffused surfaces for anti-glare. Varying levels of diffusion specified as gloss yield different levels of reduced glare. A lower gloss reading denotes a more diffuse panel. The haze ratio of AG glass used on OGS touch screen products cannot be too high, because high levels of haze would affect LCM transmittance. See below figure to have more understanding of specification categories for anti-glare glass.

An Anti-Reflection (AR) coating is a type of optical coating applied to the surface and other optical elements to reduce reflection by the vacuum evaporation process. In typical imaging systems, this improved efficiency since less light is lost due to reflection. In a complex system such as telescopes and microscopes, the reduction in reflections also improves the contrast of the image by elimination of stray light.

AR produced destructive interference in the beams reflected from the interfaces and constructive interference in the corresponding transmitted beams, which increases the transmittance of glass or transparent substrates, the transmittance of glass is approximately 91%, with single-sided coating the transmittance can increase to 94~95%, if with double-sided coating it can increase transmittance up to 98~99%.

The Anti-Fingerprint coating constructions of the advantages of the preferred embodiments like the user are prevented from being imprinted on the surface, and it remains clean and aesthetically pleasing. AFP coating makes it possible to wipe up smudge on the surface very quickly and also has a tremendous hydrophobic performance and protects AR layers and reduced friction and low surface energy and improves scratch resistance. The hydrophobic performance is evaluated each lot by measuring the contact angle. The AF effect is realized by applying a nano-coating to reduce the optical contrast of fingerprints.

The AFP effect means that fingerprint on the surface cannot be seen at all by the naked eye, or only very slightly. Although the fingerprint is on the surface, it is essentially “invisible.” The colour to be coated under visible and infrared light is transparent. The coating is with characteristics like low coefficient of friction, contact angle >100 degrees. It utilizes a vacuum coating process which is also thinner and more even than spread coating.

Anti-Vandal display protective films work by protecting the glass substrate from damage and can be easily removed and replaced by a new film. This provides a quick on a cost-effective solution for those required to maintain public and private spaces from the damage and visual distortion caused by graffiti and reckless vandalism.

Anti-UV protective films are applied for outdoor Panel PCs which are operating in both outdoor and semi-outdoor applications. Even though that is indirect sunlight for the touch surface, there are still ultraviolet light that can damage the structure of touch and cause OCA film yellowing and aging issues. Anti-UV films also reject up to 97% of infrared light coming from sunlight and insulation up to 60% of the heat keep touch surface and system away from heat issues.

Additional InformationMaximize the potential of your wide-screen LCD monitor with this anti-glare filter. Anti-glare filter fits directly over your wide-screen monitors for protection from glare. Optical-quality acrylic features anti-reflective coatings to reduce glare and improve visuals. Frameless design uses hanging clips to secure tightly on your monitor. Anti-glare filter is compatible with 21.5" and 22" wide-screen LCD monitors.

Maximize the potential of your wide-screen LCD monitor with this anti-glare filter. Anti-glare filter fits directly over your wide-screen monitors for protection from glare. Optical-quality acrylic features anti-reflective coatings to reduce glare and improve visuals. Frameless design uses hanging clips to secure tightly on your monitor. Anti-glare filter is compatible with 21.5" and 22" wide-screen LCD monitors.

Based off of the RadiForce RX850 and RX650 multi-modality monitors, the new models offer all of the same features, such as a streamlined workflow and exceptional image quality, with the added benefit of anti-reflection (AR) coating, a type of optical coating that greatly reduces the amount of glare caused by ambient lighting.

AR coating offers a more vivid display of images on LCD monitors compared to more commonly used anti-glare (AG) coating. AG coating applies a small, uneven texture to the monitor’s screen that diffuses ambient light in order to reduce glare. However, the light emitted from the monitor’s backlight is also inadvertently affected, causing a loss in image detail and black areas to become washed out.

EIZO’s unique AR coating maintains image sharpness using a method that allows the light originating from the monitor to pass through the screen without being diffused. This method greatly reduces reflections from outside light while ensuring that the monitor continues to display crisp images. AR coating allows medical professionals to see the deeper blacks and subtle details in digital mammography, X-ray, and other high-resolution images with exceptional clarity in multi-modality environments.

An anti-glare screen has a coating that reduces reflections. Its efficiency is proportional to the haze value and the screen surface. Here’s a useful guide on how that might be beneficial to you.

ANSWER: An anti-glare screen has a coating that reduces reflections. The degree to which an anti-glare treatment is successful is dependent on its haze value and the screen surface (matte or glossy).

Glare occurs when light from a source (such as the Sun) reflects off a window or a screen, making it difficult to see what is happening on the display.

Matte-screen displays with an anti-glare coating absorb light rather than reflecting it. This may appear grainy or fuzzy, but it effectively eliminates reflections.

There are several anti-glare treatments available with varying haze values. A greater haze setting results in improved reflection management but also introduces additional graininess.

Ideally, you should seek out displays with light or medium matte anti-glare coatings (25% haze), which reduce reflections without impairing visual quality much.

Some glossy screens also have low-haze (1-4%) anti-glare or anti-reflective coatings, which can help with reflections without impairing the image as much as matte coatings do. However, they remain quite reflective and are unsuitable for use in extremely bright rooms (next to a window without curtains/blinds) or outdoors.

Additionally, it isn’t easy to describe different coatings because they are subjective accurately; what some see as excessively shiny or grainy may be minor to others.

When it comes to matte screens, you’re unlikely to find information about the type of matte anti-glare finish used, as well as its haze value or surface smoothness/texture.

We usually mention in our assessments if a monitor has a glossy surface or an excessively gritty matte finish. Occasionally, it may have a light or medium/normal matte anti-glare coating.

We hope you found these touchscreen or panel PCs fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996.

The 49.5-inch Ultra-Wide Stretched Bar Type LCD Panel Touchscreen design has an AG coating that effectively reduces glare. It is equipped with an HDMI waterproof interface. In addition, the 2K high-definition monitor screen can display delicate picture quality. Furthermore, optical bonding between the touch screen and LCD modules makes the image more realistic.

Optical bonding between the touch screen and the LCD module can effectively reduce the refraction of the air, increase the light transmittance, also the display effect is more clear and transparent.

Purchasing an LCD monitor can be a difficult task at the best of times. Knowledgeable buyers have to consider many aspects of their future screen, not just basing a decision on price and marketing hype. Of course decisions are ultimately driven by a buyers budget, but one must always consider the things which will make the screen suitable to their uses, which are where technologies, features, connections and design come into play. Panel technology is not always discussed by manufacturers but is one of the most important aspects to consider when buying a new screen as it will tell you a lot about the real-life performance you can expect from the display, and ensure you are buying a screen suitable for your requirements. Fortunately we are here to help and you can read our in depth panel technologies article to help you in your quest.

One thing which many buyers will be unaware of is that all LCD displays are supplied with a protective filter layer on the front of the panel itself. This coating is used to protect the panel from damage, filter and diffuse the light output and in many cases reduce glare from other light sources in your workspace. What is also tricky to understand is that different panels can have different types of coating, varying considerably by panel technology and manufacturers. This article is designed to help highlight some of those differences so that readers can make an informed decision about their next monitor purchase.

The most common type of protective coating is ‘Anti-Glare’ (AG). This is often described as a matte coating as it is non-reflective to the user since it diffuses rather than reflects ambient light. It provides a method for manufacturers to avoid glare on the viewing surface from other light sources and has been used in the LCD monitor market for many years since the first TFT displays started to emerge.

This matte coating is included as an outer polarizing later which has been coarsened by mechanical or chemical processes. This achieves a surface coating which is not smooth and so can diffuse ambient light rather than reflect it. What is particularly important to understand is that this AG coating can be applied to panels with varying thicknesses, which has an impact on the anti-glare properties, but also on the underlying image of the screen. Where the coating is particularly thick and aggressive, the image from the screen can deteriorate as the light being emitted is also affected. This can have some impact on contrast and colour vibrancy and the perceived image can sometimes look dull as a result. Sharpness degradation can also occur in some extreme cases where AG coating is too thick. Users may also sometimes see the graininess of the coating, particularly when viewing white or light backgrounds. This can be particularly distracting for office work and images can look grainy or dirty if the coating is too aggressive. I would point out that not everyone would even notice this at all, and many users are perfectly happy with their screens even where aggressive AG is used. It’s just something to be wary of in case you have found problems with image quality in the past or are susceptible to it.

In other cases, AG coating is applied but it is light and far less obtrusive. The polarizer is less rough and has a lower haze value. Sometimes users refer to it as “semi-gloss” to distinguish the difference between these and the heavy AG coatings. This provides anti-glare properties but does not result in the grainy appearance of images. It is not a fully glossy solution though.

AG coating has long been the choice for nearly all professional-grade displays as well, helping to avoid issues with reflections and external light sources which are vital for colour critical work. In addition it should be noted that AG coating is less susceptible to dust, grease and dirt marks which can become an issue on reflective glossy coating alternatives.

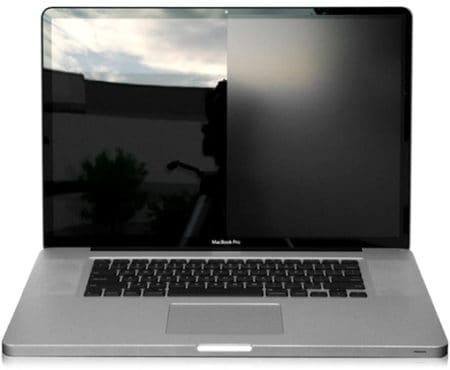

Some users have even taken matters into their own hands and removed the AG coating from their screens to produce a glossy surface. This will of course void your warranty and should be done with caution and entirely at the users risk. We mention it here as the above images are a good demonstration of the aggressive coating applied to the screen in some cases. You can see from the top picture the film being peeled off to leave a glossy reflective surface underneath. The second image is of course exaggerated quite a lot but you can see how the image is affected when the photograph is taken with the AG coating in front, on the right hand side. Of course this is far less obvious when the coating is in contact with the surface of the screen but it’s a fairly good demonstration of the coating being used in some cases (note, these were taken from an LG.Display IPS panel on the Dell U2312HM).

It is important to realise that different manufacturers tend to use different levels of AG coating, often linked to the panel technology they are developing. See our following sections for more information about specific panel manufacturers and technologies.

As an alternative some manufacturers choose to supply their screens with a glossy screen surface. This gives somewhat of a “wow factor” when you first see the screen and has often been used by manufacturers like Apple for their screens and tablets. The glossy panel coating is sometimes combined with a glass protective layer to give a hard exterior surface to the display and to emphasise that overall glossy appearance.

Glossy coatings provide very clear, clean and crisp images, free from any form of graininess or dirtiness you might see from AG alternatives. Images can look and feel nicer in some cases, often helping colours and blacks “pop” in practice. However, they aren’t without their own problems as the glossy coating can cause a lot of unwanted reflections in certain conditions. You have to be very careful of your ambient lighting conditions and the position of lamps and windows near your screen. Finger prints, dust and dirt can also become an issue and are more noticeable on shiny, reflective, glossy surfaces. In some instances chemical coatings are applied to help try and reduce some of the ambient light reflections but in reality they still remain reflective in practice and very different to AG coatings. Glossy screens aren’t for everyone at all, and it would be advisable to try and see one in person in a shop before making a purchase if you can.

Where glass coatings are applied as an additional protective layer buyers should also be aware that there is sometimes the risk of trapped dust or particles behind the glass which can become an annoyance over time. Some screens are completely free from this, but it’s just something to be aware of (e.g. dust issues were found on some Hazro’s HZ27WA/C/D screens where glass layers were used). Glass layers are also often provided on touch-screen displays for that added level of protection.

Glossy screen coatings have been offered over the years in several forms including older models featuring Sony X-Black, Acer CrystalBrite and NEC OptiClear technologies. Apple have used glossy coatings on their Cinema Displays for many years and in fact a lot of the modern glossy offerings are based on IPS panels. More recently other manufacturers like Hazro (HZ27WA/C/D) and DGM (IPS-2701WPH) have produced screens based on the 27” glossy IPS panels available. Samsung have also released their first glossy PLS panel in the Samsung S27B970D.

As we’ve already mentioned, the type of coating applied to a panel is very dependent on the manufacturer and the technology being used. Trends have emerged over the years and here is a summary of the typical coating usage from different panel solutions:

LG.Display IPS – These panels are often criticised for their aggressive AG coating. Where AG is used it is normally very aggressive and some people find the images are too grainy or dirty looking. As an example the Dell UltraSharp series (U2410, U2412M, U2711, U3011) are all using aggressive AG coating on their IPS panels. Some IPS panels are provided with a glossy screen coating as an alternative which avoids issues with grainy coating, but can result in distracting reflections.

AU Optronics AMVA – Modern versions of these panels are provided with a light AG coating which is sometimes referred to as semi-gloss. It is not overly grainy or obtrusive.

Samsung PLS – early versions of the panels were provided with a light AG coating, similar to that of AMVA panels although not quite as low haze. It was not overly grainy or distracting. More recently PLS panels have also been supplied with a glass glossy coating. The technology is in its infancy and so it is hard to establish a future trend.

TN Film panels – these are nearly always provided with AG coating although some glossy models have been produced from time to time. Coating tends to vary but is normally considered to be ‘medium’ in terms of its aggressiveness. Not as aggressive as the IPS panels, but not “semi-gloss” like AMVA offerings.

Above is a comparison of macro images taken of varying panel types. This was designed to capture the structure of the panel at a pixel level but can also be used to demonstrate the coating type being used and the resulting image clarity. You will see that the aggressive AG coating of the IPS panels leads to a blurry and grainy image, but the glossy equivalent leaves a clear and crisp view of the underlying pixels. TN Film is a medium AG coating and while not as aggressive as the IPS AG coating, it can lead to noticeable graininess in some cases. AMVA has a light AG coating and as you can see does not deteriorate the image quality too much.

This hopefully gives you a summary of the common types of coating used on the main panel technologies in the market. Of course there are always variations and so we will try to discuss the coatings in our reviews so you have an idea.

As a final thought I would like to reiterate the point that not everyone is bothered by the screen coating being used on their displays. This article is not designed to scare or concern people, just provide a reference point and information to help buyers make an informed decision. AG coating has been the main choice for many years now and continues to be popular with some manufacturers. While some people might be put off by the grainy coating, others may not even notice it. Glossy solutions also have their pros and cons and so it’s important to try and see screens in person if you can if you worry you may be affected by any of the characteristics described here.

Glare is the reflection of light from a source (such as the sun) off of a window or a screen, which can make it hard to see what is happening on the display.

Displays with matte screen finish and anti-glare coating diffuse light instead of reflecting it. This can make the picture appear somewhat fuzzy, but it efficiently prevents reflections.

Ideally, you should look for displays with light or medium matte anti-glare coatings (25% haze), as they help with reflections without notably affecting the image quality.

Some glossy screens also have low-haze (1-4%) anti-glare or anti-reflective treatments, which can help with the reflections without affecting the picture as much as matte coatings do, but they’re still quite reflective and hardly usable in very bright rooms (next to a window without curtains/blinds) or outdoors.

It’s also hard to properly describe different types of coatings as it can be subjective – what’s too reflective or grainy to some, might be negligible to others.

However, it’s usually clearly noted if a monitor has a glossy screen and/or an anti-glare or anti-reflective treatment, but these types of displays are somewhat rare anyway.

As for matte screens, you most likely won’t find what type of matte anti-glare finish it has or any details regarding its haze value or surface smoothness/texture.

In our reviews, we’ll always point out if a monitor has a glossy surface or a too grainy matte finish. Other times, assume it has either a light or medium/normal matte anti-glare coating.

Protection for displays used outdoors have special challenges. These displays are very prone to glare from the sun and reflections from other surfaces. To minimize this impact on the display, manufacturers may treat their screens with antireflective coatings. These consist of thin layers that are designed to cancel out the reflected light while allowing transmitted light through. They create an internal reflective surface that is 1/4 wavelength thick. These two surfaces allow light to be 180° out of phase with light reflecting off the top surface, destructively interfering and canceling out the light intensity.

By carefully controlling the coating thickness and refractive index of the coatings, reflected glare is dramatically reduced through this destructive interference.

NuShield DayVue antireflective (AR) film replicates the AR coating on your display and protects it from damage. It will upgrade a screen that does not have AR capabilities for better performance. Our latest version of this film has several top layers with carefully chosen index of refraction minimizing the blue end of the spectrum. This means that the screen can be seen clearly even with polarized sunglasses. The film largely eliminates blue-violet banding.

NuShield is pleased to provide a superior antireflective film. Our films for electronic displays have excellent scratch resistance and optical properties. They are as good as the original antireflective navigation screens in glare reduction and provide superior scratch protection at a reasonable cost. They are designed for a variety of applications.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey